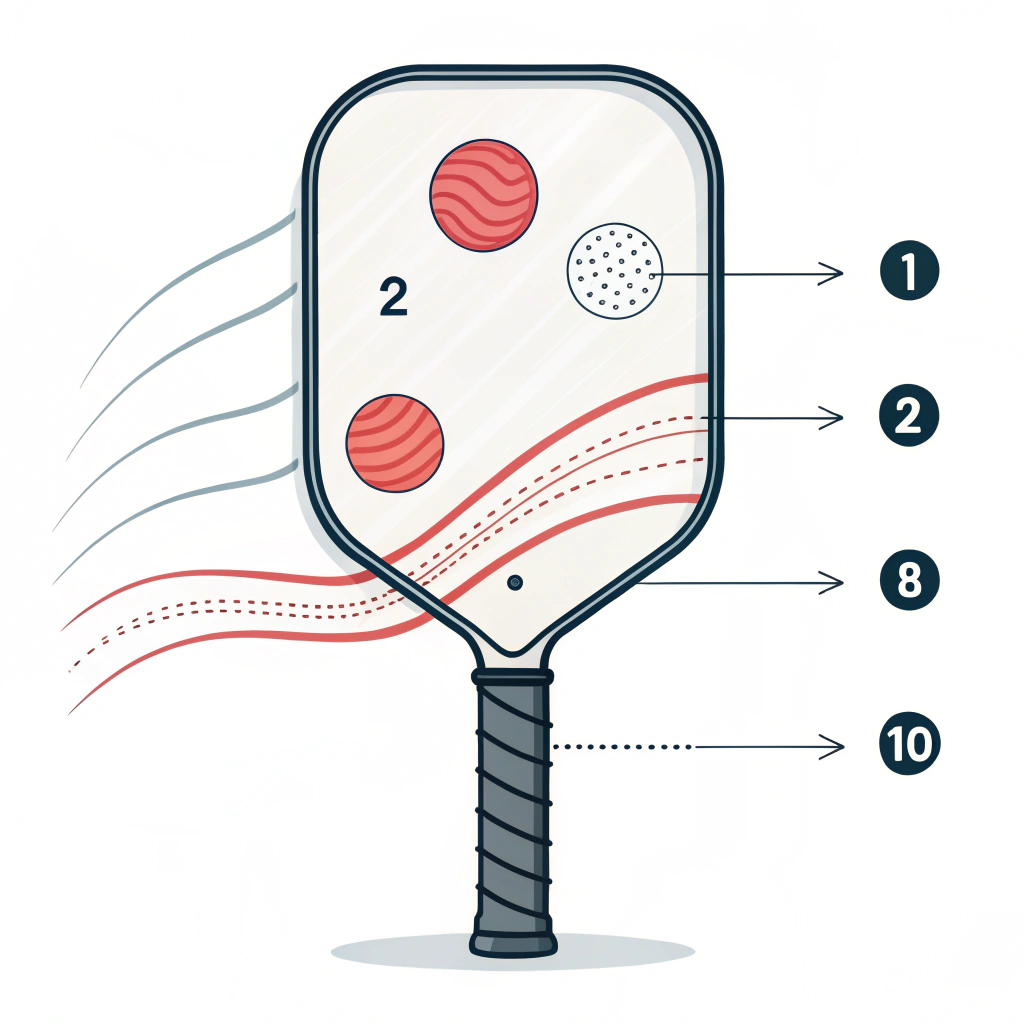

A quick answer: Twist weight1 is a crucial parameter in pickleball paddle design that affects performance by influencing stability, control, and power. Both the paddle's manufacturing process and material composition play major roles in achieving the optimal twist weight for different player levels and game styles.

Pickleball paddle performance hinges on many factors, and one of the most critical yet often misunderstood metrics is twist weight1. Twist weight measures how a paddle reacts to off-center hits and rotational forces. It greatly influences the balance, control, and overall feel of the paddle during play. In the B2B landscape of sports equipment manufacturing, understanding and optimizing twist weight is essential to produce paddles that cater to both beginners and elite-level competitors.

Production and design experts encounter frequent challenges when addressing paddle performance. One such challenge is optimizing twist weight to provide the best ball control and stability without compromising power. Paddles with improper twist weight can lead to inconsistent performance, affecting players’ ability to consistently hit precise shots. For manufacturers like NEX Pickleball, which use advanced materials such as carbon fiber2 (3K, 12K, T300) and fiberglass3, it is essential to balance the twist weight against other design features like ergonomic shape, core materials, and production techniques.

A high twist weight can be forgiving for beginners because it minimizes the loss of power on off-center hits, while a lower twist weight offers experienced players better feedback and control. However, setting the ideal twist weight is just one part of the equation. Manufacturers must also consider other production factors like material selection and pressing techniques to achieve optimal paddle performance.

Various materials bring different characteristics to the twist weight. Here are the primary materials used and how they contribute:

-

Carbon Fiber (3K, 12K, T300):

Carbon fiber types have distinct thread densities and strength attributes. For instance, 12K carbon fiber offers a smoother surface and greater hardness, contributing to a lower twist weight and a more rigid paddle, advantageous for experienced players. In contrast, 3K carbon fiber offers flexibility and can help cushion the twist for more forgiveness on off-center hits. -

Fiberglass:

Fiberglass3 paddles have excellent elasticity and tend to be more forgiving due to their naturally higher twist weight. They are ideal for players who need consistency and stability. -

Composite Materials:

Composites that combine carbon fiber and fiberglass, or even incorporate a bamboo core or honeycomb core, provide a balanced twist weight. This balance allows a mix of control and power, making them suitable for a broader range of players.

Different combinations of these materials affect the paddle’s overall weight distribution. Manufacturers must consider how these interactions influence twist weight, ensuring that paddles meet both performance and durability targets.

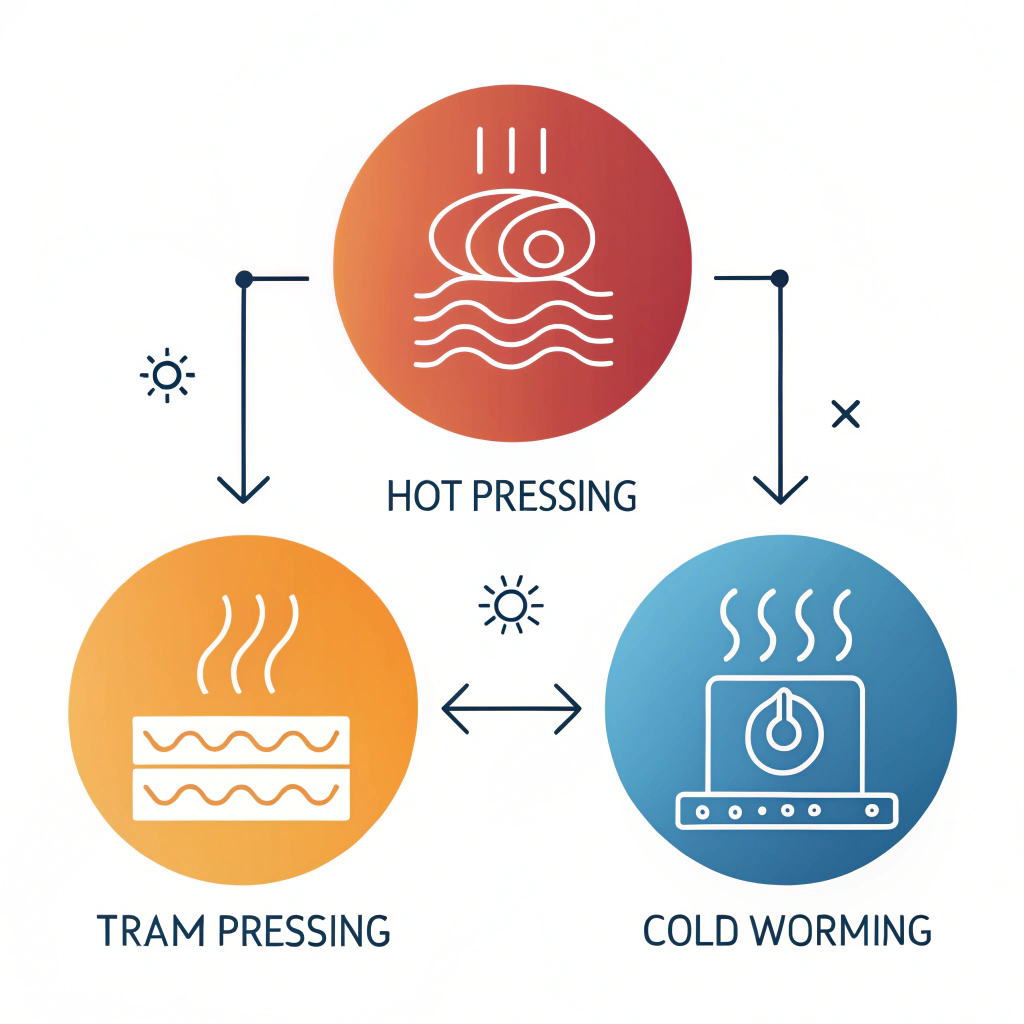

The production technique plays a significant role in defining the twist weight. At NEX Pickleball, three main processes are used:

-

Hot Pressing:

- This method applies heat and pressure to the materials, resulting in a strong, durable paddle structure.

- It increases production efficiency, but the high temperatures can sometimes alter the inherent flexibility of the composite materials. This change directly influences the twist weight, often creating a stiffer paddle that may reduce control for less experienced players.

-

Cold Pressing:

- Cold pressing shapes the paddle at room temperature, preserving the original properties of the materials.

- It offers improved control over paddle thickness and maintains a more natural twist weight, ensuring better ball response while keeping production time longer due to its precise nature.

-

Thermoforming:

- Thermoforming4 involves heating the material to soften it and then molding it into complex shapes.

- This method allows for detailed design adjustments, which can be used to calibrate twist weight very precisely. However, the process is time-consuming and requires expensive equipment, making it best suited for premium performance paddles.

The method chosen directly affects the paddle's performance metrics including twist weight. Manufacturers must decide on the best production process that offers a balance between cost, production time, and the desired performance outcomes.

| Production Process | Key Advantages | Impact on Twist Weight | Considerations |

|---|---|---|---|

| Hot Pressing | - High efficiency - Strong, durable paddles | May lead to a stiffer paddle with lower twist weight stability | High investment in equipment; potential material property changes |

| Cold Pressing | - Precise thickness control - Maintains original material properties | Offers natural twist weight for better ball control | Longer cycle time; demands precision equipment |

| Thermoforming | - Enables complex shapes - Precise material distribution | Allows custom calibration of twist weight for premium performance | Higher production cost; longer production time |

The above table clearly illustrates the trade-offs between different manufacturing processes, highlighting how each method influences twist weight and overall paddle performance.

For B2B decision-makers evaluating paddle designs or considering production partnerships, here are some clear steps to ensure that the twist weight is optimized for performance:

-

Define Use-Case Requirements:

Understand the target market and player skill levels:- Higher Twist Weight: Best suited for beginners who benefit from increased forgiveness on off-center hits.

- Lower Twist Weight: Ideal for advanced players who require a more rigid and controlled paddle play.

-

Material Selection:

Choose materials based on the desired twist weight:- Use fiberglass3 or softer composites for higher twist weight scenarios.

- Opt for carbon fiber2 variants like 12K for a lower twist weight that delivers superior stiffness and control.

-

Select Optimal Production Processes:

Decide on a production method based on your performance and scale requirements:- For high-volume productions where cost and efficiency matter, hot pressing might be the best approach.

- For premium paddles and small batches, consider cold pressing or thermoforming4 to better control twist weight and overall performance.

-

Quality Control and Testing:

Rigorous testing is essential. Every paddle should undergo testing to evaluate how the twist weight influences performance metrics:- Include vibration and impact resistance testing.

- Check balance and ergonomics to ensure that the twist weight aligns with design expectations.

-

Iterate Based on Feedback:

Utilize feedback from players and distributors to continuously refine the paddle design. Data-driven adjustments can further optimize twist weight by recalibrating material choices or production methods.

Manufacturers that incorporate these steps can ensure that the resulting paddle not only meets the performance metrics but also builds a competitive edge in the market.

Consider a scenario where a leading paddle brand partnered with NEX Pickleball to develop a new high-performance paddle targeting competitive players. The design requirements emphasized a low twist weight to enhance precision and responsiveness. Here’s how the process unfolded:

-

Material Analysis:

The product team evaluated various materials. It was determined that a composite of 12K carbon fiber paired with a Nomex honeycomb core5 provided the best balance of strength and reduced vibration. -

Production Technique:

Given the precision required, the cold pressing technique was selected. This approach maintained the material integrity and allowed for meticulous control over thickness, resulting in a paddle with an ideal twist weight that offered consistent hit feedback. -

Quality Control:

Every prototype underwent a rigorous series of tests simulating in-game conditions. The resulting data showed a high level of consistency, with the low twist weight translating directly to better shot precision and control, especially in competitive play situations. -

Outcome:

The final product successfully met the performance targets and became well received among professional players. This case underscores the value of thoughtful material and process selection when targeting specific twist weight parameters for different player profiles.

This data-driven approach not only enhanced paddle performance but also provided internal case studies that shaped future production strategies. For procurement specialists and technical directors, such case examples are invaluable when deciding on manufacturing partners or product collaborations.

In summary, twist weight is a pivotal element in pickleball paddle design that dictates how the paddle responds to off-center hits and impacts overall performance. By carefully selecting the right materials and production processes, manufacturers can create paddles tailored to specific player needs.

Key takeaways include:

- Clearly define the target market and corresponding performance needs.

- Evaluate and select materials (carbon fiber2, fiberglass3, composites) based on their contribution to twist weight.

- Choose an appropriate manufacturing technique—hot pressing for efficiency, cold pressing for precision, or thermoforming4 for custom designs.

- Employ rigorous quality control methods to ensure consistency and performance.

- Use iterative feedback loops and case studies to continually refine the paddle design and optimize twist weight.

For sports equipment professionals and B2B decision-makers looking to enhance their product portfolios, partnering with manufacturers who prioritize such detailed performance metrics can offer a significant competitive advantage. Leveraging technical insights into twist weight not only improves product performance but also builds buyer trust by delivering products that meet high industry standards.

By applying these strategies, businesses can ensure that their offerings remain competitive in an increasingly demanding market. Companies like NEX Pickleball are committed to excellence in design and production, using advanced techniques to produce paddles that strike the perfect balance between power, control, and consistency.

Q: Is a higher or lower twist rate better for pickleball?

A: A high twist weight typically favors players seeking consistency and enhanced stability, particularly those focused on ball placement. Conversely, a low twist weight is more advantageous for experienced players who can reliably hit the sweet spot, offering a lighter and more maneuverable paddle.

Q: What is a high twist weight?

A: A high twist weight is characterized by higher numerical values—for example, a twist weight of around 15 is considered high. This makes the paddle more forgiving on off-center hits, maintaining power and control even when the ball isn’t struck exactly in the center.

Q: Is it better to have a heavier or lighter pickleball paddle?

A: The ideal paddle weight is a balance. A heavier paddle can provide more power but may sacrifice some control and agility, whereas a lighter paddle generally offers better control but with less inherent power. Finding a middle ground often delivers the optimal balance between power and control.

-

Twist weight: Click to explore how twist weight measures a paddle's resistance to off-center impacts and its role in balancing power, control, and stability in paddle design. ↩ ↩2

-

Carbon fiber: Click to learn about the properties of carbon fiber, its variants (3K, 12K, T300), and how it influences paddle rigidity and performance. ↩ ↩2 ↩3

-

Fiberglass: Click to read about fiberglass characteristics and why it is used to offer flexibility and added forgiveness in paddle design. ↩ ↩2 ↩3 ↩4

-

Thermoforming: Click to understand the thermoforming process, its role in achieving complex paddle shapes, and how it allows for fine-tuning performance metrics like twist weight. ↩ ↩2 ↩3

-

Nomex honeycomb core: Click to delve into the benefits of using a Nomex honeycomb core in paddle construction, including enhanced strength-to-weight ratios and vibration reduction. ↩