Pickleball paddles for beginners in 2025 offer the ideal combination of performance, durability, and ease of use. In today’s guide, we compare various materials and manufacturing processes to help you decide which paddle lineup best meets your B2B purchasing needs for beginner-friendly equipment.

For sporting goods distributors and retail managers, selecting the right paddle model is crucial for addressing the growing demand among new players. Beginners need paddles that provide a forgiving hitting surface, balanced control, and a reliable performance—all at a competitive price point. At NEX Pickleball, our expertise as a contract manufacturer for top brands like Joola and Selkirk means we focus on using cutting-edge processes and premium materials to build paddles that deliver on these demands.

Our paddles are made using advanced materials such as Carbon Fiber1, Fiberglass2, and innovative composite cores. This article examines the materials, design considerations, and manufacturing techniques that enable us to produce paddles highly suitable for beginners. We also provide a comparison table to clearly highlight the benefits of each option.

Carbon fiber, used in many high-performance paddles, comes in several grades. Each variant has unique characteristics that can impact paddle performance:

- 3K Carbon Fiber: Offers high flexibility and a strong rebound force. It reduces vibration, which is helpful for beginners who need a forgiving paddle feel.

- 12K Carbon Fiber: Known for its higher thread density, making the paddle surface smoother and harder. Paddles built with this material tend to be more durable and better at impact resistance.

- T300 Carbon Fiber: Balances strength and lightweight properties, providing skilled players with both power and maneuverability.

For beginners, the right carbon fiber option is one that marries performance with an extended sweet spot, ensuring a larger margin for error during off-center hits.

Fiberglass paddles are popular for their unique balance between power and control. They provide:

- A wider sweet spot that is forgiving for new players.

- Enhanced ball control through increased paddle flexibility.

- Reduced impact vibration, thus offering a softer feel that helps reduce fatigue for beginners.

Composite paddles that combine carbon fiber and fiberglass offer a synergistic effect:

- Carbon Fiber and Fiberglass Composite: These paddles deliver the best of both worlds, combining strength, lightness, and improved shock absorption.

- Bamboo Core Composite: Ideal for achieving a clear hitting feel and lightweight design, making them great for players who may be new to the game.

- Honeycomb Core Variations: These include Nomex, Aluminum, and Polymer honeycomb cores. Each offers benefits such as shock absorption, durability, and better weight distribution.

The following table outlines various material options with their key features:

| Material Option | Key Benefits | Ideal For |

|---|---|---|

| 3K Carbon Fiber | Flexibility, reduced vibration | Beginners needing forgiving impact |

| 12K Carbon Fiber | Smoother surface, extreme durability | Competitive play with high durability |

| T300 Carbon Fiber | Balanced strength and light weight | Players seeking agile performance |

| E-Glass Fiberglass | Wider sweet spot, excellent control | Beginners needing enhanced ball control |

| Carbon Fiber & Fiberglass Composite | Combines power and flexibility | Versatile play style |

| Bamboo Core Composite | Lightweight, clear hitting feel | Long-lasting recreational play |

| Nomex/Aluminum/Polymer Honeycomb | Shock absorption, tailored weight distribution | Consistent performance under stress |

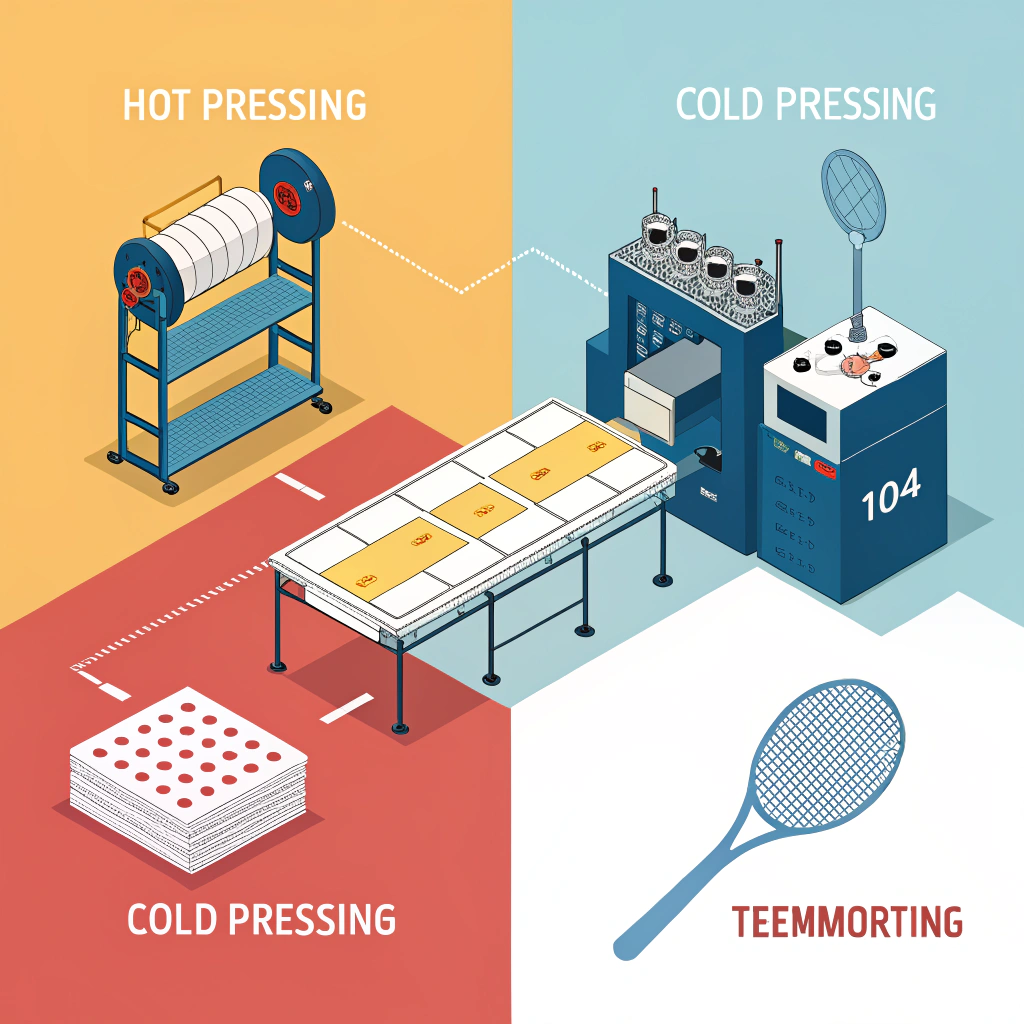

Manufacturing Techniques: Hot pressing3, Cold pressing4, and Thermoforming5

The production process is a vital factor in ensuring consistent quality and performance of the paddles. NEX Pickleball utilizes three main manufacturing techniques, each with distinct advantages:

Hot pressing involves heating materials and applying pressure to create a durable paddle. This process is known for:

- High production efficiency, ideal for large-scale orders.

- Producing paddles with strong impact resistance and excellent structural integrity.

- Suitability for high-performance paddles aimed at intense play.

However, hot pressing sometimes alters the subtle material properties that affect the paddle’s feel. This method is optimal when durability and high impact resistance are priorities.

Cold pressing shapes the paddle materials at room temperature under controlled mechanical pressure. Its benefits include:

- Precise control over paddle thickness and structural uniformity.

- Retaining the intrinsic material properties, thereby preserving the paddle's natural ball feel.

- Enhanced control and responsiveness—key elements for beginners still developing technique.

The trade-off is a longer production cycle, which may not be as cost-effective for very large orders despite its advantages in performance.

Thermoforming entails heating the material until it softens before molding it into precise shapes. This technique is particularly beneficial for:

- Crafting paddles with intricate designs and optimized internal structure.

- Maintaining stability and performance through even material distribution.

- Innovation in design that can cater to both aesthetics and functionality.

The downside of thermoforming is the higher production cost and longer processing time, making it best suited for premium products or custom orders.

A summary of the three production methods is shown in the table below:

| Process | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Potential alteration in feel | Bulk production of high-durability paddles |

| Cold Pressing | Precision control, retains natural material properties | Longer production time | Paddles emphasizing control and response |

| Thermoforming | Complex designs, uniform material distribution | Higher costs, longer processing | Premium/custom-designed paddles |

For beginners, paddle dimensions are critical. A paddle that is too heavy or one with limited control can deter progress. A 16 mm core is often recommended; it balances power and control, offering support to players as they develop their technique. Thinner core paddles (10 mm to 14 mm) deliver more power or “pop” but may sacrifice some control—key for novice performance.

The ergonomic design, including grip size and balance, is vital. Features include:

- An ergonomic handle to reduce wrist strain.

- Optimal weight distribution to ease handling during long sessions.

- Surface texture treatments that enhance grip and spin control.

For B2B buyers, offering customization in grip sizes can attract diverse customers, as it meets varied player needs.

Consistency in production ensures that every paddle delivers the same level of performance. At NEX Pickleball, rigorous testing standards are in place. Our production processes, whether hot pressing, cold pressing, or thermoforming, are continually refined to guarantee durability and performance. Such consistency is especially important for retailers who depend on reliable products to build their brand reputation.

From a B2B perspective, cost efficiency in manufacturing is closely linked to production scalability. Hot pressing is typically more cost-effective for larger orders, while cold pressing may suit orders with requirements for specific performance attributes. The choice of production method directly impacts pricing and the viability of offering competitive products within your distribution network.

Recent trends indicate a growing interest in beginner-level pickleball paddles due to the sport’s rising popularity. Market leaders often highlight paddles like the 11SIX24 Pegasus Jelly Bean in the $100 range, which offers a wide playing surface and a large sweet spot—features ideal for beginners. Additionally, options like the Six Zero Sapphire, Bison Summit/Rampage, and Hudef Viva Pro Gen 2 have seen increasing popularity among new players.

For B2B buyers, it’s essential to align your portfolio with market demands, ensuring a mix of performance, durability, and cost-effectiveness. By comparing different models and material options, you can provide your customers with products that not only meet but exceed their expectations.

When evaluating paddle options, consider the following decision-making factors:

-

Product Performance:

- Emphasize paddles with a larger sweet spot and enhanced control.

- Evaluate the benefits of various core materials such as Nomex Honeycomb for shock absorption and stability.

-

Material and Production Quality:

- Compare the advantages of carbon fiber variants versus fiberglass in terms of performance and durability.

- Assess the manufacturing technological consistency and quality control measures your supplier employs.

-

Pricing and Scalability:

- Consider the cost differences related to production processes.

- Factor in the potential for on-demand customization and bulk order discounts.

-

Market Adaptability:

- Understand the evolving trends among beginner players.

- Ensure that your product lineup includes options for different skill levels and ergonomic needs.

Below is a simplified decision guide table to help structure your evaluation:

| Evaluation Factor | Considerations | Practical Impact |

|---|---|---|

| Product Performance | Sweet spot size, balance, vibration reduction | Determines player satisfaction and progress |

| Material Quality | Carbon fiber vs. fiberglass, composite benefits, core thickness | Affects durability and product reliability |

| Production Process | Hot pressing for efficiency, cold pressing for control, thermoforming for design | Influences pricing and manufacturing lead times |

| Customization Options | Grip size, paddle weight, surface texture | Meets diverse consumer needs in targeted markets |

| Cost Efficiency | Bulk order pricing, on-demand print services | Maximizes ROI and competitive pricing |

In summary, selecting the best beginner-friendly pickleball paddle involves understanding the trade-offs between various materials and production processes. For distributors and retail managers, emphasizing products that combine user-friendly design with robust performance can drive market growth and customer loyalty. By focusing on factors such as a 16 mm core for balanced performance, ergonomic grip design, and consistent quality control, you can build a product lineup that stands out in the competitive sporting goods market.

We recommend a close evaluation of the following:

• Compare material options—carbon fiber, fiberglass, and composite—using the provided tables to match your buyer requirements.

• Clarify your supplier’s manufacturing practices to ensure quality and scalability.

• Explore customization options to cater to diverse beginner profiles, ensuring your offerings align with market trends.

Taking these steps will not only satisfy the immediate needs of beginner players but will also position your brand as a forward-thinking distributor in a rapidly evolving market.

Q: What is the best pickleball paddle for beginners 2025?

A: The best paddle for beginners in 2025 often combines a wide playing surface, a large sweet spot, and a textured carbon-fiberglass surface. Such features deliver the ideal mix of forgiveness, consistency, precision, and spin at an affordable price point around $100.

Q: What is the most popular pickleball paddle for beginners?

A: Popular beginner paddles include models like the Six Zero Sapphire, Bison Summit/Rampage clones, Electrum Model E 16MM, Hudef Viva Pro Gen 2, and the Selkirk SLK Evo Series. These selections have earned recognition for their balanced performance and cost efficiency.

Q: What size pickleball paddle is best for beginners?

A: Beginners generally benefit from using a paddle with a 16 mm core. This thickness provides an optimal balance between power and control, ensuring a performance level suitable for developing players.

-

Carbon Fiber: Click to learn about the different grades of carbon fiber, including properties such as flexibility, strength, and weight benefits that impact paddle performance. ↩

-

Fiberglass: Click to explore the characteristics of fiberglass, including its balance between power and control, and why it is a preferred choice for beginner-friendly paddle designs. ↩

-

Hot pressing: Click to understand how the hot pressing manufacturing process works, its benefits in high-volume production, and its impact on paddle durability and performance. ↩

-

Cold pressing: Click to read about the cold pressing technique, which preserves the natural material properties for enhanced control and consistency, and why it may be chosen for precision paddle production. ↩

-

Thermoforming: Click to delve into the thermoforming process, detailing how heat and molding techniques create intricate designs and uniform structures for premium paddle products. ↩