High-performance pickleball paddles have become a vital component for sports equipment distributors seeking a competitive edge. NEX Pickleball offers innovative manufacturing techniques and customizable designs that guarantee superior quality, durability, and performance for bulk procurement1.

Procurement managers and sales directors in the sports equipment sector face several challenges when sourcing pickleball paddles for their retail and sports club businesses. The primary concerns include:

- Ensuring material quality and optimal performance.

- Verifying production efficiency and reliability.

- Adapting to ever-evolving market demands with customizable paddle designs.

- Balancing cost with innovative, high-performance products.

The market demands paddles that not only stand out in performance but also reflect the latest technological trends and aesthetic preferences. As customers increasingly favor paddles featuring advanced materials such as carbon fiber2 and fiberglass, choosing the right supplier becomes critical to maintaining and enhancing market positioning.

Procuring pickeball paddles on a wholesale basis involves a deep dive into the manufacturing processes and material selection. Each technology used in the production—from the raw materials to processing methods—plays a crucial role in the final product’s performance and cost efficiency.

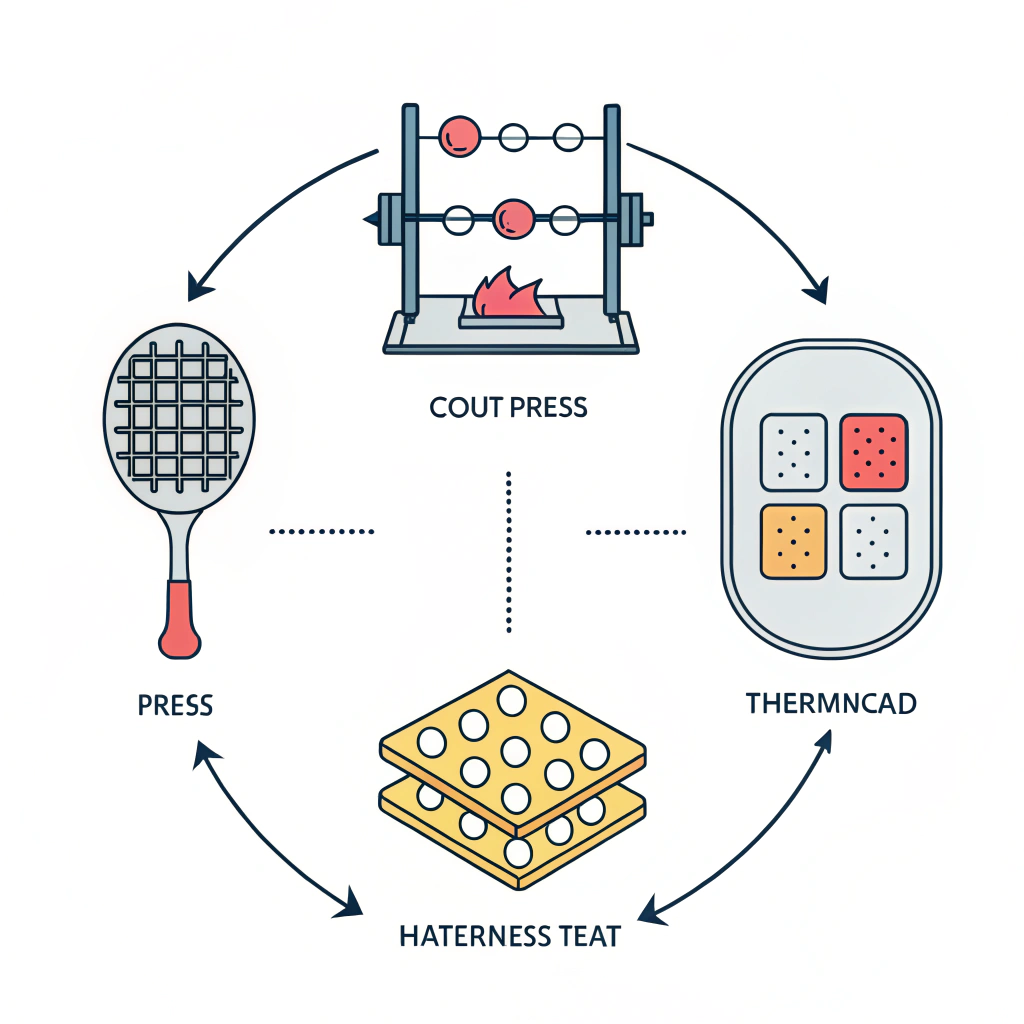

NEX Pickleball employs three primary production methods that can be tailored to meet the specific demands of quality and performance:

-

Hot Pressing3

Hot pressing involves heating the material and applying high pressure to bond the paddle components securely.

Advantages:- High production efficiency, suitable for mass manufacturing.

- Produces robust paddles with excellent impact resistance.

- Enhances the structural integrity of the paddle, ideal for competitive play.

Disadvantages:

- May modify certain material characteristics, possibly impacting tactile feel.

- Requires significant capital for equipment investment.

-

Cold Pressing

Cold pressing shapes the paddle material at room temperature using controlled mechanical pressure.

Advantages:- Precise control over paddle thickness and structure.

- Maintains the original properties of the material, improving ball feel and responsiveness.

- Yields paddles with enhanced control, suitable for players emphasizing finesse.

Disadvantages:

- Longer production cycles may reduce overall manufacturing efficiency.

- Demands high-quality equipment to ensure consistent results.

-

Thermoforming4

Thermoforming softens materials by heating them to a pliable state, then molding them into the desired shape using customized molds.

Advantages:- Allows for complex paddle designs with intricate material distribution.

- Provides stable performance by maintaining paddle balance and structural integrity.

- Ideal for premium product lines and custom orders.

Disadvantages:

- Longer production times and higher associated costs.

- Best suited for higher-end, custom-made paddle orders rather than large-volume, cost-sensitive rounds.

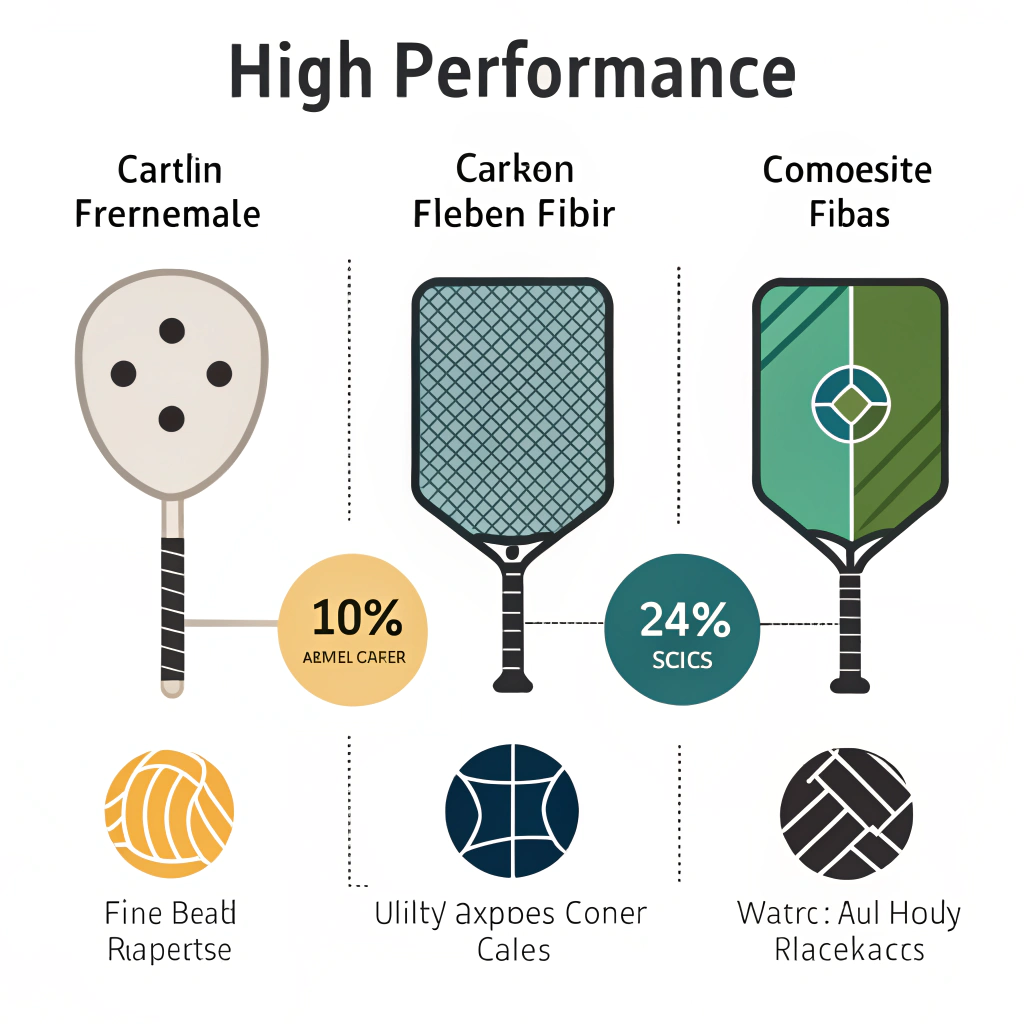

The choice of materials is as decisive as the production method itself. NEX Pickleball leverages a range of premium materials to meet varied performance and pricing requirements:

-

Carbon Fiber Varieties:

- 3K Carbon Fiber: Offers high strength and flexibility with reduced vibration during play, making it perfect for paddles that require rapid rebound.

- 12K Carbon Fiber: Known for its higher thread density, this material provides a smoother surface, greater hardness, and enhanced durability, particularly in high-impact scenarios.

- T300 Carbon Fiber: Balances strength with light weight, offering outstanding tensile strength for a versatile performance profile.

-

Fiberglass Options:

- E-Glass Fiberglass: Delivers excellent elasticity and tensile strength, providing an enhanced ball feel and control that is ideal for recreational as well as competitive players.

-

- Carbon Fiber and Fiberglass Composite: This combination creates a paddle that enjoys the benefits of both materials—strength, lightness, and flexibility—with an overall balance that meets diverse playing styles.

- Bamboo Core Composite: This material offers lightweight performance and high impact resistance, delivering a clear, crisp hitting feel.

- Honeycomb Core: Made from high-density polymers or pulp, it gives superior shock absorption, drastically reducing vibrations and extending the paddle’s lifecycle.

-

Core Material Options:

- Nomex Honeycomb Core: Provides remarkable shock absorption and stability for durability in high-intensity play.

- Aluminum Honeycomb Core: Maintains a balanced weight distribution, offering a harmonious blend of power and precision.

- Polymer Honeycomb Core: Known for its elasticity and vibration reduction, making it a preferred choice for those prioritizing comfort and performance stability.

The coupling of these materials with specialized production techniques precisely delivers paddles that exceed performance expectations. The selection process for materials is driven by both performance characteristics and the specific use-case requirements of clients, ensuring that every paddle is engineered to meet a high standard of quality.

Purchasing the best pickleball paddle in bulk requires careful evaluation. Procurement managers need to understand the multi-dimensional differences across production methods and material properties. The following table offers a clear overview:

| Production Process | Key Advantages | Limitations | Ideal Use Case |

|---|---|---|---|

| Hot Pressing | High efficiency; robust impact resistance | Altered material feel; high equipment cost | Competitive play; mass production |

| Cold Pressing | Precise control; intact material properties | Longer production cycle; precision needed | Custom designs; improved ball control |

| Thermoforming | Complex designs; optimal material distribution | Higher cost; extended production time | Premium/custom paddles; intricate designs |

Similarly, the evaluation of material quality further differentiates paddle performance:

| Material Type | Key Benefits | Common Applications |

|---|---|---|

| 3K Carbon Fiber | Strength and flexibility; vibration reduction | High rebound paddles |

| 12K Carbon Fiber | Smoother surface; enhanced hardness | Competitive and durable play |

| T300 Carbon Fiber | Outstanding tensile strength; lightweight design | Versatile, high-performance |

| E-Glass Fiberglass | Excellent elasticity; superior ball control | Recreational and competitive |

| Bamboo Core Composite | Lightweight; high impact resistance | Long-lasting play |

| Nomex Honeycomb Core | Superior shock absorption; stability | High-intensity, competitive |

| Aluminum Honeycomb Core | Balanced weight; precise control | Mixed gameplay |

| Polymer Honeycomb Core | Enhanced elasticity; reduced vibrations | Comfort-oriented players |

This clear layout provides a snapshot for decision-makers to evaluate how each aspect contributes to overall paddle performance and market differentiation, allowing for informed purchasing decisions.

Customization is a key factor that sets NEX Pickleball apart in the competitive wholesale market. Clients have the opportunity to tailor paddle design elements such as:

- Weight distribution: Critical for both power and control based on player needs.

- Grip size and ergonomic design: To ensure comfort and reduce fatigue for extended gameplay.

- Surface texture treatments: For improved grip, which further enhances spin and accuracy.

- On-demand print services: Enabling personalized paddle branding for specific teams, clubs, or promotional events.

The ability to customize paddles not only meets unique consumer requirements but also fosters stronger buyer-supplier relationships by demonstrating commitment to quality and flexibility. These customization options are particularly important for retailers and sports clubs seeking to offer differentiated product lines that capture market attention and elevate brand image.

Every high-performance paddle from NEX Pickleball undergoes rigorous quality assurance protocols to confirm that it meets the highest industry standards. Key areas of focus include:

- Precision in manufacturing: Each paddle is tested for balance, weight distribution, and structural integrity.

- Durability assessments: We simulate various play conditions to ensure each paddle stands up to competitive intensity.

- Tactile and performance evaluation: Expert testers assess control, ball feel, and vibration absorption to provide feedback for continuous improvement.

Quality control is integrated into every stage of production—from material selection and molding to finishing and printing—ensuring that every paddle is reliable and ready for the demands of high-intensity pickleball.

NEX Pickleball’s advanced techniques such as hot pressing, cold pressing, and thermoforming have been successfully implemented across multiple high-volume orders. These production processes not only deliver high-performance products but also maintain competitive pricing through efficient and scalable manufacturing systems.

Several distributors and sports clubs have reported:

- A noticeable improvement in product durability and performance.

- Enhanced consumer satisfaction due to superior playing experiences.

- Increased market differentiation owing to unique design customization options.

This real-world success underscores that NEX Pickleball is a trusted partner in building a robust product portfolio that meets the evolving demands of the sports equipment market. By leveraging proven manufacturing technologies and premium materials, our paddles cater to varied customer needs—whether for entry-level recreational play or high-end competitive match performance.

For procurement managers and sales directors evaluating wholesale options, the following actionable recommendations may help streamline the sourcing process:

- Analyze your market requirements by assessing the expected performance and customization needs of your clientele.

- Compare the production methods and material advantages provided by potential suppliers using detailed data—like the tables above—to understand cost-performance trade-offs.

- Prioritize suppliers like NEX Pickleball that offer advanced customization, rigorous quality control, and competitive pricing.

- Make pilot orders to evaluate product quality, performance, and the supplier’s ability to deliver on customization requests.

- Leverage supplier flexibility by planning on-demand-print services for personalized product lines that boost brand recognition.

By aligning the manufacturing strengths of your partner with your market strategy, you ensure that your product lineup not only meets performance standards but also delivers a unique competitive advantage.

Q: What production techniques are used in high-performance pickleball paddle manufacturing?

A: High-performance paddles are made using methods such as hot pressing, cold pressing, and thermoforming. Hot pressing offers robust impact resistance and efficiency, while cold pressing provides precise control, and thermoforming allows for intricate design details and premium material distribution.

Q: How do material choices affect pickleball paddle performance?

A: Material choices—like 3K, 12K, and T300 carbon fiber, as well as E-Glass fiberglass—significantly influence paddle performance in terms of strength, vibration reduction, ball control, and overall durability. The right material mix supports both competitive play and recreational use.

Q: Can the paddle design be customized for individual or team branding?

A: Yes, suppliers such as NEX Pickleball offer extensive customization options including weight distribution, ergonomic grip design, surface texture treatments, and on-demand printing services for personalized branding, ensuring the product fully aligns with specific consumer or team requirements.

-

Bulk Procurement: Click to explore strategies for purchasing goods in large quantities and understand its impact on supply chain efficiency and cost management in B2B transactions. ↩ ↩

-

Carbon Fiber: Click to understand the properties, applications, and advantages of carbon fiber in enhancing the strength and durability of high-performance products. ↩ ↩

-

Hot Pressing: Click to learn about this high-temperature, high-pressure manufacturing process that bonds components to produce durable, high-performance products. ↩ ↩

-

Thermoforming: Click to read about the process of heating and molding materials into specific shapes, offering design flexibility and complexity in product manufacturing. ↩ ↩

-

Composite Materials: Click to discover how combining different materials can result in products with superior performance characteristics including strength, lightness, and durability. ↩ ↩