The heat pressing1 process for pickleball paddle manufacturing is an efficient method that ensures high production efficiency while delivering products with excellent impact resistance and structural integrity2. In this article, we explore in detail how heat pressing1 compares with other manufacturing methods such as cold pressing3 and thermoforming4. We'll provide a technical overview, data-supported advantages and disadvantages, and guidance to help you decide which process best meets your production needs.

Heat pressing1 involves heating materials and applying pressure to form a durable, high-performance paddle. This technique is capable of producing paddles that meet strict quality control requirements. The process is widely recognized for its ability to improve the overall strength of the paddle and to ensure structural integrity throughout mass production.

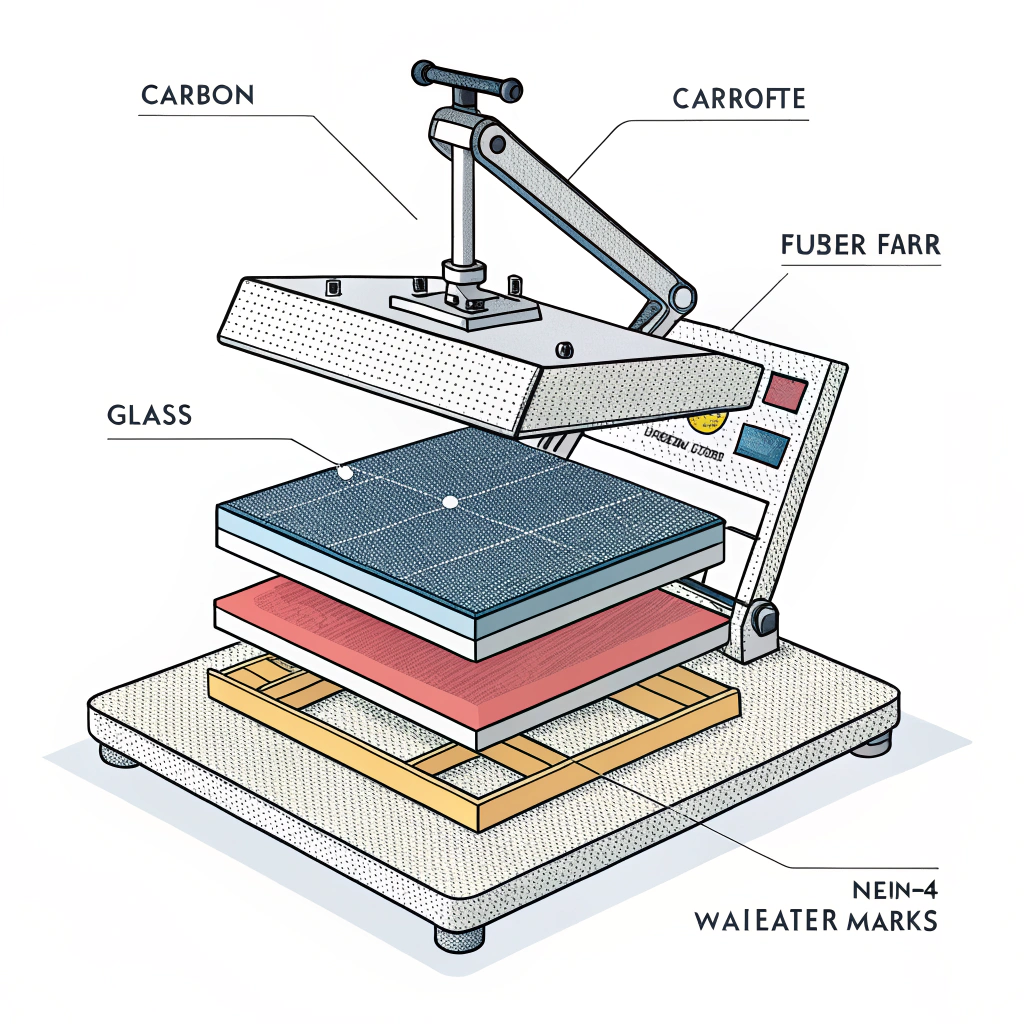

At its core, heat pressing1 leverages the combined effects of heat and pressure to bond multiple layers, whether carbon fiber5, fiberglass, or composite materials. This allows for uniform material distribution and consistency in paddle density, making it an ideal process for achieving repeatable performance characteristics in sports equipment manufacturing.

When evaluating manufacturing processes, many production managers and engineering leads focus on production efficiency, material performance, and the cost-to-benefit ratio. Below are some detailed advantages associated with the heat pressing process for pickleball paddles:

-

High Production Efficiency

The heat pressing process allows for rapid cycle production suited to large-scale manufacturing. The simultaneous application of heat and pressure reduces labor intensity and speeds up production times, which can be critical when meeting large orders or tight deadlines. -

Enhanced Impact Resistance

The process ensures that paddles have excellent impact resistance. By applying uniform pressure, heat pressing helps to solidify the union between core and face materials, drastically reducing the risk of delamination or warping when paddles undergo rigorous use. -

Structural Integrity

Heat pressing is favored for achieving exceptional structural integrity. A paddle produced via this method exhibits a balanced weight distribution and consistent thickness, which underpins stable performance during high-impact hits. -

Cost-Effective for High Volume

Although the initial equipment investment can be high, the absence of extensive manual labor and the ability to produce large quantities at speed make heat pressing economically viable for manufacturers with high-volume production.

To further assist in your decision-making, let’s compare heat pressing with two alternative paddle manufacturing methods: cold pressing and thermoforming. The following table summarizes their characteristics:

| Process | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Heat Pressing | High production efficiency, excellent impact resistance and structural integrity, consistent quality across batches | Can alter material properties affecting feel, requires high initial investment in specialized equipment | Large-scale production; high-performance paddles |

| Cold Pressing | Precise control over paddle thickness and structure, preserves inherent material properties for optimal ball feel | Longer production cycles, lower efficiency, and demands stringent pressure controls | Producing paddles where feel and control are prioritized |

| Thermoforming | Ability to create intricate designs with precise material distribution, maintains paddle stability to enhance shot control | Requires longer production times, higher equipment and maintenance costs | Custom-made or premium paddles requiring complex shapes |

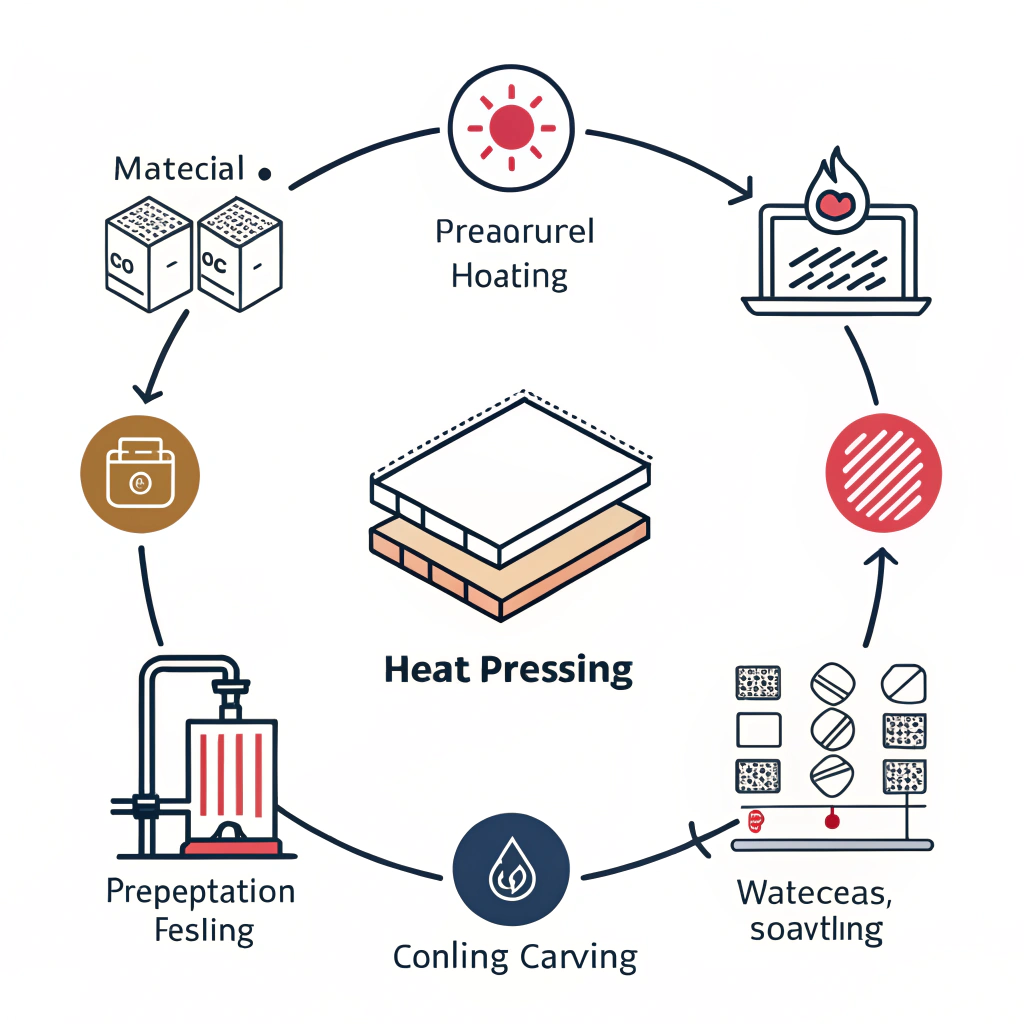

Heat pressing involves several sequential steps:

- Material Preparation: The raw materials, such as carbon fiber or composite layers, are pre-cut and arranged in specific orientations. This stage is critical to ensuring uniformity across paddles.

- Heating Stage: The pre-arranged materials are then heated in a controlled environment. The heat softens the resins and prepares the materials for fusion.

- Pressure Application: Once the materials are at the optimal temperature, high pressure is applied using specialized presses. This step is crucial, as it bonds the materials together into a cohesive structure.

- Cooling and Finishing: After the pressure is maintained for a determined cycle time, the paddle is allowed to cool gradually. The result is a paddle with a robust outer layer and a well-cured core essential for high-impact resistance.

When setting up a heat pressing line, consider the following elements:

- Equipment Quality: Invest in high-grade presses that ensure consistent temperature distribution and uniform pressure application.

- Process Control: Utilize sensors and automated controls to monitor temperature, pressure, and cycle time. This ensures that every paddle meets your quality standards.

- Material Compatibility: Not all materials react the same way to heat and pressure. For example, carbon fiber5 variants like 3K, 12K, and T300 have distinct characteristics that may influence the parameters you set during the heat pressing process.

- Production Environment: A well-regulated ambient environment helps maintain product consistency. Fluctuations in temperature or humidity can affect the resin curing process, leading to variability in paddle performance.

Although establishing a heat pressing line requires substantial investment, the long-term payoff in production efficiency is noteworthy. Manufacturers often report a significant reduction in both labor cost and production time per unit. Furthermore, with proper equipment and regular calibration, the process consistently produces paddles that meet high-performance standards—a critical factor for competitive sports equipment.

For any manufacturing process, and especially for heat pressing, rigorous quality control is essential. Key measures include:

- Pre-Press Inspections: Checking material quality and correct assembly before the pressing process.

- In-Process Monitoring: Real-time sensors that log temperature and pressure ensure that deviations from optimal settings are flagged immediately.

- Post-Production Testing: Each paddle should undergo tests for impact resistance, balance, and surface quality. This final check guarantees that only products meeting stringent quality standards leave the production line.

Manufacturers considering heat pressing should invest in testing equipment and training for the quality assurance team. These investments secure the production process and protect the brand's reputation for high-quality products.

When deciding whether to implement or refine a heat pressing process, production managers should assess several factors:

- Scale of Production: Heat pressing is most effective in high-volume production environments where the high throughput offsets the initial equipment cost.

- Product Specifications: If your product requires a robust build and high impact resistance, heat pressing can be the right choice. However, for products where tactile feel and fine control are paramount, cold pressing might offer better advantages.

- Cost & Return on Investment: Evaluate both the upfront costs for equipment and the long-term gains in efficiency. In high-volume production lines, the cost per unit is considerably reduced with heat pressing.

- Material Considerations: Understanding the behavior of various materials under heat and pressure is key. For instance, carbon fiber5-based paddles may behave differently under heat pressing compared to fiberglass or composite materials, impacting production parameters and final product performance.

Several leading sports equipment manufacturers have successfully integrated heat pressing into their production lines. For instance, a case study from a reputable paddle manufacturer showcased a 30% increase in daily output after switching to heat pressing. This improvement not only led to lower per-unit costs but also enhanced the overall durability of the paddles, reducing post-sale warranty claims.

Moreover, feedback from competitive players has highlighted that paddles manufactured with heat pressing show greater consistency in performance, especially in high-paced environments where impact resistance is critical. These real-world insights emphasize how the process can bridge the gap between efficient production and high-performance output.

Based on the analysis, production managers should consider the following steps when evaluating or upgrading their manufacturing processes:

- Conduct a detailed cost-benefit analysis comparing heat pressing with alternative processes, factoring in the scale of production and desired paddle performance.

- Invest in high-quality equipment and automated process controls to enhance production consistency and reduce variability.

- Train staff extensively on quality control measures specific to heat pressing to ensure that every product meets industry standards.

- Consider pilot testing the heat pressing process with a small batch before full-scale implementation to measure improvements in product strength and manufacturing efficiency.

By taking these steps, companies can position themselves to achieve both immediate gains in production efficiency and long-term reductions in manufacturing costs while delivering high-performance pickleball paddles that meet the rigorous demands of competitive sports.

Can you leave a pickleball paddle in a hot car?

No, leaving a pickleball paddle in a hot car is not advisable. Extreme temperatures can damage the paddle by causing warping, delamination, or even melting the grip. It is best to store the paddle in a cool, dry place when it is not in use.

How to make a pickleball paddle more powerful?

To enhance the power of a pickleball paddle, one common approach is to add weight to the paddle’s head, such as by applying lead tape. This adjustment alters the paddle's balance, providing extra force when hitting the ball. However, it's important to consider that increased weight can also affect maneuverability and control.

Are thermoformed pickleball paddles better?

Thermoformed paddles offer superior shot stability by minimizing vibrations upon ball contact. This results in improved control and greater accuracy during play. The effectiveness of thermoforming depends on the specific design requirements and intended use, making it a strong option for customized, high-performance paddles.

-

Heat pressing: Click to learn how combining heat and pressure creates strong, consistent bonds in materials for high-speed, high-volume manufacturing. ↩ ↩2 ↩3 ↩4

-

Structural integrity: Click to discover why maintaining uniform strength and durability is critical in high-performance manufacturing. ↩

-

Cold pressing: Click to explore the process that uses room temperature techniques for precise thickness control and material preservation in production. ↩

-

Thermoforming: Click to understand how heat and mold shaping yield intricate designs and stable structures in custom manufacturing. ↩

-

Carbon fiber: Click to delve into the properties and applications of carbon fiber, a key material known for its strength and lightweight characteristics in advanced composites. ↩ ↩2 ↩3