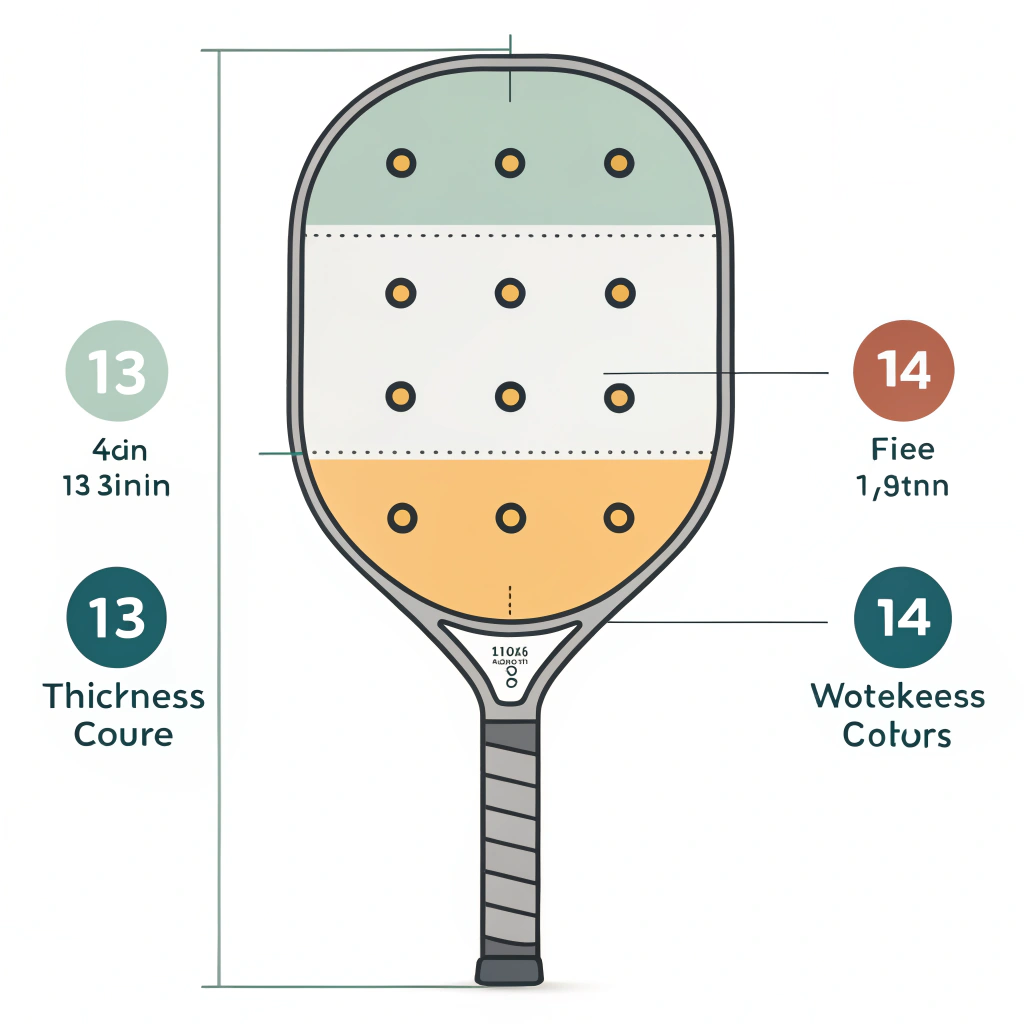

Quick Answer: The optimal pickleball paddle core thickness1 depends on the intended playing characteristics – 13mm offers a direct, power-focused feel, 16mm delivers enhanced control and shock absorption, while 14mm can be seen as a balanced compromise. B2B buyers should consider market needs, production constraints, and materials when deciding which specification best fits their portfolio.

In today’s competitive pickleball market, paddle core thickness1 plays a crucial role in determining player performance, production feasibility, and overall product appeal. Choosing between a 13mm, 14mm, and 16mm core is not simply a matter of aesthetics. Instead, it involves a detailed understanding of technical specifications, trade-offs in performance, and consumer feedback. In this article, we will compare the three core thickness options, presenting data-driven insights for B2B procurement managers and product development executives looking to make informed decisions.

The paddle core is the heart of any pickleball paddle. It not only affects the paddle’s performance but also plays a vital role in aspects such as vibration reduction, ball control, and overall durability. Here, we define key performance factors related to core thickness:

- Control and Precision: Thicker cores, such as 16mm, are known to absorb more energy, leading to increased control and stability during drop shots and blocks.

- Power and Pop: Thinner cores, like 13mm, provide increased “pop” off the paddle surface, granting players more power during offensive plays.

- Material Durability: Core thickness can impact the paddle’s longevity. Thicker cores usually lead to enhanced shock absorption and improved durability over long-term use.

- Feel and Comfort: The tactile response during play is crucial. A balanced design such as a 14mm core might cater to both power and control while maintaining a comfortable feel.

Understanding these factors helps inform the design and production process, ensuring that each paddle meets the specific needs of its target market.

The following sections outline the technical differences and performance trade-offs between each core thickness:

A 13mm paddle core is usually associated with:

- Enhanced Power: A thinner core offers a more direct impact with a higher rebound effect. This may benefit players who rely on fast offensive shots.

- Direct Feedback: Provides a more ‘pop’ sensation, allowing a rapid transfer of ball energy.

- Reduced Absorption: Less material is available to absorb shock; hence, players might experience slightly higher vibrations during heavy impact.

Acting as a middle ground, the 14mm core provides:

- Balanced Performance: A compromise between power and control, delivering adequate energy transfer with sufficient shock absorption.

- Improved Versatility: Suitable for a broader player demographic, including those who want both precision in control and a satisfactory level of ball pop.

- Moderate Durability: While effective for many players, this thickness may not be ideal for high-impact, professional-level competition where minimal vibration is critical.

The 16mm core is favored by competitive players who prioritize:

- Ultimate Control: Thicker cores are excellent at reducing vibration, resulting in precise ball handling and better control over blocks and drop shots.

- Enhanced Shock Absorption: Greater material density leads to superior impact dampening, which can improve the paddle’s longevity.

- Trade-off in Power: Compared to 13mm cores, the thicker design might slightly reduce the ball’s ‘pop’ or power, prompting players to generate additional swing force for energy transfer.

To further compare these options, consider the table below:

| Core Thickness | Power/Pop | Control | Shock Absorption | Target Audience |

|---|---|---|---|---|

| 13mm | High | Moderate | Lower | Aggression-driven players, fast plays |

| 14mm | Balanced | Balanced | Moderate | Versatile players who need dual benefits |

| 16mm | Lower | High | Superior | Professionals focused on precision |

As the table shows, no single core thickness is categorically superior; rather, each offers distinct advantages depending on the playing style and market segment.

When selecting core thickness, B2B buyers must also consider the production techniques and material choices.

At NEX Pickleball, our advanced manufacturing methods—Hot Pressing2, Cold Pressing3, and Thermoforming4—allow us to produce paddles that meet strict performance and durability standards for each core thickness specification.

- Hot Pressing: Ideal for producing strong cores with excellent impact resistance, making it suitable for 16mm paddles where structural integrity is paramount.

- Cold Pressing: Offers precision and helps maintain the inherent properties of materials, suitable for 13mm and 14mm cores that require a fine balance between control and power.

- Thermoforming: Particularly effective for custom paddle designs, allowing for intricate material distributions irrespective of the core thickness, thus providing additional flexibility for bespoke production.

These production techniques are carefully selected based on the desired core thickness and overall performance target, balancing efficiency against the quality of the final product.

Materials play an inherent role alongside core thickness in defining paddle characteristics:

- Honeycomb Cores5 (Nomex, Aluminum, Polymer): Each material offers varying benefits. For example, a Nomex honeycomb core in a 16mm configuration offers exceptional shock absorption, while an aluminum honeycomb core strikes a balance between power and control.

- Composite Options: Combining carbon fiber and fiberglass can help achieve the desired playing characteristics by blending the strengths of both materials. For instance, pairing a carbon fiber surface with a 14mm core might optimize durability while providing a good ball pop.

By aligning core thickness with optimal material choices, manufacturers can better target specific market segments and usage scenarios.

Understanding the end-user’s requirements is essential for making an informed procurement decision. Here’s how various player profiles might react to each core thickness:

- Preference: Likely to favor a 13mm core for its higher rebound and quick energy transfer.

- Implication: The thin core elevates the “pop” effect but may expose players to higher vibration levels.

- Recommendation: This option is ideal for recreational to semi-professional players who rely on rapid offense rather than long rallies.

- Preference: The 14mm core serves as a balanced solution.

- Implication: Offers neither extreme power nor excessive dampening, providing a quality trade-off that appeals to a larger market base.

- Recommendation: Suitable for distributors targeting a broad range of players, from recreational enthusiasts to mid-level competitors.

- Preference: These players usually opt for a 16mm core, which prioritizes vibration reduction and precision.

- Implication: The increased thickness enhances control and is particularly beneficial during defensive plays and special technique shots like drop shots.

- Recommendation: Best for professional or high-level competitive markets where performance finesse is critical.

While technical specifications and player performance are central to the decision-making process, B2B procurement managers should also consider manufacturing aspects such as cost, production scalability, and consistency across batches.

- Thinner Cores (13mm): Generally cheaper to produce due to lower material usage, but may require higher quality surface treatments to mitigate increased vibrations.

- Thicker Cores (16mm): Higher material costs and extended production times, yet the premium pricing can be supported by the added benefits of durability and control.

- Balanced Option (14mm): Offers a middle-tier investment option which can capture broader market segments without significant cost escalations.

Reliable quality control requires that production methods align with the chosen core thickness. For instance:

- Cold Pressing can maintain a consistently even paddle surface, which is vital for the precise demands of a 14mm or 13mm core.

- Hot Pressing and Thermoforming are often preferred for thicker cores, ensuring the structural integrity needed for a 16mm design.

- Value Proposition: A 13mm paddle might be marketed as a performance tool for aggressive play, while a 16mm paddle targets control-focused segments with premium pricing and durability assurances.

- Customization Options: NEX Pickleball’s capacity for on-demand printing and custom design allows businesses to tailor cores (and overall paddles) to their specific market requirements, further enhancing product differentiation.

A well-informed procurement decision not only ensures that the product meets performance standards but also aligns with strategic market positioning, production capabilities, and overall cost management objectives.

The choice between 13mm, 14mm, and 16mm core thicknesses depends on a delicate balance of performance requirements, production capabilities, and market positioning. For aggressive, power-driven play, the 13mm core offers a high-rebound performance, though with a trade-off in vibration damping. The 16mm core, with its superior control and shock absorption, is ideally suited for competitive players who require precision under high-impact conditions. The 14mm core, meanwhile, represents a versatile option accommodating a broad spectrum of player preferences.

As you evaluate which option best fits your product portfolio, consider the following steps:

- Conduct a thorough market analysis to identify the predominant player profiles in your target demographic.

- Evaluate internal production capacities against the demands of each core specification.

- Leverage customization options to differentiate your product offerings within various market segments.

- Collaborate closely with manufacturing experts to ensure that material selection and production techniques align perfectly with your chosen specifications.

With these factors in balance, procurement managers and product development teams can make informed, strategic decisions that cater to both performance excellence and market viability.

Q: What is the best core thickness for a pickleball paddle?

A: The best core thickness depends on the desired performance. A 13mm core offers a powerful “pop” for fast play, while a 16mm core enhances shock absorption and control, ideal for precision shots. A 14mm core can serve as a balanced option between power and control.

Q: What is the difference between proxr 13mm and 16mm?

A: A 13mm paddle typically provides more direct power and a vibrant hitting feel, making it ideal for aggressive play. In contrast, a 16mm paddle offers greater control and shock absorption, enhancing precision and stability during defensive plays.

Q: Which mm is best for pickleball paddle?

A: Although 16mm is regarded as a standard for control, the optimal choice ultimately depends on player needs. A 13mm core delivers high rebound power, while a 16mm core provides superior control. Buyers should select based on the specific performance requirements of their target market.

-

paddle core thickness: Click to learn about the technical aspects and benefits of optimizing paddle core thickness for performance and durability. ↩ ↩ ↩2

-

Hot Pressing: Click to explore how hot pressing techniques contribute to structural integrity and enhanced impact resistance in paddle manufacturing. ↩ ↩

-

Cold Pressing: Click to understand the precision and material preservation benefits offered by cold pressing in paddle production. ↩ ↩

-

Thermoforming: Click to delve into the thermoforming process and its role in achieving custom paddle designs with complex material distributions. ↩ ↩

-

Honeycomb Cores: Click to examine the properties and advantages of various honeycomb core materials such as Nomex, Aluminum, and Polymer in paddle construction. ↩ ↩