Rapid prototyping for high-performance pickleball paddles is achieved by balancing speed and quality through carefully directed manufacturing processes and material selection. In simple terms, using methods like hot pressing, cold pressing, and thermoforming1 while selecting superior materials such as carbon fiber2 and fiberglass3 helps streamline product development and ensures durable, high-performance results.

The Rapid prototyping4 challenge is common in the sports equipment manufacturing industry. As technical product development managers and manufacturing leads, you must meet market demand quickly without sacrificing quality control. In the context of pickleball paddle production, this means selecting the right manufacturing processes and materials to produce durable prototypes and ultimately final products that meet performance standards.

Manufacturers face several challenges:

• The need to quickly produce and test prototypes while maintaining consistent quality.

• Balancing the competing needs of production efficiency with the structural integrity of high-performance paddles.

• Ensuring that the chosen production processes preserve the unique material properties required for maximum rebound, control, and vibration dampening.

When entering a market, rapid prototyping must not only be fast but also deliver a product that meets technical and regulatory requirements such as USAPA standards5. This challenge is magnified further by the demand for unique custom paddle designs for various customer segments.

Delays and quality issues in rapid prototyping can often be traced to the following factors:

- Inadequate process selection: Traditional production methods without innovation may compromise speed or quality.

- Poor material choices: Using suboptimal materials can lead to inferior paddles that do not perform well or endure wear.

- Lack of optimized workflow: A misalignment between design, manufacturing, and testing phases often results in bottlenecks, increased costs, and slower market entry.

Understanding these issues is the first step towards crafting a solution that integrates rapid prototyping techniques with rigorous quality control.

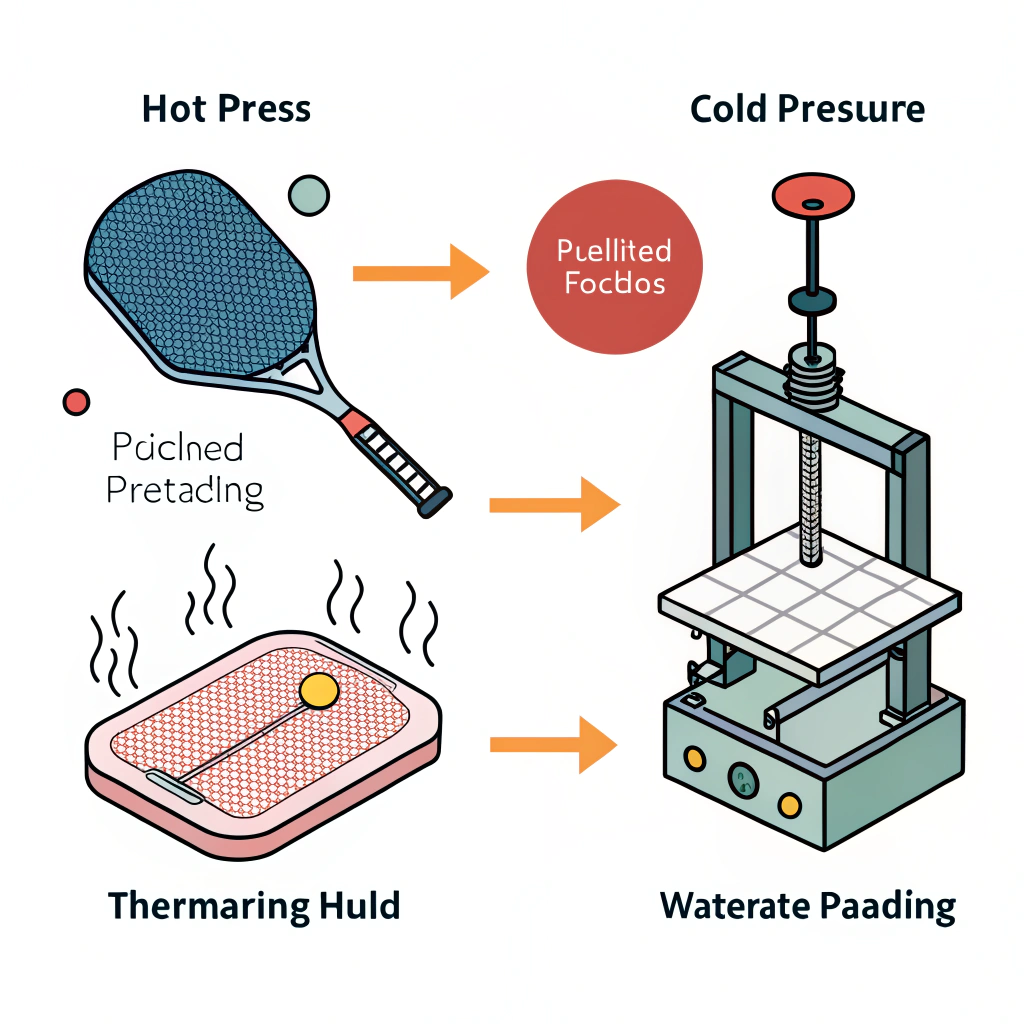

To overcome these challenges, manufacturers can consider the three main production processes:

Hot pressing involves heating the paddle materials and applying pressure simultaneously to form the paddle.

• Advantages:

– High Production Efficiency: Suitable for scaling up manufacturing with consistent cycle times.

– Structural Integrity: Produces paddles with excellent impact resistance, important for high-performance play.

– Durability: Results in paddles that can withstand the stresses of competitive use.

• Disadvantages:

– Potential Material Alteration: The heat may alter some delicate material properties that affect paddle feel.

– High Equipment Investment: Requires significant ongoing operational costs.

Cold pressing uses mechanical pressure at room temperature to shape the paddle.

• Advantages:

– Precision Control: Offers fine control over paddle thickness and internal structure without altering material properties.

– Excellent Ball Feel: Maintains material’s natural characteristics for better tactile feedback and control.

– Flexibility: Ideal for designs where maintaining the raw properties of the materials is vital.

• Disadvantages:

– Slower Production Cycle: Longer processing times can hinder rapid prototyping needs.

– High-Quality Equipment Demand: Requires machines that can apply precise and consistent pressure.

Thermoforming involves heating selected materials to a softening point and then molding them into the desired shape using specialized molds.

• Advantages:

– Intricate Designs: Allows production of paddles with complex shapes and optimal material distribution.

– Stability: Retains structural strength and ensures consistent performance across batches.

– High-Performance Materials: Ideal for premium materials that require a delicate forming process.

• Disadvantages:

– Extended Production Times: The heating and cooling cycles can slow down overall production.

– Cost: Equipment and molds for thermoforming typically involve higher capital expenditure.

Below is a summary table comparing these processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, durable | May change material properties, high investment costs |

| Cold Pressing | Precise control, maintains material integrity, superior ball feel | Longer cycle times, requires high-precision equipment |

| Thermoforming | Intricate design capabilities, stable construction, versatile | Longer production time, higher equipment costs |

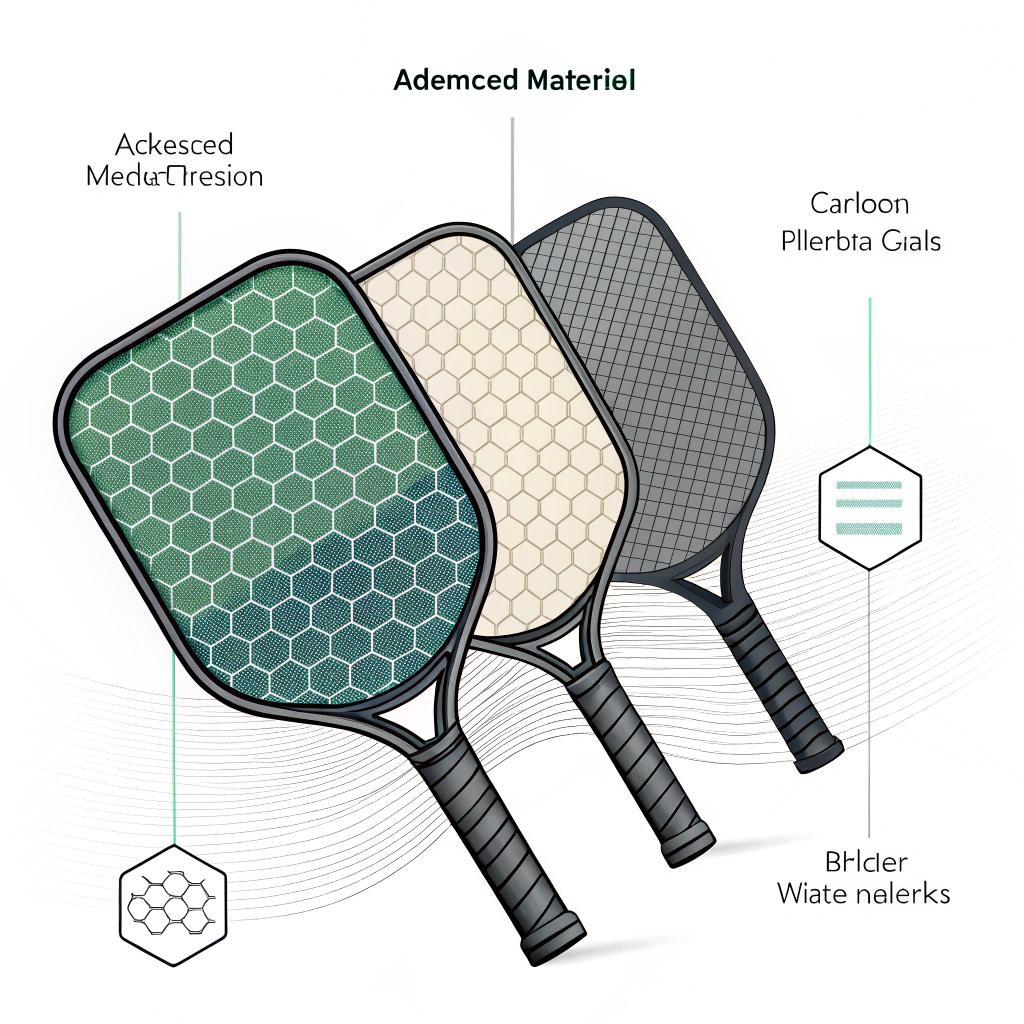

Choosing the right materials is as critical as selecting the production process. For high-performance pickleball paddles, advanced materials such as carbon fiber2 and fiberglass3 are frequently used. Here’s a closer look at key materials:

• 3K Carbon Fiber:

– Known for its balance between strength and flexibility.

– Offers excellent durability and reduces vibration, ensuring a powerful rebound effect.

• 12K Carbon Fiber:

– Has a higher thread density providing a smoother surface finish.

– Delivers extreme strength and meets the demands of competitive play through improved impact resistance.

• T300 Carbon Fiber:

– Recognized for its outstanding tensile strength.

– Perfect for paddles requiring a balance of light weight and strength.

• E-Glass Fiberglass:

– Provides a wider sweet spot and balanced performance between power and control.

– Known for its elasticity and ability to enhance ball control, making it ideal for various player levels.

Combining different materials can yield paddles with a unique mixture of properties:

• Carbon Fiber and Fiberglass Composite: This blend is engineered to deliver both power and precision.

• Bamboo Core Composite: Offers a clear, natural hitting feel while providing excellent shock absorption.

• Honeycomb Core: Manufactured using high-density polymer or pulp, this option maximizes durability by reducing vibration significantly.

In rapid prototyping, selecting the right material depends on the target design and the specific performance metrics required. The balance between material properties and manufacturing process must be carefully optimized, which is why customizable options are critical. With the ability to design custom paddles, companies can meet unique performance standards and market demands.

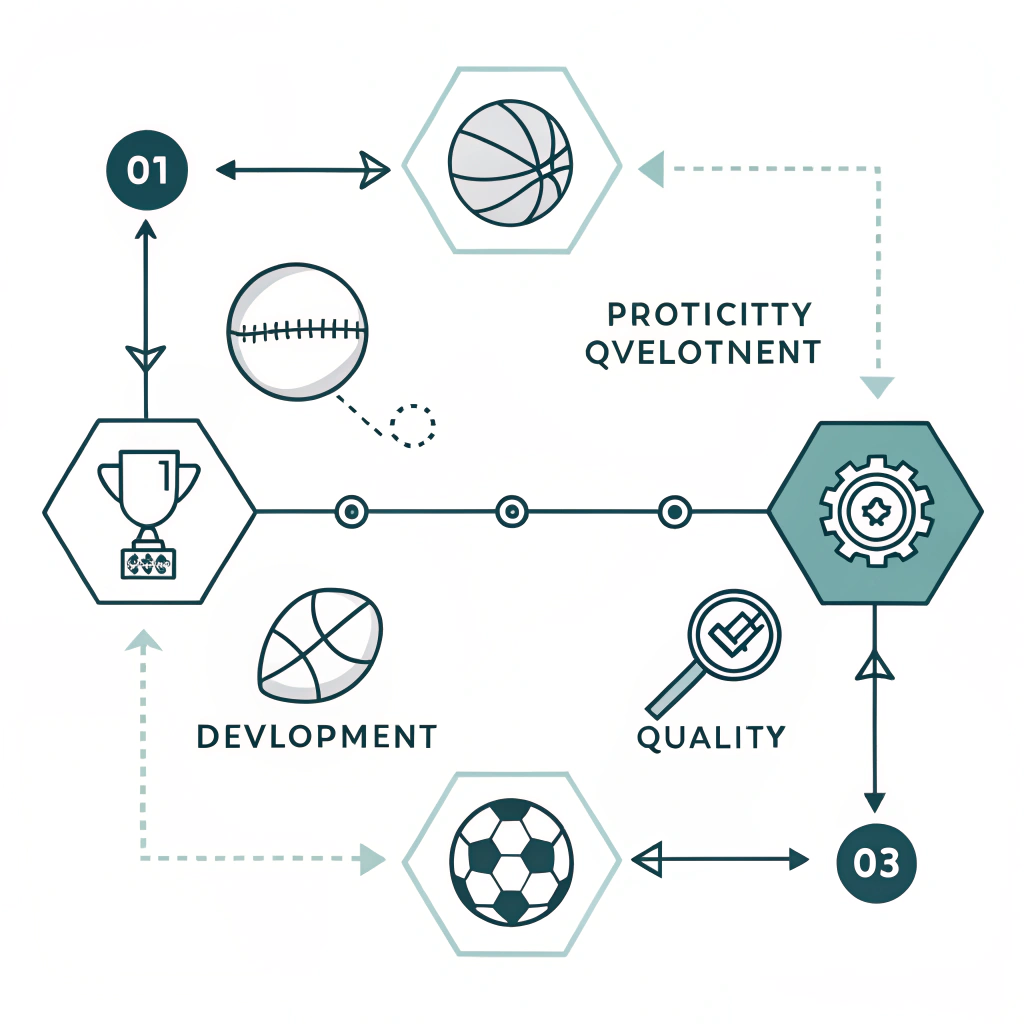

For manufacturers, time is of the essence. A well-planned prototyping workflow often includes the following steps:

-

Concept Development and Material Testing

– Develop digital prototypes incorporating various material and design options.

– Conduct small-scale tests to determine optimal material compatibility. -

Process Selection Based on Prototype Requirements

– Evaluate the benefits of hot pressing, cold pressing, or thermoforming1 through preliminary tests.

– Consult data from industry benchmarks and past production runs. -

Rapid Prototype Production

– Execute the chosen process using short production cycles while ensuring precision in thickness and overall design.

– Use pilot runs to catch any deviations early in the process. -

Rigorous Quality Control and Testing

– Each paddle undergoes standardized testing procedures to ensure the correct balance of durability and performance.

– Align testing protocols with USAPA standards5 and other international standards. -

Iterative Feedback and Process Refinement

– Collect detailed performance data and customer feedback to continuously refine production techniques.

– Regularly update machine calibration and adjust pressure or heat parameters as needed. -

Final Approval and Market Deployment

– Once the prototype meets all technical and regulatory standards, proceed with larger-scale manufacturing.

– Coordinate with testing facilities for USAPA approval, usually requiring 4 to 6 weeks for standard testing or 3 to 8 business days through expedited channels.

An organized workflow not only reduces errors but significantly shortens the time from concept to market-ready product. This is crucial when entering fast-paced markets where innovation and market responsiveness are key competitive advantages.

Quality control is an integral part of the manufacturing process. Rigorous testing standards ensure that every paddle meets performance expectations. For high-performance paddles, testing includes:

• Impact Resistance: Ensuring the materials can withstand high-impact collisions without deforming.

• Vibration Dampening: Testing in conditions that simulate heavy play to confirm the effectiveness of material choices and core designs.

• Balance and Weight Distribution: Confirming optimal design for playing comfort and performance.

Adhering to these testing benchmarks is essential, especially when meeting standards set by regulatory bodies such as USAPA standards5. Under standard testing conditions, USAPA approval can take 4 to 6 weeks, whereas expedited channels offer turnaround within 3 to 8 business days. This dramatically impacts the prototyping speed and final deployment timing.

A leading sporting goods company recently faced production delays in their high-performance pickleball paddle line. By implementing a redesigned workflow that emphasized rapid material testing and process optimization, they achieved significant improvements:

• Switching part of the production process from traditional molding to thermoforming1 allowed for complex designs and improved material consistency.

• An iterative testing protocol using quick cycle production tests reduced error rates by nearly 30%.

• Introducing a blend of carbon fiber variants enabled a paddle design that offered consistent power, improved durability, and reduced production time without compromising quality.

This case underscores the importance of carefully aligning manufacturing processes with product design and market expectations. It also demonstrates how rapid prototyping can be efficiently integrated with quality control protocols to deliver a market-ready product quickly.

In conclusion, rapid prototyping for pickleball paddles is not just about speed—it encompasses a delicate balance between advanced production techniques and material innovation. By selecting the optimal manufacturing process, whether that is hot pressing for rapid efficiency, cold pressing for fine control, or thermoforming1 for intricate designs, manufacturers can ensure that their paddles meet both performance and durability standards.

Key takeaways include:

• Understanding the advantages and limitations of each process method through comparative analysis.

• Emphasizing material selection—especially high-performance carbon fiber2 and fiberglass3—to enhance paddle quality.

• Streamlining production workflows to integrate rapid prototyping with stringent quality control measures.

• Utilizing pilot runs and iterative feedback to continuously refine production processes and accelerate USAPA approvals.

For manufacturers and product development managers, the path forward lies in embracing innovative production methods that maintain a sharp focus on quality. By leveraging our experiences and insights at NEX Pickleball, you can strategically optimize your paddle prototyping process, achieve faster market entry, and meet the high-performance demands of today’s competitive sports market.

People Also Ask

Q: Can I create my own paddle for pickleball?

A: Yes, custom paddle design is available. Manufacturers can offer tailor-made paddles that meet USA Pickleball regulations with no minimum order requirement, allowing you to create a paddle that fits both your design vision and performance needs.

Q: How long does it take to break in a new pickleball paddle?

A: Similar to breaking in a baseball glove, new pickleball paddles typically have a break-in period that may require between 5 to 15 games of play. Factors like paddle material and design, such as carbon fiber thermoformed structures, can influence this period.

Q: How long does USAPA approval take?

A: Under standard procedures, USAPA approval normally takes 4 to 6 weeks. However, expedited testing processes can shorten this timeframe to anywhere between 3 to 8 business days once the paddle is received at the testing facility.

-

Thermoforming: Click here to study the process of heating and molding materials into complex shapes for innovative product manufacturing. ↩ ↩2 ↩3 ↩4

-

Carbon fiber: Click here to learn about the high-strength, lightweight composite material used in advanced manufacturing. ↩ ↩2 ↩3

-

Fiberglass: Click here to understand the properties of fiberglass and its application in durable product design. ↩ ↩2 ↩3

-

Rapid prototyping: Click here to explore methodologies that accelerate product development cycles while ensuring quality and performance. ↩

-

USAPA standards: Click here for an overview of the regulatory requirements set by the USA Pickleball Association to ensure safety and performance. ↩ ↩2 ↩3