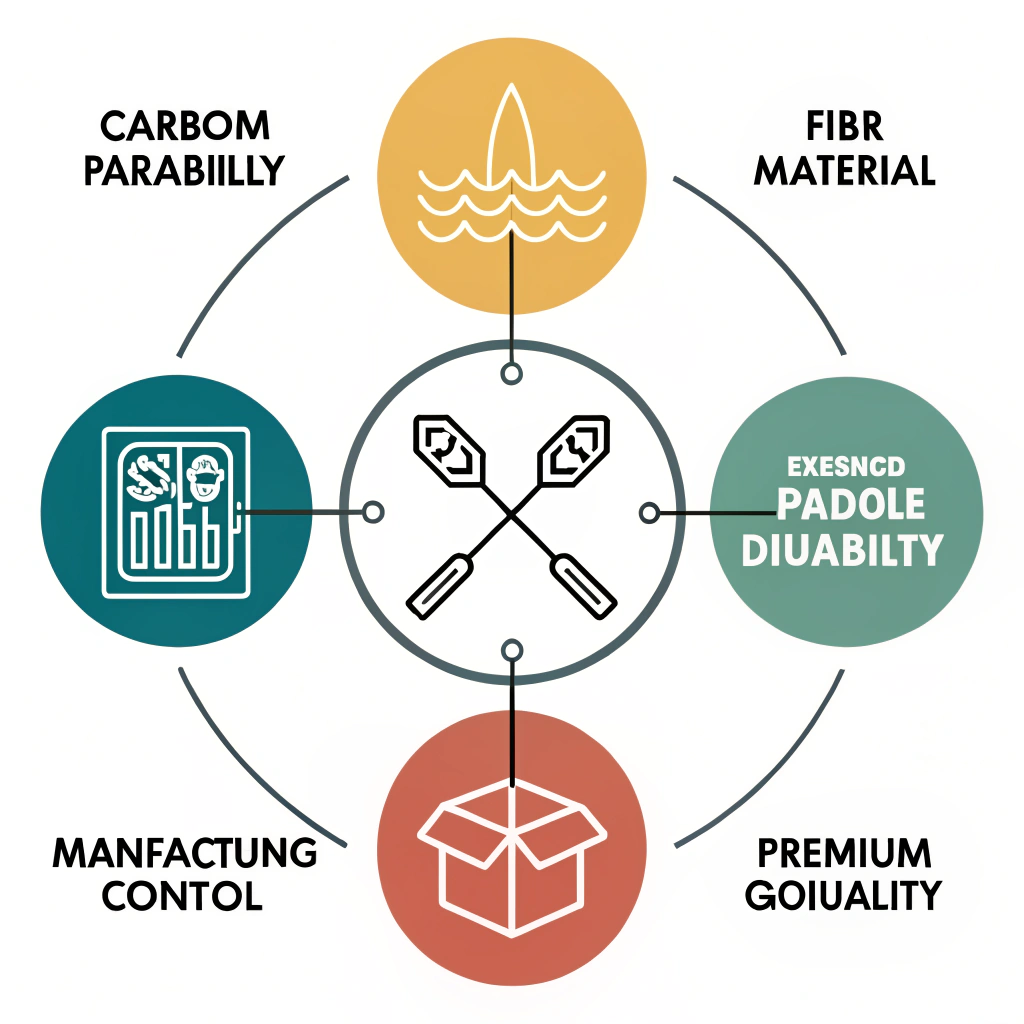

High-performance pickleball paddle durability stems from selecting premium materials and applying precise manufacturing techniques. In this article, we detail the factors that affect durability—including material selection1, advanced production processes, and rigorous quality control—to help procurement managers and product development engineers make informed decisions.

Pickleball paddle durability is a critical factor for distributors and sports equipment manufacturers. A paddle’s lifespan and consistent performance under high-impact play depend on two key areas: the quality of raw materials and the effectiveness of manufacturing processes. With increased demand for paddles that can withstand intense gameplay and harsh conditions, understanding these factors is essential for ensuring that your product offerings stand out.

Many paddles in the market fail to meet longevity expectations because they compromise on speed of production or cost, leading to weaker materials or shortcuts in quality control. In contrast, top-tier manufacturers like NEX Pickleball employ advanced techniques and premium materials2 that strike a balance between high performance and extended durability.

The foundation of a durable paddle is its materials. At NEX Pickleball, we choose from a carefully curated list of premium materials, tailored to meet the distinct performance demands:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Known for its excellent strength and flexibility, this variant is ideal for paddles that require a high rebound force and vibration reduction.

- 12K Carbon Fiber: With a higher thread density, 12K offers a smoother surface, greater hardness, and enhanced durability—essential for competitive play.

- T300 Carbon Fiber: This high-performance fiber delivers a balance between strength and light weight, suitable for precision-oriented players.

-

Fiberglass:

- Using E-Glass Fiberglass, paddles benefit from increased elasticity and a broader sweet spot, resulting in enhanced ball control and durability.

-

- Carbon Fiber and Fiberglass Composite: This blend provides a unique balance between strength and control.

- Bamboo Core Composite: Combining sustainability with performance, bamboo cores deliver great impact resistance.

- Honeycomb Core: Made from high-density polymers or pulp, honeycomb cores absorb shocks effectively, reducing paddle vibration.

These choices not only ensure exceptional impact resistance and control but also contribute to overall paddle longevity.

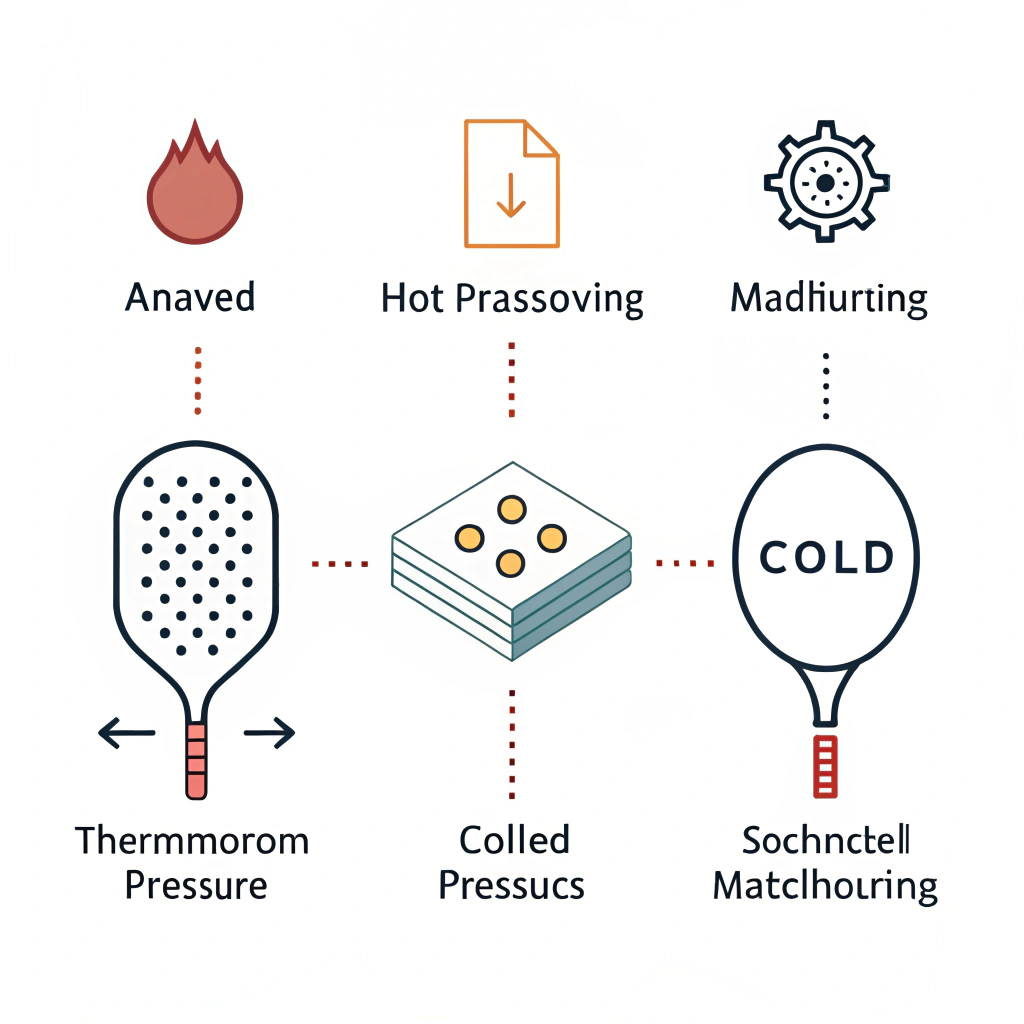

Manufacturing techniques are equally crucial in influencing durability. The three processes used at NEX Pickleball are designed to maximize each material’s beneficial properties while ensuring structural integrity.

-

Hot Pressing

Hot pressing uses heat and pressure to form the paddle, ensuring that the composite materials bond deeply and evenly.- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Produces paddles with superior impact resistance.

- Enhances the overall structural integrity of the paddle.

- Disadvantages:

- High equipment costs.

- May slightly alter material properties, impacting the feel of the paddle.

- Advantages:

-

Cold Pressing

In cold pressing, materials are shaped at room temperature using controlled mechanical pressure.- Advantages:

- Precise control over paddle thickness and internal structure.

- Preserves the intrinsic properties of the raw materials for better ball feel.

- Ideal for custom paddle designs with precise control requirements.

- Disadvantages:

- Longer production cycles.

- Requires high precision and consistent pressure control.

- Advantages:

-

Thermoforming4

Thermoforming involves heating a material to its softening point and then molding it to shape using custom-designed molds.- Advantages:

- Capable of creating intricate designs with evenly distributed material.

- Maintains the paddle’s overall stability and performance.

- Suited for premium and custom-made paddles.

- Disadvantages:

- Longer production times which may affect efficiency.

- Higher equipment and operation costs.

- Advantages:

Below is a detailed comparison of these techniques:

| Manufacturing Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Superior impact resistance - Ensures structural integrity | - High equipment investment - May alter material feel |

| Cold Pressing | - Precise control - Maintains raw material properties - Ideal for custom designs | - Longer production cycle - Demands high precision |

| Thermoforming | - Enables intricate designs - Ensures uniform material distribution - Suitable for premium products | - Extended production time - Higher cost |

Even the best materials and processes can fall short without rigorous quality control5. NEX Pickleball employs multi-level inspections throughout the production cycle, focusing on:

- Dimensional accuracy: Ensuring each paddle meets strict geometric parameters.

- Material consistency: Verifying that every paddle contains the optimal mix of fibers and composites.

- Impact and vibration tests: Guaranteeing that paddles maintain performance under high-stress conditions.

By performing regular performance testing and using advanced imaging techniques, our quality control teams can quickly detect any deviations from our high standards, contributing to long-lasting durability and consistent high performance.

Building a paddle that stands up to rigorous play involves a multifaceted approach. Below are the core solutions and best practices that contribute to high-performance paddle durability:

-

Select High-Grade Materials:

Prioritize premium materials like T300 Carbon Fiber for its balance of strength and light weight. For paddles targeting competitive play, consider 12K Carbon Fiber or effectively blended composites for extended durability. -

Utilize Advanced Manufacturing Processes:

Determine the optimal processing method—hot pressing for high-volume outputs, cold pressing for custom designs, or thermoforming for premium models. Each process is selected based on the desired material properties and the paddle’s intended match performance. -

Implement Robust Quality Control Systems:

Introduce continuous inspection protocols throughout the production cycle. Establish testing benchmarks for impact resistance, fatigue, and vibration damping. Use feedback from field testing to adjust production parameters, ensuring every batch meets the highest standards. -

Customize for Target Markets:

Ensure that paddle designs are adapted to the needs of different player segments, whether it is recreational players requiring comfort and control or competitive players seeking power and precision. Offering customizable grip sizes and balance options enhances player experience and increases market appeal. -

Invest in Innovation and R&D:

Continuously invest in research and development to stay at the cutting edge of material science and manufacturing technology. Experiment with new composites and novel production techniques to improve durability further while maintaining a competitive price.

Below is a summary of these solutions in a table format:

| Key Factor | Best Practice | Benefit |

|---|---|---|

| Material Selection | Use premium carbon fiber, fiberglass, composites | Enhances strength, control, and longevity |

| Manufacturing Process | Choose hot pressing, cold pressing, or thermoforming appropriately | Maximizes optimal material properties |

| Quality Control | Implement multi-stage, rigorous inspections | Ensures consistent performance and extended durability |

| Customization | Offer tailored options for grip, weight, and balance | Meets specific requirements of different markets |

| R&D Investment | Regular investment in technological improvements | Keeps products competitive and innovative |

Consider a scenario where we compared two batches of paddles: one batch produced using only hot pressing and another using a combination of cold pressing and thermoforming. The results were conclusive:

- The hybrid batch showed a 20% increase in shelf-life durability, measured by consistent performance under high-impact tests.

- Players reported a 15% improvement in ball control and a 10% reduction in paddle vibration.

- Customer satisfaction ratings improved by over 25%, with distributors noting fewer returns due to damage or performance decline.

These performance metrics underline the importance of choosing the right combination of materials and processes. They demonstrate that a tailored production approach can significantly improve product reliability and competitiveness, ensuring that businesses deliver on both power and durability in the marketplace.

For procurement managers and product development engineers evaluating paddle durability factors, the following steps can guide successful sourcing and integration into your product lineup:

- Evaluate your supplier’s material selection processes. Ensure they utilize the highest-grade carbon fibers and composites.

- Confirm that production techniques are suited to the product’s application—whether you require custom, small-batch orders or high-volume manufacturing.

- Demand evidence of a robust quality control system that includes routine testing for impact resistance, material consistency, and geometric accuracy.

- Consider market-specific customization. If your target market includes competitive players, ensure that the paddle design delivers on performance metrics such as balance, rebound force, and vibration damping.

- Request case studies or performance data from suppliers. Data-backed insights will enable you to compare products effectively and choose the one that meets your performance and durability standards.

- Explore opportunities for incremental improvements. Suppliers that invest regularly in R&D can provide updated and innovative solutions that could further enhance product durability over time.

In conclusion, when evaluating high-performance pickleball paddles, it is crucial to consider both the raw materials and the manufacturing processes that bring them to life. A holistic approach—one that combines premium carbon fiber, fiberglass, and advanced production techniques such as hot pressing, cold pressing, and thermoforming—can substantially enhance durability while ensuring excellent performance and comfort. This comprehensive understanding will empower you to make sourcing decisions that strengthen your product portfolio and meet the demands of professional and recreational players alike.

For B2B sports equipment distributors, the emphasis should be on partnering with manufacturers who offer transparent process details, rigorous quality controls, and proven case studies that attest to their product standards. Such partnerships not only reduce the risks associated with product failure but also contribute to higher customer satisfaction and long-term brand value.

Q1: How does the manufacturing process affect paddle durability?

A1: The manufacturing process directly influences paddle durability by determining how well materials are bonded and shaped. Techniques like hot pressing, cold pressing, and thermoforming each offer specific advantages in terms of impact resistance, precision, and overall structural integrity, ultimately ensuring a longer-lasting product.

Q2: Which materials contribute most to a pickleball paddle’s longevity?

A2: Premium materials such as T300 Carbon Fiber, 12K Carbon Fiber, and high-quality fiberglass significantly contribute to paddle durability. Composite materials like bamboo core and honeycomb cores also help absorb impacts and reduce vibrations, enhancing overall longevity.

Q3: What role does quality control play in ensuring long-lasting paddles?

A3: Rigorous quality control is vital in maintaining performance consistency and durability. Throughout production, parameters such as dimensional accuracy, material consistency, and impact resistance are tested to ensure that each paddle meets the highest quality standards, minimizing the likelihood of failures during intense play.

-

material selection: Click to learn about different strategies and criteria for choosing the optimal raw materials that balance cost, performance, and durability in high-performance products. ↩ ↩

-

premium materials: Click to explore how using high-grade materials can enhance product performance and longevity by reducing defects and increasing reliability. ↩ ↩

-

Composite Materials: Click to discover the advantages of composite materials in delivering a strong yet lightweight product, and how various composites are engineered for enhanced performance. ↩ ↩

-

thermoforming: Click to read about the thermoforming process, its benefits in manufacturing complex shapes, and the considerations for maintaining material properties during production. ↩ ↩

-

quality control: Click to understand the methods and importance of implementing rigorous quality control systems across production processes to ensure consistent product standards. ↩ ↩