The Best Pickleball Paddles of 2025 are defined by advanced materials, innovative production processes, and a keen focus on performance durability—all crucial factors for B2B buyers in sports equipment. This guide offers a detailed comparison of the latest pickleball paddles available in 2025, breaking down the differences in materials, manufacturing techniques, performance attributes, and overall value to help procurement managers make informed decisions.

The pickleball equipment market is evolving at a rapid pace. Buyers are faced with the challenge of sifting through a wide range of products that differ in technical specifications, production methods, and material quality. In 2025, high-performance pickleball paddles are largely influenced by innovations in material science and precision manufacturing processes.

Procurement managers and sports equipment distributors demand products that deliver:

- Enhanced power and control for competitive play.

- Consistent quality for mass production and brand reliability.

- Customization options for personalized team branding or specialized play styles.

- Durable construction to withstand intensive usage.

However, the choice is not straightforward. With multiple materials such as carbon fiber, fiberglass, and composites influencing performance characteristics, making the right selection requires detailed technical insights and a firm grasp of production processes.

High-performance paddles today use premium materials that directly affect their playing attributes. Some of the key materials include:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Offers flexibility and high rebound force, ideal for players who demand both durability and a controlled response.

- 12K Carbon Fiber: Known for its smoother surface and higher density, this material boosts toughness and exceptional strength for competitive use.

- T300 Carbon Fiber1: Delivers an optimal balance of light weight and tensile strength, making it perfect for paddles that require a mix of speed and power.

-

Fiberglass Options:

Fiberglass paddles, particularly those using E-Glass fiberglass2, are preferred for their wider sweet spots and excellent ball control. Their elasticity and tensile strength provide a comfortable yet reliable hitting surface. -

Composite Materials:

Combining the best properties of carbon fiber and fiberglass, composite materials deliver both strength and flexibility. Options like the Carbon Fiber and Fiberglass Composite or Bamboo Core Composite provide benefits such as superior shock absorption and extended durability.

These materials not only define the paddle’s core performance but also impact its longevity and vibration reduction during play.

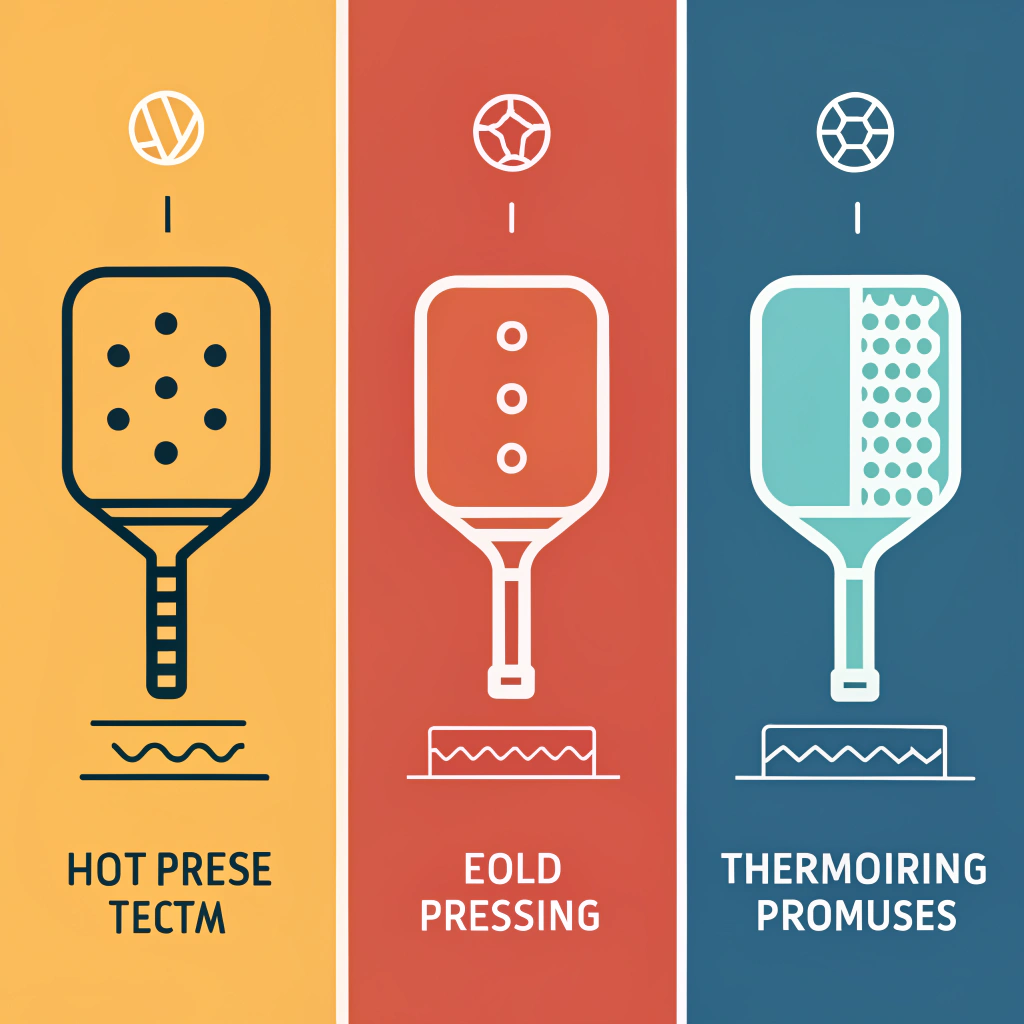

Understanding production techniques is as important as knowing the materials. At the core of paddle manufacturing, three dominant processes help define product performance:

-

Hot Pressing:

This method involves heating the material and applying pressure to achieve a uniform, structurally sound paddle.

Advantages:- High production efficiency, suitable for large-scale orders.

- Produces paddles with excellent impact resistance and strength.

Disadvantages: - The heat may alter some material properties, impacting the overall feel.

- Requires significant investment in specialized equipment.

-

Cold Pressing3:

Cold pressing shapes the materials at room temperature and is ideal for designs needing precise thickness and structure.

Advantages:- Maintains the intrinsic properties of the material for better control and flexibility.

- Produces a highly responsive paddle with refined ball feel.

Disadvantages: - Slower production cycles compared with hot pressing.

- Demands robust pressure control mechanisms to ensure quality consistency.

-

Thermoforming4:

In this process, materials are heated until pliable and then molded into the desired shape using precision molds.

Advantages:- Delivers intricate designs with precise material distribution, enhancing stability and performance.

- Ideal for creating custom paddles with specific weight distributions and ergonomic features.

Disadvantages: - Requires more time and higher cost per unit, making it best suited for premium or custom-made orders.

Below is a concise table summarizing these methods:

| Production Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High production efficiency; excellent strength | Potential alteration in feel; high equipment cost | Large-scale manufacturing |

| Cold Pressing | Precise control; retains material properties | Longer production cycle; requires precise control | Custom playability and responsiveness |

| Thermoforming | Intricate designs; precise material distribution | Higher cost per unit; extended production time | Premium and custom-made paddles |

When selecting pickleball paddles, B2B buyers should weigh several key factors:

-

Performance vs. Durability:

For competitive sports or club-level orders, high-performance paddles that maintain consistency over long periods are critical. Production methods such as hot pressing might be favored for their durability, while cold pressing offers precision needed in advanced competitive play. -

Customization and Branding:

Custom paddle options allow for personalized designs, making them suitable for team branding or exclusive retail offers. Clients can choose specific core materials (e.g., Nomex Honeycomb Core5, Aluminum Honeycomb Core, or Polymer Honeycomb Core) that impact the paddle’s weight and vibration absorption. -

Cost Efficiency and Scale:

Manufacturing techniques like hot pressing allow for higher volume, which is appealing for retailers looking to order in bulk without compromising on quality. However, niche markets may opt for the precision of cold pressing or the artistic customization of thermoforming, despite the higher costs. -

Technological Edge and Testing:

Investing in paddles that have undergone rigorous testing can reduce quality control issues down the line. Cutting-edge production and quality assurance processes ensure that every paddle meets high standards of power, control, and ergonomic design. -

Global Supply Chain Considerations:

Given the global market for sports equipment, consistent quality across production batches is paramount. Manufacturers like NEX Pickleball, based in Jiaxing, Zhejiang, China, focus on stringent quality control and advanced production techniques to cater to international distributors.

Let’s consider an example where a sports equipment distributor needed to secure a reliable supply of high-performance paddles for a major sports club. The distributor faced a challenge: choosing between multiple production methods and materials. By analyzing key performance metrics and production techniques, the distributor discovered that paddles manufactured through thermoforming, though slightly costlier, offered the best balance of customized design and performance consistency.

The distributor collaborated with NEX Pickleball, leveraging their expertise in using advanced T300 Carbon Fiber and Nomex Honeycomb Core in combination with thermoforming techniques to produce paddles with a perfect balance of strength and responsiveness. The result was a product that not only met the performance needs of top-tier players but also provided a unique branding opportunity for the sports club.

This case underscores the importance of understanding the interplay between material selection, manufacturing processes, and end-user needs. When armed with this information, procurement managers can negotiate better terms and ensure a steady supply of premium-grade pickleball paddles.

High-performance pickleball paddles in 2025 are engineered to address several specific areas:

-

Enhanced Ball Control:

Materials such as fiberglass and composite mixtures are specifically selected to optimize control. For example, paddles with E-Glass Fiberglass allow for a softer hitting surface that improves precision and reduces mis-hits in fast-paced games. -

Shock Absorption and Vibration Reduction:

The core material plays a significant role. Nomex Honeycomb Core and Polymer Core are engineered to dampen vibrations, ensuring a comfortable playing experience even during extended matches. -

Weight Distribution and Ergonomic Design:

Modern paddles are designed with meticulous care to balance weight distribution and ergonomic handles. This minimizes fatigue and enhances grip, which is critical for both novice and professional players. NEX Pickleball’s design philosophy emphasizes these factors to deliver paddles that support long-term performance. -

Customization Capabilities:

In today’s marketplace, custom-order paddles cater to diverse customer requirements. Customization options include grip sizes, weight preferences, and visual designs tailored to individual brands or teams.

Organizing these factors into a technical performance matrix can help buyers quickly assess the best fit for their requirements:

| Attribute | Key Material/Process | Benefit | Suitable For |

|---|---|---|---|

| Ball Control | Fiberglass / Composite | Provides wider sweet spot, precise hits | Recreational and competitive |

| Shock Absorption | Nomex Honeycomb Core | Reduces vibration, enhances comfort | Professional competitive play |

| Durability and Strength | 12K Carbon Fiber | Ensures long-lasting performance | High-impact play |

| Customization | Thermoforming Process | Intricate designs and personalized options | Team branding and exclusive orders |

- Identify the primary performance needs of your target market. If durability and impact resistance are priorities, lean towards paddles manufactured with hot pressing using 12K Carbon Fiber.

- Evaluate customization requirements that could add value to your branding or product offering. Consider paddles produced by thermoforming methods if unique designs are a priority.

- Request technical datasheets and performance test results from suppliers. This ensures that the paddle meets all critical criteria such as shock absorption, control, and power.

- Consider establishing long-term relationships with manufacturers who focus on quality assurance and consistency. Collaborations with experienced factories like NEX Pickleball can lead to better order outcomes and streamlined custom production opportunities.

- Organize pilot orders to test the performance and durability of the paddles in actual play scenarios before committing to large-scale orders.

In conclusion, the best pickleball paddles of 2025 offer an impressive blend of advanced materials, precise production processes, and customizable features tailored for both competitive and recreational players. With detailed technical insights and proven performance metrics, procurement managers can confidently choose paddles that are not only cost-effective but also align with the high-performance demands of modern pickleball.

Q: What paddle do most pickleball pros use?

A: Many professional players opt for paddles designed for high control and power, such as those manufactured with 3K or 12K Carbon Fiber. Leading models include selections from brands like JOOLA and Selkirk, which emphasize a balanced mix of strength, spin, and precision.

Q: Which pickleball paddle hits the hardest?

A: Paddles designed for maximum impact often incorporate advanced composite materials and optimal core structures. For instance, some models utilize a blend of high-performance carbon fibers and thermoformed designs that deliver the hardest impact while maintaining control.

Q: What is the best pickleball paddle for seniors?

A: For senior players, lightweight paddles made from materials like fiberglass or advanced composites are ideal. These paddles provide enhanced control and reduced vibration, ensuring a comfortable and precise playing experience even during extended games.

-

T300 Carbon Fiber: Click to read an article that explains how T300 Carbon Fiber balances lightweight properties with high tensile strength, offering a competitive edge in sports equipment manufacturing. ^Return ↩

-

E-Glass fiberglass: Click to explore the benefits of E-Glass fiberglass, including its elasticity and durability that make it ideal for sports equipment designed for improved ball control. ^Return ↩

-

Cold Pressing: Click to read more about the cold pressing manufacturing process, which utilizes room temperature forming to preserve material properties for enhanced paddle responsiveness. ^Return ↩

-

Thermoforming: Click to understand the thermoforming process, a specialized molding technique that enables precise custom shapes and tailored material properties for premium paddle designs. ^Return ↩

-

Nomex Honeycomb Core: Click to learn about the Nomex Honeycomb Core, a key material that delivers superior shock absorption and vibration reduction in high-performance sports paddles. ^Return ↩