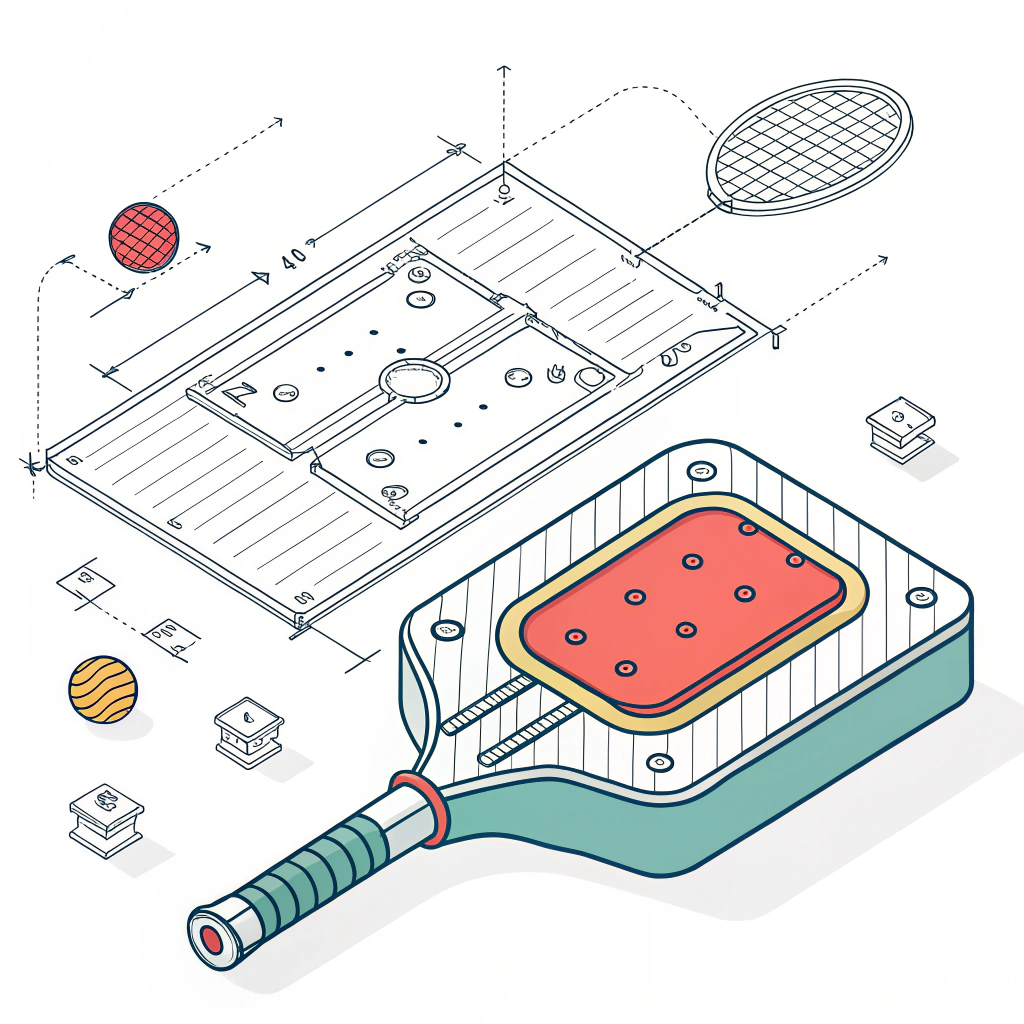

Investing in advanced tooling1 in pickleball paddle production is essential—it increases mold precision, improves production efficiency, and enhances overall product performance, delivering long-term ROI2 by reducing manufacturing errors and ensuring consistently high-quality paddles.

In today’s competitive sports equipment market, manufacturers face mounting pressure to produce pickleball paddles that meet high-performance standards while optimizing production costs. Traditional mold-making methods can lead to inconsistencies such as uneven surfaces, variable core density, and compromised material properties. These issues affect important factors such as paddle weight balance, vibration damping, and overall durability. For companies aiming to supply premium equipment, addressing these challenges early in the production process is imperative. Inefficient tooling may result in increased waste, rework, and delays that ultimately drive up costs and reduce customer satisfaction.

Several factors contribute to the challenges manufacturers face with pickleball paddle molds:

- Inconsistent Mold Precision: Variability in mold design or production can lead to differences in paddle shape and performance. This inconsistency affects players' experience, from grip comfort to balanced weight distribution.

- Production Efficiency: Outdated tooling methods may slow down production cycles. Techniques like hot pressing, cold pressing, and thermoforming3 require precise control over temperature, pressure, and timing to deliver consistent results.

- Material Properties: The selection of high-performance materials such as carbon fiber4 (3K, 12K, T300) or fiberglass has a direct impact on paddle behavior. Improper mold creation leads to weak bonding or uneven distribution of these premium materials.

- • Quality Control5 Gaps: Minor deviations during the manufacturing process can compound over a production run, resulting in increased rejects and diminished brand reputation.

Addressing these root causes through advanced tooling not only streamlines production but also secures a competitive edge in the market.

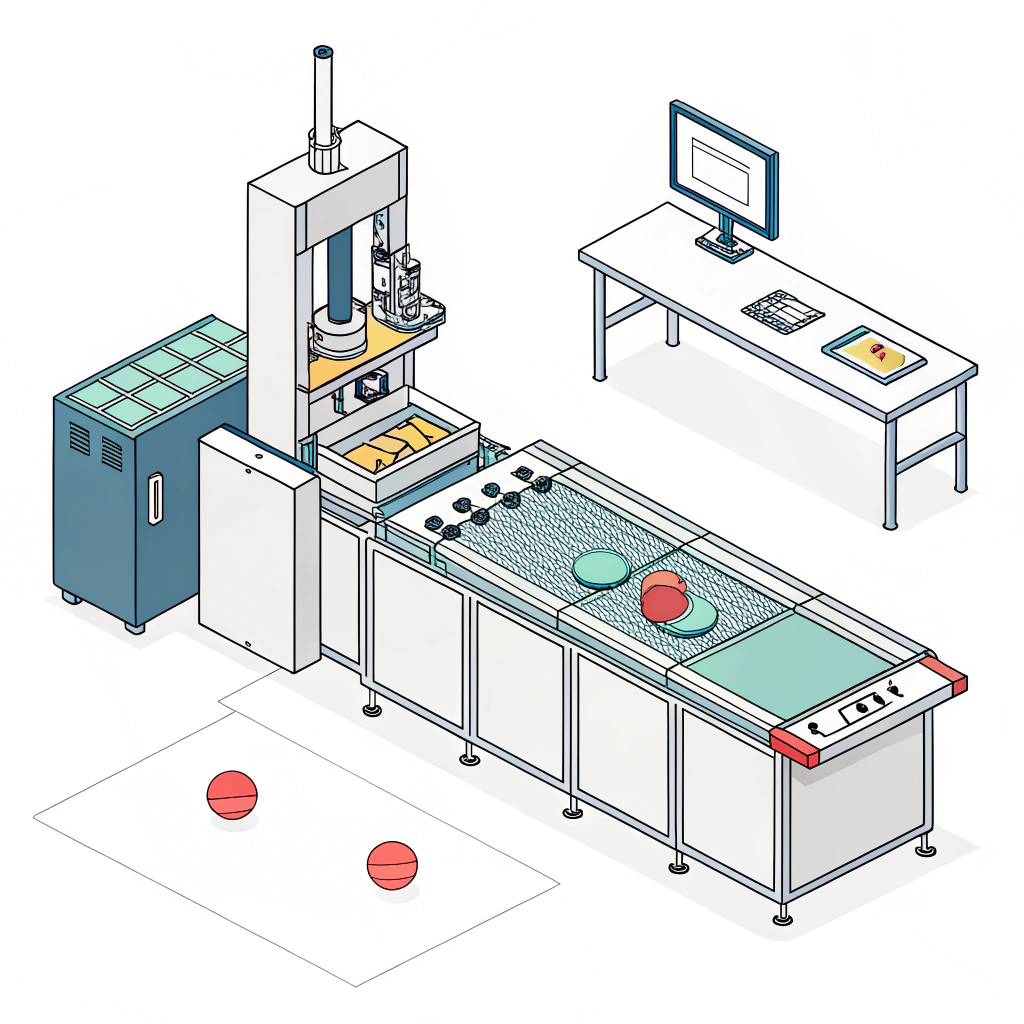

To combat these challenges, industry leaders invest in advanced tooling technologies that focus on precision manufacturing. These techniques can be classified broadly into three production processes:

-

Hot Pressing:

In hot pressing, materials are heated and subjected to high pressure. This accelerates the curing of the paddle components, resulting in increased strength and enhanced impact resistance.- Advantages:

- High production efficiency

- Structural integrity and durability

- Ideal for high-performance paddles

- Disadvantages:

- Requires significant capital investment in specialized equipment

- Potential alteration of material properties if not finely controlled

- Advantages:

-

Cold Pressing:

Cold pressing shapes the paddle material at room temperature, applying mechanical pressure to achieve precise control over thickness and structure. This method preserves the intrinsic properties of the materials, offering better control and responsiveness during play.- Advantages:

- Maintains material properties for superior control

- Enhanced ball feel and responsiveness

- Disadvantages:

- Slower production cycles due to longer curing times

- Demands high-quality pressure controls and precision equipment

- Advantages:

-

Thermoforming:

Thermoforming involves heating the material to a softening point before molding it into the desired shape using precision molds. This process is particularly effective for creating paddles with intricate designs and variable thicknesses.- Advantages:

- Allows for intricate design and precise material distribution

- Enhances paddle stability and performance

- Disadvantages:

- Requires prolonged production time

- Increased equipment and setup costs, making it best suited for premium or custom products

- Advantages:

To provide a clearer view, the following table summarizes these processes:

| Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structural integrity, durable paddles | High equipment cost, risk of altered material properties | High-performance, durable paddles |

| Cold Pressing | Precise control, preserved material properties, better ball feel | Slower production cycle, requires precise pressure control | Custom paddles, improved accuracy |

| Thermoforming | Intricate design capability, even material distribution, enhanced stability | Longer production time, higher setup costs | Premium or custom-made paddles |

This table illustrates that each process embodies a balance between speed, cost, and product performance. Manufacturers must assess their production volumes and product requirements to determine which process aligns best with their strategic needs.

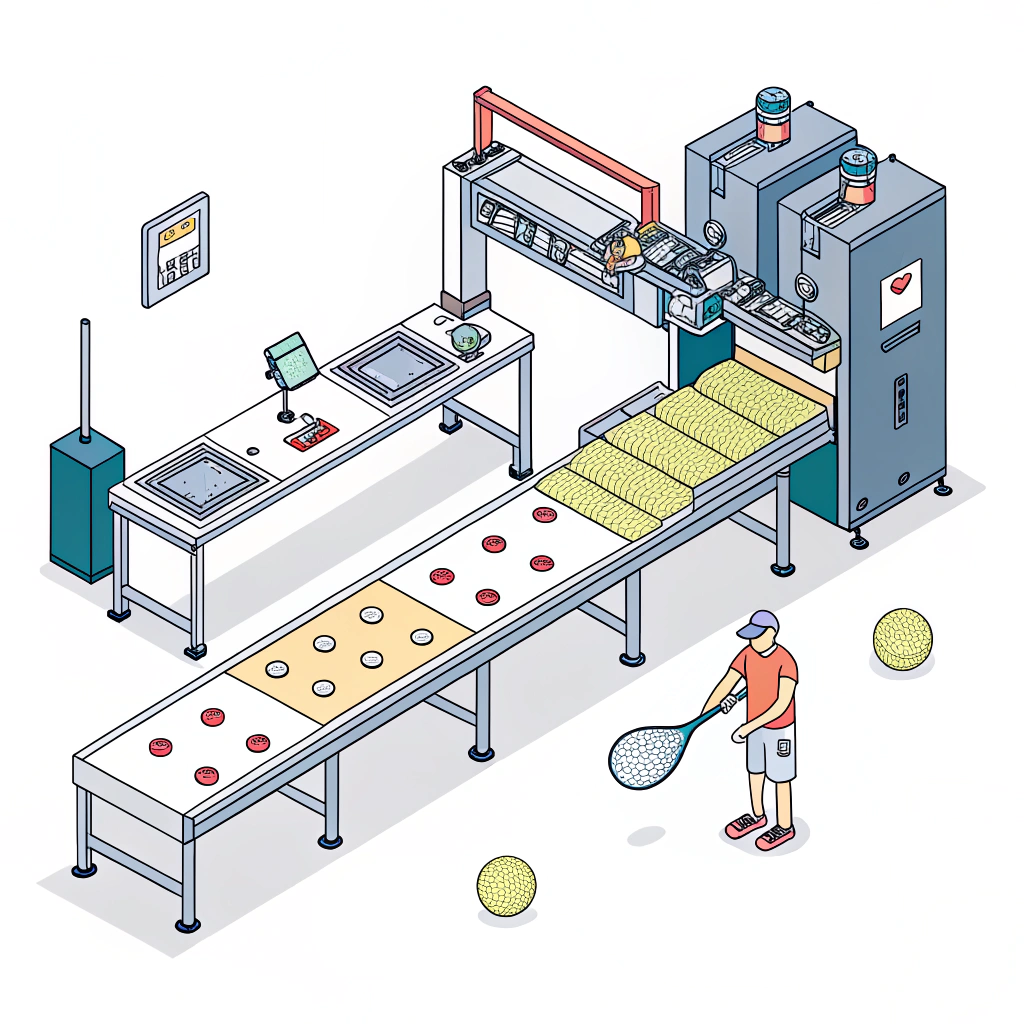

Advanced tooling not only improves production consistency but also translates into tangible business benefits:

-

Consistent Product Performance:

Enhanced precision in mold creation ensures that each paddle meets stringent quality standards. Consistency in paddle weight, balance, and rigidity increases customer satisfaction and competitive advantage, especially in a market where even slight imperfections can alter game performance. -

Reduced Production Waste:

Investment in better tooling minimizes the risk of defects. This directly reduces material wastage and the costs associated with rework or unsellable inventory. In turn, manufacturers can achieve a better ROI by avoiding unnecessary material and labor costs. -

Faster Production Cycling:

With the right advanced tooling, production run times decrease as high repeatability helps in automating quality control checks. Manufacturers can scale up output without sacrificing quality, meeting both market demand and tight delivery schedules. -

Improved Material Utilization:

The use of premium materials—such as various types of carbon fiber and fiberglass—depends heavily on proper tooling. Advanced setups ensure that the unique qualities of the material (like the tensile strength of T300 carbon fiber or the elasticity of E-Glass fiberglass) are fully utilized, resulting in paddles that offer excellent power and control.

For instance, when NEX Pickleball uses advanced hot pressing techniques in conjunction with precision molds, each paddle is engineered with optimal weight distribution and an enhanced ergonomic grip. This level of quality assurance not only elevates product performance but also reinforces customer trust in a highly competitive market.

Adopting advanced tooling methods involves several critical steps to ensure smooth integration into existing production lines. Manufacturers and product development managers should consider the following strategies:

-

Evaluate Current Production:

Conduct a thorough assessment of existing production processes to identify gaps in mold precision, material consistency, and quality control. This inventory is critical for selecting the appropriate tooling upgrade. -

Technology Alignment:

Choose advanced tooling methods that align with your product requirements. For high-volume production, hot pressing may offer the best ROI, while cold pressing might be ideal for custom or high-precision paddles. -

Invest in Training:

Equip your production teams with the knowledge and skills required to operate new equipment and manage advanced tooling processes. An initial investment in training helps to reduce errors and speeds up the adoption process. -

Continuous Monitoring and Quality Checks:

Implement robust quality control measures throughout the production process. Technologies like real-time monitoring and automated inspection help catch deviations early, ensuring long-term consistency and reliability. -

Supplier Collaboration:

Work closely with tooling suppliers who understand the specific needs of pickleball paddle production. A strong collaboration can result in customized solutions that are better tailored to your quality requirements and cost constraints.

Below is a checklist summarizing these implementation steps:

| Implementation Step | Key Focus | Expected Outcome |

|---|---|---|

| Evaluate Current Production | Identify production gaps and defect patterns | Clarity on areas for tooling improvement |

| Technology Alignment | Match process efficiency with product needs | Optimal process selection (e.g., hot vs. cold pressing) |

| Invest in Training | Train staff on new equipment and quality control | Reduced errors and smoother operations |

| Continuous Monitoring | Introduce real-time feedback and inspection systems | Maintenance of consistent product quality |

| Supplier Collaboration | Custom solutions from experts in advanced tooling | Cost-effective, tailored tooling investments |

Successful implementation of these strategies has proven effective in various industries. By leveraging advanced tooling, companies like NEX Pickleball have not only maintained high quality but also driven innovation in their production processes—ensuring that every paddle produced supports the performance expectations of both recreational players and competitive athletes.

NEX Pickleball’s adoption of advanced tooling technologies provides a clear example of how investment in mold precision can lead to substantial performance improvements. When the company integrated a combination of hot pressing and thermoforming, the following benefits were observed:

-

Enhanced Durability:

Paddles manufactured using advanced hot pressing techniques exhibited fewer structural inconsistencies and improved shock absorption. The robust mold precision directly contributed to extended paddle lifespans and better performance under high impact. -

Increased Production Efficiency:

The inclusion of automated monitoring systems reduced the rate of production errors by over 20%, which in turn reduced waste and increased the overall output. This allowed NEX Pickleball to meet rising market demands without compromising quality. -

Superior Material Utilization:

Precision in mold design ensured even distribution of premium materials such as 12K carbon fiber and E-Glass fiberglass. This precise integration allowed the paddles to achieve the perfect balance between power and control—a combination highly valued by players.

These improvements underscore the importance of aligning tooling investments with desired product outcomes. By continually refining their processes, NEX Pickleball demonstrates that advanced tooling is not merely an operational upgrade—it is a strategic investment in product excellence and market leadership.

Advanced tooling for pickleball paddle molds is a critical investment that directly affects product precision, durability, and overall performance. By understanding the challenges related to mold consistency, production efficiency, and material properties, manufacturing managers can select the right combination of hot pressing, cold pressing, and thermoforming techniques that align with their production goals.

Implementing these advanced techniques not only optimizes the manufacturing process but also enhances quality control and reduces long-term costs through minimized waste and rework. With robust training, supplier collaboration, and continuous monitoring in place, companies can ensure that each paddle meets the high-performance standards demanded by today’s competitive market. For decision-makers, embracing these investments means reaping benefits that extend from superior product quality to improved customer satisfaction and a clear competitive advantage.

People Also Ask

Q1: What makes pickleball paddles better?

A1: High-performance pickleball paddles feature design elements such as a well-balanced weight distribution, a consistent sweet spot, and advanced materials like carbon fiber and fiberglass. These paddles often incorporate features like elongated shapes, optimized core density, and ergonomic grips, ensuring improved feedback, enhanced control, and superior durability during play.

Q2: How to choose pickleball paddle material?

A2: When selecting pickleball paddle material, it is important to consider factors such as the paddle’s thickness, core consistency, and surface treatment. High-performance paddles usually use carbon fiber for its strength and light weight or graphite for better control and feel. Additionally, materials that include edge foam can offer increased stability and impact resistance, ensuring both power and comfort during play.

-

advanced tooling: Click to learn how investments in advanced tooling can streamline production processes, reduce errors, and enhance product quality for competitive advantage. ↩ ↩

-

ROI: Click to discover how a strong return on investment (ROI) is achieved through improved efficiency, decreased waste, and higher product quality. ↩ ↩

-

thermoforming: Click to explore the thermoforming process, its benefits in achieving intricate designs, and its role in advanced manufacturing. ↩ ↩

-

carbon fiber: Click to understand the properties of carbon fiber, its applications in high-performance paddles, and how it enhances product strength and durability. ↩ ↩

-

Quality Control: Click to read about quality control strategies that ensure consistency, reduce waste, and maintain high production standards. ↩ ↩