A quick answer: NEX Pickleball offers a comprehensive OEM1 manufacturing solution for private-label2 pickleball accessories by leveraging advanced production techniques, premium materials, and rigorous quality control measures to help your brand achieve competitive differentiation in a rapidly growing market.

In today’s competitive sports accessories market, procurement managers and product development professionals constantly seek reliable partners to produce high-performance, custom paddle designs that stand out. With the global interest in pickleball surging, private label solutions have become a key strategy for distributors and retailers looking to differentiate their offerings.

The challenge many face is finding a partner who not only understands technical production nuances but can also scale quality production while offering material innovations like carbon fiber, fiberglass, and Composite Materials3 cores. At NEX Pickleball, our expertise in advanced production methods such as hot pressing, cold pressing, and Thermoforming4 addresses these challenges directly.

Manufacturers must decide on the right materials to deliver paddles with optimal strength, rebound, and control. Choosing between 3K Carbon Fiber5, 12K Carbon Fiber: or T300 carbon fiber involves understanding the product’s usage context. For example:

- 3K Carbon Fiber: Offers strength and flexibility, making it ideal for paddles requiring high rebound and durability.

- 12K Carbon Fiber: Provides a smoother surface and extreme strength, suitable for competitive-level play.

- Fiberglass and Composite Materials: Provide a balanced sweet spot and enhanced ball control, essential for recreational play and players who prefer a softer hit.

This decision-making process is critical because it determines the paddle’s performance, durability, and overall market competitiveness.

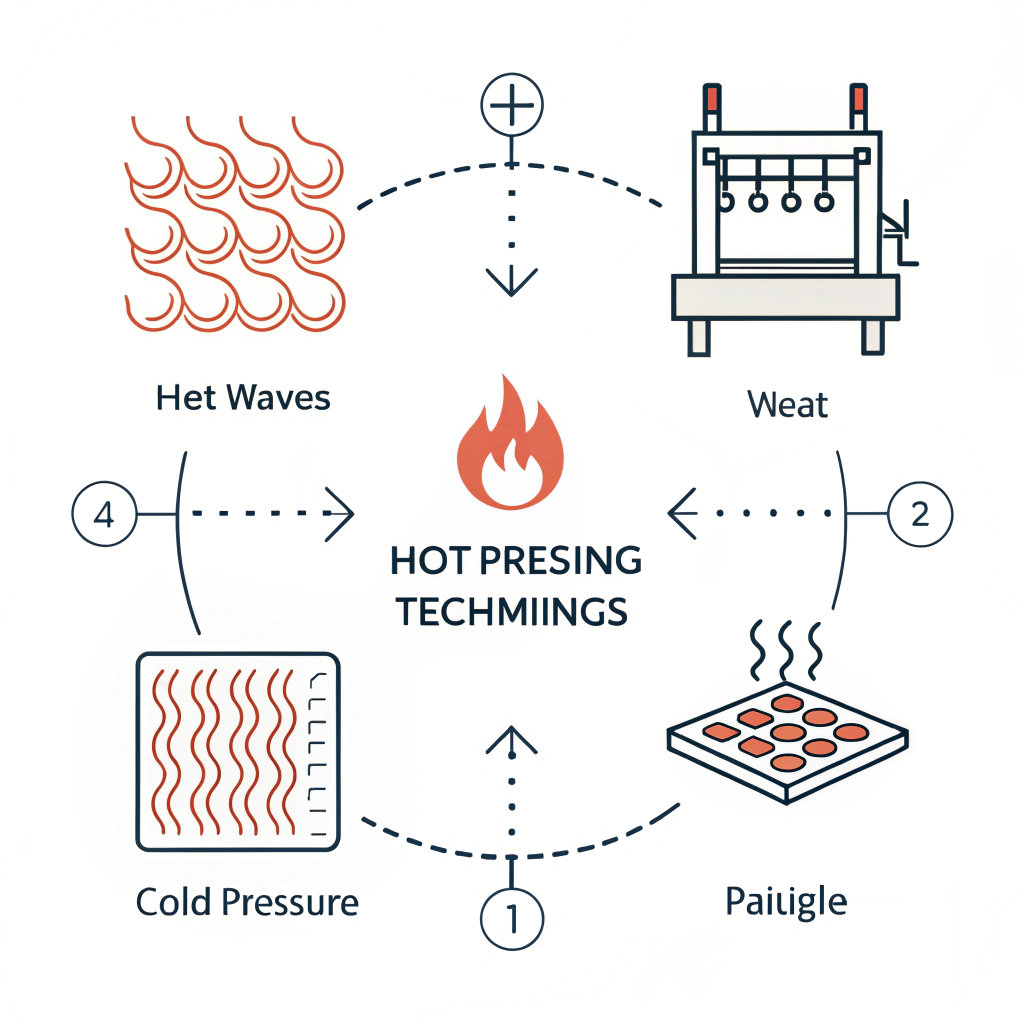

Each manufacturing method comes with its own advantages and limitations:

- Hot Pressing: Delivers high production efficiency and strong paddles with excellent impact resistance. However, the process can alter material properties and requires significant investment in machinery.

- Cold Pressing: Maintains the intrinsic properties of materials, resulting in better control and ball feel. The process is more time-consuming, which may limit production scalability.

- Thermoforming: Ideal for creating intricate designs with exact material distribution. Although high in cost and production time, it is best for premium and custom paddle offerings.

Understanding these production processes helps procurement managers weigh the trade-offs between production speed, quality, and customization.

For B2B decision-makers, quality control is non-negotiable. NEX Pickleball’s rigorous testing ensures each paddle meets high standards of strength, flexibility, and performance. This allows businesses to confidently market products under their private label, knowing they reflect well-established quality benchmarks.

Furthermore, the availability of custom paddle options – including specific design modifications, weight distribution, and grip sizes – enables your brand to target specific customer segments. These customization options are key drivers in market differentiation, especially in a competitive space where every advantage matters.

Below is a table summarizing the key differences and benefits of each production method used by NEX Pickleball:

| Production Process | Advantages | Disadvantages | Best Used For |

|---|---|---|---|

| Hot Pressing | - High efficiency - Excellent impact resistance - Consistent structural integrity | - May alter material properties - High equipment investment | Large-scale manufacturing requiring durability |

| Cold Pressing | - Precise control over thickness - Maintains natural material properties - Superior ball feel | - Longer production cycles - Requires high-quality pressure control | Products emphasizing control and responsive play |

| Thermoforming | - Enables complex designs - Precise material distribution - Enhanced paddle stability | - Higher production cost - Longer production time | Premium, custom-made paddles with intricate design features |

This detailed comparison assists decision-makers in aligning the production process with their specific private label or customization needs.

Procurement managers often encounter bottlenecks when production can't keep up with market demands, particularly in highly competitive sectors such as sports accessories. In our experience, combining efficient production methods with strict quality control measures is critical. By using a hybrid strategy that aligns hot pressing for mass production with cold pressing or thermoforming for premium products, companies can achieve both scale and product differentiation.

The importance of consistency in a product cannot be understated. At NEX Pickleball, every paddle undergoes extensive tests to ensure that quality is never compromised. Specific quality measures include:

- Material Testing: Verifying the integrity of carbon fiber variants and composite materials through stress and durability tests.

- Process Verification: Inspecting the uniformity of paddle dimensions and material distribution in each production batch.

- End-of-Line Assessment: Ensuring each paddle meets ergonomic standards and performance specifications before shipment.

These processes minimize the risk associated with product recalls, enhance brand reputation, and contribute to overall customer satisfaction.

Customization is one of the primary drivers in the current market. Private label products allow your brand to tailor products to address specific customer needs. For example, offering paddles with variable grip sizes or custom surface textures can create a unique selling proposition. By collaborating with a reliable OEM partner like NEX Pickleball, you can access:

- Custom Design Options: Tailor your product's appearance and performance traits.

- Flexible Order Quantities: Adapt production volumes to your market's demands.

- Speed to Market: Fast production cycles that align with your sales and marketing strategies.

- Innovation Integration: The latest production technologies and materials to keep your offerings ahead of the competition.

These benefits, paired with advanced production capabilities, make partnering with NEX Pickleball a strategic move for enhancing your private label portfolio.

Hot pressing is often the go-to production method for large-scale manufacturing. By applying both heat and pressure, this method ensures that the paddle’s materials bond firmly, delivering remarkable durability and strength. However, the heat may change certain material factors, which is why it is essential to balance production efficiency with the desired tactile feel of the final product.

Cold pressing provides a more controlled environment where the physical properties of the material remain intact. This technique is particularly suitable for paddles that require a delicate balance between control and responsiveness. Although production cycles take longer, the superior ball feel achieved through cold pressing offers a significant advantage for brands focusing on premium quality and targeted player experiences.

Thermoforming stands out when intricate design details or non-standard shapes are required. The process softens the material, allowing for greater design flexibility, and is ideal for producing custom paddles with unique ergonomic shapes and weight distribution. While the process has higher equipment and time costs, the resulting product is highly distinctive and tailored to meet specific market needs.

Procurement and product development managers are encouraged to consider the following tips when selecting an OEM partner for pickleball accessories:

- Evaluate Production Capabilities: Understand the specific production processes your potential partner uses. Verify that they can efficiently handle both mass-production and custom design requirements.

- Review Quality Control Protocols: A partner with stringent quality control practices ensures that every product meets your standards. Ask for documentation and case studies of quality assurance processes.

- Assess Customization Potential: Determine how flexible your partner is in modifying designs, materials, and finishing touches. This adaptability will be invaluable in customizing products under your private label.

- Consider Technological Advancements: Innovative production techniques provide added advantages. A partner with state-of-the-art production technologies can offer enhanced product durability and performance.

- Evaluate Supply Chain Reliability: Timely production and delivery are crucial. Ensure that your potential partner has robust supply chain systems in place to maintain consistent production schedules.

By following these best practices, you can secure a manufacturing partner that not only meets your technical requirements but also helps drive your brand’s competitive differentiation in the market.

In summary, the decision to partner for private label pickleball accessories should not be taken lightly. It requires a careful assessment of production methods, material choices, and quality control practices. With advanced production techniques, such as hot pressing, cold pressing, and thermoforming, NEX Pickleball stands out as a reliable OEM manufacturer that can meet both large-scale and customized production demands.

For procurement professionals and product development managers, aligning with a partner who excels in quality control and innovative production processes is key to sustaining market growth and long-term brand success. We invite you to consider NEX Pickleball as your trusted partner in achieving superior product performance and competitive differentiation in the pickleball accessories market.

Consider reaching out today to discuss how our tailored production solutions can support your private label strategy and help you capture a larger share of this rapidly growing market.

-

What pickleball brands have market share?

The global pickleball equipment industry is highly fragmented with several prominent players. Notably, brands like Selkirk Sport, Engage Pickleball, Gamma Sports, Franklin Sports, and Head NV each hold a market share of approximately 15%-20%. Among these, Head NV often leads due to its broad product portfolio and competitive pricing strategies. -

How to make money in the pickleball industry?

There are multiple avenues to profiting in the pickleball industry including coaching, renting courts, selling or renting gear, merchandising, and hosting tournaments or leagues. Additionally, identifying specific market pain points and leveraging your unique strengths to meet customer needs can drive revenue growth. -

How big is the pickleball equipment market?

The pickleball equipment market is experiencing significant growth and is expected to nearly double in value. Projections indicate that the market will grow from approximately $1.61 billion in 2024 to around $3.1 billion by 2032, fueled by a compound annual growth rate (CAGR) of roughly 10.3%.

-

OEM: Click to learn about Original Equipment Manufacturer solutions and how partnering with OEMs can streamline production and offer customized manufacturing services. ↩

-

private-label: Click to discover the benefits of private label strategies, including enhanced brand control and market differentiation. ↩

-

Composite Materials: Click to read about composite materials, their integration with fiberglass, and how they contribute to improved durability and performance. ↩

-

Thermoforming: Click to understand the thermoforming process, its role in achieving complex designs, and the balance between cost and customization. ↩

-

Carbon Fiber: Click to explore the properties of carbon fiber, different variants like 3K and 12K, and their implications for product performance. ↩