The quick answer: While both aramid fiber1 and carbon fiber2 deliver high performance for advanced applications, they do not share identical properties. Each material has unique strengths, weaknesses, and cost implications that make them better suited for specific manufacturing needs and performance requirements.

In today’s competitive manufacturing environment, procurement managers and technical designers must choose the best material for their advanced products. One common dilemma is selecting between aramid fiber and carbon fiber. This article breaks down the key differences and similarities between these two high-performance materials, empowering you with the technical insights necessary for informed decision-making.

For businesses involved in manufacturing sports equipment, automotive parts, aerospace components, or high-strength structural elements, material performance is critical. On one hand, carbon fiber is celebrated for its superior tensile strength and stiffness. On the other, aramid fiber—famously recognized in applications like Kevlar—offers exceptional impact resistance and energy absorption. Each choice affects product performance, manufacturing process efficiency, and overall cost.

Procurement managers are often faced with several questions:

- Which material offers the best balance of strength and weight?

- How do the materials perform under high-impact conditions?

- What are the cost versus performance trade-offs?

By understanding these core factors, decision-makers can strategically align material selection with their product’s requirements.

A detailed comparison based on material properties, performance under load, and usability in manufacturing provides clarity. Below is a table summarizing some key properties of aramid fiber and carbon fiber:

| Property | Aramid Fiber | Carbon Fiber |

|---|---|---|

| Tensile Strength3 | High, but typically lower than carbon fiber | Extremely high, with exceptional rigidity |

| Impact Resistance | Outstanding energy absorption and toughness | Moderate; may be brittle under shock loads |

| Weight | Lightweight with excellent flexibility | Ultra-lightweight with high strength-to-weight ratio |

| Stiffness | Lower stiffness, providing flexibility | Very high stiffness for structural integrity |

| Cost | Generally more affordable | Often higher due to advanced production techniques |

| Heat Resistance | Good performance in high-heat conditions | May necessitate special handling to prevent degradation |

| Application Suitability | Ideal for protective gear, automotive components, and ballistic applications | Preferred for aerospace, high-performance sports equipment, and structural components |

The table above reveals that the aramid fiber excels in impact resistance and energy absorption, making it ideal for applications where protective qualities are key. In contrast, carbon fiber is the material of choice for applications demanding high tensile strength and rigidity.

Carbon fiber is renowned for its superior tensile strength. Its structure, composed of tightly bonded carbon atoms, creates fibers that are incredibly stiff and resilient under tension. This high rigidity makes carbon fiber a go-to material in sectors where maintaining structural integrity is essential—such as aerospace components and high-performance sports equipment like pickleball paddles. For example, NEX Pickleball’s advanced paddle designs take advantage of carbon fiber’s strength to ensure maximum power and control.

In contrast, aramid fiber, often recognized as the base for materials like Kevlar, offers high tensile strength but in a slightly different manner. Although it may not reach the same level of rigidity as carbon fiber, its ability to absorb and dissipate energy makes it incredibly useful in applications requiring resistance to impact and burst. Its flexibility under stress also adds a level of durability, especially in environments where sudden impacts are frequent.

One of the standout features of aramid fiber is its exceptional impact resistance. In scenarios where safety and energy absorption are paramount, such as in protective gear or automotive applications, aramid fiber can mitigate damage during high-impact events. This makes it an excellent choice for products that must withstand unpredictable stresses.

On the flip side, while carbon fiber is very strong, its brittle nature under certain impact conditions can lead to sudden failure if not properly engineered. Engineers must often incorporate additional design measures or composite reinforcements to offset this vulnerability in high-impact environments.

Both materials are lightweight, which is crucial for high-performance applications where minimizing mass is as important as maximizing strength. Carbon fiber is particularly valued for its exceptional strength-to-weight ratio. This characteristic is especially beneficial in sports equipment manufacturing, where even small weight reductions can significantly enhance performance.

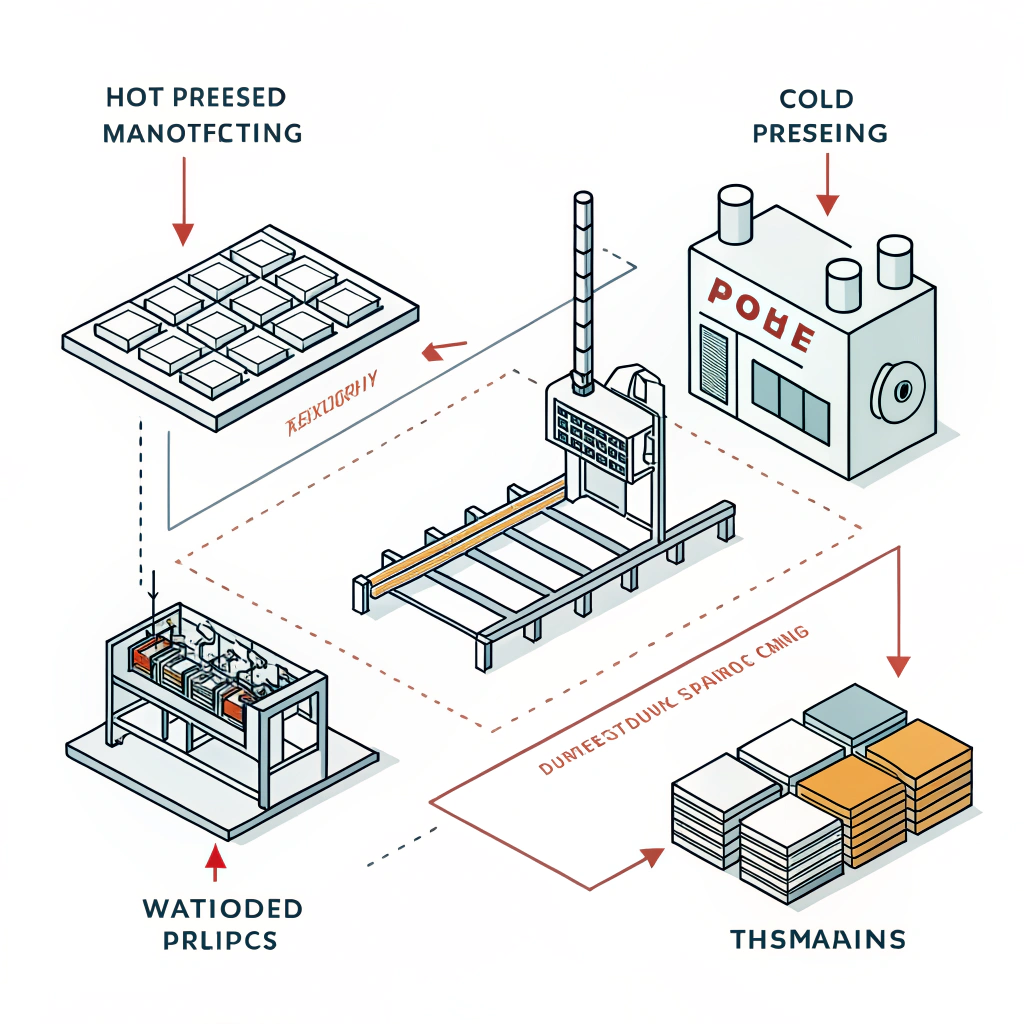

However, the production process for each fiber influences their final performance characteristics. For instance:

-

Carbon fiber is processed using methods such as hot pressing, cold pressing, and Thermoforming4. These processes ensure that the final component maintains optimal strength, durability, and precision. In applications like high-performance pickleball paddles, our own experience at NEX Pickleball demonstrates that advanced carbon fiber production results in products that excel in both responsiveness and longevity.

-

Aramid fibers require different handling during manufacturing due to their unique molecular structure. While the production of aramid-based components is well-established, the integration of aramid fibers within composite materials often demands special techniques to preserve their energy absorption qualities while merging with other materials.

In advanced manufacturing, the compatibility of a material with different production techniques is crucial. At NEX Pickleball, our production processes are designed to maximize the performance benefits of carbon fiber:

- Hot Pressing applies heat and pressure to bond the fibers into a solid structure. This method is efficient for large-scale production, ensuring a high degree of structural integrity and impact resistance.

- Cold Pressing allows for meticulous control of the paddle’s thickness and ensures the preservation of the material’s properties, giving a better feel and responsiveness.

- Thermoforming4 enables the creation of complex shapes, crucial for modern, ergonomically designed sports equipment.

For aramid fiber components, while production can be similarly advanced, care must be taken to ensure that the inherent flexibility and toughness of the fibers are not compromised during high-temperature curing processes. The balance between maintaining material properties and achieving desired product aesthetics is a key consideration.

Both fibers are often used in composite materials5 to harness their strengths while mitigating their respective limitations. A hybrid approach—combining carbon fiber and aramid fiber—is emerging as an attractive solution in several industries. This strategy leverages the stiffness and strength of carbon fiber along with the impact resistance of aramid fiber to produce a composite that offers superior performance across a range of metrics.

By incorporating both fibers into composite structures, manufacturers can tailor the properties of the final product to meet specific requirements. For example, in our industry, composite paddles that merge carbon fiber with flexible core materials can provide unbeatable performance in terms of power, control, and durability.

When evaluating materials for advanced product development, consider the following:

-

Performance Requirements:

Define the critical performance attributes needed for your product. For components that need high stiffness and tensile strength, carbon fiber is likely preferable. For applications where impact resistance and energy absorption are key, aramid fiber might be the better option. -

Cost Considerations:

While carbon fiber generally offers superior mechanical performance, it typically comes at a higher cost. Evaluate the total cost of ownership, factoring in not just material costs but also production and maintenance expenses. -

Manufacturing Capabilities:

Assess whether your existing manufacturing processes are equipped to handle the specific requirements of each material. The advanced processes used in our paddle production at NEX Pickleball illustrate the importance of matching material characteristics with capable production techniques. -

Application Environment:

Consider the specific challenges of the operating environment. For products exposed to high-impact scenarios or variable thermal conditions, understanding the material’s behavior under stress is essential. -

Hybrid Solutions:

Don’t rule out composite or hybrid approaches. Often, combining aramid fiber and carbon fiber can offer a balanced solution, merging the strengths of both materials.

A strategic approach to material selection involves not only comparing material properties in isolation but also understanding how they integrate into your overall product design and manufacturing process. A collaborative review between procurement, engineering, and production teams can lead to more informed, holistic decisions that drive both performance excellence and cost efficiency.

At NEX Pickleball, our expertise in carbon fiber manufacturing demonstrates the benefits of this material in high-performance sports equipment. Our paddles, for example, utilize advanced pressing and thermoforming techniques to produce components with exceptional strength-to-weight ratios and precise balance. In a similar fashion, several companies have begun exploring the integration of aramid fiber to enhance impact absorption in safety gear and specialty equipment.

These examples illustrate that while the raw properties of aramid fiber and carbon fiber differ, their optimal use depends on the specific performance goals of the product. Deploying the right material—or combination thereof—can significantly impact the product’s durability, user experience, and overall success in the market.

To summarize, while aramid fiber and carbon fiber share the common goal of enhancing product performance, they are optimized for different applications:

- Carbon Fiber: Superior tensile strength, high rigidity, and excellent stiffness. Ideal for applications where structural integrity is paramount.

- Aramid Fiber: Exceptional impact resistance, energy absorption, and flexibility. Best suited for environments where safety and shock resistance are critical.

For procurement managers and technical designers, the decision should be guided by a detailed analysis of material properties, manufacturing capabilities, and application requirements. Consider initiating pilot projects or prototype testing sessions to evaluate material performance in real-world conditions. Engaging in collaborative cross-department discussions can further refine the selection process, ensuring alignment with both technical standards and business objectives.

Looking forward, as market demands shift and hybrid composite materials become more prevalent, the lines between traditional material classifications may blur. Staying updated on industry trends and maintaining a close relationship with material suppliers—like NEX Pickleball in the sports equipment sector—will ensure your product innovations remain at the cutting edge.

By taking a comprehensive, data-driven approach to material comparison, you can optimize product performance, reduce manufacturing risks, and ultimately achieve a competitive edge in the marketplace.

People Also Ask

Q1: What are the main differences between aramid fiber and carbon fiber?

Answer: Aramid fiber generally offers superior impact resistance and energy absorption, while carbon fiber is known for its higher tensile strength and stiffness. Each material is best suited for different applications based on these properties.

Q2: Which material is more cost-effective for high-performance applications?

Answer: Although carbon fiber delivers outstanding structural integrity, it is typically more expensive than aramid fiber. The choice depends on whether the application demands high stiffness and strength (favoring carbon fiber) or enhanced impact resistance (favoring aramid fiber).

Q3: Can aramid fiber and carbon fiber be used together in composite materials?

Answer: Yes, combining aramid fiber and carbon fiber in composites can leverage the strengths of both materials. This hybrid approach often results in components that offer both high rigidity and excellent energy absorption, making them suitable for specialized applications.

-

aramid fiber: Click to read a detailed explanation on the unique properties, common applications, and manufacturing considerations of aramid fibers in high-performance industries. ↩ ↩

-

carbon fiber: Click to explore an in-depth guide on carbon fiber, including its benefits, limitations, and the advanced techniques used in its production for various sectors. ↩ ↩

-

Tensile Strength: Click to learn more about tensile strength, its measurement, and why it is a critical parameter in determining the performance of high-strength materials. ↩ ↩

-

Thermoforming: Click to read an article detailing thermoforming processes, how they work, and their importance in shaping advanced composite components. ↩ ↩ ↩2

-

composite materials: Click to discover how composite materials are engineered by combining different fibers, and how this approach enhances overall material performance for diverse applications. ↩ ↩