A high-performance pickleball paddle’s surface finish is key to product durability and player performance. In this article, we examine practical Surface Finishing1 techniques, understand how manufacturing processes affect paddle quality, and outline actionable steps for optimizing your paddle production.

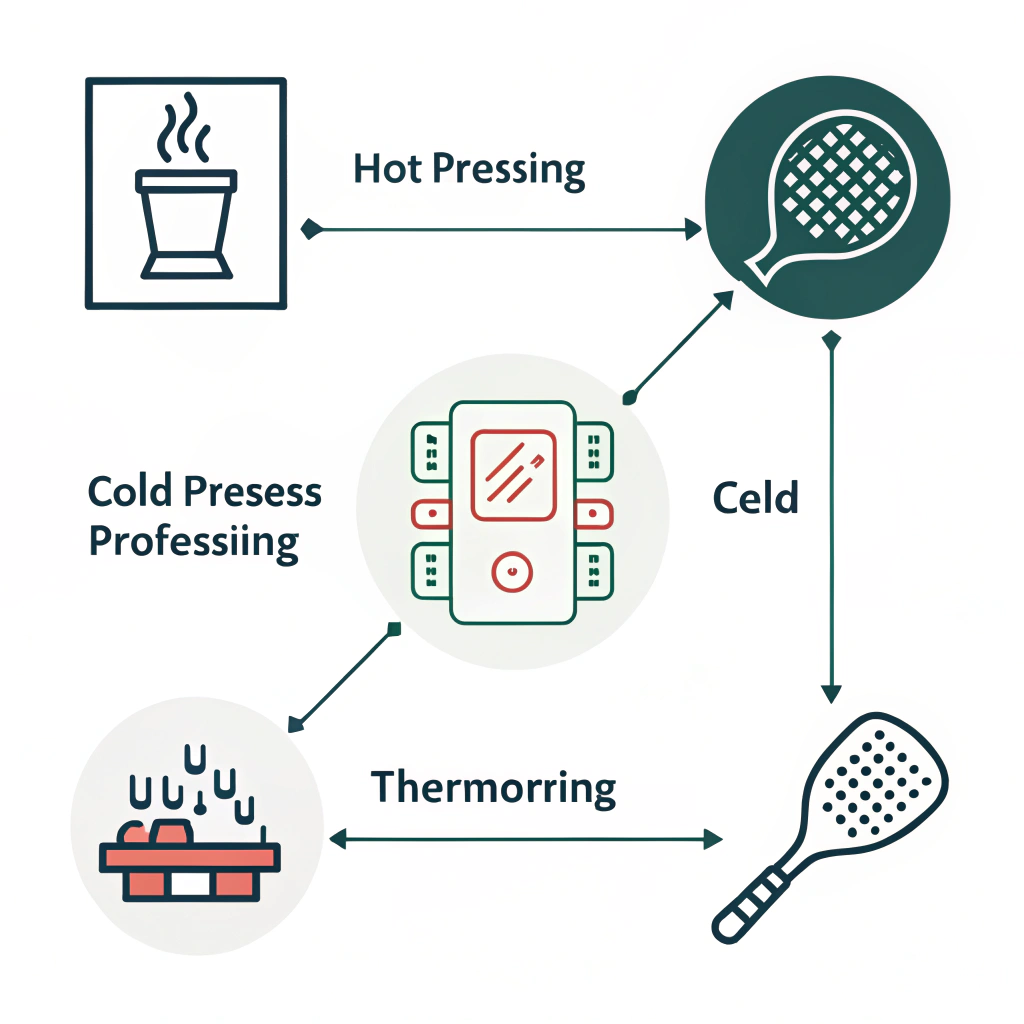

Surface finishing is the final step that defines not only a paddle’s aesthetic appeal, but also its functional performance. For production engineers and procurement managers, optimizing surface finishing means delivering paddles that balance durability, control, and playability. A well-finished paddle minimizes excessive friction, ensures proper ball interaction, and enhances overall durability. In our experience at NEX Pickleball, leveraging advanced processes such as Hot Pressing2, Cold Pressing3 and Thermoforming4 together with premium materials has been essential to achieving this balance.

For B2B decision-makers in the sports equipment manufacturing industry, one of the main challenges is ensuring a consistent surface finish that meets strict performance and durability standards. Variations in surface roughness can affect the ball’s spin, speed, and overall gameplay. A surface with excessive roughness might allow a player to impart unpredictable spins on the ball, while an overly smooth surface might result in reduced control.

Common issues include:

- Variability in texture due to imprecise finishing methods.

- Sub-optimal adherence of coatings or surface treatment layers.

- Inconsistent performance due to material flaws or process variations.

Several factors contribute to surface finishing challenges:

- Material Inconsistencies: Different materials such as carbon fiber, fiberglass, and composite materials have unique properties. The way these materials respond to finishing processes can vary significantly.

- Manufacturing Process Limitations: Techniques like hot pressing, cold pressing, or thermoforming each have inherent advantages and downsides. For example, high production efficiency from hot pressing might compromise some surface properties.

- Equipment and Quality Control: The precision of pressure control, temperature, and curing time affects the final finish. Inadequate calibration can lead to variability in paddle surfaces.

- Environmental Factors: The operating conditions during production, such as humidity and temperature, can affect resin curing and coating adhesion, impacting the final paddle quality.

Achieving an optimal surface finish requires an integrated approach involving advanced production techniques and precise quality control. Let’s compare the three main methods used in paddle production:

Hot pressing applies heat and pressure simultaneously to form a paddle. It is well-suited for manufacturing paddles with high-strength materials.

- High Production Efficiency: Allows for large-scale production due to shorter cycle times.

- Improved Impact Resistance: High temperature and pressure ensure the paddle develops a robust surface.

- Structural Integrity: Techniques allow manufacturing of paddles that meet strict strength requirements.

- Altered Material Properties: Elevated temperatures may change the material’s inherent characteristics.

- Equipment Investment: Requires specialized machinery with high capital costs.

Cold pressing uses mechanical pressure at room temperature. This method is ideal for maintaining the original properties of the material and achieving a precise finishing texture.

- Preservation of Material Strength: Maintains the natural properties and finesse of the material.

- Improved Control: Enables precise management of paddle thickness and texture.

- Enhanced Ball Feel: By keeping the material’s integrity, the paddle offers better ball responsiveness.

- Longer Production Cycle: Compared to hot pressing, cold pressing usually requires more time.

- Sensitive Pressure Controls: High precision equipment is essential, increasing setup complexity.

Thermoforming involves heating a pliable material and then shaping it using molds, making it suitable for paddles with intricate designs or novel material combinations.

- Design Flexibility: Allows for complex paddle designs with varied surface textures.

- Stable Material Distribution: Ensures a consistent surface finish even with premium composites.

- Enhanced Aesthetic Quality: Customized mold designs can offer tailored surface finishes that align with player needs.

- Prolonged Production Time: Heating and molding cycles require more extended production periods.

- Higher Equipment Costs: Advanced machinery is needed to guarantee consistent quality.

Below is a comparative table summarizing the pros and cons of these processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, robust surface, structural integrity | Potential material property alteration, high cost |

| Cold Pressing | Preserves material finesse, precise control, better ball feel | Longer production cycle, requires precision equipment |

| Thermoforming | Complex design capability, stable surface finish, tailored aesthetics | Extended production time, higher equipment investment |

To ensure that surface finishing meets stringent quality standards, consider these actionable recommendations:

- Thorough Material Testing: Begin with a precise evaluation of surface roughness. For instance, the allowable roughness limit should be maintained at no greater than 40 micrometers on average to control ball spin and speed.

- Surface Pre-Treatment: Clean and prepare surfaces to remove contaminants before applying any finishing techniques. This improves coating adhesion and overall finish consistency.

- Controlled Environment: Maintain controlled production conditions to ensure the curing process occurs uniformly. This is especially critical in thermoforming, where temperature fluctuations can alter the final finish.

- Regular Equipment Calibration: Ensure that machinery used in hot pressing, cold pressing, or thermoforming is calibrated regularly. This minimizes deviations in pressure and temperature, stabilizing the surface finish.

- Coating Application: Techniques such as spraying or dipping can be applied post-pressing to provide an extra protective layer. For high-performance paddles, specialized coatings can significantly reduce vibration and wear.

- Quality Inspection: Implement consistent quality checks. Surface roughness testing, using both optical and tactile methods, guarantees each paddle meets the specified tolerances.

- Optimized Texture for Grip: An ideal surface finish not only looks smooth but also enhances grip and control. Balancing these aspects is crucial, particularly in custom orders for competitive play.

- Custom Finishing Options: Offering customizable finishes (with various textures and colors) can also differentiate your product in a competitive B2B marketplace. This flexibility can drive better alignment with clients’ brand and performance expectations.

At NEX Pickleball, we have honed our manufacturing and finishing processes to deliver top-quality paddles to our partners. Our approach involves:

-

Advanced Material Use: Incorporating advanced levels of 3K, 12K, and T300 Carbon Fiber alongside quality fiberglass and Composite Materials5. These choices ensure paddles strike the perfect balance of speed, control, and vibration reduction.

-

Process Integration: By integrating hot pressing for structural strength, cold pressing for precision control, and thermoforming for design innovation, we have created a robust framework for optimal surface finishes.

-

Quality and Consistency: With rigorous testing at each stage, our paddles exhibit consistent surface texture. In practice, this means every paddle maintains the ideal roughness (typically below 40 micrometers) to support predictable ball behavior.

-

Customization for Competitive Edge: We provide on-demand printing services and tailored finishing solutions, meeting both commercial and bespoke needs. This flexibility positions us as a strategic partner for global sports equipment manufacturers.

Investing in optimized surface finishing processes is essential for standing out in the competitive landscape of pickleball paddle production. Production engineers, procurement managers, and technical decision-makers should:

- Review and adjust material selection to ensure compatibility with the chosen finishing technique.

- Optimize manufacturing environments to reduce variability in finish quality.

- Embrace a multi-process approach that leverages the best features of hot pressing, cold pressing, and thermoforming.

- Prioritize rigorous quality control and testing, especially of the surface roughness, to meet international performance standards.

By implementing these best practices, manufacturers can guarantee a product that not only meets strict regulatory standards but also delivers enhanced performance on the court. The integration of advanced surface finishing techniques not only enhances product quality but also paves the way for innovative paddle designs that meet diverse market demands. If you are aiming to improve your paddle production processes or are exploring new materials and methods, now is the perfect time to adopt these strategies and collaborate with leading experts in the field.

What is the surface roughness of a pickleball paddle?

Surface roughness in pickleball paddles is carefully controlled during production. Typically, the allowable roughness limit is maintained at no greater than 40 micrometers on average to ensure that the paddle’s surface does not unduly influence the ball’s spin and speed.

What are the different surfaces for pickleball paddles?

Pickleball paddles are usually manufactured using materials such as graphite, carbon fiber, fiberglass, and wood. Additionally, hybrid surfaces combining these materials are emerging, offering a balance between control and power, depending on the material properties and finishing technique used.

What are the surface regulations for pickleball paddles?

According to USA Pickleball Paddle Standards, the paddle must be made of a rigid, non-compressible material. The hitting surface should be free of any holes, indentations, rough texturing, or features that could allow a player to impart excessive spin on the ball.

-

Surface Finishing: Click to learn how advanced surface finishing techniques enhance both the aesthetic appeal and performance durability of high-performance sports equipment. ↩

-

Hot Pressing: Click to explore the hot pressing process, its advantages in mass production, and the technical considerations involved in using heat and pressure for material consolidation. ↩

-

Cold Pressing: Click to understand how cold pressing preserves material properties and the precision challenges associated with this manufacturing method. ↩

-

Thermoforming: Click to delve into thermoforming, a versatile process that enables complex design geometries and ensures consistent material distribution. ↩

-

Composite Materials: Click to discover the role of composite materials in modern manufacturing, their unique properties, and how they contribute to enhanced product performance. ↩