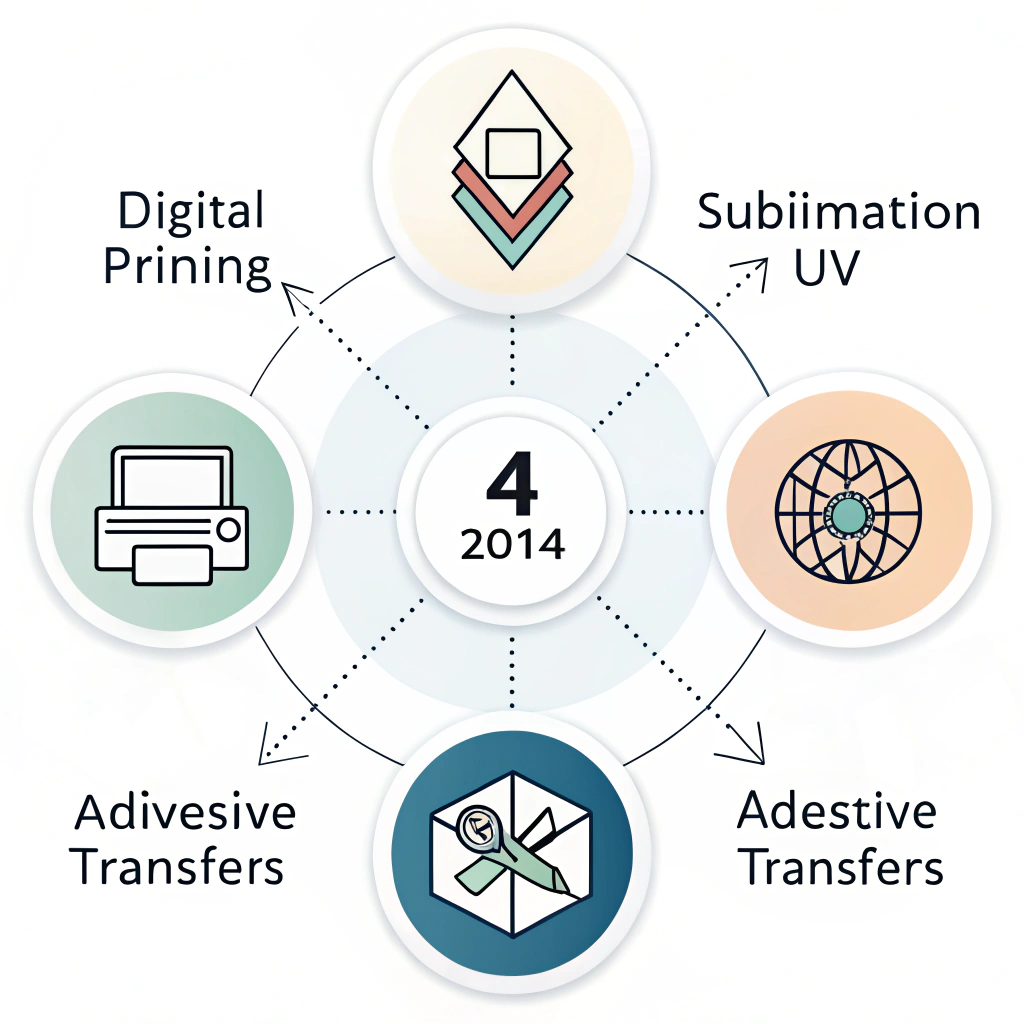

The best printing technique for custom graphics on pickleball paddles depends on your brand’s priorities for durability, visual impact, and cost-efficiency. In this article, we compare the leading printing options—Digital Printing, UV Printing1, Sublimation2, and Adhesive Transfers3—using insights from our factory experience to help you make an informed procurement decision.

For companies and clubs looking to enhance their product appeal, choosing the right printing method for custom graphics on pickleball paddles is key. High-performance sports equipment not only requires precision manufacturing but also a robust and striking design that wins over customers. With brands increasingly investing in visual identity, the printing process becomes as critical as the paddle’s mechanical construction.

At NEX Pickleball, our approach combines advanced production techniques with detailed quality control procedures. We understand that your decision is not only about cost but also about ensuring the final product remains durable under intense gameplay. Our insights are backed by years of factory testing and real-world applications—helping you strike the perfect balance between performance and aesthetics.

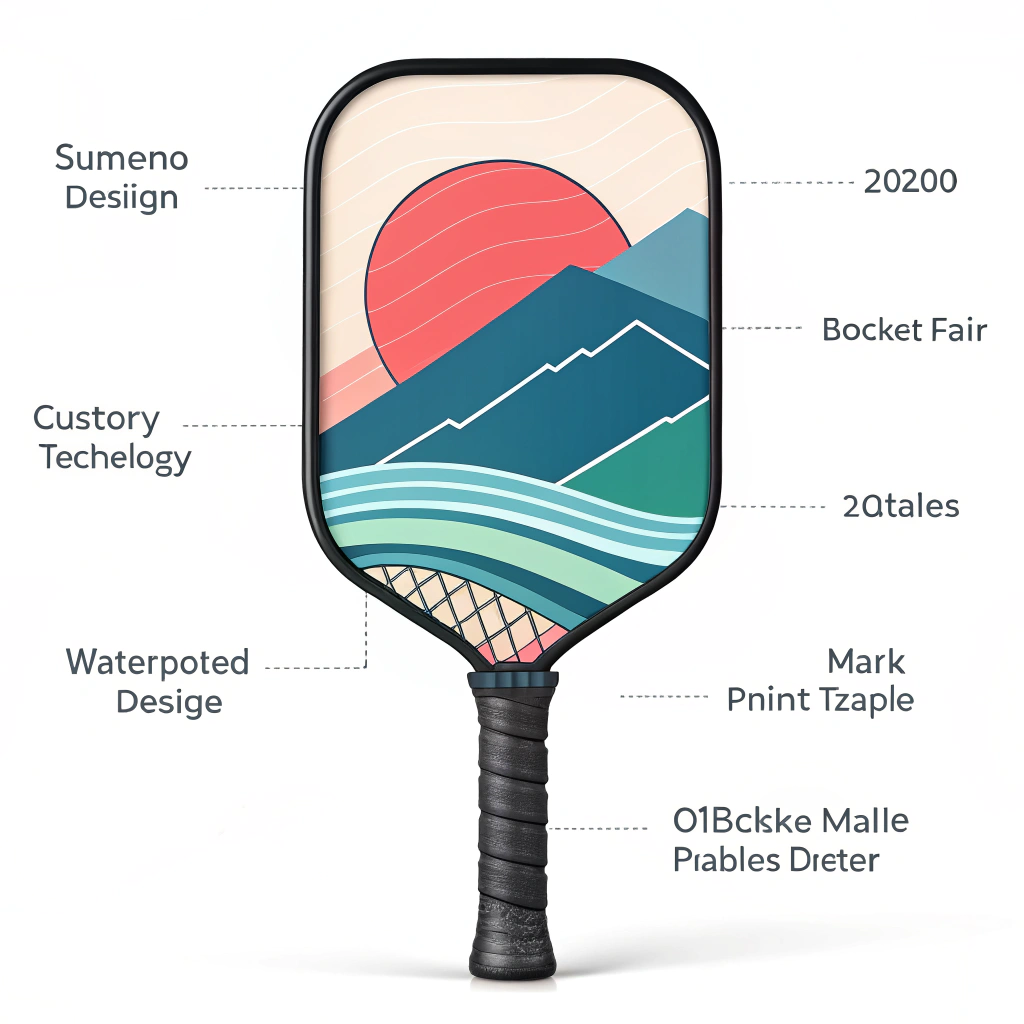

Custom printing on pickleball paddles involves embedding designs onto various paddle materials such as carbon fiber4, fiberglass, and composite materials5. The choice of printing method influences both the look and longevity of the graphics. Below, we detail four popular techniques and evaluate their pros and cons.

Digital printing is a modern method that uses high-resolution printers to transfer images directly onto the paddle surface.

- Advantages:

- High precision and resolution

- Quick turnaround time and flexibility for on-demand printing

- Cost-effective for small-to-medium production runs

- Disadvantages:

- Limited material compatibility

- The printing layer may wear off with heavy use if not properly sealed

- Best For:

- Brands prioritizing vibrant, detailed graphics in moderate production volumes

2. UV Printing1

UV printing employs ultraviolet light to cure ink as it is printed, leading to a durable finish.

- Advantages:

- Exceptional durability and resistance to weathering and scratches

- Superior adhesion on various substrate types, including high-performance composites

- Fast curing process leading to high production efficiency

- Disadvantages:

- Higher initial equipment cost

- Some inks can be more expensive, affecting cost efficiency in large runs

- Best For:

- High-traffic and outdoor environments where the paddle is subject to wear

- B2B clients requiring long-lasting visual branding

3. Sublimation2

Sublimation printing converts solid dye into gas, embedding the color directly into the material rather than on its surface.

- Advantages:

- Produces a permanent, vibrant image that becomes part of the paddle

- Excellent for full-color, high-resolution images

- Resistant to fading and peeling even under extreme conditions

- Disadvantages:

- Works best with polymer-based surfaces, which may limit its application on some composite paddles

- Requires strict temperature and pressure control during production

- Best For:

- Products where longevity and seamless integration of the design are paramount

- Custom orders with intricate graphics and multiple color layers

Adhesive transfers involve printing the graphic on a specialized adhesive film and then applying it over the paddle surface.

- Advantages:

- Flexibility to work on a variety of surface shapes and textures

- High repeatability with controlled placement

- Can be removed or replaced if updates are needed

- Disadvantages:

- May face issues with adhesion over time, especially under prolonged stress or environmental exposure

- Laboratory conditions are often needed to ensure proper surface preparation

- Best For:

- Limited-run custom series or team branding where periodic updates are expected

- Situations demanding rapid prototyping and approval cycles

Below is a comparison table summarizing the key factors of each printing method. This table will help you quickly assess the options based on critical performance and cost considerations.

| Printing Method | Durability | Cost Efficiency | Production Speed | Material Compatibility | Ideal Use Case |

|---|---|---|---|---|---|

| Digital Printing | Moderate (requires sealing) | High (low setup cost) | Fast | Limited (best with smooth surfaces) | Moderate volume; detailed graphics |

| UV Printing | High (weather & scratch resistance) | Moderate to High (ink & equipment costs) | Very fast due to instant curing | Broad (works well on composites) | High-performance, outdoor, long-term branding |

| Sublimation | Very High (integrated into material) | Moderate (needs specialized materials) | Moderate (process needs controlled conditions) | Best with polymer surfaces | Premium visual integration; intricate designs |

| Adhesive Transfers | Variable (depends on adhesive quality) | High (flexible production) | Variable (quick if conditions are optimal) | Very High (applies to varied surfaces) | Limited run custom series; prototype testing |

This table provides a snapshot to help you compare and select the appropriate printing technique based on your brand’s strategy, material requirements, and production volume.

At NEX Pickleball, our factory experience has taught us that there is no one-size-fits-all solution when it comes to applying custom graphics on pickleball paddles. Instead, the decision must consider multiple factors such as the type of core materials used, the intended environment for use, and the producer’s capability for advanced production processes.

High-performance paddles often utilize advanced composite materials such as Carbon Fiber (3K, 12K, T300) and various honeycomb cores (Nomex, Aluminum, Polymer). The printing process must not compromise the structural integrity of these materials. For example, while sublimation integrates seamlessly with polymer surfaces, it might not be as effective on certain carbon fiber substrates unless the surface is treated.

Similarly, the UV printing process is very effective on high-performance paddles as it cures instantly, avoiding potential disruption of the paddle’s balance and aerodynamics. This alignment between material properties and printing techniques ensures that the final product maintains both aesthetic appeal and athletic performance.

-

Surface Preparation:

Regardless of the printing technique chosen, surface preparation is paramount. This involves cleaning, priming, and sometimes texturing the paddle surface to guarantee proper ink adhesion. Laboratory tests help determine the optimal preparation method to ensure longevity and resistance against impacts. -

Ink and Material Compatibility Testing:

For UV and digital printing methods, rigorous testing helps in selecting the right ink formulation. These tests simulate long-term usage conditions including repeated impacts, UV exposure, and temperature fluctuations. Our quality control labs run these durability tests to validate each combination of materials and inks. -

Controlled Environment Production:

Techniques like sublimation require a highly controlled environment—where temperature and pressure are finely regulated—to achieve a consistent quality finish. By maintaining such conditions, factories can produce paddles that not only offer vivid graphics but also maintain the paddle’s inherent performance characteristics. -

Post-Printing Quality Checks:

After printing, the paddles undergo additional quality control processes. This includes adhesion tests, vibration analysis during gameplay simulation, and visual inspections. These measures help in immediately identifying any issues that might compromise the paddle’s durability or brand aesthetics.

Given the requirements of large-scale orders and B2B procurement, cost efficiency becomes as vital as quality. Here’s how each printing method scales in a factory setting:

-

Digital Printing:

Its low setup cost and adaptability make it ideal for on-demand printing where customization is necessary without retooling a production line. The major trade-off lies in its durability, which can be mitigated through advanced sealing techniques. -

UV Printing:

While the initial investment is higher, UV printing offers excellent scalability due to its rapid curing process and minimal waste. This method is highly suited for orders where long-term performance is critical, especially in competitive environments. -

Sublimation:

The sublimation process is a premium solution. Its strength lies in delivering unparalleled integration of graphics with the paddle material. However, it may be less cost-effective for bulk runs unless the material suitability is ensured from the outset. -

Adhesive Transfers:

Offering high flexibility and quick turnaround, adhesive transfers are more cost-effective for prototypes and limited-edition products. They allow brands to experiment with designs without committing to large production runs.

For procurement managers and brand specialists, the selection of a printing technique should align with your product’s market positioning and the technical requirements of your paddles. Below are a few key recommendations based on our comparative analysis:

-

Assess Your Brand Priorities:

- If your brand demands cutting-edge aesthetics with vibrant visuals for competitive play, consider UV Printing1 or Sublimation2.

- For economically agile models that allow for frequent design updates, Digital Printing or Adhesive Transfers3 might be preferable.

-

Consider Field Testing Results:

- Draw on empirical testing data where durability and performance under game conditions have been benchmarked.

- Evaluate products from suppliers like NEX Pickleball that conduct rigorous quality assurances to ensure the graphics do not compromise the paddle’s structural integrity.

-

Focus on Material Compatibility:

- Ensure the printing method is compatible with the paddle’s manufacturing process. For instance, advanced carbon fiber paddles require a printing method that won’t degrade the surface or alter the aerodynamic profile.

-

Plan for Long-Term Scalability:

- Factor in the demands of large-scale orders and consistent quality. Scalable production methods like UV printing, despite higher initial costs, may offer long-term cost savings and brand consistency.

In conclusion, selecting the optimal printing technique for your custom pickleball paddles demands a holistic evaluation of graphics quality, process durability, production speed, and overall cost efficiency. Whether you choose Digital Printing for its cost advantages, UV Printing1 for its durable finish, Sublimation2 for its seamless graphic integration, or Adhesive Transfers3 for their flexibility in custom branding, it is critical to align the method with your brand’s performance and marketing goals.

Our experience at NEX Pickleball shows that an informed decision—supported by technical testing and material compatibility studies—can significantly enhance the visual appeal and durability of your sports equipment. By understanding the strengths and limitations of each method, B2B buyers can confidently select a printing solution that complements their product line while meeting stringent performance standards.

Taking these factors into consideration will ensure that your custom-painted pickelball paddles not only captivate your target customers but also withstand the rigors of competitive play.

-

Who makes the best quality pickleball paddles?

The best quality pickleball paddles are made by manufacturers that focus on high-performance materials and rigorous quality control. Leading makers, including those working with advanced carbon fiber, fiberglass, and composite cores—like NEX Pickleball—offer paddles that combine durability with precision design for both beginners and professional players. -

What to look for in a quality pickleball paddle?

Key factors include the paddle shape, core material, and face material, along with important aspects such as handle length, paddle weight, and a grip that suits your hand size and play style. Beyond these physical characteristics, effective branding and custom graphics can enhance the paddle’s market appeal. -

What do pro pickleball players use for paddles?

Professional players often use paddles that blend high-performance features with innovative materials. Paddles such as those from Selkirk, Joola, and Franklin are favorites in the professional arena, offering surfaces engineered for optimal control and power while also reflecting a commitment to quality production techniques.

-

UV Printing: Reading the article will help you understand how ultraviolet light cures ink for enhanced durability and efficiency, especially suitable for high-performance surfaces. Back ↩ ↩2 ↩3 ↩4

-

Sublimation: Reading the article provides insights on converting solid dye into gas, integrating graphics permanently into materials for a lasting finish. Back ↩ ↩2 ↩3 ↩4

-

Adhesive Transfers: Reading the article explains the process of applying pre-printed adhesive films onto surfaces, ideal for flexible customizations and rapid prototyping. Back ↩ ↩2 ↩3 ↩4

-

Carbon Fiber: Reading the article will help you learn about carbon fiber’s properties, applications in high-performance manufacturing, and its role in ensuring structural integrity. Back ↩

-

Composite Materials: Reading the article offers an overview of composite materials and their importance in manufacturing durable and lightweight products. Back ↩