Quick Answer: When evaluating high-performance pickleball paddle manufacturers in China, procurement managers should compare production techniques—such as hot pressing1, cold pressing2, and thermoforming3—and material technologies, including high-grade carbon fiber, fiberglass, and composite cores, to ensure the supplier meets both performance and customization demands. NEX Pickleball, with its advanced production processes and rigorous quality control, stands out as a leading partner for sports equipment sourcing.

In today’s competitive sports equipment market, making an informed decision about sourcing high-performance pickleball paddles is crucial. Procurement managers and sourcing specialists must weigh factors such as material quality, production processes, and the ability to customize products. In this article, we compare the key technical aspects and production methodologies used in manufacturing advanced pickleball paddles, with a focus on distinguishing Chinese manufacturers like NEX Pickleball. This overview will help you make data-driven decisions that align with your company’s performance and cost objectives.

International procurement in the sports equipment market often involves balancing quality with cost-efficiency. Chinese manufacturers have garnered attention due to their state-of-the-art production techniques and competitive pricing. However, questions remain: Can these manufacturers deliver consistent high performance and meet the rigorous standards expected by competitive players? How do production techniques such as hot pressing, cold pressing, and thermoforming translate into paddle performance?

NEX Pickleball provides an excellent case study in answering these questions. As a leading manufacturer, their solutions not only meet, but often exceed industry expectations, offering paddles that feature premium materials such as 3K Carbon Fiber, 12K Carbon Fiber, and T3004, alongside advanced composite designs. For procurement managers, the decision hinges on carefully examining these key production parameters and understanding how they impact product durability, performance, and overall cost-effectiveness.

A reliable manufacturer must select the right production process to balance performance and production efficiency. NEX Pickleball employs three major production processes to tailor paddles for varying performance needs:

-

Hot Pressing

This process involves heating the material and applying significant pressure to produce a robust paddle. It offers high production efficiency suitable for large-scale operations and results in paddles with excellent impact resistance and structural integrity. However, a potential downside is that high temperatures might slightly alter the feel of the paddle, which is a trade-off worth considering. -

Cold Pressing

In this approach, the paddle materials are shaped at room temperature, preserving their inherent properties. This method provides enhanced control over paddle thickness and structure, leading to a superior ball feel and responsiveness. The longer production cycle and need for precise pressure control are challenges that manufacturers need to overcome. -

Thermoforming

This technique involves heating materials to a soft state before shaping them in a mold. Thermoforming is ideal for crafting paddles with intricate designs and consistent material distribution, resulting in an ergonomic and high-performance product. The higher cost of equipment and longer production time means this method is generally reserved for premium or custom-made paddles.

Below is a comparative table summarizing the key strengths and limitations of these processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; excellent impact resistance; strong structural integrity | Material properties can be altered; high equipment cost |

| Cold Pressing | Superior control over thickness; preserved material properties; exceptional ball feel | Longer production cycle; requires precision equipment |

| Thermoforming | Allows intricate designs; precise material distribution; maintains stability | Extended production time; higher cost; best for premium products |

Understanding these differences is essential for procurement managers comparing suppliers based on their ability to deliver consistent, high-quality performance.

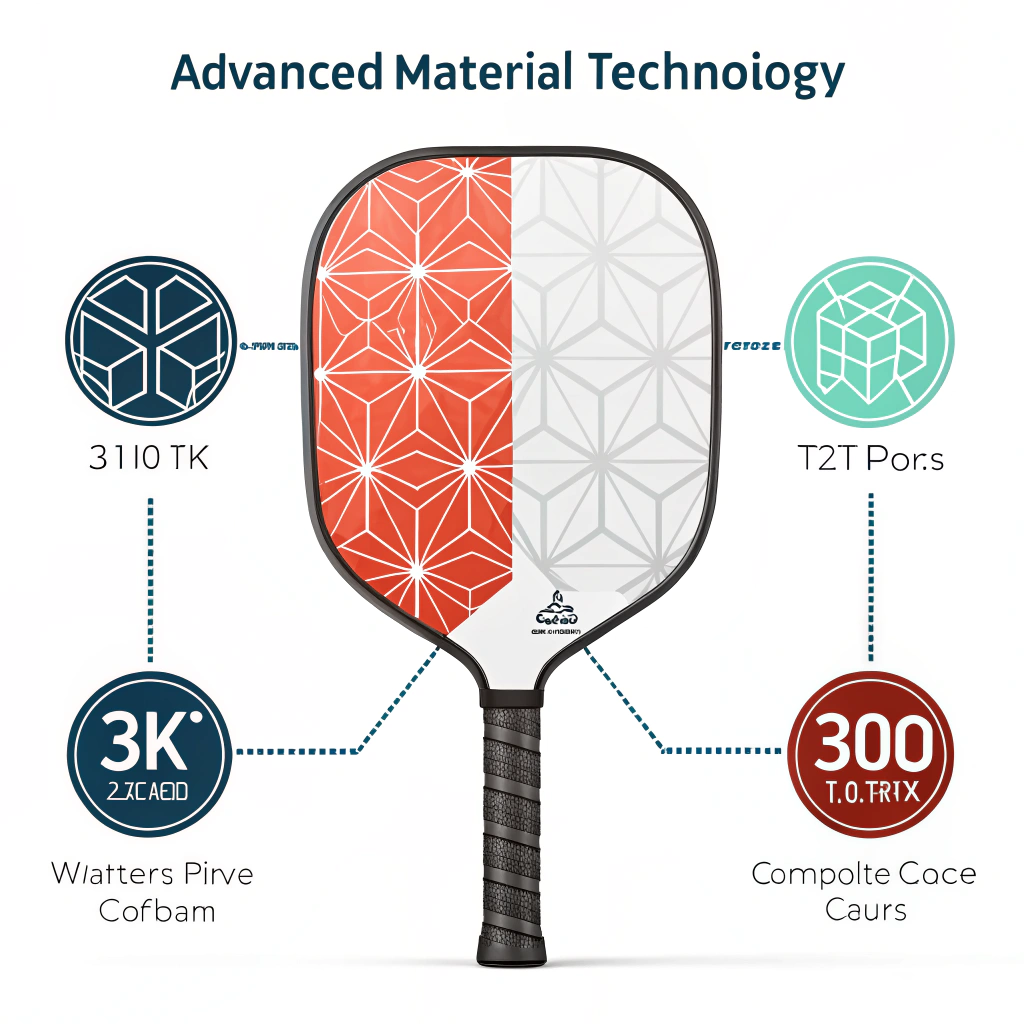

The performance of pickleball paddles is heavily influenced by the materials used. NEX Pickleball integrates a range of advanced materials designed to meet diverse playing requirements:

-

3K Carbon Fiber:

Known for its strength and flexibility, 3K carbon fiber drastically increases the paddle’s rebound force. Its excellent durability also minimizes vibration, making it suitable for competitive play where responsiveness is key. -

12K Carbon Fiber:

With a higher thread density, 12K carbon fiber offers a smoother surface finish, greater hardness, and enhanced durability. Ideal for paddles that endure high-impact play, this material provides extreme strength and impact resistance. -

T300 Carbon Fiber:

Revered for its superior tensile strength, T300 strikes a fine balance between strength and light weight. This makes it an optimal choice for paddles that require both high performance and balanced agility.

-

Fiberglass:

Often used to create a balance between power and control, fiberglass paddles feature a wider sweet spot that enhances ball control. E-Glass Fiberglass in particular provides excellent elasticity and tensile strength, resulting in a consistent and pleasing feel during play. -

Composite Materials:

Combining different materials allows manufacturers to harness the best attributes of each. Options include:- Carbon Fiber & Fiberglass Composite: Offers a robust mix of power, lightness, and flexibility.

- Bamboo Core Composite: Recognized for its lightweight and high impact resistance, delivering a crisp hitting feel.

- Honeycomb Core: Made with high-density polymers or pulp, these cores significantly reduce vibration and ensure durability.

The core of a pickleball paddle is arguably the most critical element, directly affecting playability:

- Nomex Honeycomb Core5: Provides excellent shock absorption and durability, ideal for players who stress stability and performance across long matches.

- Aluminum Honeycomb Core: Balances weight and strength to impart both power and precision.

- Polymer Honeycomb Core: Enhances elasticity and minimizes vibration, offering an optimal experience for both recreational and competitive players.

Procurement specialists must consider these advanced material choices. Consistency in using premium materials is a key differentiator, ensuring that paddles remain durable and maintain performance regardless of play intensity.

For procurement managers, quality control is paramount in achieving a long-term partnership with a manufacturer. NEX Pickleball employs meticulous testing procedures at every stage of production to ensure each paddle meets the highest performance standards. Some notable quality control measures include:

- Rigorous in-line inspection during production

- Real-time performance testing for impact resistance and vibration reduction

- Final quality assurance procedures to verify structural integrity and ergonomic design

Furthermore, NEX Pickleball offers fully customizable paddle options. Clients can specify design parameters such as weight distribution, grip size, balance, and even incorporate custom branding. This level of customization is particularly beneficial for businesses seeking unique products for team branding or retail differentiation in a crowded market.

A custom order process typically involves:

- Initial consultation to discuss specific requirements

- Detailed design and material selection

- Prototype development with rigorous testing

- Final adjustments based on client feedback before mass production

The integration of personalized production is a significant advantage when comparing manufacturers. It enables businesses to secure a product that not only meets technical performance standards but also aligns perfectly with market demands.

To aid your decision-making process, here is a matrix that assesses key sourcing attributes for high-performance pickleball paddles:

| Key Attribute | Importance | Evaluation Criteria | Example (NEX Pickleball) |

|---|---|---|---|

| Production Efficiency | High | Cycle time, equipment reliability | Advanced hot pressing & thermoforming |

| Material Quality | Critical | Type of carbon fiber, fiberglass quality, composite balance | 3K, 12K, T300 carbon fiber; E-Glass |

| Technical Precision | High | Consistency in weight distribution, center-of-gravity control | Ergonomic design & precise mold formation |

| Customization Capabilities | Moderate to High | Availability of custom designs, branding options | Fully customizable paddle options |

| Quality Control Measures | Critical | In-line inspection, final product testing | Rigorous multi-stage quality checks |

This detailed matrix should help you compare various manufacturers based on technical and qualitative factors, guiding you to a partner that meets your exact requirements.

When evaluating potential suppliers in the realm of pickleball paddle manufacturing, we recommend the following actions:

- Clearly define your performance and material requirements. Consider the specific needs of your target market—be it professional competitive play or recreational use.

- Assess the manufacturer’s production capabilities by requesting detailed technical briefs and process audits. Look for evidence of rigorous quality control measures and consistent production metrics.

- Leverage supplier evaluations and due diligence reports. Comparative analysis, as shown in the decision matrix, will help highlight the strengths and limitations of each candidate.

- Prioritize fields of customization. Unique market demands often necessitate a product that stands out through tailored designs or unique material combinations.

- Request prototypes or samples to gauge material performance and ergonomic feel. Field testing is essential in confirming that performance claims translate into real-world conditions.

- Finally, negotiate agreements that prioritize on-time delivery and flexibility. In today’s fast-changing market, supply chain agility is as critical as product quality.

Following these strategic steps ensures that the manufacturer you choose not only meets the desired technical specifications but also aligns with your long-term business goals.

Sourcing high-performance pickleball paddles requires a multifaceted evaluation of production processes, material technologies, and quality control systems. Chinese manufacturers, such as NEX Pickleball, demonstrate excellence through advanced production methods and rigorous quality standards, making them a compelling option for businesses seeking to enhance their sports equipment offerings. By carefully comparing production techniques like hot pressing, cold pressing, and thermoforming, alongside material innovations in carbon fiber, fiberglass, and composite cores, procurement managers can confidently select a partner with proven performance and custom production capabilities.

The detailed insights provided here—supported by comparative tables and a decision-making matrix—are designed to assist you in making an informed sourcing decision. As the market for pickleball paddles continues to evolve, aligning with a manufacturer that prioritizes innovation and reliability will give your business the competitive edge it needs.

Q1: What is the best pickleball paddle manufacturer?

A: While various brands are renowned in the market, leading manufacturers like NEX Pickleball distinguish themselves by offering advanced production techniques, custom production capabilities, and superior quality control systems that meet the demands of high-performance play.

Q2: Are Paddletek paddles made in China?

A: No, Paddletek paddles are generally manufactured in the USA. This contrasts with Chinese manufacturers such as NEX Pickleball, which focus on advanced production processes and competitive pricing.

Q3: What pickleball paddles are not made in China?

A: Some recognized pickleball paddles manufactured in the USA include models like the Gamma 405 Graphite Pickleball Paddle, PROLITE Stealth GS2 Carbon Fiber Pickleball Paddle, and Paddletek Bantam Carbon Fiber Pickleball Paddles. These are known for their domestic production contrary to many Chinese manufactured options.

-

hot pressing: Click to learn about the process involving heat and pressure to mold materials for enhanced structural integrity and production efficiency. ↩ ↩

-

cold pressing: Click to understand how shaping materials at room temperature preserves their inherent properties and improves product control. ↩ ↩

-

thermoforming: Click to discover the method of heating materials to achieve precise, intricate designs with uniform material distribution. ↩ ↩

-

T300: Click to explore this specific carbon fiber variant known for its high tensile strength and optimal balance of weight and durability. ↩ ↩

-

Nomex Honeycomb Core: Click to find out how this advanced core material offers excellent shock absorption and durability for sustained high performance. ↩ ↩