Our cost-effective pickleball paddles harness advanced production techniques, premium materials, and competitive pricing—delivering an exceptional balance between performance and affordability in the evolving 2025 sports equipment market.

Procurement managers and sports equipment distributors face a constant challenge: sourcing pickleball paddles that do not compromise on performance while meeting budget constraints. In today’s competitive environment, understanding the nuances of production processes, material quality, and overall cost efficiency is crucial. In this article, we compare various manufacturing techniques and materials that influence paddle performance, enabling you to make a well-informed B2B purchasing decision.

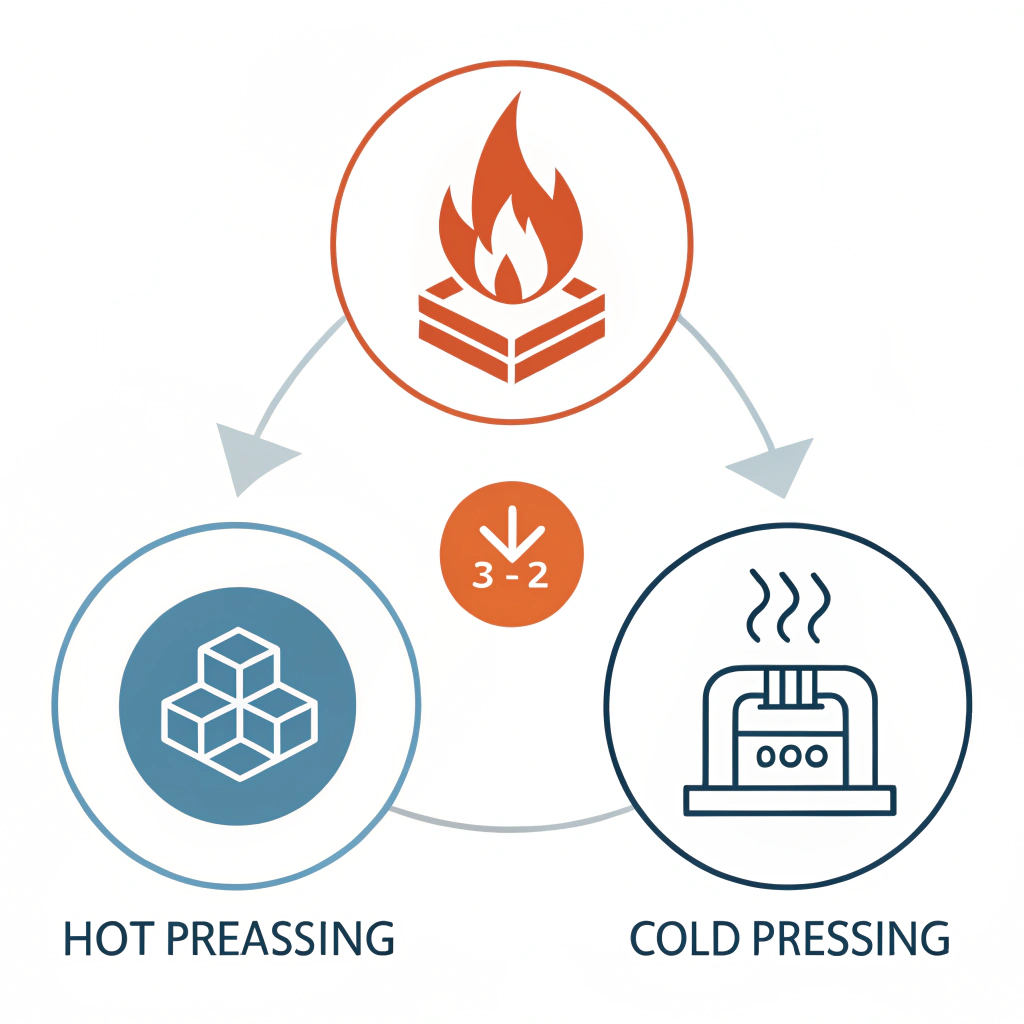

Understanding Production Processes: Hot Pressing1, Cold Pressing2, and Thermoforming3

An essential aspect of paddle quality lies in the production processes used to craft them. NEX Pickleball employs three primary methods—hot pressing, cold pressing, and thermoforming—to achieve optimal weight, durability, and playability. Let’s delve into each process:

Hot pressing involves applying heat and pressure to the paddle materials. This method is popular for its efficiency in high-volume production and its ability to yield paddles with exceptional structural strength.

- Advantages:

- High production efficiency for large-scale manufacturing.

- Creates paddles with excellent impact resistance.

- Ensures structural integrity under high-performance play.

- Disadvantages:

- May alter intrinsic material properties, affecting the paddle’s surface feel.

- Requires significant investment in specialized equipment.

- Suitable For: Paddles where high durability and impact resistance are a priority.

Cold pressing shapes the paddle at room temperature through mechanical pressure. This method maintains the material’s original properties, making it ideal for precision and enhanced control.

- Advantages:

- Provides precise control over paddle thickness and structure.

- Maintains the material’s natural properties, enhancing ball feel and responsiveness.

- Disadvantages:

- Longer production cycles compared to hot pressing.

- Demands sophisticated pressure control technology.

- Suitable For: Paddles focused on precision and tactile feedback, especially favored by players seeking control.

Thermoforming involves heating materials to a pliable state and molding them into complex shapes. This method allows for intricate designs that distribute material evenly, reinforcing paddle stability.

- Advantages:

- Facilitates intricate design features and precise material distribution.

- Enhances paddle stability and performance.

- Disadvantages:

- Longer production times and higher equipment costs.

- Primarily utilized for premium or custom-made products.

- Suitable For: Custom orders or paddles that require complex design elements and precision material configurations.

The following table summarizes the key aspects of these production techniques:

| Production Process | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Potential modification of material feel, high cost | Large-scale production with emphasis on durability |

| Cold Pressing | Precise thickness control, excellent ball feel | Longer cycles, precision equipment required | Paddles needing enhanced control and responsiveness |

| Thermoforming | Intricate design, even material distribution | Longer production, higher equipment costs | Premium or custom-designed paddle production |

Material Selections: Carbon Fiber4, Fiberglass, and Composites5

The performance and cost-efficiency of pickleball paddles are intimately linked to the material selection. At NEX Pickleball, various materials are used to cater to a range of customers—from budget-sensitive distributors to premium brands. Below, we outline the benefits and cost considerations of each material.

Carbon Fiber is widely respected in the sports industry for its strength-to-weight ratio. There are several types of carbon fiber employed in paddle production:

- 3K Carbon Fiber: Known for its flexibility combined with strength, it is ideal for paddles requiring high rebound force. This type offers noticeable durability and vibration reduction.

- 12K Carbon Fiber: With a higher thread density, 12K provides a smoother surface and improved hardness, making it excellent for competitive play where impact resistance is crucial.

- T300 Carbon Fiber: This high-performance variant strikes a balance between strength and weight, making it a favorite for paddles designed for both power and precision.

Each variant has its own cost dynamics; higher thread densities and specialized types such as T300 generally command a premium price, but they do deliver higher performance when budget permits.

Fiberglass paddles deliver a balanced experience in terms of both power and control. They are particularly favored when a wider sweet spot and enhanced durability are needed.

- E-Glass Fiberglass: Recognized for its elasticity and tensile strength, this material offers players excellent ball control and a reliable feel during extended play sessions.

Its cost is typically lower when compared to high-grade carbon fiber options, making it an attractive choice for budget-friendly market segments.

For a combination of benefits, composite materials merge the advantages of different fibers:

- Carbon Fiber and Fiberglass Composite: This option provides an outstanding balance between power and control, making it a versatile choice.

- Bamboo Core Composite: Known for a lightweight and impact-resistant structure, bamboo cores offer a distinct hitting feel along with longevity.

- Honeycomb Core: With superior shock absorption and vibration reduction, honeycomb cores protect the paddle’s integrity over time.

Table below summarizes the benefits and market positioning for these materials:

| Material | Key Benefits | Cost Consideration | Suitable For |

|---|---|---|---|

| 3K Carbon Fiber | Flexibility, durability, reduced vibration | Mid-range to high cost | Players seeking high rebound without significant weight |

| 12K Carbon Fiber | Smooth surface, extreme strength | Higher cost than 3K | Competitive play requiring impact resistance |

| T300 Carbon Fiber | Balanced strength and light weight | Premium pricing | High-performance paddles for advanced players |

| Fiberglass (E-Glass) | Wide sweet spot, excellent control | Generally more affordable | Budget segments and recreational use |

| Carbon Fiber & Fiberglass Composite | Optimized power-control balance | Mid to high range pricing | Versatile performance in a broad range of scenarios |

| Bamboo Core Composite | Lightweight, durable, unique feel | Affordable with long-term durability | Cost-effective options with added longevity |

| Honeycomb Core | Superior shock absorption, reduced vibration | Competitive cost with enhanced performance | Distributors looking for extended paddle lifecycle |

For B2B buyers, the primary challenge is evaluating performance against price. While high-performance paddles typically command a premium, it is possible to identify options that offer superior performance at affordable prices without compromising on essential features.

When assessing cost-effective paddles, consider the following:

- Durability: Paddles produced with hot pressing or high-grade carbon fiber may last significantly longer, resulting in lower long-term costs.

- Playability: Materials like fiberglass and polymer cores provide excellent ball control and reduced vibration—ideal for recreational and mid-level competitive play.

- Production Efficiency: Simplified processes like cold pressing may offer better control and consistency in manufacturing, ensuring that every paddle meets quality standards.

- Customization Options: On-demand printing and custom paddle options allow distributors and clubs to brand their products, adding significant value without drastic cost increases.

Providing a clear balance between these parameters will help you align your product mix with market expectations while meeting budget targets.

The following aspects are crucial when comparing production methods:

- Speed vs. Precision: Hot pressing offers speed but might sacrifice subtle material properties, whereas cold pressing grants precision at the cost of slower throughput.

- Cost of Equipment: Thermoforming requires a higher initial investment, making it a preferred choice only for premium orders.

- Material Compatibility: Not all materials respond similarly across production processes. For instance, carbon fiber is optimally used with hot pressing for high strength, whereas fiberglass is better preserved through cold pressing.

As market trends shift toward sustainability and operational efficiency, manufacturers who adopt advanced and adaptable production processes tend to offer a more robust product portfolio—meeting both performance needs and budget constraints for mid-market customers.

Market analysis indicates that cost-effective pickleball paddles are evolving in response to several key trends:

- Innovation in Material Science: The continued research in new composites and core materials will drive greater performance at lower prices.

- Advanced Production Techniques: Manufacturers are increasingly investing in processes that blend the benefits of hot pressing, cold pressing, and thermoforming. The ability to tailor production methods to specific materials means that cost-effective solutions will not compromise on quality.

- Sustainability: Eco-friendly production methods and the use of sustainable materials like bamboo composites are becoming more prominent. These developments appeal to distributors aiming to enhance their brand value while meeting regulatory standards.

- Customization and On-Demand Printing: Offering customized paddles is not only a trend but a strategic advantage in the B2B market. Customized products allow retailers and clubs to build brand identity while leveraging cost-effective volumes.

Manufacturers like NEX Pickleball are poised to lead the industry by harnessing these trends, continuously refining the balance between quality, performance, and affordability. The combination of effective production techniques, premium material use, and market insight positions suppliers to meet the dynamic demands of both recreational and competitive players.

To capitalize on these developments and secure the best value for your business, consider the following steps:

-

Assess Your Requirements:

Outline the key performance metrics (durability, playability, brand customization) that matter to your target customers. Identify which production process best meets your volume and quality needs. -

Compare Material Options:

Use comparative tables to evaluate the benefits of Carbon Fiber variants versus Fiberglass and Composite materials. Focus on long-term durability and user experience to determine the total cost of ownership. -

Engage with Reputable Manufacturers:

Partner with manufacturers like NEX Pickleball whose expertise in advanced techniques (hot pressing, cold pressing, and thermoforming) and commitment to quality control ensures that each paddle meets the required standards of performance and reliability. -

Negotiate Customization Deals:

Explore on-demand print services and custom paddle options that enhance your product offerings without significantly increasing the cost. Tailored branding can differentiate your inventory in a competitive market. -

Monitor Market Trends:

Stay updated with industry trends such as sustainable materials and innovative production processes. Frequent interactions with your supplier can yield insights into upcoming advancements that might further reduce costs while enhancing product performance.

Taking these steps will ensure that your portfolio of pickleball paddles is not only cost-effective but also well-positioned in a market increasingly focused on quality, performance, and sustainability.

What are the best pickleball paddles in 2025?

The best pickleball paddles in 2025 combine advanced production methods with premium materials. High-performance options include those featuring high-grade carbon fiber variants like T300, which balance strength and lightweight design, while some models leverage cold pressing for precision ball control. Overall, these paddles strike a balance between durability, responsiveness, and cost-effectiveness.

What is the best value pickleball paddle for the money?

A great value pickleball paddle offers a mix of affordability and performance. Paddles produced with effective cost-management techniques—such as optimized thermoforming or cold pressing methods—coupled with materials like fiberglass or composite cores provide excellent playability and durability without high price tags. Balancing these factors ensures you get the best performance for your investment.

What is the #1 rated pickleball paddle?

Rated pickles in expert reviews often highlight paddles that excel in playability, durability, and design precision. While many factors contribute to a “#1 rated” paddle, top contenders generally include models that feature superior materials like high-performance carbon fiber and are produced using advanced methods to ensure consistency and quality across batches.

-

Hot Pressing: Click to learn how this heat and pressure-based production method enhances manufacturing speed and structural strength while potentially affecting material texture. ↩

-

Cold Pressing: Click to explore the precision benefits of shaping materials at room temperature and how this method preserves the material’s integrity. ↩

-

Thermoforming: Click to understand the process of heating materials to create complex shapes, and how this method enables intricate design features. ↩

-

Carbon Fiber: Click to delve into the advantages of carbon fiber’s strength-to-weight ratio and its impact on high-performance sports equipment. ↩

-

Composites: Click to discover how composite materials merge the benefits of different fibers for a balanced performance in sports equipment. ↩