The fastest answer: High-performance pickleball paddles in 2025 are ranked based on advanced materials, precision production processes, and optimized performance features such as weight distribution, durability, and ball control. B2B buyers should assess the quality of carbon fibers1 and composite cores, compare manufacturing methods like hot pressing2 versus cold pressing3, and consider overall product consistency for competitive distribution.

In today’s highly competitive sports equipment market, understanding the nuances behind top-tier pickleball paddles is essential for making informed procurement decisions. For B2B buyers such as sports equipment distributors and retail chain managers, the focus is not only on the final performance of the paddle but also on the manufacturing precision that drives durability and consistency. At NEX Pickleball, our advanced production methods and quality materials position us at the forefront of innovation, enabling us to offer paddles that meet the demanding requirements of competitive play and long-term distribution.

Selection Dilemma in the Market

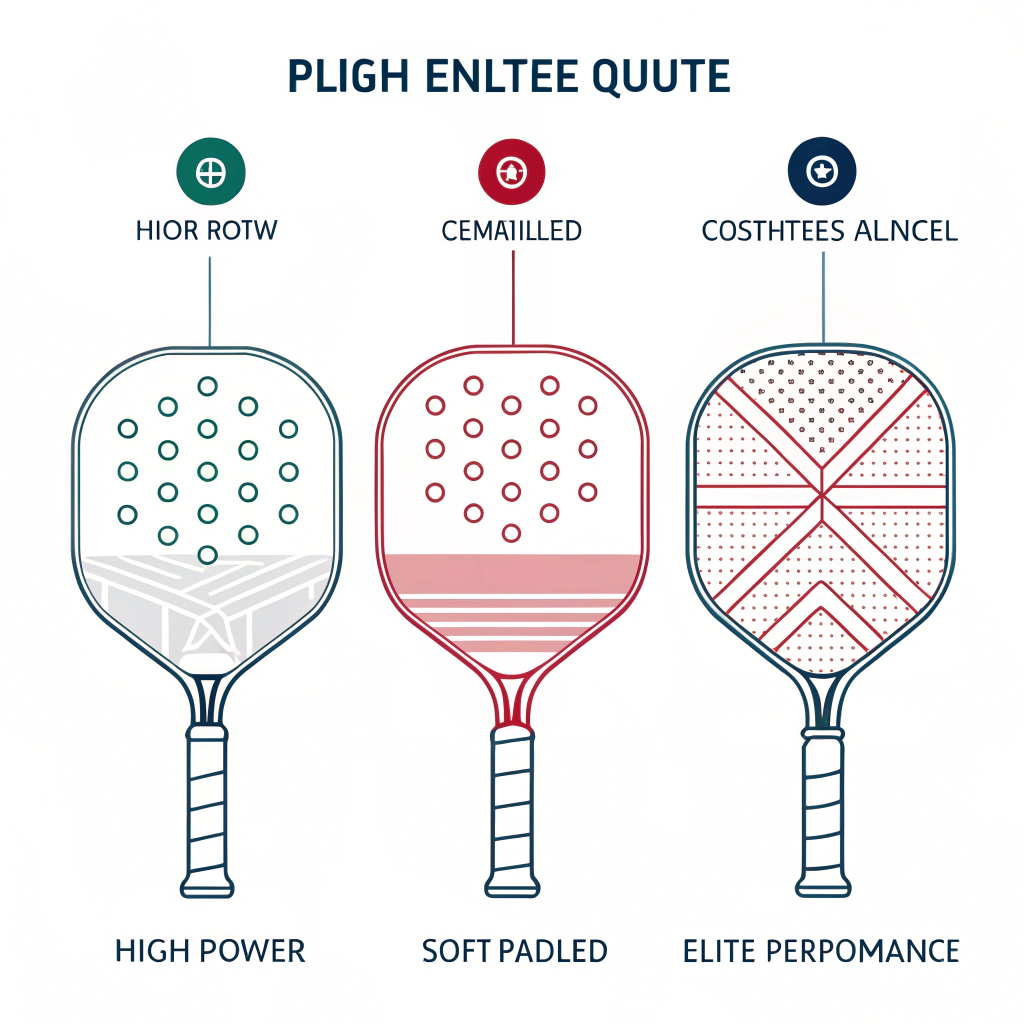

Procurement specialists are often faced with the challenge of choosing between multiple paddle varieties, each claiming superior quality. The decision-making process involves comparing detailed performance metrics, production techniques, and material compositions. Key factors that influence the ranking of high-performance pickleball paddles include:

• Material Quality: The type of carbon fiber or fiberglass used.

• Core Composition: Options like Nomex honeycomb4, aluminum honeycomb, or polymer cores which determine shock absorption and impact resistance.

• Production Process: Techniques such as hot pressing, cold pressing, or thermoforming5 can impact the paddle’s consistency and performance characteristics.

• Customizability: Input on paddle design, grip size, and weight distribution can be critical for meeting the extensive needs of retail chains.

Selecting the right paddle is pivotal for achieving a balance between power and control, durability and comfort. Below is a detailed comparison table that outlines several key dimensions in the decision-making process:

| Paddle Type | Material Composition | Core | Production Process | Advantages | Limitations |

|---|---|---|---|---|---|

| High-Power Paddle | 12K and T300 Carbon Fiber | Aluminum Honeycomb Core | Hot Pressing | High rebound, superior strength; great for competitive play | Can sometimes alter material properties |

| Balanced Control Paddle | Combination of Carbon Fiber & Fiberglass | Polymer Honeycomb Core | Cold Pressing | Excellent ball feel, enhanced control; preserves material | Longer production cycle |

| Customized Elite Paddle | Premium composite (Bamboo + Carbon Fiber) | Nomex Honeycomb Core | Thermoforming | Custom design options, distinctive hitting feel, best durability | Highest production cost, longer lead times |

In-Depth Technical Analysis

A closer look at the technical aspects reveals that every detail counts when it comes to paddle performance:

-

Carbon Fiber Variants:

- 3K Carbon Fiber is prized for its flexibility and impact reduction. It is widely used in paddles where vibration dampening and durability are critical.

- 12K Carbon Fiber offers a high thread density, providing a smoother paddle surface with greater hardness. This type is particularly suitable for racing circumstances and high-speed games.

- T300 Carbon Fiber balances tensile strength with lightweight design, making it ideal for precision play. Each type fulfills a unique role in balancing power and control.

-

Fiberglass and Composite Materials:

- Fiberglass paddles often deliver a broader sweet spot, giving players better control and easier handling. The use of E-Glass fiberglass further enhances elasticity—ideal for recreational and intermediate players.

- Composite materials are engineered to combine the best qualities from different fibers. For example, a composite of carbon fiber and fiberglass can offer a mix of strength, lightness, and flexibility. This synergy creates paddles that excel across multiple performance metrics.

-

Core Innovations:

- The core of a paddle strongly influences its rigidity, shock absorption, and overall balance. Nomex honeycomb cores deliver enduring performance with exceptional impact resistance, making them a favorite for long-term use in high-performance settings.

- In contrast, aluminum honeycomb cores provide a balanced weight distribution, ensuring that paddles remain agile while still offering robust control during high-intensity play.

- Polymer cores are celebrated for reducing vibration, which adds comfort during extended play sessions—crucial for recreational markets and beginner players.

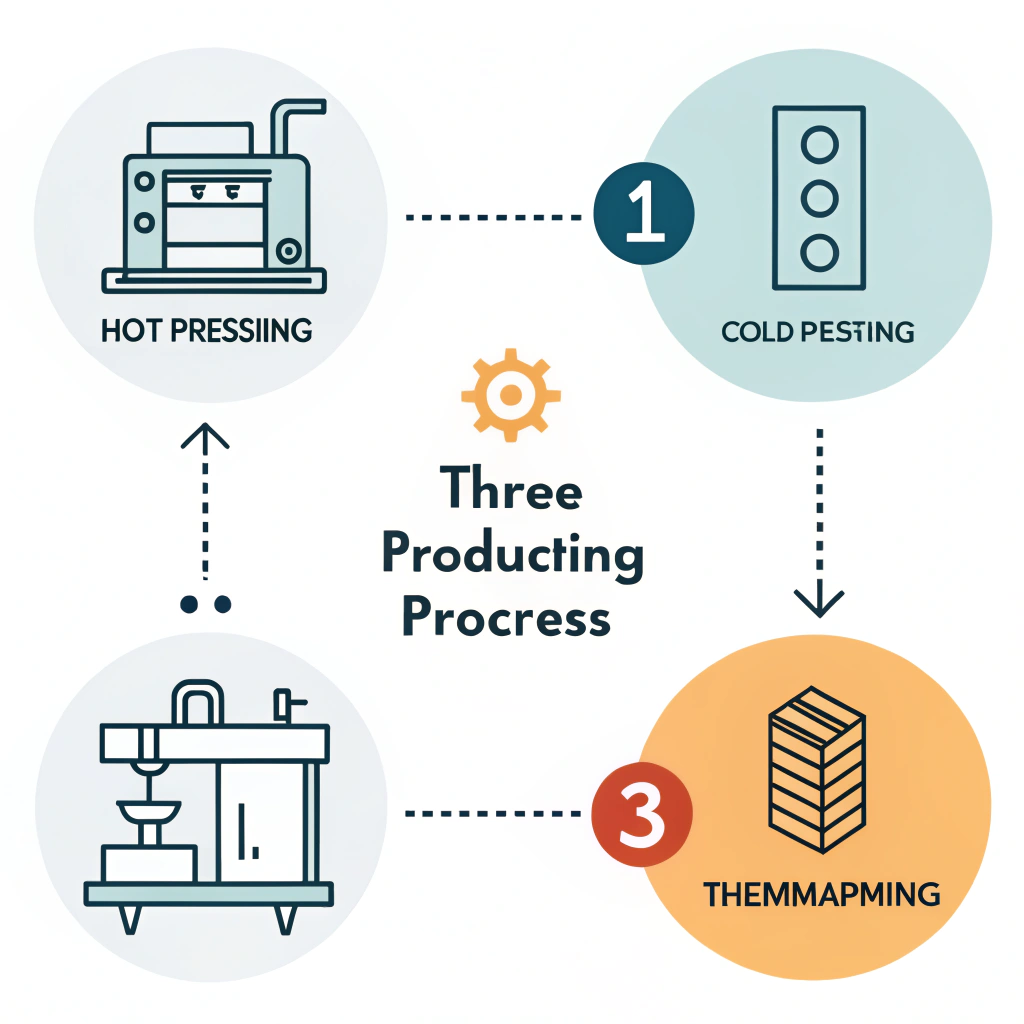

Comparing Production Processes

Manufacturing processes are not one-size-fits-all. At NEX Pickleball, we employ three main methods:

• Hot Pressing:

This process involves applying heat and pressure simultaneously to form a solid, unified paddle structure. The advantages include:

- High production efficiency suitable for large-scale manufacturing.

- Enhanced impact resistance, resulting in a more durable paddle.

- Consistent performance output, ideal for players who demand robust quality.

Nevertheless, the high pressure and thermal exposure may alter the tactile feel of the paddle, a factor that may not be preferred for designs emphasizing precision ball control.

• Cold Pressing:

Employed to maintain the intrinsic properties of the material by shaping them under mechanical pressure at room temperature, cold pressing allows for precise control over the paddle’s dimensions. This technique:

- Retains the natural characteristics of the surface materials, ensuring excellent control and ball feel.

- Offers tailored thickness management, leading to paddles that balance power and finesse.

- Is often chosen for custom paddle orders where design precision is essential.

However, the longer production cycles and need for precise equipment can result in higher production costs and more limited scalability.

• Thermoforming:

This technique involves heating materials to a pliable state and then forming them within specific molds. Thermoforming stands out when intricate designs and specific material distributions are required. Its benefits include:

- The capability to create paddles with complex geometries.

- Superior material distribution that enhances stability and performance.

- Tailored solutions for premium product lines and custom orders.

The trade-offs are longer production times and higher capital expenditure on specialized equipment, making thermoforming best suited for high-end paddle offerings.

Below is a comparative table summarizing these production processes:

| Production Process | Key Advantages | Limitations | Best Used For |

|---|---|---|---|

| Hot Pressing | High efficiency; robust impact resistance | Alters some material properties; high equipment cost | Large-scale, high-impact paddles |

| Cold Pressing | Retains material properties; precise dimensions | Longer production cycle; requires precision | Custom, balanced control paddles |

| Thermoforming | Intricate designs; customized material distribution | Long production time; higher equipment investment | Premium, high-performance paddles |

Integrating Quality and Consistency

For B2B purchasers, quality consistency is as important as innovation. Every paddle manufactured at NEX Pickleball goes through rigorous quality control testing, ensuring it meets the highest standards in strength, flexibility, and playability. This reliability is grounded in our continuous investment in advanced production techniques and a relentless focus on material quality.

Key quality measures include:

- Standardized tests to evaluate rebound force, vibration dampening, and grip surface texture.

- Regular calibration of equipment to maintain precise pressure and temperature control in both cold and hot pressing environments.

- Batch testing to ensure that custom paddle orders consistently meet client specifications.

Manufacturers and distributors deserve products that not only perform well in a controlled environment but can also withstand the varied demands of competitive play. Our commitment to innovation, paired with extensive testing, supports our claim as a trusted partner for sports equipment distributors globally.

Moreover, the ability to customize paddle options—from grip sizes to weight distribution—further sets high-performance paddles apart in a competitive market. Offering flexibility in design while maintaining industry-leading production standards means our products address both mass-market needs and specialized niche requirements.

Conclusion and Action Recommendations

In summary, the future of high-performance pickleball paddles lies in a strategic combination of advanced materials and cutting-edge production processes. For B2B buyers, the decision should be based on the following actionable insights:

- Evaluate which material composition—be it carbon fiber, fiberglass, or composites—best meets the performance expectations and durability needed by your customer base.

- Factor in the specific production process used. Hot pressing is ideal for mass production and durability, cold pressing preserves material details for superior ball feel, and thermoforming offers custom solutions for premium segments.

- Consider the overall design, including core materials and ergonomic elements, to match the paddle performance with target consumer preferences.

- Request product samples or visit production facilities when possible to verify quality and consistency firsthand, ensuring your procurement aligns with long-term market trends.

For sports equipment distributors and procurement specialists, leveraging detailed production insights and comparative data is key to making informed decisions that bolster your product offerings in a competitive market.

NEX Pickleball is dedicated to providing not only exceptional paddles but also transparent insight into our manufacturing processes and technology. We invite you to connect with our product specialists to explore how our customized solutions can strategically enhance your portfolio and offer your customers a superior playing experience.

People Also Ask

Q1: What factors determine the performance ranking of pickleball paddles?

A1: The ranking is influenced by factors such as the quality of materials (e.g., various types of carbon fiber and fiberglass), core composition (like Nomex honeycomb or aluminum honeycomb), precision in production processes (hot pressing, cold pressing, thermoforming), and design features including weight distribution and ergonomic grip.

Q2: How do production methods like hot pressing, cold pressing, and thermoforming compare?

A2: Hot pressing offers high-efficiency and superior impact resistance, making it ideal for mass production; cold pressing preserves the material’s natural properties with precise control over dimensions; and thermoforming enables intricate, custom designs but requires longer production times and higher equipment costs.

Q3: What are the benefits of using carbon fiber over fiberglass in pickleball paddles?

A3: Carbon fiber provides increased strength, better rebound force, and reduced vibration, making it suitable for competitive play, while fiberglass offers enhanced flexibility, a broader sweet spot, and improved ball control ideal for recreational and intermediate-level players.

-

carbon fibers: Click to read an in-depth analysis on the properties, manufacturing techniques, and performance benefits of carbon fibers, including their impact on the durability and lightweight design of sports equipment. ↩ ↩

-

hot pressing: Click to explore how the hot pressing process works, its role in mass production, and why it contributes to the superior impact resistance of high-performance paddles. ↩ ↩

-

cold pressing: Click to learn about the cold pressing technique, its advantages in retaining material properties, and how it helps achieve precision craftsmanship in paddle production. ↩ ↩

-

Nomex honeycomb: Click to understand the structure, benefits, and applications of Nomex honeycomb cores in sports equipment, highlighting their shock absorption and impact resistance features. ↩ ↩

-

thermoforming: Click to read about the thermoforming process, its capability to create intricate designs, and why it's a key technique for manufacturing custom, high-performance paddles. ↩ ↩