Quick Answer: To achieve superior spin performance in a pickleball paddle, manufacturers must balance premium materials like carbon fiber1 and fiberglass2 with advanced production processes such as hot pressing3, cold pressing4, and thermoforming5. The optimal paddle depends on the desired blend of power, control, and durability that aligns with competitive play standards.

For B2B decision-makers in the sports equipment industry, understanding how manufacturing techniques and material selection affect a paddle's spin performance is crucial. This article provides a comprehensive comparison of different pickleball paddle technologies. We analyze how material choices and production processes contribute to spin characteristics and overall performance. Our discussion offers insights based on technical specifications, factory production methods, and performance testing, ensuring that procurement managers can confidently select the best product for their retail or club offerings.

Spin performance refers to the paddle's ability to impart spin on the ball. In competitive pickleball, spin can change the ball's trajectory, create unpredictable bounces, and offer players a strategic advantage. The effectiveness of spin is influenced by factors such as the paddle’s surface texture, weight distribution, and material elasticity. Manufacturers invest significant effort in balancing these elements to produce paddles that perform exceptionally on the court.

For example, a paddle with a slightly rough surface or a well-calibrated edge design may offer increased friction against the ball, resulting in enhanced spin. B2B buyers should consider such nuanced design details while comparing products from different manufacturers.

Spin performance is not an isolated feature; it results from a combination of elements in paddle construction. The three primary factors include:

-

Materials

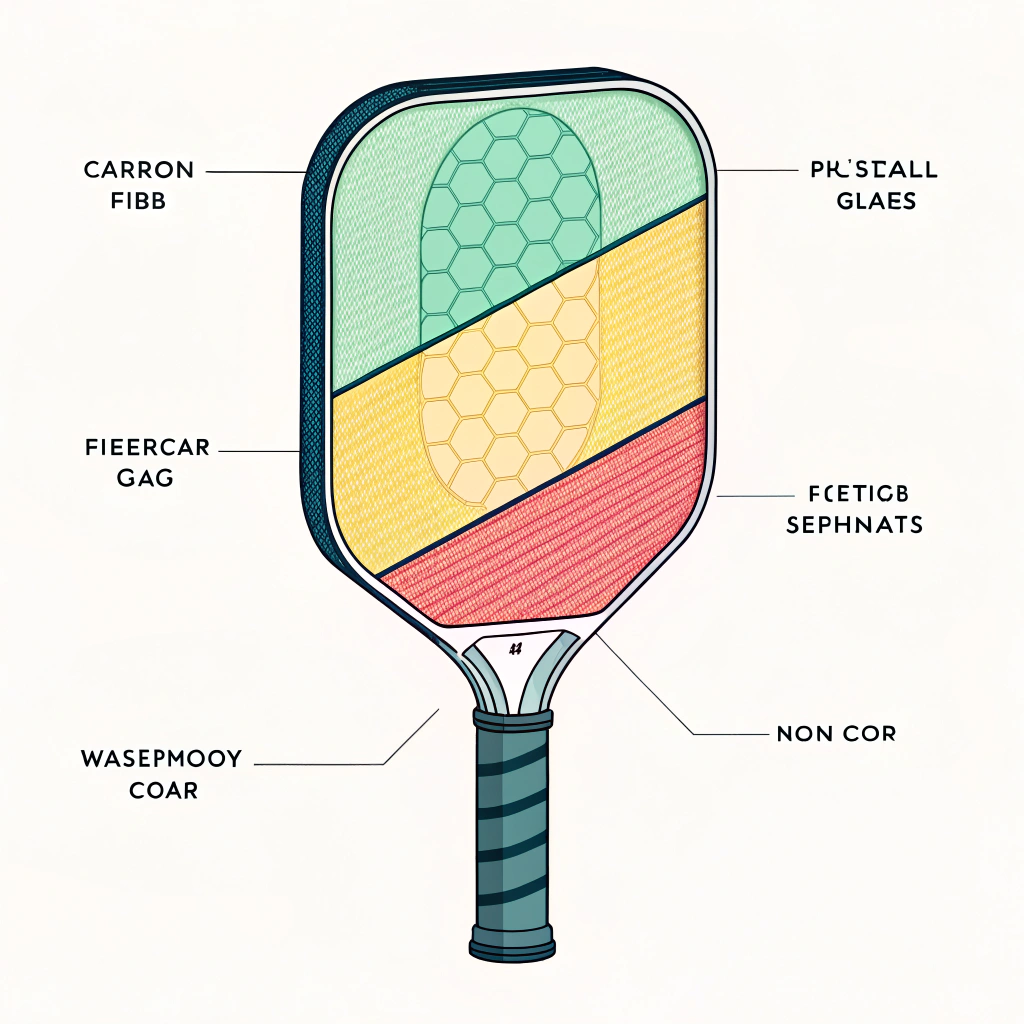

Material selection is fundamental in building a paddle that delivers optimal spin performance. At NEX Pickleball, we utilize advanced materials such as:- Carbon Fiber1: Variants like 3K, 12K, and T300 provide different balances of strength, flexibility, and damping properties. For instance, 12K carbon fiber offers a smoother surface, which can allow a better transfer of spin.

- Fiberglass2: Known for its elasticity and wider sweet spot, fiberglass paddles are excellent for players seeking enhanced ball control.

- Composite materials that combine carbon fiber and fiberglass merge the benefits of both, delivering a balance of control and power.

-

Production Processes

The manufacturing process plays a critical role in defining a paddle’s surface integrity and internal structure:- Hot Pressing3: This method ensures high production efficiency and strong structural integrity. The heat and pressure applied during production help forge a durable paddle but may slightly alter material properties.

- Cold Pressing4: Ideal for preserving the natural properties of materials, cold pressing offers enhanced precision and control over paddle thickness. This process is particularly beneficial when the aim is to maintain material elasticity and deliver a consistent spin.

- Thermoforming5: Useful for creating intricate paddle shapes, thermoforming allows for precise control of material distribution. This process is critical when manufacturers need to design paddles tailored to specific player needs.

-

Core Materials

The core of the paddle, whether it’s made from Nomex honeycomb, aluminum honeycomb, or polymer honeycomb, also affects spin. Core selection influences vibration dampening, weight distribution, and the overall feel of the paddle—factors that contribute directly to spin performance.

The following table compares key attributes of various materials and production processes that influence spin performance:

| Feature/Attribute | Carbon Fiber (3K, 12K, T300) | Fiberglass | Composite Materials |

|---|---|---|---|

| Spin Performance | High spin transfer due to hardness and smoothness (especially 12K) | Moderate spin with a wider sweet spot | Optimized spin: balances power, control, and durability |

| Production Compatibility | Suitable for hot pressing and cold pressing | Works well with thermoforming | Ideal for hybrid production techniques |

| Durability and Impact Resistance | Excellent, especially T300 for tensile strength | Good elasticity and control | Enhanced with combined properties from carbon and fiberglass |

| Vibration Dampening | Depends on material density and production process | Provides a natural damping effect | Superior damping with designed composite layers |

On the production side, consider the following table:

| Production Process | Key Advantages | Potential Disadvantages |

|---|---|---|

| Hot Pressing | Fast production, excellent structural integrity, high durability | Possibility of altering material feel and slight rigidity |

| Cold Pressing | Maintains material properties, precise thickness control | Longer production cycles, requires high precision equipment |

| Thermoforming | Enables complex designs, optimum material distribution | Higher cost and longer production time, best for premium products |

This detailed comparison highlights that decision-makers must evaluate not only the materials but also the manufacturing techniques to achieve the desired performance metrics.

At NEX Pickleball, our production experts emphasize that the spin performance of a pickleball paddle is a product of both advanced material science and precise manufacturing. Here are some insights from our factory floor experience:

-

An advanced carbon fiber1 paddle that uses 12K fibers is engineered to maintain a balance between high rebound force and consistent ball contact. The smoother surface created by 12K fibers is particularly effective at generating topspin, essential in fast-paced competitive environments.

-

Fiberglass2 paddles, while offering a naturally softer touch, provide excellent ball control and energy transfer. This is due to the material's inherent elasticity, which ensures that the paddle conforms slightly to the ball upon impact, maximizing spin.

-

Production processes such as cold pressing help maintain the natural flexibility of materials, preserving the critical features needed for high spin performance. By carefully managing pressure levels, our experienced technicians ensure that the paddle's surface remains optimal for delivering both control and spin.

-

Thermoforming adds value by allowing for customized paddle designs. It enables us to experiment with different grip designs and surface textures tailored to customer needs. This level of customization ensures that competitive players get paddles suited to their unique play styles.

These insights are supported by rigorous testing, where every paddle undergoes performance evaluations that measure spin, control, durability, and vibration absorption. Our data indicates that a well-engineered paddle featuring balanced material choices and production techniques can significantly enhance a player's competitive edge.

For procurement managers evaluating paddles for retail or club distribution, the selection process should consider several practical factors:

-

Competitive Players: For players demanding high spin and rapid reactions, paddles made with 12K carbon fiber using cold pressing techniques offer the best control and spin transfer. These paddles excel in high-speed gameplay, where precise spin assists in strategic shot placement.

-

Recreational Players: For casual players who prioritize ease of use and durability, fiberglass paddles created via thermal processing may be more appropriate. Their design, with a broader sweet spot and built-in shock absorption, often adds comfort for long play sessions.

-

Customization and Branding: Consider paddles that allow on-demand printing and custom design options. This is especially beneficial for clubs and sports organizations that want to integrate personalized branding, enhancing team identity and marketing efforts.

While cost is an important factor, B2B buyers should focus on long-term value:

- Premium Materials & Advanced Techniques: Although they often come at a higher cost, paddles incorporating advanced materials like carbon fiber and composite cores have proven durability and performance. These paddles incur lower replacement rates and deliver consistent high-level performance.

- Mid-Range Options: Paddles using a blend of materials or less complex production processes may be ideal for non-professional segments. They offer a reliable performance, though they might lack the nuanced spin characteristics of top-tier paddles.

Ensuring that a manufacturer stands behind their product is critical:

- Quality Control: Regular performance testing and strict quality assurance methods are essential. At NEX Pickleball, each paddle is subjected to rigorous testing, ensuring that every unit meets precise standards in spin capability, durability, and impact resistance.

- Technical Support: The ability to provide detailed product information, including production methods and performance metrics, can be a persuasive factor when making a procurement decision.

When evaluating which paddle technology delivers superior spin performance, we recommend the following steps:

- Analyze the balance between material quality and manufacturing precision. Look for paddles that use high-grade materials, especially those emphasizing 12K carbon fiber or advanced composite materials.

- Request detailed production process documentation. Understanding whether a paddle is made using hot pressing, cold pressing, or thermoforming will provide insights into its likely performance characteristics.

- Compare performance data. Use comparative tables and performance tests that include spin performance, vibration damping, durability, and impact resistance to understand product differences.

- Consider customization options. For entities looking to strengthen brand identity or tailor performance to specific groups of players, the ability to modify paddle designs is a significant advantage.

- Evaluate cost-performance ratio. While higher upfront costs may be justified by improved on-court advantages and longer product lifespans, ensure that the chosen paddle meets the market segment’s needs without unnecessary over-specification.

By integrating these considerations during the evaluation process, B2B buyers can confidently select pickleball paddles that enhance player performance and offer excellent value.

In conclusion, achieving superior spin performance in pickleball paddles is the result of a careful balance between cutting-edge materials and well-executed manufacturing processes. A comparative analysis of carbon fiber, fiberglass, and composite materials alongside production techniques like hot pressing, cold pressing, and thermoforming reveals that the best paddle technology hinges on delivering the perfect balance of power, control, and durability. For procurement managers looking to optimize their product lines, understanding these nuances can drive better purchasing decisions and ultimately lead to improved performance on the court.

Adopt a data-driven approach when comparing paddles and ensure close scrutiny of the production process documentation provided by manufacturers. By doing so, you're not only investing in a product but also in the long-term success and satisfaction of your end customers. The actionable insights provided here are designed to aid B2B decision-makers in choosing pickleball paddles that stand out in performance and durability.

Q1: Which pickleball paddle gives you the most spin?

A: Paddle spin performance is optimized in models that combine advanced carbon fiber1—especially the 12K variant—with precise manufacturing processes like cold pressing. These paddles offer a smoother surface and consistent ball contact, providing superior topspin.

Q2: Do more expensive pickleball paddles make a difference?

A: Yes, higher-end pickleball paddles often utilize premium materials such as carbon fiber1, raw carbon, and fiberglass. These materials can enhance control, power, and spin, though the most expensive option is not always necessary if the paddle meets performance requirements.

Q3: What's better, a 13MM or 16MM pickleball paddle?

A: The choice between a 13MM and 16MM paddle depends on player needs. Generally, a 16MM paddle is more suited for players seeking greater control, while a 13MM paddle tends to offer more power.

-

Carbon Fiber: Read the article to understand the unique properties of carbon fiber, its manufacturing variations (3K, 12K, T300), and how they influence strength, flexibility, and spin performance in sports equipment. Back to Carbon Fiber ↩ ↩2 ↩3 ↩4 ↩5

-

Fiberglass: Explore detailed insights into fiberglass as a material, covering its elasticity, impact resistance, and how its broader sweet spot benefits control and spin in high-performance paddles. Back to Fiberglass ↩ ↩2 ↩3

-

Hot Pressing: Learn about the hot pressing production process, including the application of heat and pressure to achieve strong structural integrity and its effects on material properties and performance. Back to Hot Pressing ↩ ↩2

-

Cold Pressing: Discover the advantages of cold pressing techniques, which preserve material properties and provide enhanced precision, vital for maintaining elasticity and consistent spin in sports equipment. Back to Cold Pressing ↩ ↩2

-

Thermoforming: Understand thermoforming as a manufacturing process that enables complex design shapes and tailored material distribution, directly impacting customization and performance of high-end products. Back to Thermoforming ↩ ↩2