Quick Answer: The best pickleball paddles for 2025 combine advanced materials like 12K Carbon Fiber1 with high-precision production processes such as hot pressing2 and thermoforming3, offering superior durability, control, and performance—qualities that B2B buyers looking to supply top-tier equipment should prioritize.

In today's competitive sports equipment market, selecting the right pickleball paddle is as much about advanced manufacturing processes as it is about performance on the court. For 2025, the leading paddles incorporate cutting-edge materials and precise production techniques that not only elevate gameplay but also meet the rigorous demands of retail and distribution partners. This guide provides an in-depth comparison of the materials, design methodologies, and production technologies behind the top pickleball paddles, aiding procurement managers and B2B buyers in making informed purchasing decisions.

Modern pickleball paddles are engineered using a variety of premium materials. Each material brings distinct advantages to the table:

-

Carbon Fiber Options:

- 3K Carbon Fiber: Renowned for its flexibility and high rebound force, this option is excellent for players needing quick reaction times and reduced vibration.

- **12K Carbon Fiber1: Provides a smoother surface and greater hardness, making it ideal for competitive play with extreme impact resistance.

- T300 Carbon Fiber: Offers a balance between strength and light weight, delivering excellent tensile strength without compromising speed.

-

Fiberglass:

- E-Glass Fiberglass is widely used for the balance it provides between power and control. Its elasticity and ball control capabilities make it a popular choice for paddles that require a larger sweet spot.

-

Composite Materials:

- Carbon Fiber and Fiberglass Composite: Combines the advantages of both materials, ensuring a good mix of power and precision.

- Bamboo Core Composite: Offers high impact resistance and a clear hitting feel, ideal for long-lasting durability.

- **Honeycomb Core4: Designed for superior shock absorption, reducing vibration and ensuring player comfort during extended sessions.

These materials not only determine the paddle’s performance but also impact its longevity, durability, and overall cost-effectiveness—factors that are essential for B2B procurement decisions.

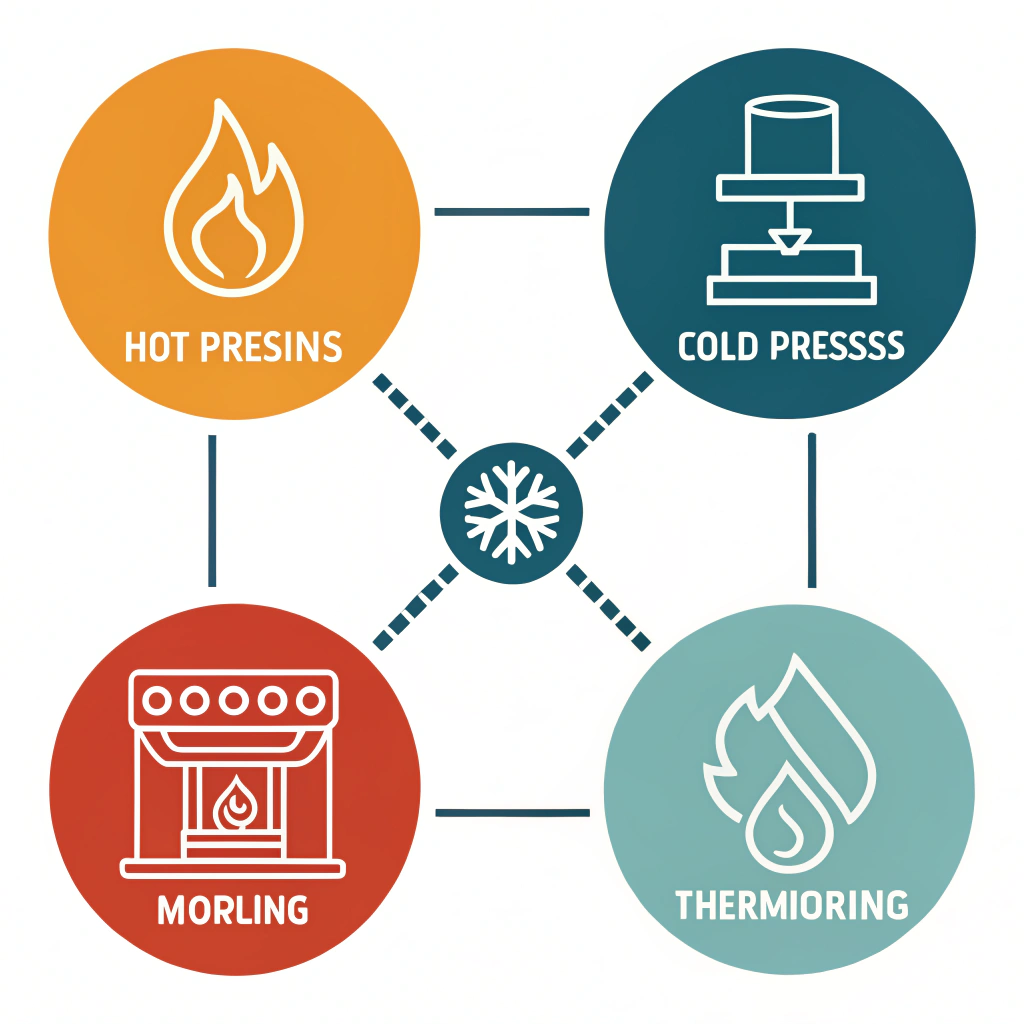

The manufacturing techniques employed in paddle production significantly influence both quality and performance. NEX Pickleball, a leader in this field, utilizes three main production processes:

Hot pressing2 involves heating the materials and applying pressure to form the paddle. This technique is characterized by:

-

Advantages:

- High production efficiency suitable for mass production.

- Results in robust paddles with excellent impact resistance.

- Ensures uniform structural strength and consistency.

-

Disadvantages:

- Potential alteration of delicate material properties, slightly affecting the tactile feel.

- Requires significant investment in specialized equipment.

Cold pressing shapes the paddle using mechanical pressure at room temperature, leading to:

-

Advantages:

- Precise control over paddle thickness and internal structure.

- Retains the intrinsic properties of materials, offering excellent control and responsiveness.

- Superior ball feel achievable due to the integrity of the original material structure.

-

Disadvantages:

- Longer production cycles compared to hot pressing.

- Necessitates high-quality machinery to maintain consistency throughout production.

Thermoforming3 uses controlled heating to soften the material before molding it into shape. Characteristics include:

-

Advantages:

- Ability to create intricate designs and optimized weight distribution.

- Maintains stability, enhancing overall paddle performance.

- Versatile for incorporating multiple premium materials simultaneously.

-

Disadvantages:

- Longer production times and higher equipment costs.

- Often used for premium or custom-made paddles, which may increase unit cost.

Below is a detailed comparison table outlining these processes:

| Production Process | Key Advantages | Limitations | Suitable For |

|---|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; uniform structure | Material property impacts; high capital investment | Mass production, competitive play |

| Cold Pressing | Precise structural control; superior ball feel; material integrity | Longer production cycles; stringent machine requirements | Premium performance and control |

| Thermoforming | Intricate designs; enhanced stability; versatile material usage | Higher production time; increased equipment costs | Custom and high-end paddles |

Understanding these production methods is critical for B2B buyers, particularly when aligning inventory with market trends and ensuring a product portfolio that appeals to both recreational players and professionals.

While materials and production processes form the cornerstone of high-performance pickleball paddles, the overall design is equally important. Features such as ergonomic grip design5, weight distribution, and surface textures play a pivotal role in player performance.

- Ergonomic Grip: Ensures comfort during prolonged play, minimizing fatigue and reducing the risk of injury.

- Weight Distribution: Balances power and control by optimizing the paddle’s center of gravity.

- Surface Treatments: Enhance ball control by improving the grip on the ball and ensuring accurate spin during strikes.

- Custom Options: Many manufacturers, including NEX Pickleball, offer customizable paddle options where design, weight, balance, and grip size can be tailored to individual needs.

This focus on design ensures that the final product meets or exceeds players' expectations, translating into repeat business and enhanced brand reputation for retailers and distributors alike.

Successful procurement isn’t solely about the initial appeal of a product—it is also about consistent performance and quality control over its life cycle. The best pickleball paddles for 2025 are produced under rigorous testing criteria that assess factors such as strength, flexibility, and overall performance.

- Rigorous Testing: Each paddle undergoes comprehensive testing to ensure the integrity of materials and manufacturing processes.

- Quality Certifications: Meeting or exceeding industry standards and compliance regulations.

- Consistency in Production: Adopting advanced technology to maintain uniform quality across batches.

- Feedback Loop: Continuous improvement based on real-world performance data and customer feedback.

Companies like NEX Pickleball have established robust quality control systems to deliver paddles that not only perform under competitive conditions but also satisfy long-term durability requirements—a critical consideration for B2B buyers.

As the pickleball market evolves, several trends are emerging that directly impact procurement strategies.

- Increased Demand for High-Performance Paddles: As the sport grows in popularity globally, there is a rising demand for paddles that offer both power and precision.

- Customization and Branding: Retailers are increasingly looking for paddles that can be customized to reflect their brand or meet specific player preferences, driving the need for flexible manufacturing processes.

- Technological Advancements: Innovations in materials like 12K Carbon Fiber1 and improvements in production techniques such as thermoforming are setting new standards for performance.

- Sustainability: There is growing attention to sustainable production practices and eco-friendly materials, which can serve as a unique selling point in a competitive market.

- Performance Metrics: Evaluate paddles based on key performance metrics such as control, durability, and ergonomics.

- Production Consistency: Ensure that the manufacturer can consistently deliver high-quality products through rigorous quality control measures.

- Technological Capability: Consider the manufacturer's expertise in advanced production processes and material engineering.

- Cost Efficiency: Balance between performance enhancements and production costs to meet budget constraints while offering premium products.

For procurement managers and sports equipment buyers, aligning inventory with these trends means not only securing products that offer competitive advantages on the court but also future-proofing their offerings in a rapidly evolving market.

In conclusion, the elite pickleball paddles for 2025 are defined by a combination of advanced materials, precision production techniques, and thoughtful design. The integration of premium options such as 12K Carbon Fiber1, innovative composites, and state-of-the-art production methods like hot pressing and thermoforming ensures that these paddles deliver unmatched performance, durability, and player comfort.

For B2B buyers, the following actionable recommendations are key to making informed procurement decisions:

- Evaluate paddle performance based on both material quality and production technique.

- Ensure the product portfolio offers customization to meet market-specific demands.

- Choose manufacturers with robust quality control practices and proven market track records.

- Balance production costs with performance standards to maximize ROI while catering to both professional and recreational segments.

- Stay attuned to evolving market trends, including sustainability and technological advancements, to maintain a competitive edge.

By taking these steps, companies can secure products that not only meet current market standards but also anticipate future changes in consumer demand and competitive landscape.

What is the best pickleball paddle for 2025?

The best pickleball paddles for 2025 are those that integrate premium materials, such as 12K Carbon Fiber1, with advanced production processes like hot pressing and thermoforming. These paddles deliver excellent balance, durability, and control, meeting the high performance standards demanded by both professionals and recreational players.

What paddle is Ben Johns using in 2025?

In 2025, top athletes like Ben Johns are using high-performance paddles that incorporate cutting-edge materials and production techniques. For instance, models such as the JOOLA Ben Johns Perseus Pro IV 16mm Pickleball Paddle Gen 4 are among the preferred choices due to their superior blend of control, power, and durability.

What is the most popular pickleball paddle used by the pros?

Many professional players opt for paddles that offer a perfect balance of power and precision. Models like the JOOLA Perseus, Selkirk VANGUARD Power Air Invikta, and others have become popular among pros for their advanced material construction and reliable performance, making them a staple on elite competitive circuits.

-

12K Carbon Fiber: Click to read more about this advanced material, which offers a smooth surface, greater hardness, and high impact resistance—key benefits for competitive play and superior product durability. ↩ ↩2 ↩3 ↩4 ↩5

-

Hot pressing: Click to learn about this production process that uses heat and pressure to form strong, consistently structured paddles ideal for mass production. ↩ ↩2

-

Thermoforming: Click to understand the thermoforming process, where controlled heating softens materials for intricate molding and optimized weight distribution in high-performance paddles. ↩ ↩2

-

Honeycomb Core: Click to discover the benefits of a honeycomb core structure, which provides superior shock absorption and reduces vibration, ensuring long-lasting player comfort. ↩

-

Ergonomic grip design: Click to explore how ergonomic grip designs enhance player comfort and reduce fatigue, a critical factor in the overall performance and market appeal of sports equipment. ↩