NEX Pickleball offers a competitive edge in the wholesale pickleball market by delivering high-performance paddles crafted through advanced production techniques. In short, our production processes integrate hot pressing1, cold pressing2, and thermoforming3 to ensure that every pickleball paddle meets the highest standards of performance, durability, and cost-effectiveness for B2B procurement managers.

Our discussion today focuses on comparing the key manufacturing techniques and materials that set apart our pickleball paddles from others in the industry. For procurement managers, distributors, and retail buyers, understanding these detailed comparisons can help you make informed purchasing decisions that maximize value without compromising quality. By evaluating material choices, production processes, quality assurance strategies, and pricing efficiency, you can confidently select NEX Pickleball as your preferred partner.

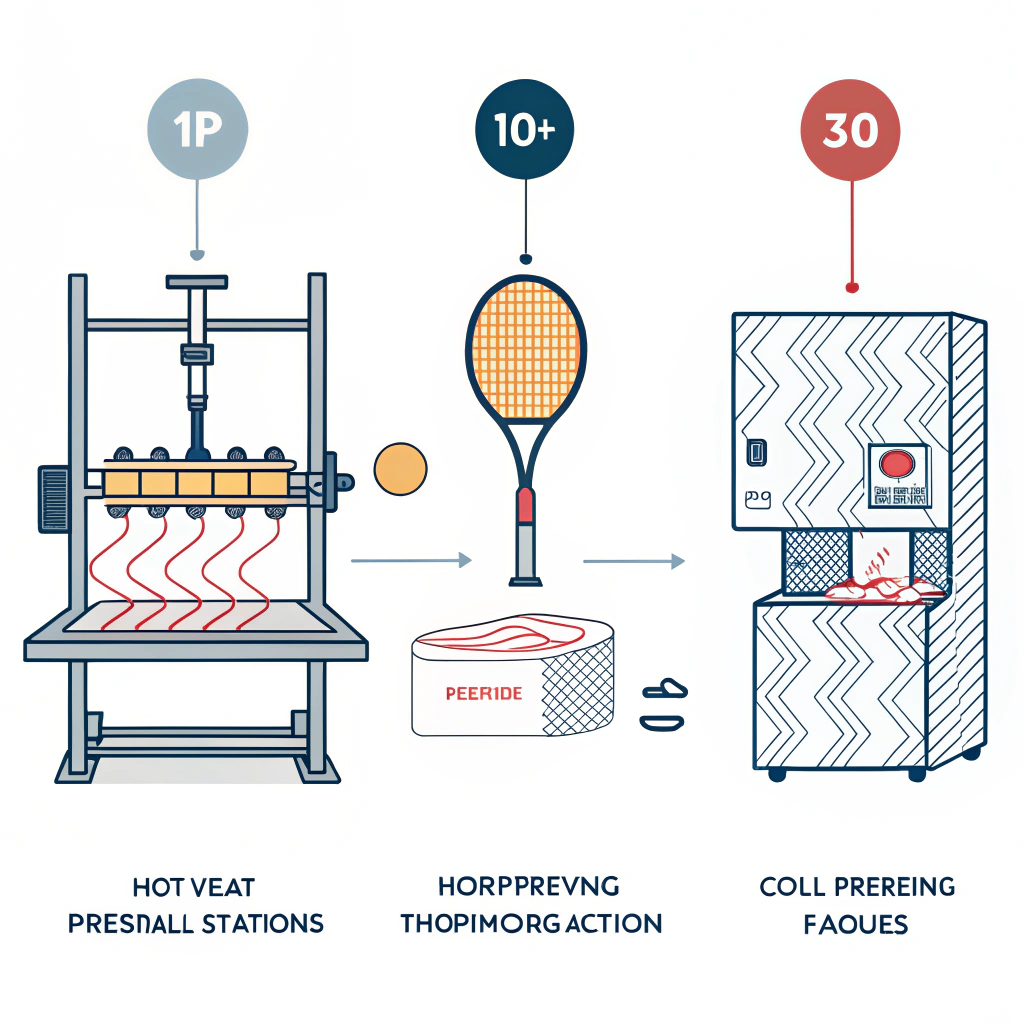

At NEX Pickleball, our advanced production capabilities are driven by three key processes:

-

Hot Pressing

Hot pressing is a process where materials are heated and pressed to form the paddle structure. This method is preferred for producing paddles with:- High Impact Resistance: The process forms a strong bond among the materials, enhancing durability.

- Efficient Mass Production: Ideal for large-scale manufacturing.

- Structural Integrity: Ensures that each paddle maintains the necessary rigidity throughout gameplay.

Advantages

- Quick, high-volume production.

- Produces paddles that can withstand intense use by competitive players.

Disadvantages

- The high heat may alter the intrinsic feel of the paddle.

- High investment cost in specialized equipment.

-

Cold Pressing

In cold pressing, material shaping occurs at room temperature under controlled mechanical pressure. This method is typically used when precision is paramount.- Precise Control Over Thickness: Ideal for producing paddles with exact specifications.

- Retention of Material Properties: The paddle’s original material feel remains intact.

- Enhanced Ball Feel and Responsiveness: Perfect for players who value control over power.

Advantages

- Maintains raw material properties, leading to more consistent performance.

- Yields paddles with a better “feel,” which is critical for controlled gameplay.

Disadvantages

- Longer production cycles reduce overall efficiency.

- Requires high-quality equipment with precise pressure control.

-

Thermoforming

Thermoforming involves heating materials until they soften and then molding them into the desired shape using high precision molds.- Intricate Designs: Allows for creative and complex paddle shapes.

- Uniform Material Distribution: Ensures even weight distribution, crucial for balance.

- Stability and Performance: Enhances durability and performance by preserving structural design.

Advantages

- Suitable for premium products and custom designs.

- Provides high precision in paddle geometry, optimizing play attributes.

Disadvantages

- Longer production times.

- Higher equipment costs mean investment is substantial.

Below is a comparison table outlining these processes:

| Production Process | Key Benefits | Main Drawbacks |

|---|---|---|

| Hot Pressing | High-volume production, strong impact resistance | May alter material feel, high equipment cost |

| Cold Pressing | Precision, better ball feel, preserves properties | Longer cycles, requires precision equipment |

| Thermoforming | Complex shapes, even material distribution | Slower process, higher cost per unit |

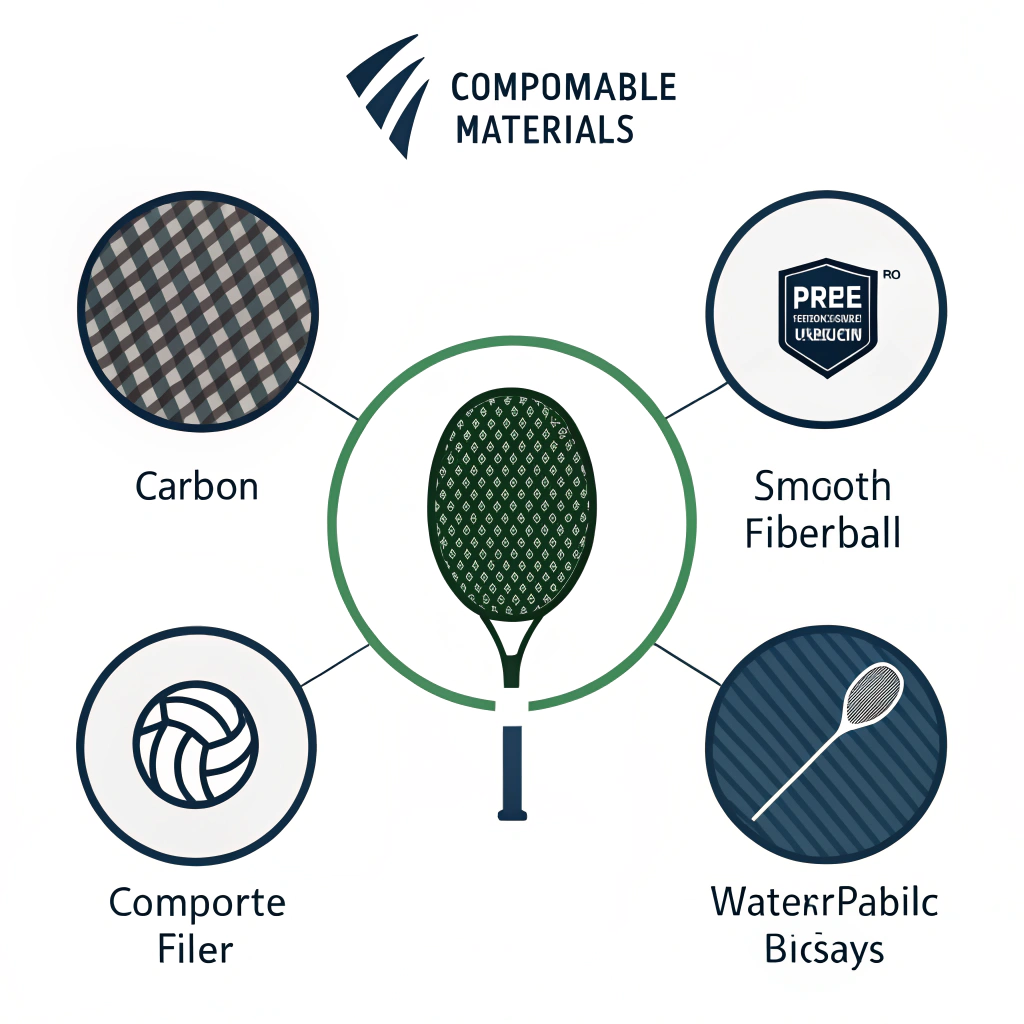

Apart from advanced production methodologies, material selection plays a critical role in determining the performance and durability of pickleball paddles. At NEX Pickleball, we offer several high-quality materials to cater to different playing needs.

Carbon Fiber Paddles

- 3K Carbon Fiber: Renowned for high strength and flexibility, ideal for paddles requiring a high rebound force.

- 12K Carbon Fiber4: Features a high thread density for a smooth surface, offering enhanced hardness and durability.

- T300 Carbon Fiber: Combines strength with light weight, making it perfect for competitive play.

Fiberglass Paddles

- E-Glass Fiberglass: Offers a balance of power and control with a wider sweet spot, excellent elasticity, and tensile strength.

Composite Materials

- Carbon Fiber and Fiberglass Composite: Merges features from both materials for a balanced play experience—ideal for players seeking both power and control.

- Bamboo Core Composite: Provides a lightweight and impact-resistant option that has a distinct hitting feel.

- Honeycomb Core Materials5: Include high-density polymers that offer superior shock absorption and reduced vibrations.

Each material is chosen with the goal of maximizing player performance while ensuring long-term durability. The right choice depends on your target market and the demands of your customers—whether they are competitive athletes or recreational players.

When making bulk purchasing decisions, cost is always a central consideration; however, quality and performance should never be compromised:

-

Cost Efficiency:

NEX Pickleball continuously optimizes production processes to lower manufacturing costs without sacrificing quality. Our hot pressing method, for instance, is highly effective for large-scale orders, making it particularly attractive for wholesale buyers looking for cost advantages. -

Quality Assurance:

Each paddle is rigorously tested for strength, balance, and play performance. Our quality control standards ensure that every product leaving our facility meets or exceeds industry benchmarks. B2B buyers can be confident of consistent quality across large orders. -

Production Flexibility:

We offer various customization options including adjustments in paddle weight, grip sizes, and material compositions. This flexibility helps meet the specialized demands of different markets, ensuring that distribution partners and retail buyers receive products that match customer expectations. -

Competitive Pricing Strategies:

Our pricing not only reflects advanced manufacturing practices but also offers competitive wholesale rates. This ensures long-term business relationships and mutual growth between our company and our B2B partners.

A projected cost-benefit matrix might look like this:

| Factor | Benefit for B2B Buyers | Consideration |

|---|---|---|

| Production Method | Efficient bulk production | Balance material feel vs. production speed |

| Material Quality | Long-lasting performance and control | Selection must match end-user usage |

| Customization Options | Tailored products for niche markets | Lead times may vary based on specifics |

| Pricing Strategy | Competitive rates with high manufacturing efficiency | Ensure volume discounts for large orders |

In today’s dynamic market, flexibility is key. NEX Pickleball offers custom paddle options that allow distributors and retailers to differentiate their product range. This includes personalized designs for team branding, unique weight distributions, and adjustable grip sizes for different player demographics.

Key Advantages:

- Brand Differentiation: Custom paddles can feature your company’s branding or special design elements that appeal to your target customers.

- Tailored Performance: Adjusting paddle weight and balance helps meet the specific needs of various playing styles—whether for enhanced power, control, or comfort.

- Market Positioning: Offering exclusive custom designed paddles can set you apart from competitors who distribute generic products.

Given these options, companies can better serve specialty markets such as sports clubs, high-end retail outlets, and competitive teams.

Quality control is a cornerstone of our manufacturing process. To guarantee the highest standards, each paddle undergoes a series of tests designed to simulate real-world play:

- Strength Testing: Ensures that the paddle withstands high impact and repeated play without degradation.

- Balance Tests: Verifies optimal weight distribution, crucial for control and performance.

- Material Integrity Tests: Confirms that composite materials, including carbon fiber and fiberglass composites, maintain their properties over time.

- Vibration Analysis: Reduces excessive vibration for a smoother play experience, protecting the player’s arm and improving accuracy.

These tests are conducted in a controlled environment, following strict guidelines to replicate the various stresses experienced during competitive play. The results are then used for continuous process improvements, giving our partners confidence in product reliability.

For B2B procurement managers evaluating manufacturing partners, several key action points should be considered:

-

Evaluate Production Capacity and Flexibility:

Ensure the manufacturer can handle large-scale orders while still offering customization to cater to your market demands. -

Analyze Material Choices:

Understand whether the paddle materials (e.g., 12K Carbon Fiber vs. E-Glass Fiberglass) align with your customers’ performance expectations. Consider that different materials offer varying levels of control, power, and durability. -

Assess Quality Control Processes:

Choose a partner who demonstrates rigorous testing and quality assurance protocols to ensure consistency across products. -

Consider Pricing Structures:

Look for manufacturers with competitive pricing that also offer volume discounts or tailored pricing strategies for bulk orders. -

Long-Term Partnership Potential:

Identify a manufacturer who not only excels in production capabilities but is also committed to innovation and continuous improvement. Establishing a long-term partnership with a reliable manufacturer like NEX Pickleball can provide a strategic advantage in a competitive market.

In conclusion, NEX Pickleball provides an excellent balance of advanced production techniques, quality materials, competitive pricing, and customizable options. By opting for our pickleball paddles, you secure a product that has been rigorously tested, continuously improved, and designed for the high demands of both competitive and recreational play.

People Also Ask

Q: What company makes the best pickleball paddles?

A: While numerous brands offer quality pickleball paddles, NEX Pickleball stands out due to its advanced production processes and rigorous quality control. Our paddles combine high-performance materials like carbon fiber and fiberglass with state-of-the-art production techniques, ensuring superior durability, precise control, and competitive pricing ideal for wholesale markets.

Q: Which pickleball paddles are not made in China?

A: Many well-known brands manufacture their paddles in the USA; however, NEX Pickleball is based in Jiaxing, Zhejiang, China and serves as a trusted manufacturer with expertise in producing high-performance paddles. Our focus is on superior production methods and quality assurance, which positions us as a reliable partner despite our manufacturing location.

-

hot pressing: Read more about how heating and pressing materials together creates a durable bond, ideal for high-volume manufacturing while maintaining structural integrity. Back ↩

-

cold pressing: Discover the precision of shaping materials without heat, preserving the natural material properties for a superior tactile experience. Back ↩

-

thermoforming: Learn how heating materials to a malleable state and molding them ensures intricate designs and uniform weight distribution in high-performance products. Back ↩

-

12K Carbon Fiber: Explore the technical specifications behind 12K Carbon Fiber, a material known for its smooth surface and enhanced durability, critical for high-impact sports equipment. Back ↩

-

Honeycomb Core Materials: Delve into the benefits of honeycomb core structures, offering superior shock absorption and vibration reduction, essential for maintaining performance in sports gear. Back ↩