Quick Answer: NEX Pickleball’s advanced production processes—including hot pressing1, cold pressing, and thermoforming2—combined with premium materials like Carbon Fiber3 and Fiberglass4, enable us to deliver high-performance pickleball paddles tailored for wholesalers seeking reliability, customization, and competitive pricing.

In today’s competitive sports equipment market, purchasing managers and procurement specialists must balance product quality, manufacturing reliability, and cost efficiency. With the increasing demand for high-performance pickleball paddles, understanding the nuances of production techniques and material properties becomes vital. NEX Pickleball has mastered this balance, offering paddles that not only meet but often exceed industry standards.

Our approach is built on three pillars: advanced production techniques, premium materials, and customized solutions. This article will walk you through our manufacturing processes, highlight the differences between key materials, and outline the customization options and quality control measures that place us ahead of the competition.

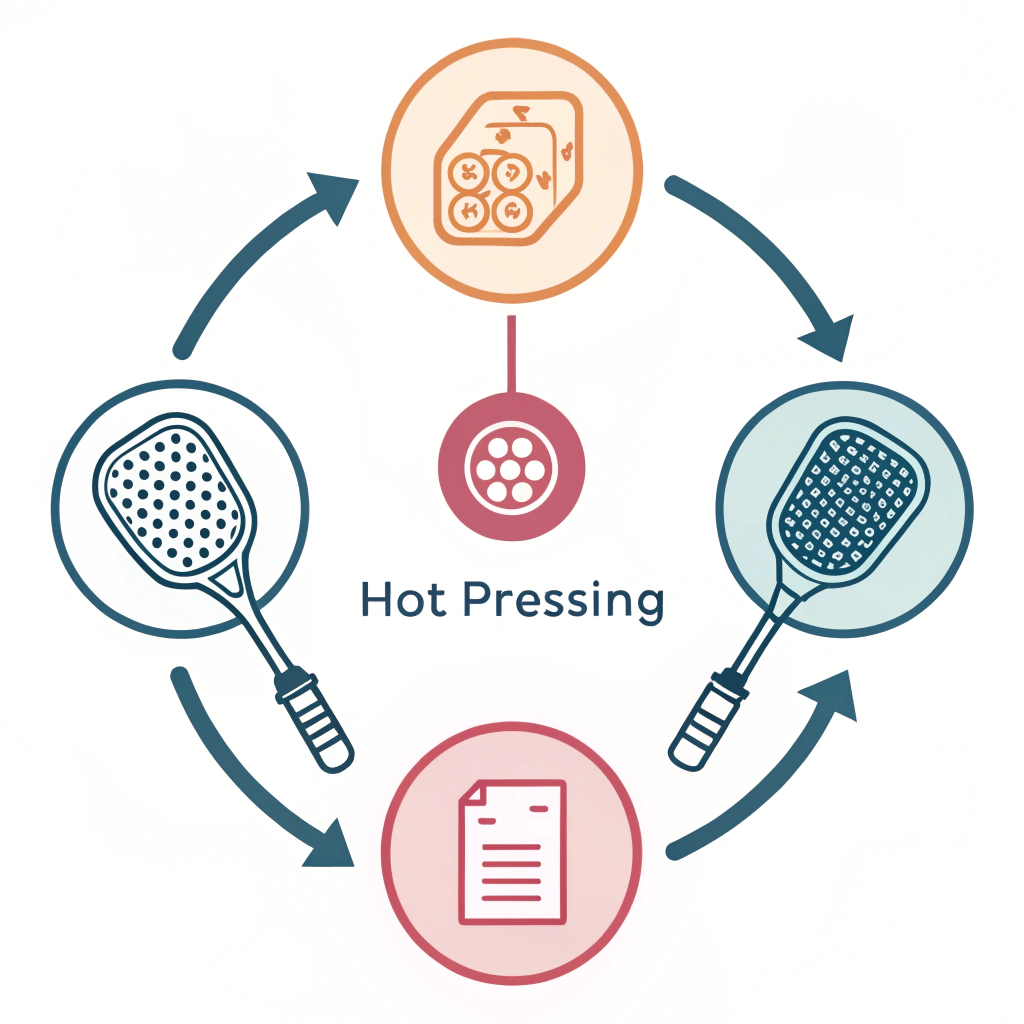

Understanding our production processes is essential for B2B purchasers evaluating suppliers. At NEX Pickleball, we deploy three primary techniques: hot pressing, cold pressing, and thermoforming. Each method offers a unique set of advantages and adaptations based on the product’s design and intended performance.

Hot pressing1 involves heating the paddle materials before applying pressure, resulting in a fusion that enhances durability and mechanical strength. This technique is ideal for paddles that demand high impact resistance and long-lasting performance.

Advantages of hot pressing include:

- High production efficiency, which is crucial for large-scale orders.

- Exceptional impact resistance due to improved material bonding.

- Superior structural solidity that suits competitive play.

However, there are also a few trade-offs:

- The heat may alter some material properties, potentially affecting the paddle’s feel.

- High initial investment is required for specialized equipment.

Cold pressing is a process that forgoes heating, instead using precise pressure to mold the paddle at room temperature. This method preserves the intrinsic properties of the materials and contributes to a more controlled and nuanced paddle feel.

Cold pressing is especially beneficial because:

- It provides accurate control over thickness and material distribution.

- The process maintains the natural characteristics of sensitive materials.

- It enhances responsiveness and ball feel, which is vital for players requiring precision.

Considerations for cold pressing include:

- Longer production cycles compared to hot pressing.

- The need for high-quality pressure control systems to ensure consistency.

Thermoforming2 heats materials to their softening point and then forms them using molds, which is perfect for complex paddle designs. This technique allows for intricate designs and precise material distribution, ensuring that every paddle is optimized for performance.

Key benefits include:

- The ability to create paddles with detailed designs and controlled distribution of materials.

- Maintaining excellent stability and performance consistency.

- Suitability for high-end, custom-made paddles.

Challenges associated with thermoforming are:

- Longer production times due to the heating and cooling cycles.

- Increased equipment costs, which can typically translate to premium pricing for the end product.

Below is a comparative table summarizing the key aspects of each production process:

| Production Method | Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency, strong bond, excellent impact resistance | May affect material feel, high equipment investment |

| Cold Pressing | Precise control, maintains material properties, better ball feel | Longer production cycle, requires precise pressure control |

| Thermoforming | Detailed design options, precise material distribution, enhances stability | Longer production cycle, higher equipment costs |

The quality and characteristics of the paddle materials significantly affect performance, durability, and user comfort. At NEX Pickleball, we employ a range of premium materials to meet diverse performance requirements.

Carbon Fiber3 is a staple in our manufacturing process due to its exceptional strength and lightweight properties. We utilize multiple types of carbon fiber to optimize paddle performance under various conditions:

- 3K Carbon Fiber: Favored for its blend of strength and flexibility, this type is used where high rebound force is required and vibration reduction is critical.

- 12K Carbon Fiber: Its higher thread density delivers a smoother surface, increased hardness, and superior impact resistance—ideal for competitive play.

- T300 Carbon Fiber: Offers balanced performance with high tensile strength and light weight, ensuring a precise blend of power and control.

Each carbon fiber type is selected based on its specific performance attributes, ensuring that every paddle meets tailored performance standards.

Fiberglass4 offers a softer feel with a wider sweet spot, making it an excellent alternative when balance between power and control is desired. Specifically, we use:

- E-Glass Fiberglass: Known for its high elasticity and tensile strength, creating paddles that excel in providing an optimal ball feel and improved control.

In an effort to deliver the best of both worlds, composite materials merge the benefits of different material types. Options include:

- Carbon Fiber and Fiberglass Composite: Combining strength with flexibility, this composite creates paddles that deliver both power and remarkable precision.

- Bamboo Core Composite: The lightweight yet impact-resistant bamboo core offers a crisp hitting feel and long-term durability.

- Honeycomb Core: Constructed from high-density polymer or pulp, this core maximizes shock absorption, minimizing vibration for more comfortable play.

The paddle’s core is pivotal in determining its overall feel and performance. At NEX Pickleball, we offer various core materials, including:

- Nomex Honeycomb Core: Provides excellent durability and stability through superior shock absorption.

- Aluminum Honeycomb Core: Balances weight and power, delivering a mix of precision and strength.

- Polymer Honeycomb Core: Enhances ball feel with better elasticity and reduced vibration, ideal for recreational players and beginners.

A critical aspect of B2B purchasing is the ability to provide tailored products. NEX Pickleball stands out by offering robust OEM5 and ODM solutions, allowing our clients to customize details such as design, weight distribution, grip size, and balance.

Our flexible manufacturing processes enable various customization options:

- Custom grip sizes to cater to diverse player profiles.

- Specific weight and balance configurations based on client inputs.

- Personalized paddle designs for team branding and retail differentiation.

- On-demand printing services to incorporate company logos or unique artwork.

Meeting high standards begins with rigorous quality control protocols. Every paddle manufactured is subject to stringent testing across multiple performance parameters, including:

- Impact resistance

- Vibration absorption

- Weight and balance consistency

- Surface texture and grip efficacy

Quality control at NEX Pickleball is integrated from the initial material selection to the final inspection. Advanced testing instruments ensure each production batch aligns with defined performance benchmarks, thereby minimizing defects and ensuring robust durability.

In B2B procurement, competitive pricing and reliable delivery are as important as product quality. Our streamlined manufacturing processes, secured supply chain, and operational efficiencies allow us to offer competitive pricing without compromising product integrity.

The choice between hot pressing, cold pressing, and thermoforming may affect both unit pricing and production lead times. For bulk orders:

- Hot Pressing often yields the most cost-effective solution for standard high-performance paddles due to its efficiency.

- Cold Pressing and Thermoforming can be tailored for specific performance needs, sometimes at a premium that is justified by enhanced control and detailed designs.

Our pricing structure is transparent, and we help clients navigate the trade-offs between production methods and material quality to meet market demands and budget goals.

NEX Pickleball maintains a robust and agile supply chain that ensures:

- Timely production to meet market demands

- Consistent quality across production batches

- Flexibility to adapt to custom orders or rapid market changes

These factors make us a preferred supplier for sports equipment distributors and sports organizations worldwide, particularly in sectors where reliability and performance are paramount.

Choosing the right partner for manufacturing high-performance pickleball paddles requires evaluating multiple production and material aspects. Here’s a quick recap of why NEX Pickleball is the ideal choice for wholesale orders:

- Our advanced production techniques (hot pressing, cold pressing, and thermoforming) allow us to cater to diverse manufacturing needs, from high-efficiency bulk production to custom, high-performance designs.

- Premium materials such as multiple grades of Carbon Fiber3, Fiberglass4, and innovative composite solutions ensure that every paddle excels in durability, control, and performance.

- Robust quality control protocols guarantee consistent performance, reassuring buyers of product reliability.

- Flexible OEM/ODM offerings support customization, making it easier for businesses to cater to their specific market and branding needs.

- Competitive pricing combined with a dependable supply chain ensures that our partners receive both quality products and timely delivery, crucial for maintaining market competitiveness.

For purchasing managers and procurement specialists evaluating suppliers, our commitment to technical excellence and customer service provides a clear pathway to streamlined sourcing decisions. We invite you to explore a partnership with us and discover how our production capabilities translate into tangible market success.

People Also Ask

Q1: What are the benefits of using advanced production techniques like hot pressing in manufacturing pickleball paddles?

A1: Advanced production techniques such as hot pressing enhance the paddle’s durability and impact resistance while ensuring high production efficiency. This method improves ingredient bonding, leading to robust paddles ideal for competitive play.

Q2: How do carbon fiber and fiberglass compare in pickleball paddle manufacturing?

A2: Carbon fiber offers high strength and a lightweight profile, making it ideal for paddles requiring power and speed. In contrast, fiberglass provides a wider sweet spot and improved ball control, making it suitable for players seeking balance between power and precision.

Q3: What customization options are available for B2B bulk orders of pickleball paddles?

A3: Buyers can customize various features, including grip sizes, paddle weight and balance, and personalized designs for brand differentiation. Additionally, on-demand printing services allow for logo and artwork inclusion, enabling tailored solutions for team branding and retail distribution.

-

hot pressing: Click to learn more about how this method enhances product durability and optimizes production efficiency in high-volume manufacturing. ↩ ↩2

-

thermoforming: Click to explore the intricacies of thermoforming, including its benefits for detailed designs and material performance in custom applications. ↩ ↩2

-

Carbon Fiber: Click to read about the unique properties of carbon fiber, including its strength-to-weight ratio and its impact on high-performance product design. ↩ ↩2 ↩3

-

Fiberglass: Click to discover how fiberglass contributes to improved ball control and offers a softer feel compared to other high-tech materials. ↩ ↩2 ↩3

-

OEM: Click to understand the benefits of OEM solutions in tailoring products to specific market demands while ensuring seamless supply chain integration. ↩