Pickleball paddle performance often hinges on the manufacturing process and material composition. In this article, we explore how advanced techniques such as hot pressing1, cold pressing2, and thermoforming3 affect the paddle's power, control, and durability, helping B2B procurement managers make informed decisions.

B2B procurement managers and sports equipment distributors face the complex challenge of selecting pickleball paddles that not only meet high-performance standards but also deliver a balanced blend of power and control. The performance of a paddle is determined by the manufacturing process and the choice of premium materials such as carbon fiber4, fiberglass, and various composite materials5. As manufacturers such as NEX Pickleball refine these techniques and processes, understanding the engineering details behind each method becomes essential for ensuring quality, reliability, and market competitiveness.

Different production techniques can influence the paddle’s structural integrity, durability, and even feel during play. Below, we analyze the three primary processes used in producing high-performance pickleball paddles:

Hot pressing1 involves heating materials and applying pressure to fuse components together. This technique is widely used to manufacture paddles with robust structures and excellent impact resistance.

-

Advantages:

- Highly efficient for large-scale manufacturing, ensuring consistency in production.

- Results in paddles that withstand high impact and stress, ideal for competitive play.

- Contributes to superior structural integrity, reducing deformation over time.

-

Disadvantages:

- The process’s intense heat can alter some inherent material properties, potentially impacting the paddle’s feel.

- High investment in specialized equipment is required, affecting cost efficiency for smaller production runs.

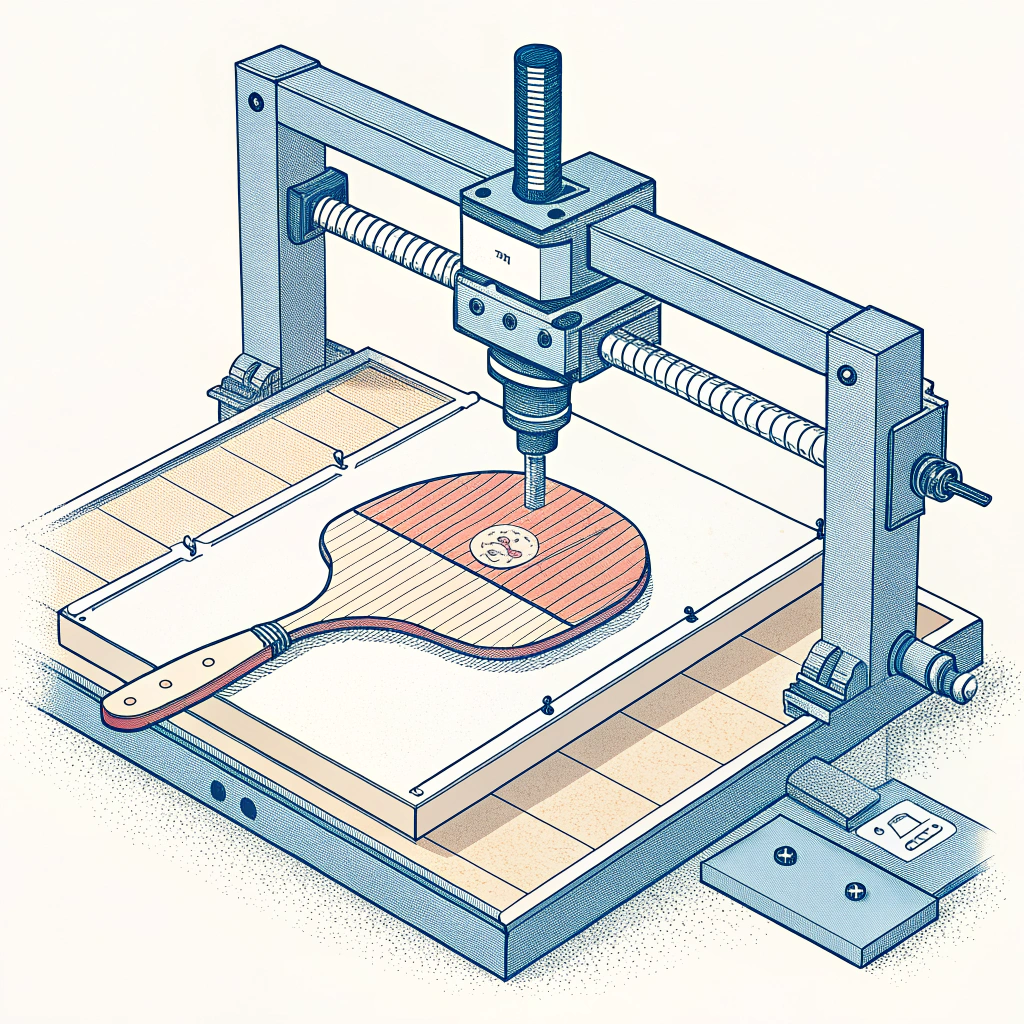

Cold pressing2 shapes the paddle's materials at room temperature using mechanical pressure. This method is preferred when exact control over the paddle's thickness and surface integrity is essential.

-

Advantages:

- Maintains the original properties of the materials, preserving the paddle’s natural response and control.

- Allows for precision in shaping the paddle, ensuring optimal consistency in product dimensions.

- Yields paddles with noticeably improved ball feel, which appeals to players who require precise control during gameplay.

-

Disadvantages:

- Extended production cycles can reduce overall efficiency.

- Requires stringent control over pressure, and any slight variation may lead to inconsistencies in the final product.

Thermoforming3 involves heating paddle materials to a pliable state, then forming them over molds to achieve intricate designs and precise material distribution.

-

Advantages:

- Ideal for crafting paddles with complex geometries, ensuring even distribution of forces during play.

- Helps maintain the structural stability of the paddle, even in high-performance scenarios.

- Suitable for both premium and custom-made paddle products, catering to niche market needs.

-

Disadvantages:

- Typically requires a longer production time compared to other methods.

- Involves higher equipment costs, making it a better fit for premium product lines.

The following table summarizes the core attributes of each manufacturing process used in paddle production:

| Production Process | Efficiency | Material Integrity | Product Consistency | Production Cost | Best For |

|---|---|---|---|---|---|

| Hot Pressing | High | Moderate | High | Higher initial investment | High-performance and competitive play paddles |

| Cold Pressing | Moderate | High | Very High | Requires precision equipment | Paddles needing refined control and ball feel |

| Thermoforming | Lower | High | High | Premium production costs | Custom-made and premium design paddles |

This table can serve as a quick reference guide for procurement managers to understand which production technique aligns best with their market requirements and performance expectations. In choosing the right method, it is essential to weigh the trade-offs between production speed, cost, and the desired playing characteristics.

At the heart of every high-performance pickleball paddle is its material composition. Manufacturers use a mix of premium materials to create paddles that meet stringent market demands:

- 3K Carbon Fiber: Renowned for its strength combined with flexibility. Paddles incorporating 3K carbon fiber benefit from reduced vibration and enhanced durability, making them ideal for players requiring dynamic response.

- 12K Carbon Fiber: Offers a smoother surface and greater hardness. Its high thread density provides increased impact resistance, crucial for competitive settings.

- T300 Carbon Fiber: Balances lightweight structure with excellent tensile strength. This type is perfect for achieving a mix of strength and maneuverability, protruding as a favorite for high-speed play.

Fiberglass paddles strike a balance between power and accuracy. Utilizing E-Glass Fiberglass gives paddles a wider sweet spot and optimal ball control, making them suitable for players at different skill levels.

Manufacturers often use combined material approaches for performance enhancement:

- Carbon Fiber and Fiberglass Composite: This blend harnesses the best features of both materials, offering a robust yet adaptable paddle structure.

- Bamboo Core Composite: The natural bamboo core ensures a lightweight paddle with excellent impact resistance, preferred for prolonged play.

- Honeycomb Core: Typically made from high-density polymers, these cores provide superior shock absorption, ensuring that the paddle maintains its longevity and reduces vibration effects.

The core is a crucial element that influences the paddle's hardness and overall feel:

- Nomex Honeycomb Core: Known for its durability and shock absorption, making it ideal for prolonged and intensive gameplay.

- Aluminum Honeycomb Core: Provides a balanced weight and enhances both power and precision, catering to players who require a moderate mix of strength and control.

- Polymer Honeycomb Core: Preferred by recreational players for its elasticity and reduced vibration, resulting in a more comfortable hitting experience.

Each material and core variant is selected to complement the specific demands of competitive play versus recreational play. In B2B purchasing decisions, understanding these nuances helps in aligning inventory with market expectations and client requirements.

High-performance paddles require rigorous quality control. At NEX Pickleball, every paddle undergoes meticulous testing to ensure it meets the highest industry standards. Detailed inspections confirm that the precision manufacturing techniques—be it through hot pressing1, cold pressing2, or thermoforming3—yield consistent results with:

- Optimized weight distribution for balance

- Ergonomic grip designs for enhanced comfort

- Specially treated surfaces that ensure improved spin and accuracy

Customization is another significant factor that appeals to B2B clients. With options to adjust design, weight, balance, and grip sizes, manufacturers like NEX Pickleball enable customized solutions that support team branding, regional market preferences, and specialized demand segments. This flexibility ensures that retailers and clubs can offer products that cater directly to their customer base while maintaining high performance on the court.

Consider a case where a sports distribution company sought high-performance paddles that could cater to both competitive players and recreational enthusiasts. The company needed products that combined durability with optimal ball feel. After comparisons, they selected paddles manufactured using a combination of cold pressing2 and innovative thermoforming3 techniques.

The outcome was impressive:

- Enhanced control due to precise material thickness and surface uniformity.

- Durability ensured by the incorporation of high-grade T300 Carbon Fiber and robust Nomex Honeycomb Core.

- Customized design adjustments that aligned with the distributor’s branding requirements.

This case underlines the importance of not only selecting the right manufacturing process but also aligning it with the superior material specifications required for different segments of the market. For B2B procurement managers, such detailed insights provide the assurance that investing in paddles built with these technologies ultimately translates into superior on-court performance and customer satisfaction.

-

Assess Production Techniques: Compare and contrast the advantages of hot pressing, cold pressing, and thermoforming based on your market’s performance demands. Utilize detailed process comparisons to evaluate which technique delivers the best balance between production efficiency and product quality.

-

Understand Material Benefits: Delve into the nuances of carbon fiber types, fiberglass, and composite materials. Focus on how specific variants like 12K Carbon Fiber or Bamboo Core Composite may serve niche competitive or recreational needs.

-

Demand Customization: Leverage manufacturing partners who offer tailored solutions. Customization options allow for differentiation in the marketplace through branding or specialized performance features.

-

Prioritize Quality Control: Ensure that manufacturing partners like NEX Pickleball are committed to rigorous quality standards. Every paddle should undergo thorough testing to secure reliability in performance, which is critical for maintaining your brand’s reputation.

-

Use Comparative Data: Rely on data and performance metrics when making procurement decisions. Comparing technical specifications side by side (as in the table above) can provide a clear picture of the trade-offs and benefits of each manufacturing process.

In the competitive sports equipment market, understanding the intersection of advanced production processes with material engineering is key for success. With platforms like NEX Pickleball leading the way in innovation, B2B procurement managers can confidently source paddles that deliver the perfect balance of power, control, and durability.

Q: How do manufacturing processes affect pickleball paddle performance?

A: Manufacturing processes such as hot pressing, cold pressing, and thermoforming significantly influence a paddle's performance by determining its structural strength, vibration absorption, and overall durability. Each method offers distinct advantages in areas like ball feel, impact resistance, and production precision.

Q: What materials are best for making high-performance pickleball paddles?

A: High-performance pickleball paddles typically use premium materials such as various types of carbon fiber (3K, 12K, T300), fiberglass, and composite cores like Nomex or Aluminum Honeycomb. These materials provide a balance of strength, power, and control, ensuring excellent performance on the court.

Q: Why is customization important in paddle manufacturing?

A: Customization allows manufacturers to tailor paddles to specific player needs and market demands. Options such as adjusting weight, grip size, and design not only enhance playability but also support team branding and meet specialized athletic requirements.

-

Hot Pressing: Click to learn more about the technique used to heat and press materials together for enhanced composite bonding and structural integrity in high-performance paddle manufacturing. ↩ ↩ ↩2 ↩3

-

Cold Pressing: Click to understand how room-temperature compression maintains material properties, ensuring a precise and reliable paddle construction process. ↩ ↩ ↩2 ↩3 ↩4

-

Thermoforming: Click to explore how heat is used to mold and shape paddle components, providing intricate design and evenly distributed material properties. ↩ ↩ ↩2 ↩3 ↩4

-

Carbon Fiber: Click to gain insights into the different types and properties of carbon fiber, highlighting its role in providing strength, flexibility, and overall performance in sporting equipment. ↩ ↩

-

Composite Materials: Click to read about the benefits of combining multiple materials to achieve improved durability, performance, and cost-effectiveness in advanced paddle manufacturing. ↩ ↩