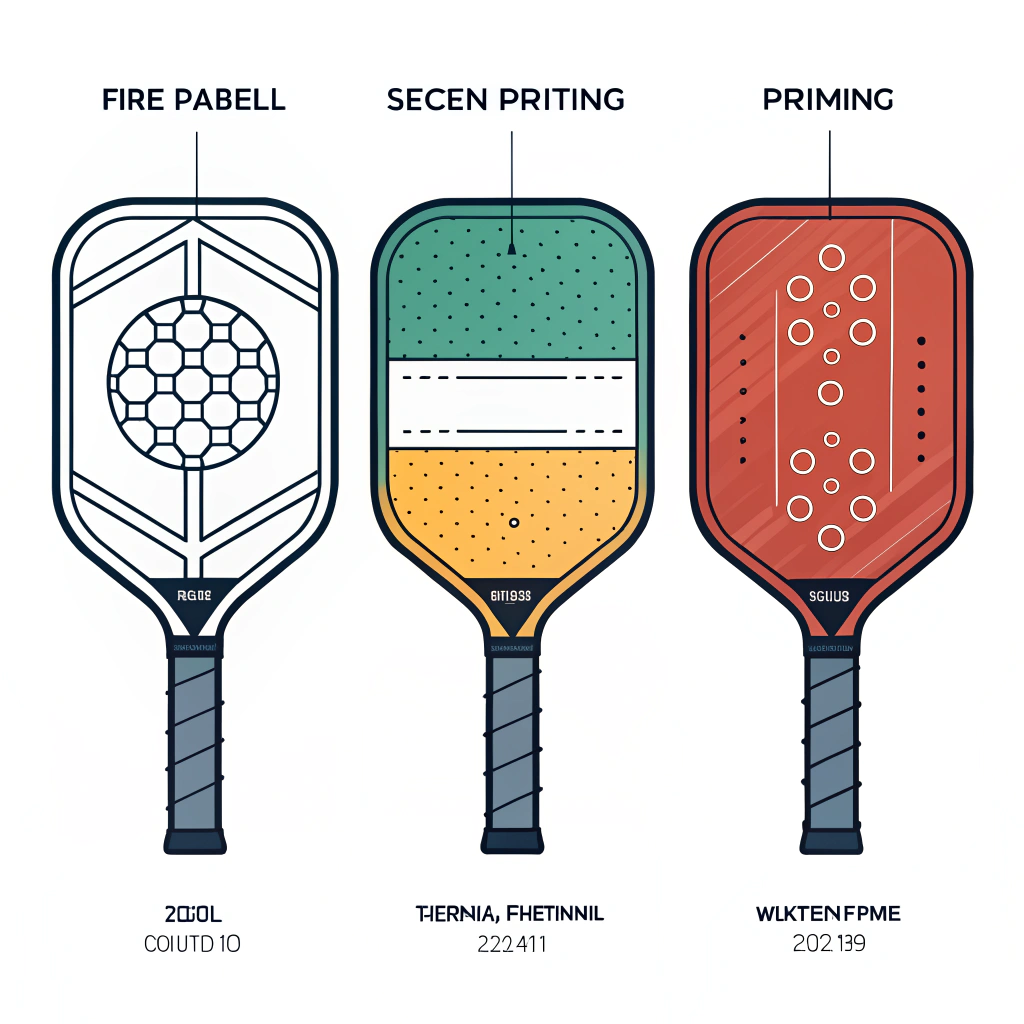

The best printing technique for your brand is one that perfectly balances production efficiency, cost, durability, and visual impact. In this article, we break down the most popular pickleball paddle printing techniques—digital printing1, screen printing2, and thermal printing3—to help your business make an informed decision that elevates your brand identity while meeting quality requirements.

Custom printing on pickleball paddles is more than just decoration. It is a key touchpoint for brand differentiation in a competitive sports equipment market. With evolving printing technology and increasing demands for visually striking products, selecting the right printing method not only enhances the aesthetic appeal but also confirms product longevity and customer satisfaction.

For brand managers and marketing directors, the focus is often on how these printing techniques can influence production costs, ensure quality control, and reinforce consistent brand identity while catering to diverse production scales.

Digital Printing has revolutionized how businesses approach product customization. It provides high-resolution imaging and is perfect for flamboyant, colorful, and highly detailed designs.

Advantages:

- High Image Quality: Digital printing supports intricate, full-color images that bring your logo and graphics to life.

- Fast Turnaround: Quick setup and production cycles suit on-demand printing4 and smaller batch orders.

- Flexibility: Easy to modify designs; ideal for limited editions or seasonal campaigns.

Disadvantages:

- Material Compatibility: Not all paddle surfaces may accept digital inks equally well, requiring special surface treatments.

- Cost Considerations: Although cost-effective for small batches, the price per unit can rise for larger production volumes compared to traditional methods.

When to Choose Digital Printing:

- When you need a vibrant, full-color image.

- For flexible, dynamic campaigns where frequent design changes are necessary.

- For on-demand printing services that focus on small order quantities or personalized designs.

Screen Printing is a time-tested method known for consistent, long-lasting prints. It is highly suited for designs requiring a limited color palette and bold lines.

Advantages:

- Durability: The ink used in screen printing generally adheres well to the paddle surface, ensuring longevity even through heavy use.

- Cost Efficiency for Large Runs: The expenses are spread over a large number of units, making it economically viable for bulk orders.

- Vibrant, Opaque Colors: Provides excellent color density, especially for designs with fewer colors.

Disadvantages:

- Setup Time: The process involves creating individual stencils, which can slow down the initial production setup.

- Limited in Color Range: Not as flexible in accommodating designs with gradients or a high number of different hues.

When to Choose Screen Printing:

- When durability is a paramount concern, and your design consists of a few strong colors.

- For large-scale production runs where the cost per unit can be optimized.

- When the brand requires a classic, consistent look across all products.

Thermal Printing, sometimes incorporated into the paddle production process via thermoforming, offers distinct qualities for creating intricate, multi-dimensional designs.

Advantages:

- Precision: This method allows for complex designs that require precise material distribution and contouring.

- Enhanced Durability: Thermal processes can help embed the print into the paddle’s surface, ensuring it withstands the physical stress during play.

- Design Flexibility: Ideal for custom designs where the paddle shape and texture play a significant role in overall performance.

Disadvantages:

- Cost and Time: Thermal printing is usually more time-consuming and demands significant investment in equipment.

- Complexity: Requires close quality control and technical expertise to avoid inconsistencies in print quality.

When to Choose Thermal Printing:

- When your brand needs to combine aesthetics with top-tier durability.

- For high-performance paddles that will see extensive use and require a premium finish.

- When your production scale justifies the higher setup costs.

Both technical performance and brand identity depend on choosing the right printing method. Below is a detailed comparison table that outlines the core attributes of each technique:

| Printing Technique | Cost Efficiency | Durability | Visual Quality | Production Speed | Best For |

|---|---|---|---|---|---|

| Digital Printing | Moderate for small runs | Good with proper ink | High-resolution, full-color | Fast; ideal for on-demand orders | Custom, limited edition designs; rapid iterations |

| Screen Printing | Economical for bulk orders | Very High | Excellent for bold, few colors | Moderate; requires stencil setup | Large volume orders; long-lasting, consistent branding |

| Thermal Printing | High due to equipment expense | Superior durability | Precise, multi-dimensional | Slow; higher technical demand | Premium paddles; high-performance, complex designs |

This table allows you to quickly identify which technique aligns best with your production needs and brand objectives.

When making a decision, consider these key factors:

- Digital printing excels in fast, on-demand, small batch production.

- Screen printing is best when large volumes are produced regularly, offering lower per-unit costs.

- Thermal printing caters to premium, custom orders, especially when time is less critical than perfection.

- The printing surface of pickleball paddles plays a crucial role. Whether the paddle face is made of composite materials, carbon fiber, or fiberglass, the chosen printing method must be compatible.

- Durability is essential in maintaining brand value. Customers expect that the printed logos and graphics remain pristine despite repeated impacts and weather conditions.

- Consider how complex or simple your designs are. For intricate multi-color artwork, digital printing might be more appropriate.

- For bold graphics with just a few colors, screen printing offers a robust solution that stands the test of time.

- Thermal printing can deliver intricate details and superior integration into the paddle material, making it ideal for a unique brand signature.

- Evaluate the overall cost of production. While digital printing might be marginally more expensive on a per-unit basis for small quantities, its flexibility can provide a better return on investment5 for specialized, high-impact campaigns.

- For regular bulk orders where consistency is key, screen printing offers the best balance of cost and durability.

- Though thermal printing is on the premium side, the investment is often justified by the enhanced product performance and superior brand perception.

- A custom look can significantly enhance brand recognition. By leveraging these techniques, your paddle not only serves as sports equipment but also as a moving billboard that promotes your brand.

- On-demand printing capabilities allow for limited-edition releases or seasonal designs, positioning your brand as innovative and dynamic.

Several leading sports brands have successfully leveraged these printing techniques to enhance their market presence. For instance, a popular retail chain recently opted for screen printing on their pickleball paddles due to its proven durability. The bright, bold colors and robust durability resonated well with their consumers, driving repeat purchases and increased brand loyalty.

Another example involved a boutique sports brand that partnered with a digital printing specialist to produce a limited-run, high-detail design for their pickleball paddles. The result was a highly sought-after product that not only drew media attention but also helped the company expand its market share in a niche segment.

Data from industry reports indicate that investing in the right printing technology can lead to a significant increase in customer satisfaction. Brands that align their printing technique with their overall product strategy often see enhanced visual appeal and longevity, which directly translates to improved customer retention and higher profit margins.

In summary, selecting the printing technique that best fits your brand involves weighing several critical factors:

- Production Volume: Determine the best method based on order quantities and turnaround times.

- Material Compatibility: Ensure the printing method matches the paddle’s materials to maximize durability.

- Visual Impact: Choose a technique that upholds the aesthetic standards your brand demands.

- Cost vs. ROI: Analyze cost-effectiveness relative to brand positioning and long-term value.

By understanding the strengths and limitations of each method—digital, screen, and thermal printing—you can make an informed decision that elevates both your product quality and your brand’s market competitiveness. Take the time to evaluate your specific requirements, consult with your manufacturing partner, and test small batches if necessary. Your commitment to quality and consistent brand messaging will set you apart in a growing marketplace.

In the fast-evolving world of sports equipment, a high-performance, well-branded paddle can be a game changer for your retail presence. Act now by aligning your printing technique with your brand strategic goals, ensuring every paddle is not just a tool for play but a testament to innovative, quality craftsmanship.

People Also Ask

Q: Which pickleball paddle suits me?

A: Pickleball paddles are typically classified into midweight, lightweight, and heavy categories. Midweight paddles, usually ranging between 7.3 and 8.5 ounces, suit beginners through balanced control, while lighter paddles offer enhanced maneuverability and control, and heavier paddles provide greater power suitable for competitive play.

Q: Which style pickleball paddle is best?

A: The best style is often considered to be one that balances performance, durability, and design, such as paddles made from proprietary carbon fiber compositions. These paddles typically showcase excellent weight distribution, ensuring both control and powerful strokes, making them a top choice among players.

Q: How to determine what pickleball paddle to buy?

A: When choosing a pickleball paddle, consider factors like weight, material composition, shape, and handle/grip size. These elements directly impact performance by influencing control, power, and comfort, thus ensuring you select a paddle that best fits your playing style and competitive needs.

-

digital printing: Click to learn about digital printing processes that offer high-resolution, full-color imagery to bring designs to life with efficiency. ↩ ↩

-

screen printing: Click to explore screen printing techniques, which provide durable, cost-efficient solutions for bulk production and bold graphic results. ↩ ↩

-

thermal printing: Click to understand thermal printing methods, known for producing precise, multi-dimensional prints ideal for premium surface finishes. ↩ ↩

-

on-demand printing: Click to discover on-demand printing capabilities that support flexible production cycles and quick turnaround for small batch orders. ↩ ↩

-

return on investment: Click to delve into return on investment (ROI) concepts, and how selecting the right printing technique can boost profitability and long-term value. ↩ ↩