In short, high-performance game improvement paddles manufactured with advanced processes and superior materials offer unmatched power, control, and durability. By understanding the differences between production techniques such as hot pressing1, cold pressing2, and thermoforming3—along with material options like various carbon fiber4 grades, fiberglass, and composite cores—B2B buyers can choose a supplier that meets both performance and market demands.

Manufacturers and suppliers face the complex task of balancing production efficiency with paddle performance. For B2B procurement managers, the critical challenge is to select paddle designs that provide high performance and longevity while aligning with market trends. Suppliers like NEX Pickleball offer expertise in advanced production processes and a variety of premium materials to meet these requirements. Understanding the technical merits behind each production technique and material composition is essential for making informed sourcing decisions.

At the heart of paddle manufacturing lie three primary production processes: hot pressing1, cold pressing2, and thermoforming3. Each method offers distinct advantages and trade-offs.

Hot pressing involves heating the material before applying pressure to bond layers of paddle components.

• Advantages:

– High production efficiency for large-scale manufacturing.

– Results in a robust paddle structure with superior impact resistance.

– Enhances the overall structural integrity needed for high-performance play.

• Disadvantages:

– High initial investment in specialized equipment.

– Can slightly alter the material’s tactile feel, impacting ball feedback.

In cold pressing, the material is shaped at room temperature under mechanical pressure.

• Advantages:

– Maintains the original properties of the material, offering excellent ball control.

– Precise control over paddle thickness and overall structure enhances playability.

• Disadvantages:

– Longer production cycles compared to hot pressing.

– Demands high-precision equipment to ensure consistent quality.

Thermoforming heats materials to a malleable state and uses molds to achieve intricate designs.

• Advantages:

– Allows for complex shapes and controlled material distribution.

– Helps maintain paddle stability and enhances on-court performance.

• Disadvantages:

– Production time is typically longer and involves higher costs.

– Best suited for premium, custom-designed paddles.

Below is a comparative table summarizing these production techniques:

| Production Process | Major Advantages | Key Limitations | Suitable For |

|---|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance; strong structural integrity | High equipment cost; potential alteration of material feel | Large-scale, high-performance paddles |

| Cold Pressing | Superior control; preserves material properties; excellent ball feel | Longer production cycle; requires precise equipment | Precision-designed paddles |

| Thermoforming | Intricate design possibilities; precise material distribution; enhanced paddle stability | Higher production costs; longer turnaround time | Premium/custom-made paddles |

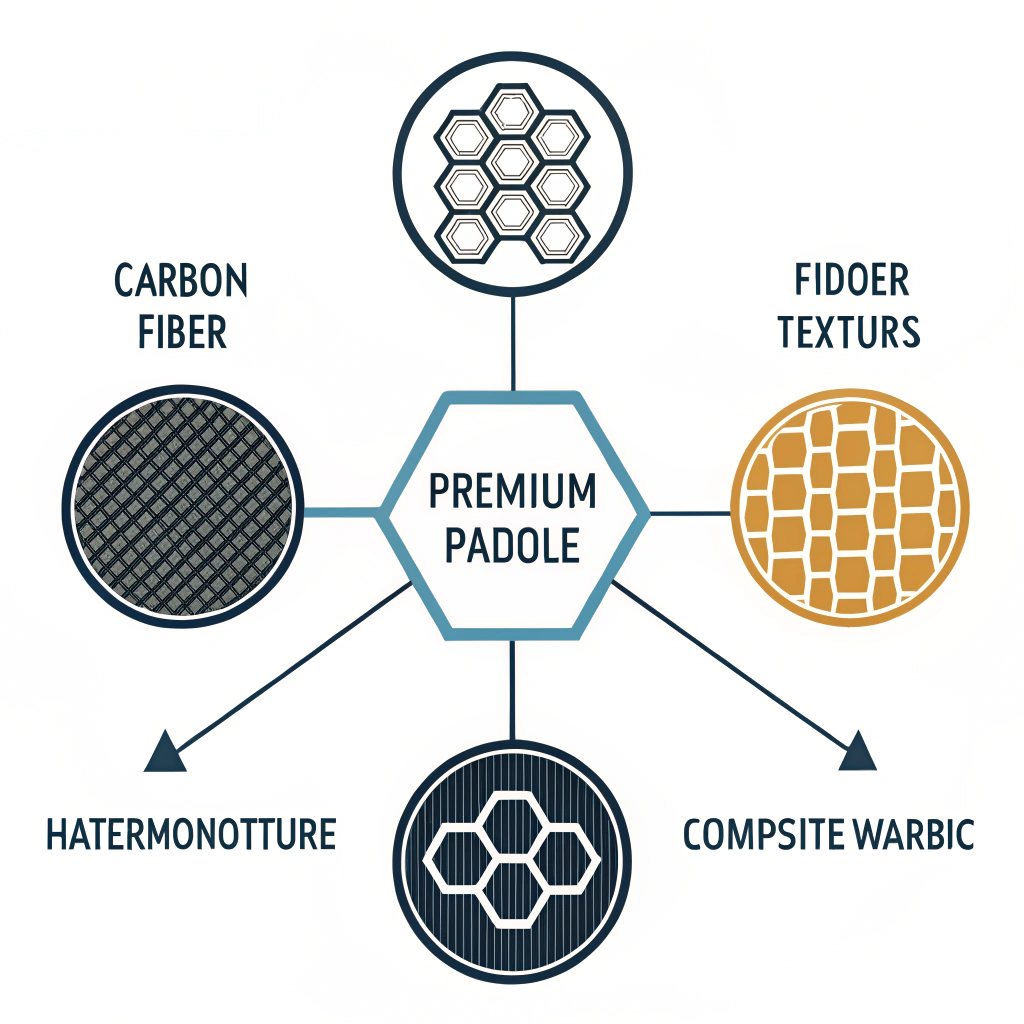

Selecting the right material is as important as choosing the production process. Paddle performance heavily depends on the combination of materials used. NEX Pickleball specializes in a diverse range of premium materials to achieve superior performance:

• 3K Carbon Fiber: Offers exceptional strength and flexibility. Its high rebound force and vibration reduction make it ideal for game improvement paddles where durability is key.

• 12K Carbon Fiber: With a higher thread density, it delivers a smoother surface, reinforced hardness, and improved impact resistance—suitable for competitive play.

• T300 Carbon Fiber: Known for its outstanding tensile strength, it provides a balanced mix of strength and lightweight performance.

Fiberglass paddles, such as those made with E-Glass Fiberglass, provide a larger sweet spot and enhanced control. This material offers excellent elasticity and tensile strength, giving players a reliable, consistent ball feel.

Composite designs, like the carbon fiber and fiberglass mix, combine the benefits of both materials to achieve an optimal balance of power and control. Additionally, special core technologies include:

• Bamboo Core Composite: Delivers a lightweight structure with high impact resistance, ideal for long-lasting play.

• Honeycomb Core (Nomex, Aluminum, Polymer): These cores reduce vibration and enhance shock absorption, with each type offering unique benefits for control and durability.

Below is a quick guide to help match material characteristics with market needs:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| 3K Carbon Fiber | Strength, flexibility, high rebound | High-performance, durable paddles |

| 12K Carbon Fiber | Smoother surface, greater hardness, extreme strength | Competitive play requiring impact resistance |

| T300 Carbon Fiber | Outstanding tensile strength, lightweight | Balanced performance situations |

| E-Glass Fiberglass | Enhanced elasticity, broad sweet spot | Recreational to semi-competitive use |

| Carbon Fiber & Fiberglass Composite | Combination of power and control | Players seeking versatility |

| Bamboo Core Composite | Lightweight, impact-resistant | Long-lasting, precision hit paddles |

| Honeycomb Cores | Superior shock absorption, reduced vibration | Vibration-sensitive applications |

When evaluating potential suppliers and production processes, it is useful to assess multiple dimensions such as manufacturing efficiency, paddle performance, and cost-effectiveness. Let’s consider these dimensions in a comparative framework:

- Performance: Does the paddle provide optimal power, control, and hitting feedback?

- Durability: Is the paddle built to withstand tournament-level play and heavy usage?

- Production Flexibility: Can the manufacturing process support both large-scale orders and customized designs?

- Material Quality: Are the materials used (e.g., high-grade carbon fiber4 and advanced composites) proven to enhance play?

For instance, hot pressing is highly efficient and supports large-scale production but might slightly compromise the fine tactile feel needed by top control players. On the other hand, cold pressing preserves material properties for players who value precision, albeit at the expense of production speed. Thermoforming emerges as the best solution for custom or premium orders that demand intricate designs, even though it may involve longer lead times and higher production costs.

Comparing these factors helps B2B buyers understand the trade-offs between cost, quality, and performance. This multi-dimensional assessment ensures that each paddle not only meets performance standards on the field but also aligns with the distributor's business goals.

A practical example of these considerations can be seen in how NEX Pickleball tailors its product line for different customer segments. For competitive players demanding high performance, paddles made with high-density 12K Carbon Fiber and a Nomex Honeycomb Core5 offer a winning combination of strength and shock absorption. Distributors targeting a broader market—including recreational players or even specific segments like seniors—may consider paddles incorporating E-Glass Fiberglass or a blend of lightweight composite materials for better control and comfort.

In real-world data, these specialized paddles have demonstrated higher durability in repeated impact tests and improved ergonomics through precise weight distribution. This ultimately results in higher customer satisfaction and better brand loyalty. Furthermore, NEX Pickleball’s capability to execute on-demand printing services for custom designs ensures that distributors can offer branded or personalized paddles, adding an extra value proposition in a competitive market.

From a strategic standpoint, aligning production processes with market demands not only improves product performance but also minimizes returns and warranty claims. It also positions your company as a technological leader in paddle production, ultimately driving more confident procurement decisions among B2B buyers.

When evaluating a supplier for high-performance pickleball paddles, consider the following action points:

• Complete a detailed comparative analysis of production processes to ensure the chosen method aligns with your product requirements.

• Request technical documentation and case studies that demonstrate how advanced materials like T300 Carbon Fiber or proprietary composites improve gameplay performance.

• Inquire about customization options that may allow for on-demand printing services and tailored paddle specifications.

• Evaluate the supplier’s quality control measures through sample testing and third-party certification reviews.

• Consider scalability and lead times when integrating a new supplier into your supply chain.

Summing up, understanding the nuances of different production techniques and material qualities is integral to making informed decisions. By leveraging comprehensive technical data and real-world performance metrics, B2B buyers can confidently choose a supplier that not only meets but exceeds the demands of today's competitive sporting goods market.

• Is Joola Gen 3 paddles still banned?

The ban on JOOLA Gen 3 paddles remains effective according to the latest tournament regulations established in 2024, meaning these paddles cannot be used in official competitions.

• What paddle do most pickleball pros use?

Most professional pickleball players favor paddles that offer a balanced mix of power and control. Popular choices include models like JOOLA Perseus and Selkirk VANGUARD Power Air Invikta, which are designed with advanced materials and specialized production processes to enhance performance.

• What is the best pickleball paddle for seniors?

For seniors, the best pickleball paddles are typically made from lightweight materials such as fiberglass and carbon fiber. These materials provide enhanced control and reduced vibration, making them ideal for players who prioritize precision and comfort over sheer power.

-

hot pressing: Click to explore an article detailing the hot pressing technique used in manufacturing, including its benefits in achieving strong material bonds and high production efficiency. Back to hot pressing ↩ ↩2

-

cold pressing: Click to learn more about cold pressing, a method that preserves material properties and fine-tunes paddle precision, essential for high-quality production. Back to cold pressing ↩ ↩2

-

thermoforming: Click to read about thermoforming processes, which enable complex designs and controlled material distribution in custom paddle manufacturing. Back to thermoforming ↩ ↩2

-

carbon fiber: Click to discover the properties and advantages of carbon fiber materials, including various grades and their performance impacts in high-end products. Back to carbon fiber ↩ ↩2

-

Nomex Honeycomb Core: Click to understand the role of Nomex Honeycomb Cores in reducing vibration and enhancing shock absorption, critical for achieving durable paddle performance. Back to Nomex Honeycomb Core ↩