Quick Answer: Advanced carbon fiber1 materials, including 3K, 12K, and T300, provide superior stiffness, durability, and responsiveness compared to traditional materials, making them a top choice for high-performance pickleball paddles when paired with the right production process like hot pressing2 or thermoforming3.

In the competitive world of sports equipment manufacturing, making the right materials choice is critical—especially when selecting materials for pickleball paddles. Decision-makers and procurement managers must consider numerous factors such as strength, durability, weight, flexibility, and production efficiency. In this article, we dive deep into the role of carbon fiber in paddle production, examine its different variants, and compare its performance to traditional materials like fiberglass4 and composite cores. We also look at various production techniques, including hot pressing, cold pressing, and thermoforming, that influence the overall performance of the paddle.

Many B2B buyers face the challenge of choosing between advanced material options and traditional manufacturing alternatives. With the rising popularity of pickleball, there is no shortage of innovation in paddle design. However, technical specifications such as impact resistance, energy absorption, and weight balance become critical factors. The primary question is not merely "is carbon fiber better?" but rather how its superior performance attributes can be maximized through appropriate production processes and design integration.

Procurement managers often encounter issues with:

• Durability under repetitive high-impact loading

• Maintaining a lightweight yet powerful paddle

• Ensuring uniform energy distribution across the paddle face

• Cost efficiency in large-scale production

• Balancing material properties with ergonomic design

These challenges arise from the inherent properties of the materials used. With traditional paddles, fiberglass and low-grade composites may compromise on strength and longevity. On the other hand, while carbon fiber offers excellent performance attributes, the benefits can be negated if not processed correctly. Therefore, understanding the production process is as important as the material choice itself.

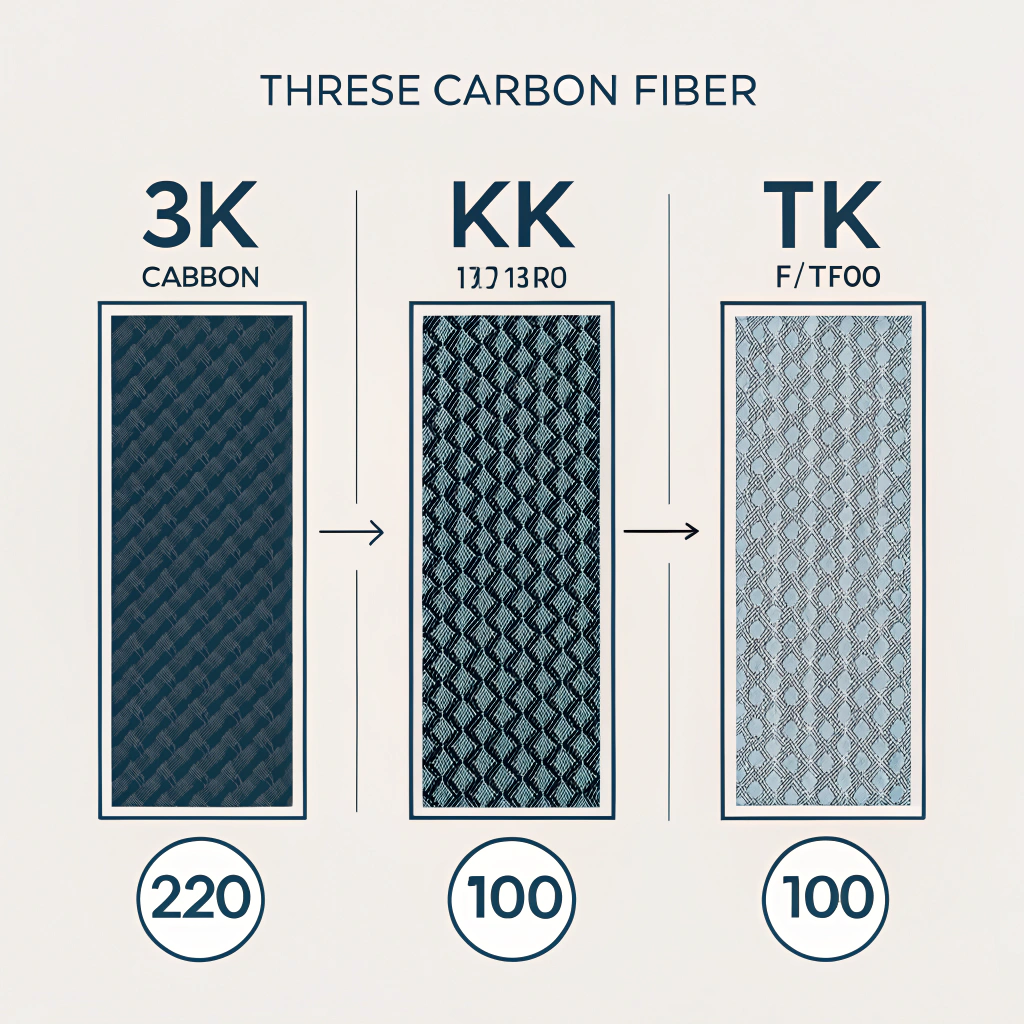

Carbon fiber stands out because of its unique structure, which gives it exceptional stiffness and durability. Let’s break down the main types:

• Known for its balance of strength and flexibility.

• It delivers high rebound force, making it ideal for competitive play.

• Reduces paddle vibration, providing a refined touch and more controlled energy absorption.

• Features a higher thread density that results in a smoother paddle surface.

• Offers improved hardness and durability, which is critical during high-impact play.

• Praised for its balance between strength and light weight.

• Provides a consistent performance with enhanced impact resistance.

Using these carbon fiber types, manufacturers like NEX Pickleball can produce paddles that meet the rigorous demands of professional athletes while also catering to recreational players.

While carbon fiber exhibits high-performance attributes, it is essential to compare it with other material options used by manufacturers.

Traditional fiberglass paddles offer a balanced combination of power and control. They are known for:

• A wider sweet spot, which translates to enhanced ball control.

• Greater flexibility, though sometimes at the expense of stiffness and rebound efficiency.

Composites, especially those that combine carbon fiber and fiberglass or incorporate bamboo cores and honeycomb structures, are designed to harness the best of both worlds:

• Carbon Fiber & Fiberglass Composite: Delivers both power and control, making it a favorite for mid-range paddles.

• Bamboo Core Composite: Provides a lightweight feel with enhanced impact resistance.

• Honeycomb Core: Offers excellent shock absorption, reducing paddle vibration significantly.

The core of a paddle influences its overall performance by dictating its control and responsiveness:

• Nomex Honeycomb Core5: Offers longevity and excellent shock absorption—commonly seen in premium paddles.

• Aluminum Honeycomb Core: Produces a balanced weight distribution ideal for precision and power.

• Polymer Honeycomb Core: Favored for its elasticity and comfort, especially beneficial for beginners and recreational players.

To illustrate the differences, consider the following table:

| Material/Technology | Strength | Flexibility | Impact Resistance | Cost Effectiveness | Use Case |

|---|---|---|---|---|---|

| 3K Carbon Fiber | High | Moderate | High | Higher | Competitive play |

| 12K Carbon Fiber | Very High | Lower | Very high | High | Professional level paddles |

| T300 Carbon Fiber | High | Balanced | High | Moderate | Versatile high-performance |

| Fiberglass | Moderate | High | Moderate | Lower | Recreational or budget use |

| Nomex Honeycomb Core5 | High | Moderate | Excellent | Moderate | Premium paddles |

| Polymer Honeycomb Core | Moderate | High | Good | Moderate | Recreational to mid-range |

This table not only highlights the benefits but also assists in deciding which combination best aligns with both performance requirements and budget constraints.

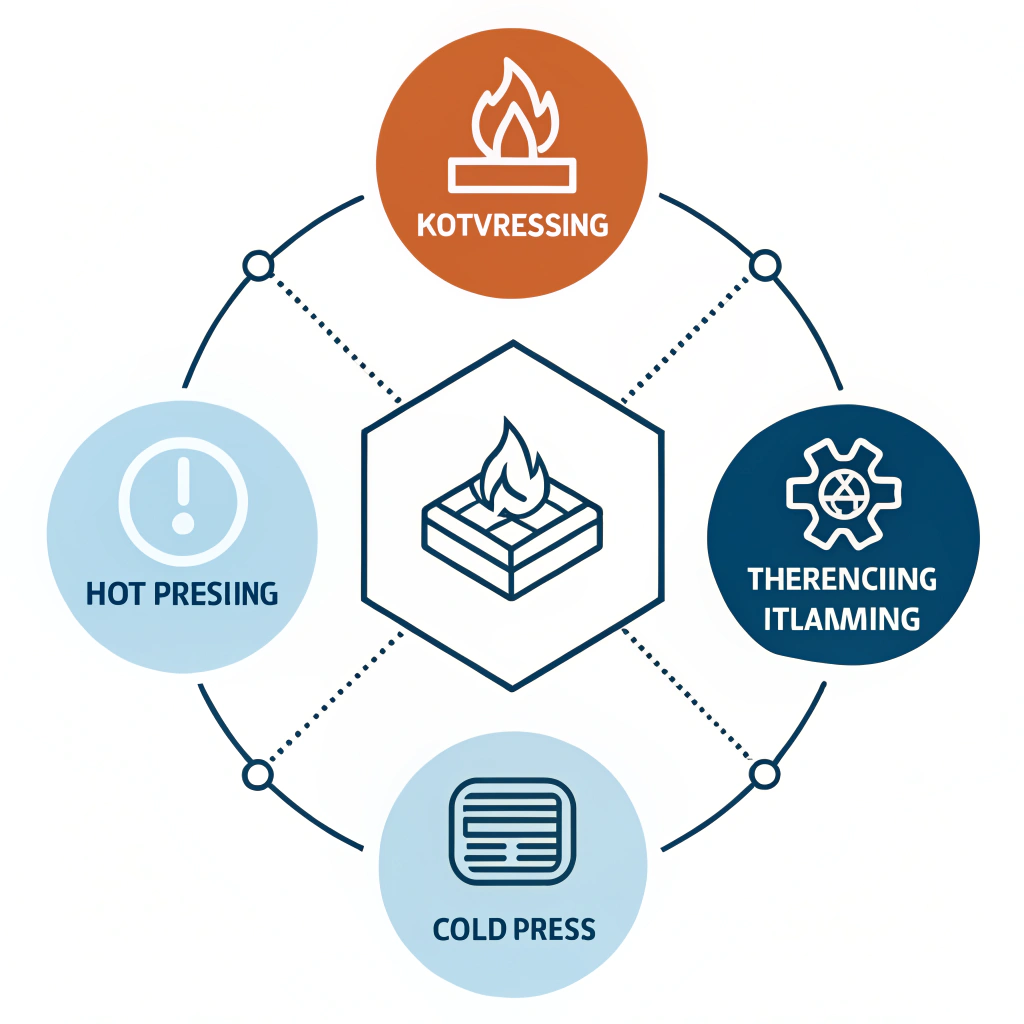

While the materials themselves are the foundation, the production process plays a significant role in the final product quality. NEX Pickleball employs three major production processes, each with its merits and limitations:

Hot pressing2 involves heating materials before applying mechanical pressure. It benefits include:

• High production efficiency: Ideal for large-scale manufacturing.

• Enhanced impact resistance: Creates a robust paddle structure.

• Structural Integrity: Essential for maintaining long-term performance.

Nonetheless, potential drawbacks involve changes in material feel and higher upfront equipment costs.

Cold pressing shapes the paddle at room temperature:

• Allows for precise control over thickness and structure.

• Retains material properties without altering the inherent qualities.

• Delivers superior ball feel and responsiveness.

The trade-off is a longer production cycle and a dependency on high precision equipment, which might not be ideal for high-volume outputs.

Thermoforming3 uses heat to mold materials into complex shapes:

• Enables intricate designs and optimized material distribution.

• Preserves stability and performance over time.

• Ideal for custom-made and high-end products.

However, this technique is more time-consuming and cost-intensive, making it best suited for premium product lines.

The following table summarizes the production methods:

| Production Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structure, robust impact force | Material feel alteration, high equipment cost | Large-scale manufacturing |

| Cold Pressing | Precise control, preserved material properties | Longer production time | Applications requiring precision |

| Thermoforming | Complex designs, optimal material distribution | Higher costs and longer cycle times | Premium and custom paddles |

Each of these processes has its context of use, and selecting the appropriate method depends on the desired paddle characteristics and production volume. For B2B buyers, understanding these processes is critical when assessing supplier capabilities and ensuring that the final product meets market expectations.

When evaluating advanced materials and production techniques, consider the following aspects:

-

Performance Requirements:

- Determine whether your paddle design leans more towards power, control, or a balanced performance. Carbon fiber types vary significantly in performance and can be chosen accordingly.

-

Production Volume and Cost-Sensitivity:

- High-volume production may benefit from hot pressing methods despite the initial high cost of equipment. Smaller runs or custom orders might justify the use of cold pressing or thermoforming.

-

Supplier Credibility and Quality Control:

- Partner with manufacturers that have a proven track record in quality assurance and advanced production methods. At NEX Pickleball, rigorous testing ensures every paddle meets precise performance metrics.

-

Market Trends and Innovation:

- Stay informed about new material innovations and production techniques. The sports equipment industry continuously evolves, and being an early adopter can provide a competitive edge.

-

Customization and Flexibility:

- Consider suppliers who offer bespoke solutions. Being able to tailor paddle characteristics to suit specific playing styles or market segments can differentiate your products in a crowded market.

To sum up, carbon fiber materials offer unmatched performance benefits for pickleball paddles. Their superior stiffness, durability, and energy dispersion capabilities provide enhanced control, power, and precision. However, simply choosing a high-performance material isn’t enough; the selected production process and supplier expertise are equally important.

For B2B procurement managers and manufacturing decision-makers, the following steps are recommended:

• Conduct a thorough evaluation of the desired paddle performance and match it with the appropriate carbon fiber type and production method.

• Compare the technical specifications of carbon fiber versus traditional materials using detailed, data-supported methods such as the tables above.

• Engage with reputable manufacturers like NEX Pickleball who maintain high quality standards, offer customizable solutions, and utilize modern production techniques for optimal results.

Proactive decision-making in material selection and production methodology not only enhances product performance but also positions your brand as a leader in innovation and quality in the sports equipment market.

Q: Is carbon fiber better for pickleball?

A: Yes, carbon fiber is generally superior for pickleball due to its stiffness, durability, and ability to absorb and distribute impact energy evenly, resulting in enhanced control and shot precision.

Q: What advantage does carbon fibre construction offer in a pickleball paddle?

A: Carbon fiber construction provides a stiffer and more responsive paddle face, which translates into more power and accuracy in every shot, making it ideal for competitive play.

Q: What is the best core material for pickleball paddles?

A: While many lower-end paddles use Nomex or aluminum cores, polymer cores are widely recognized for their superior elasticity and reduced vibration, offering improved comfort and performance for most players.

-

carbon fiber: Click to learn about advanced composite materials made from carbon fibers that deliver exceptional strength-to-weight ratios, ideal for high-performance sports equipment. ↩

-

hot pressing: Click to explore the high-efficiency production process that uses heat and pressure to mold materials, enhancing structural integrity and impact resistance. ↩ ↩2

-

thermoforming: Click to understand the process where heat is used to shape materials into complex, customized designs for premium products. ↩ ↩2

-

fiberglass: Click to read more about this traditional composite material, its manufacturing advantages, and its role as an alternative in various production contexts. ↩

-

Nomex Honeycomb Core: Click to discover how this lightweight core material offers excellent shock absorption and durability, making it a popular choice in premium paddle designs. ↩ ↩2