Testing procedures for high-performance pickleball paddles involve a systematic evaluation of material properties, production process robustness, and overall performance metrics such as impact resistance, vibration reduction, and rebound force. In this article, we explain why rigorous testing is critical, outline detailed methodologies, and provide best practices to ensure your paddles meet the highest quality standards.

In today’s competitive sports equipment market, ensuring the quality and performance of pickleball paddles is crucial for both manufacturers and procurement specialists. With numerous production techniques like hot pressing1, cold pressing2, and thermoforming3, each paddle’s characteristics can vary significantly. This article provides a comprehensive guide to testing procedures and quality benchmarks for pickleball paddles. The discussion includes the challenges in testing these dynamic sports tools and presents practical testing methodologies to guarantee products that deliver exceptional performance, durability, and user comfort.

Quality control is the backbone of competitive sports equipment manufacturing. For pickleball paddles, achieving consistent performance across every unit is challenging. Variations in material properties, production processes, and even design choices require a well-designed testing protocol. Key components such as the surface material, core composition, and overall weight distribution determine the paddle’s performance. These factors directly affect critical performance metrics, including:

- Impact Resistance: How well the paddle endures consistent strikes.

- Vibration Reduction: The ability to minimize vibration to enhance comfort.

- Paddle Rebound: The responsiveness when the ball meets the surface.

- Ergonomic Balance: Ensuring a comfortable grip and user-friendly handling.

Minimizing variability in these factors is vital for maintaining a competitive edge, and that starts with systematic testing.

The complex nature of paddle production introduces several testing challenges:

-

Material Variability:

Pickleball paddles can be made of various materials such as different types of carbon fiber4 (3K, 12K, T300) and fiberglass5. The performance properties of these materials can differ significantly. For instance, while 3K carbon fiber is known for its flexibility, 12K carbon fiber offers a smoother surface and enhanced impact resistance. -

Production Processes:

The three major production processes—hot pressing, cold pressing, and thermoforming—each bring unique challenges.

• Hot Pressing can alter the intrinsic properties of the material by heating it and applying pressure rapidly.

• Cold Pressing maintains the raw material properties but may lead to longer production cycles.

• Thermoforming allows for intricate designs but requires higher equipment investment and extended production time. -

Ergonomic and Performance Balance:

A paddle that excels in one aspect, like rebound force, may fall short in providing ergonomic comfort or effective vibration dampening. Balancing these aspects in testing is critical to cater to both professional athletes and casual players. -

Standardization of Protocols:

The lack of uniform testing standards in the sports equipment industry means that manufacturers must often develop their own benchmarks. This variability can lead to discrepancies in quality control across different suppliers.

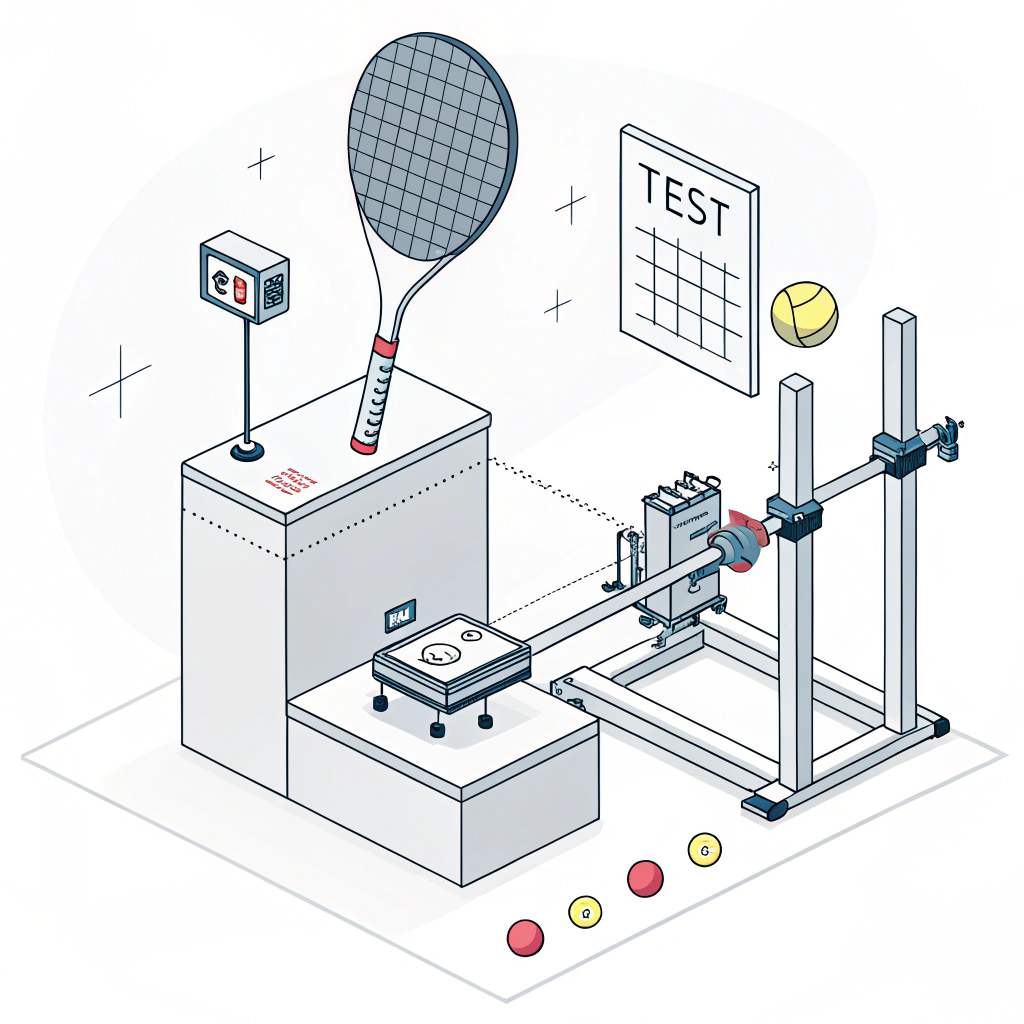

A robust quality control system should incorporate several testing methods to evaluate the paddle performance comprehensively. Below is a breakdown of essential testing procedures:

This testing confirms that each material component meets the desired strength and flexibility.

- Durability Tests:

Applying repetitive stress to the paddle to evaluate long-term durability under high-impact conditions. - Flexural Tests:

Assessing the paddle’s ability to flex without permanent deformation, targeting materials like fiberglass and composite blends. - Vibration Analysis:

Using specialized sensors to measure vibration levels during simulated play scenarios.

Each production method has its own set of testing procedures:

| Testing Aspect | Hot Pressing | Cold Pressing | Thermoforming |

|---|---|---|---|

| Production Efficiency | High, with rapid cycle times | Lower, with longer cycle durations | Moderate, with quality emphasis |

| Structural Integrity | High impact resistance; some material property changes | High control over thickness and structure | Excellent material distribution; enhanced design details |

| Equipment Investment | High upfront investment | Moderate; requires high-precision control | High; complex molds and heating systems |

| Effects on Material Feel | May slightly alter feel due to heat exposure | Preserves original material feel | Generally maintains a balanced feel |

- Thermal Imaging:

During hot pressing and thermoforming, thermal cameras can monitor the temperature to ensure consistent heat distribution. - Pressure Testing:

In cold pressing, precise pressure application is crucial; load cells and pressure sensors are used for real-time monitoring.

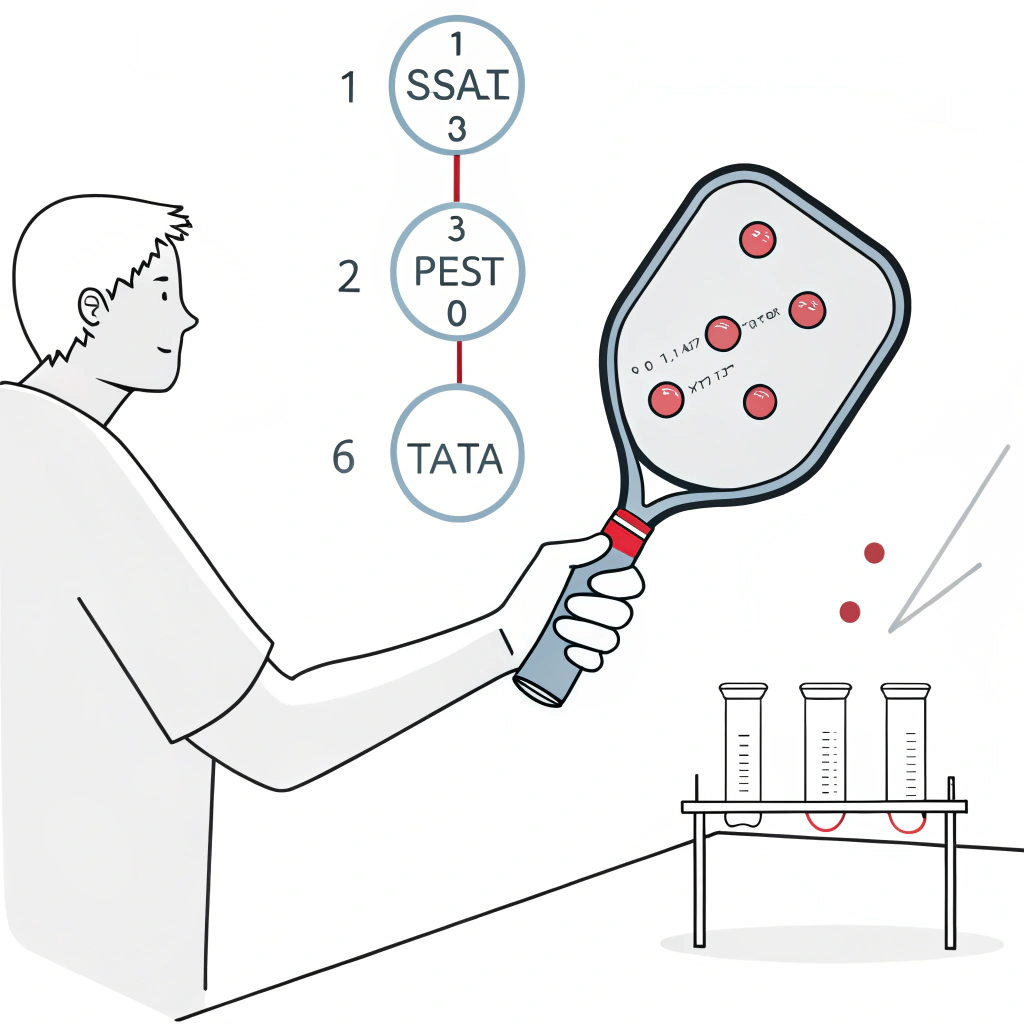

After material and production tests, the paddle must be evaluated from a user experience perspective:

- Grip and Balance Analysis:

Measuring ergonomic comfort using adjustable rigs and feedback from test players. - Impact and Rebound Test:

Simulated strikes are performed to measure rebound efficiency and vibration. This helps gauge how well the paddle performs during real gameplay. - User Testing Trials:

In-store or club-based demo programs allow for real-world feedback. This is especially useful when refining design aspects like grip size and weight distribution.

When establishing a rigorous quality control protocol for pickleball paddles, consider the following best practices:

-

Develop Comprehensive Benchmarks:

Establish industry-standard benchmarks for each performance metric. Whether it is the ideal weight or maximum allowable vibration level, these benchmarks will guide consistency in production. -

Integrate Multi-Stage Testing:

Combine initial material testing with production process evaluations and final ergonomic checks. This ensures that every paddle meets all performance criteria before reaching the market. -

Utilize Real-World Scenarios:

Incorporate actual gameplay simulations and user trials in the testing phase. This gives valuable feedback regarding comfort, handling, and overall performance. -

Continuous Improvement Loop:

Data from each testing phase should be used to refine both production processes and material selection. Regular updates in testing protocols can help identify emerging performance issues. -

Collaboration with End Users:

Engage with professional players and training clubs to participate in testing programs. Their input can uncover practical insights not evident from lab tests alone. -

Implement Advanced Diagnostic Tools:

Employ cutting-edge testing equipment like high-speed cameras, thermal sensors, and vibration analyzers to capture detailed performance data.

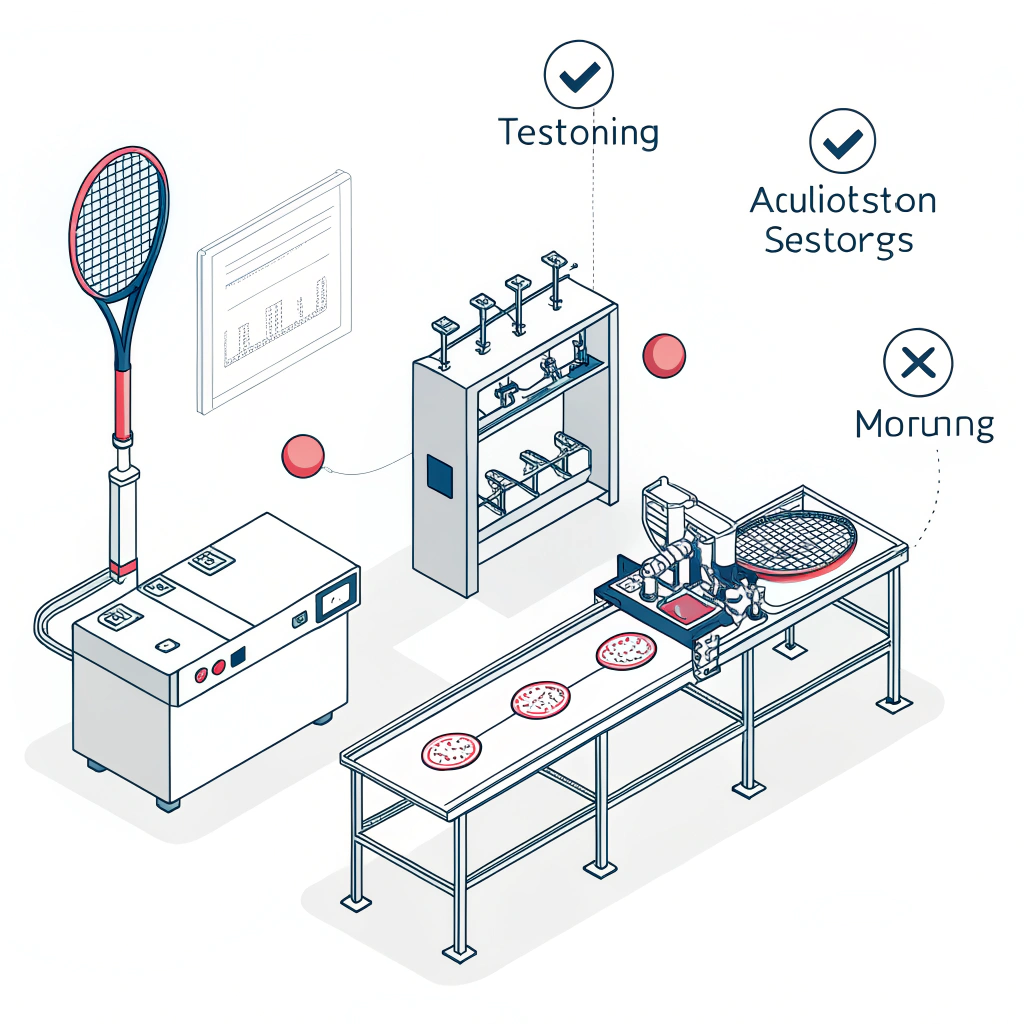

At NEX Pickleball, we pride ourselves on our meticulous approach to quality control. Using the advanced production techniques of hot pressing, cold pressing, and thermoforming, our paddles are subjected to a series of rigorous tests before they leave our facility in Jiaxing, Zhejiang, China.

Testing Process Overview:

-

Material Selection:

We use premium materials—selection ranges from various carbon fibers to fiberglass and composite materials—to ensure that the paddle meets performance demands. Our quality control manager verifies that each batch conforms to our strict strength and durability benchmarks. -

Production Process Checks:

Each production method is optimized to maximize paddle performance while preserving the intrinsic qualities of the selected materials. Sensors and monitoring equipment are deployed during each process to record critical parameters such as pressure, temperature, and cycle time. -

User-Centric Validation:

Post-production, every paddle undergoes real-world simulation testing. Feedback collected from club rentals and in-store demo programs is crucial to our continuous refinement process. These tests help us fine-tune the balance, grip comfort, and overall playability of the paddles. -

Data-Driven Adjustments:

The testing data guides our production adjustments. If a paddle does not meet the pre-defined criteria, it is re-evaluated, and production parameters are modified until the desired performance is achieved.

This multi-layered testing process is essential not only for ensuring our paddle’s high performance but also for safeguarding our reputation as a leading manufacturer in the industry.

Implementing a thorough testing protocol is fundamental for maintaining high standards in pickleball paddle manufacturing. To summarize:

- Begin with material integrity tests focusing on durability, flexibility, and vibration reduction.

- Evaluate production processes individually—hot pressing, cold pressing, and thermoforming—to safeguard against inconsistencies.

- Conduct ergonomic and functional testing to confirm that final products meet user-expected performance standards.

- Use a combination of laboratory tests and real-world user feedback to continuously refine product quality.

- Ensure that quality control data is agile enough to drive improvements in design and production techniques.

For procurement specialists and quality control managers, these structured testing protocols offer a reliable roadmap to validate supplier claims. In a highly competitive market, understanding and implementing these rigorous testing procedures not only mitigates risk but also reinforces confidence in the products you purchase.

Taking inspiration from our practices at NEX Pickleball, we recommend reviewing and upgrading your quality assurance processes regularly. Engage with industry experts, invest in advanced testing tools, and always consider the end user in your quality benchmarks.

By following these principles, sports equipment firms can secure a competitive advantage by ensuring each pickleball paddle performs consistently at a high level, ultimately leading to higher customer satisfaction and reduced warranty claims.

People Also Ask

Q: How to tell if it's a good pickleball paddle?

A: A good pickleball paddle should have the right balance of weight, optimal grip size, and be made from high-quality materials such as carbon fiber or fiberglass. Performance factors like rebound efficiency, vibration reduction, and impact resistance are crucial. Testing these aspects through both lab tests and real-world user feedback helps determine the paddle’s overall quality.

Q: How can I try pickleball paddles?

A: You can try pickleball paddles by participating in in-store demo programs or club rentals. Many retailers and pickleball clubs offer opportunities to test different paddle models on the court, allowing you to assess performance aspects like grip comfort, balance, and rebound before making a purchasing decision.

-

Hot Pressing: Click to learn about this production process that uses high heat and pressure to mold materials quickly, offering benefits in cycle time and material integration. ↩ ↩

-

Cold Pressing: Click to explore how cold pressing maintains raw material properties by applying pressure at lower temperatures, ensuring subtle material characteristics are preserved. ↩ ↩

-

Thermoforming: Click to understand this technique involving heating plastic sheets and forming them into specific shapes, ideal for intricate designs and consistent material distribution. ↩ ↩

-

Carbon Fiber: Click to read about carbon fiber properties, including its variants (3K, 12K, T300), and how its strength-to-weight ratio benefits high-performance sports equipment. ↩ ↩

-

Fiberglass: Click to discover the advantages of fiberglass in composite materials, such as flexibility and durability, which are crucial for maintaining performance integrity in sports gear. ↩ ↩