NEX Pickleball leverages advanced production techniques and premium materials to manufacture high-performance pickleball paddles that meet the diverse needs of sports equipment distributors and procurement managers worldwide.

In today’s competitive sports equipment market, selecting a reliable pickleball paddle manufacturer is critical. Procurement professionals require a partner who not only excels in production but also offers detailed insights into materials, manufacturing processes, and quality control. At NEX Pickleball, we blend industry-leading technology with expert craftsmanship to create paddles that stand out in performance, durability, and customization.

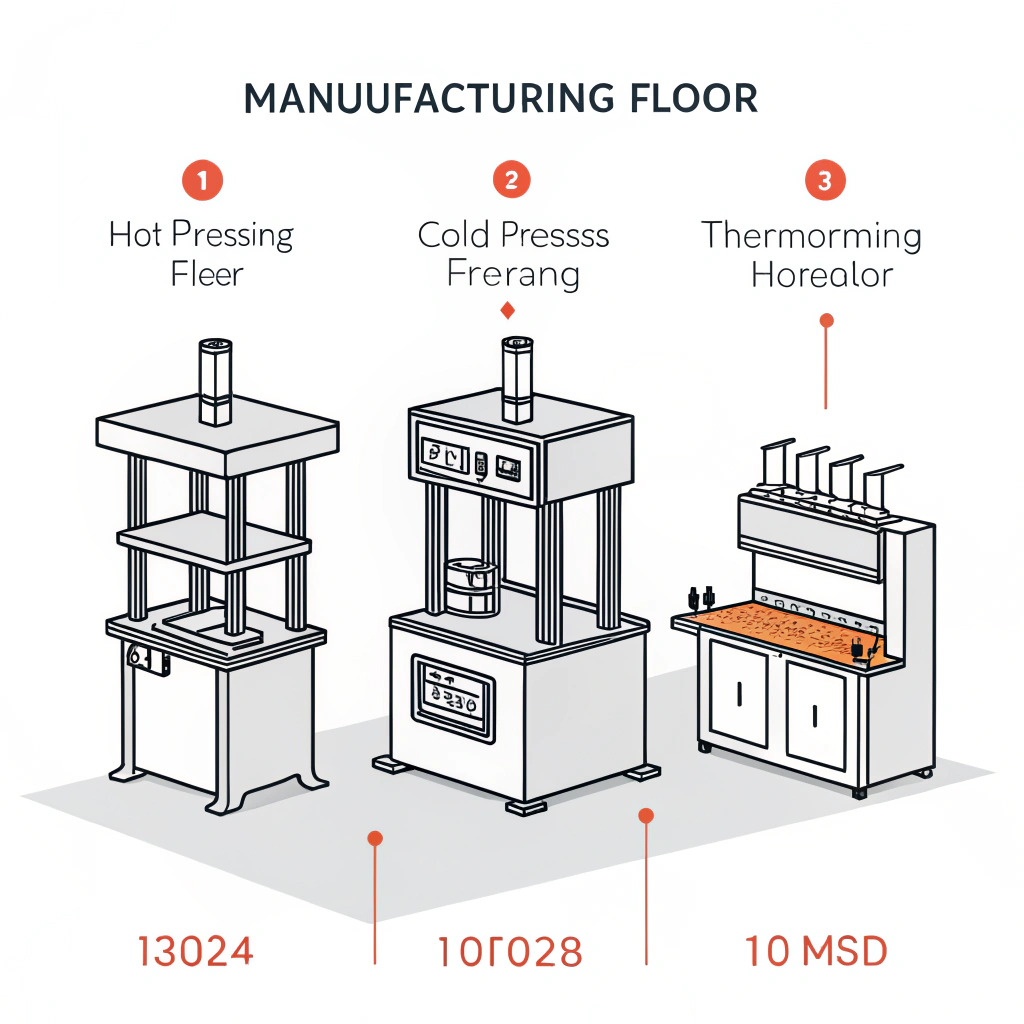

Our paddles are produced using three main techniques—hot pressing1, cold pressing2, and thermoforming3—each offering distinct benefits. This article will detail the common challenges B2B buyers face, analyze the underlying causes, present clear solutions, and offer actionable recommendations for making informed procurement decisions.

The manufacturing of pickleball paddles is a sophisticated process that directly impacts product performance. B2B procurement managers are often confronted with questions about material selection, production processes, and the balance between efficiency and product quality. The key challenges include:

• Ensuring that the chosen production process retains the integrity of high-performance materials.

• Maintaining precision in transformation techniques such as heat-based and pressure-based forming.

• Adapting the process for custom designs that meet unique market or team requirements.

To address these challenges, it is important to evaluate not only the production process but also the choice of raw materials, such as Carbon Fiber4, Fiberglass, and various composite materials.

Our approach at NEX Pickleball is centered on clear process transparency combined with rigorous quality control measures that ensure each paddle meets global standards.

There are three dominant production processes in paddle manufacturing, each with its own set of advantages and limitations:

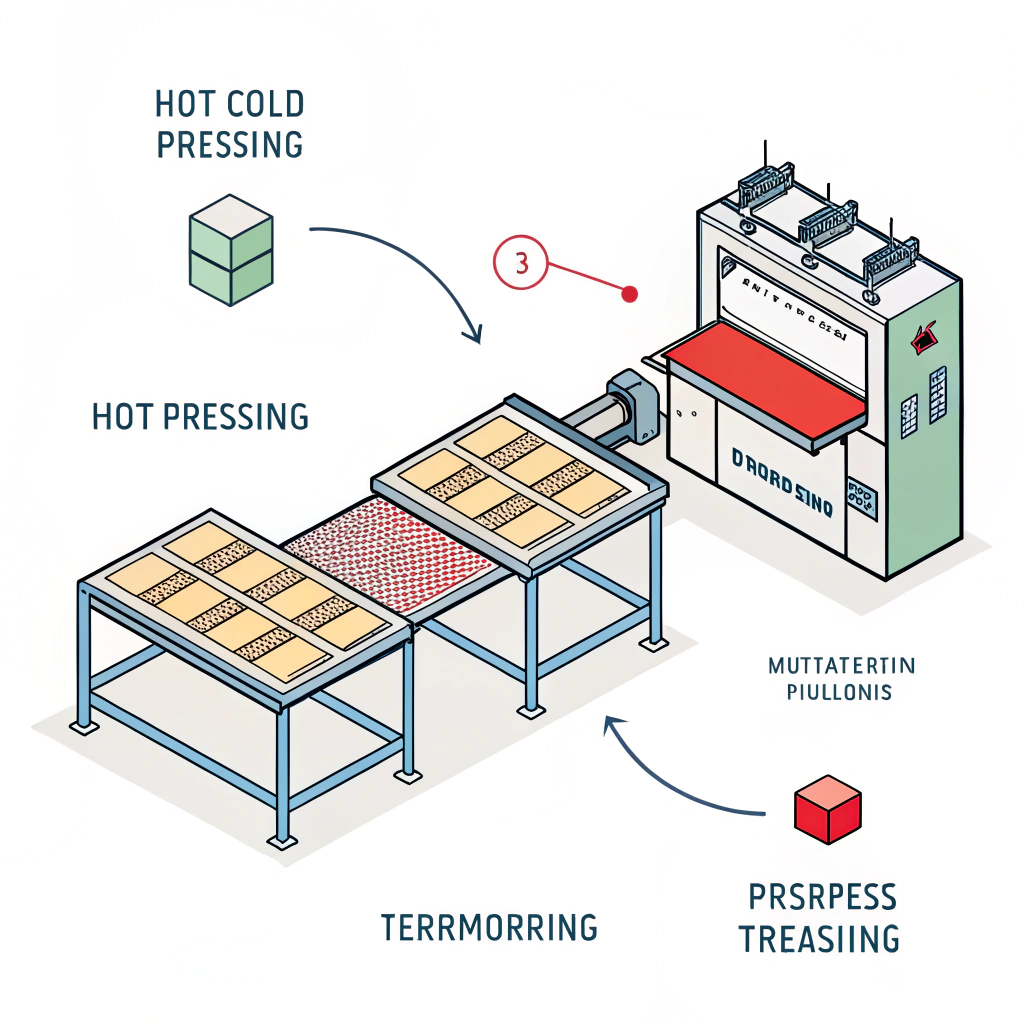

Hot pressing involves heating the materials and applying pressure to form the paddle structure. This technique is ideal for achieving high production efficiency and strong impact resistance. However, the high temperatures used can alter some material properties and the equipment investment is significant.

Cold pressing shapes the paddle material at room temperature using mechanical pressure. This method allows for more precise control of the paddle’s thickness and maintains the material’s original properties, resulting in a better ball feel. The downside is a longer production cycle and the need for high-quality pressure control equipment.

Thermoforming heats the material to a soft state before molding it into shape. This process allows for the creation of complex, intricate designs with precise material distribution. Although it enhances paddle stability, thermoforming demands longer production time and incurs higher equipment costs.

The following table summarizes key differences among these processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, structural integrity | May alter material properties; high equipment cost |

| Cold Pressing | Superior control over thickness, retains material properties, excellent ball feel | Longer cycle; requires precise pressure control |

| Thermoforming | Enables intricate designs, precise material distribution, enhanced stability | Longer production time; higher cost for equipment |

This clear breakdown helps in aligning the production process with your specific business needs—whether it is prioritizing speed, precision, or design complexity.

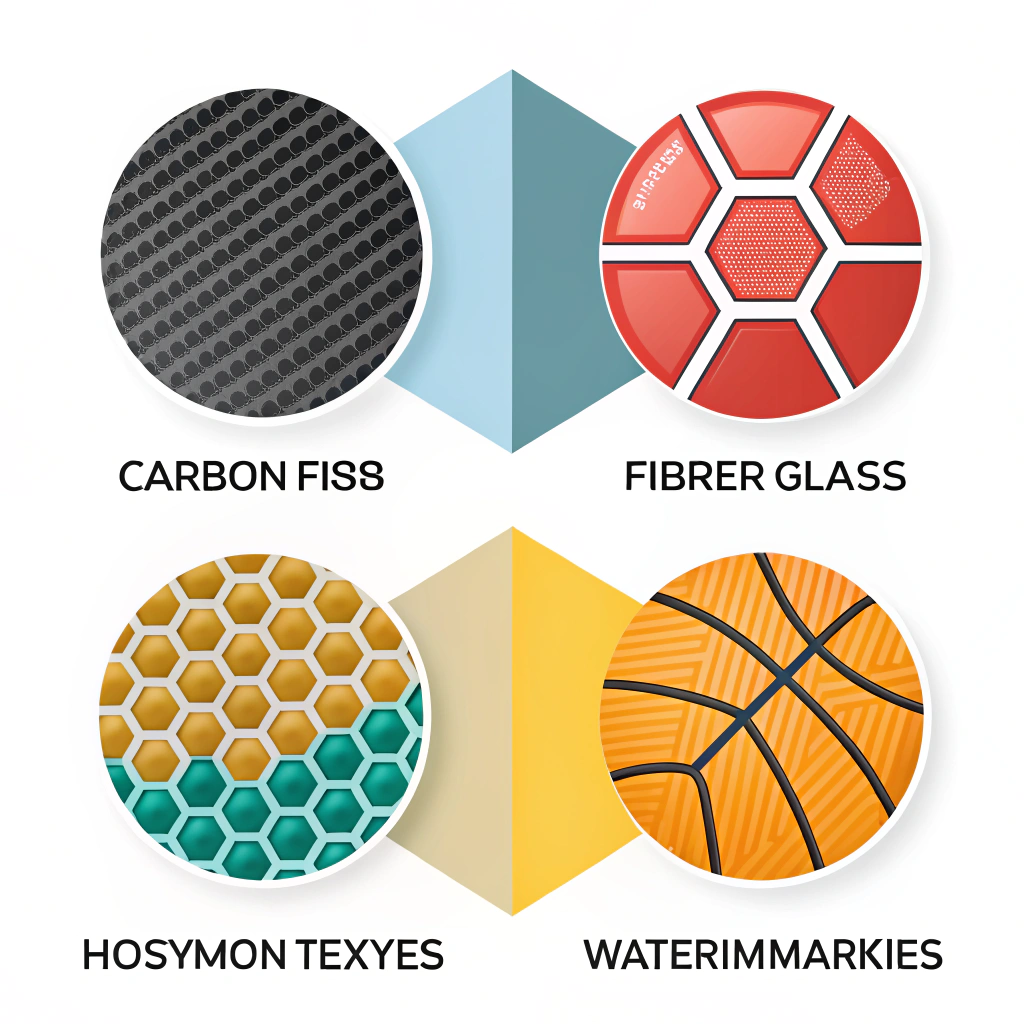

Beyond the production process, the right choice of materials is essential for paddle performance. NEX Pickleball offers a diverse selection of high-grade materials, ensuring that every paddle delivers a winning combination of power, control, and durability:

• Carbon Fiber4 (3K, 12K, T300):

- 3K Carbon Fiber is ideal for flexibility and high rebound force, offering excellent durability and vibration reduction.

- 12K Carbon Fiber provides a smoother surface with greater hardness, making it suitable for competitive play with extreme strength requirements.

- T300 Carbon Fiber strikes a balance between strength and weight, ensuring optimal performance in professional settings.

• Fiberglass:

- E-Glass Fiberglass enhances elasticity and provides an excellent ball feel with a wider sweet spot for balanced power and control.

• Composite Materials:

- Blends like Carbon Fiber and Fiberglass composites deliver a mix of power, lightweight design, and flexible control.

- Bamboo Core Composites and Honeycomb Cores offer high impact resistance and shock absorption for long-lasting play.

The core of the paddle significantly influences its hardness, control, and hitting sensations:

• Nomex Honeycomb Core5: Offers excellent shock absorption and superior durability, ideal for players who demand long-term stability.

• Aluminum Honeycomb Core: Provides a balanced weight and improved power with precise control, making it great for competitive play.

• Polymer Honeycomb Core: Enhances elasticity and reduces vibration, appealing to recreational players seeking comfort.

The combination of these materials is meticulously chosen to ensure every paddle delivers outstanding performance on the court.

A standout feature of NEX Pickleball is the ability to offer custom paddle designs. Clients can specify design elements, weight, balance, and grip size to ensure the final product meets their precise requirements. Customization options extend to incorporating specific core materials or surface treatments designed to improve grip and ball control.

Every paddle undergoes thorough testing procedures to verify that it adheres to global performance standards. Our quality control process includes:

• Rigorous stress tests to check impact resistance.

• Vibration reduction analysis to ensure a consistent playing experience.

• Detailed inspection of material integration in both composite and single-material paddles.

This commitment to quality control not only builds trust with our clients but also ensures that each manufactured paddle can withstand the challenges of competitive play.

For B2B procurement managers, selecting a manufacturer goes beyond the tangible product—it is an evaluation of reliability, consistency, and long-term partnership potential. NEX Pickleball stands out due to the following strategic benefits:

-

Precision Manufacturing: With advanced processes like hot pressing, cold pressing, and thermoforming, our production methods minimize defects and enhance performance reliability.

-

Diverse Material Portfolio: The broad selection of premium materials, from multiple types of carbon fiber to innovative honeycomb cores, allows us to cater to diverse market segments, whether it be for premium competition paddles or mass-market recreational models.

-

Customization Capabilities: We enable on-demand customization, allowing partners to market exclusive designs that resonate with targeted consumer demographics.

-

Rigorous Quality Control: Our comprehensive testing and quality assurance protocols ensure that each product delivered meets international standards.

-

Efficient Supply Chain: Based in Jiaxing, Zhejiang, China, our advanced production facilities and established relationships with leading brands like Joola and Selkirk ensure timely production and consistent quality.

These competitive advantages make NEX Pickleball a dependable partner for distributors and procurement managers looking to enhance their product offerings with high-performance, custom-designed pickleball paddles.

When evaluating potential manufacturing partners in the competitive sports equipment market, consider the following factors:

• Production Technology: Ensure the use of advanced and diversified techniques (hot pressing, cold pressing, thermoforming) that align with your product’s performance requirements.

• Material Supply: Look for manufacturers who offer a varied portfolio of Carbon Fiber4 and Fiberglass, as this flexibility can address different customer segments.

• Customization: The ability to customize designs and material choices can give you a competitive edge in target markets.

• Quality Control: Rigorously tested products ensure reliability, reducing the risk of returns or performance-related issues.

• Supply Chain Efficiency: Strong logistics and consistent production schedules are essential for maintaining inventory levels and meeting market demand.

By aligning these factors with your business goals, you can foster a partnership that not only supports your immediate procurement needs but also contributes to long-term market success.

In summary, NEX Pickleball is well-equipped to meet the evolving demands of B2B procurement managers and sports equipment distributors. Through our advanced manufacturing techniques, diverse material selections, and robust quality control measures, we ensure that every paddle we produce is a testament to precision engineering and performance excellence. Our commitment to customization further allows our partners to differentiate their product lines in an increasingly competitive market.

Partnering with NEX Pickleball means embracing a solution-oriented approach that prioritizes reliability, quality, and innovation in every paddle produced. We invite you to explore our capabilities and see firsthand how our high-performance paddles can provide the competitive edge you need.

People Also Ask

Q: What is the best pickleball paddle manufacturer?

A: The best pickleball paddle manufacturers are those who combine advanced production techniques with high-quality materials. NEX Pickleball, for example, utilizes hot pressing, cold pressing, and thermoforming along with premium materials such as carbon fiber and fiberglass to produce paddles designed for excellence in performance and durability.

Q: Are Selkirk pickleball paddles made in China?

A: While Selkirk & Selkirk LABS paddles are designed and quality-controlled in the USA, it is common for certain components to be manufactured in China. The country of origin for many paddle components can be China, but final assembly and quality assurance are controlled to meet high standards.

Q: Are Paddletek paddles made in China?

A: Not all pickleball paddles are manufactured in China. Some companies, such as Paddletek and Engage, produce paddles in the USA with locally sourced materials, including carbon fiber for the face material. Each manufacturer follows rigorous quality protocols to ensure optimal performance regardless of the production location.

-

hot pressing: Click to read more about this high-temperature production process that combines heat and pressure to form durable materials while optimizing manufacturing efficiency. ↩ ↩

-

cold pressing: Click to learn about this room-temperature shaping technique that maintains material properties and provides precise control over product dimensions. ↩ ↩

-

thermoforming: Click to explore the process where heated materials are molded into complex shapes, offering detailed insights into design flexibility and production challenges. ↩ ↩

-

Carbon Fiber: Click to understand the properties and benefits of carbon fiber in manufacturing, including its strength-to-weight ratio and applications in high-performance products. ↩ ↩ ↩2 ↩3

-

Nomex Honeycomb Core: Click to discover how Nomex honeycomb cores provide superior shock absorption and durability, making them a popular choice for high-impact applications in sports equipment. ↩ ↩