UV-resistant coatings1 are essential for extending the lifespan of outdoor pickleball paddles by protecting against harmful UV rays that can cause material degradation and impact performance.

Outdoor sports equipment, such as pickleball paddles, faces constant exposure to sunlight. Over time, UV rays can break down the structural integrity of paddle materials, resulting in reduced durability, compromised performance, and inconsistent ball response. In extreme conditions, this degradation may lead to surface cracks, color fading, and a loss in rebound capability. For procurement and product development managers, understanding how UV-resistant coatings improve outdoor durability is key to making informed decisions when selecting suppliers or upgrading product lines.

When pickleball paddles are left under the sun, the energy from ultraviolet light can initiate a process called photodegradation2. This process affects various components of the paddle:

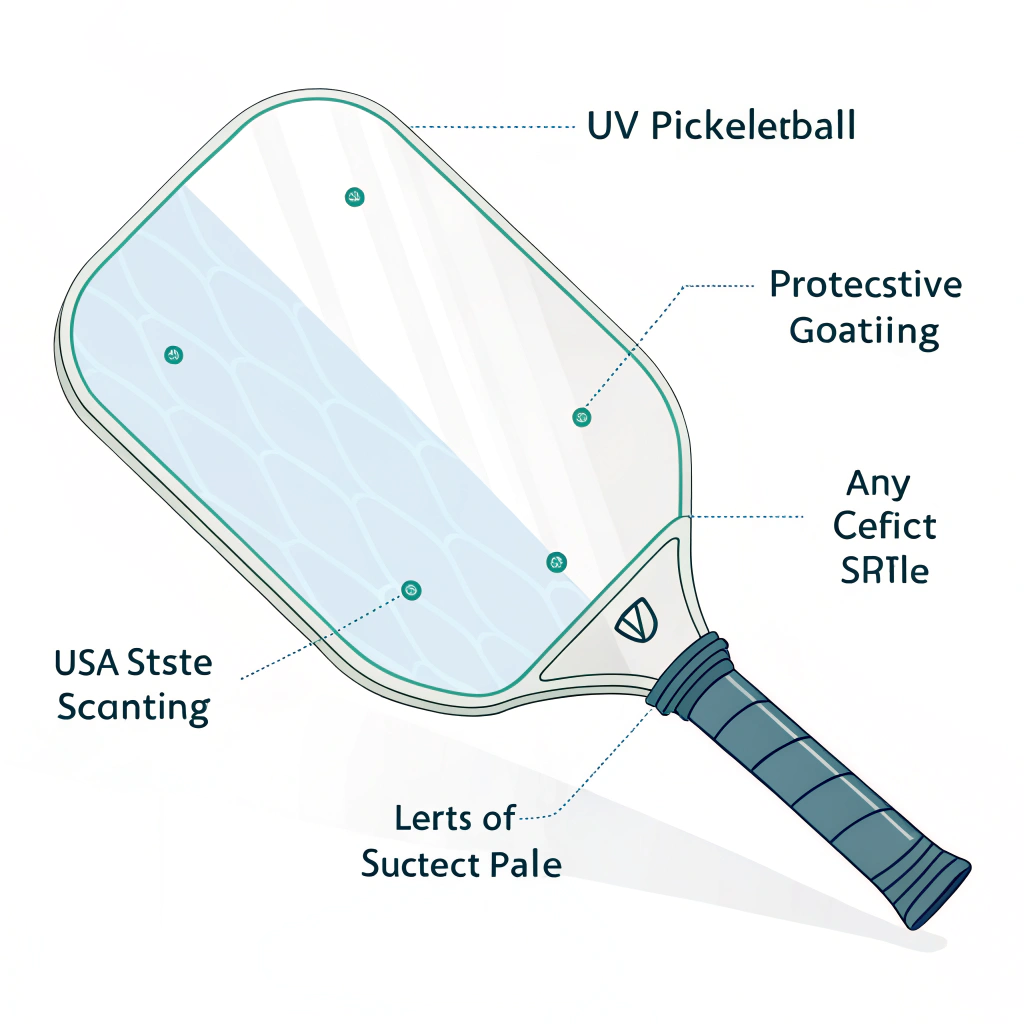

- Surface Treatments3: The protective films and coatings that enhance grip can break down, leading to reduced friction and control.

- Core Materials: Cores using materials like Nomex Honeycomb or Polymer may experience reduced shock absorption and even warping over time.

- Composite Layers: Manufacturers use different composite materials such as carbon fiber, fiberglass, or bamboo core composites. Continuous UV exposure may weaken the bond between these layers, affecting overall paddle performance.

Due to these risks, the implementation of UV-resistant coatings becomes a critical step in safeguarding the product’s longevity.

- Chemical Breakdown: UV rays can trigger chemical reactions in the paddle’s surface materials, causing a breakdown of molecular bonds. This deterioration may result in brittleness and reduced elasticity.

- Thermal Expansion & Contraction: Constant heating from the sun leads to expansion of the paddle’s material, and when temperatures drop, contraction occurs. This cycle strains the structure and may lead to micro-cracks.

- Fading and Aesthetic Damage: UV exposure can also affect the aesthetics of the paddle as colors fade, potentially diminishing brand appeal and perceived quality.

UV-resistant coatings act as a shield to mitigate the adverse effects of sunlight. These coatings are designed to absorb, reflect, or disperse UV radiation, preventing it from reaching the underlying material. Here’s how these coatings benefit pickleball paddles:

- Enhanced Durability: By preventing UV-induced degradation, coatings help maintain the paddle’s structural integrity even after prolonged outdoor exposure.

- Consistent Performance: A stable surface ensures that players enjoy reliable ball response, reducing the chances of unexpected performance drops mid-game.

- Color Retention: UV coatings preserve vibrant colors and graphics, ensuring that the product maintains its aesthetic appeal throughout its lifecycle.

- Cost-Effectiveness: Although the initial cost might be higher, the long-term benefits of reduced maintenance and fewer replacements justify the investment.

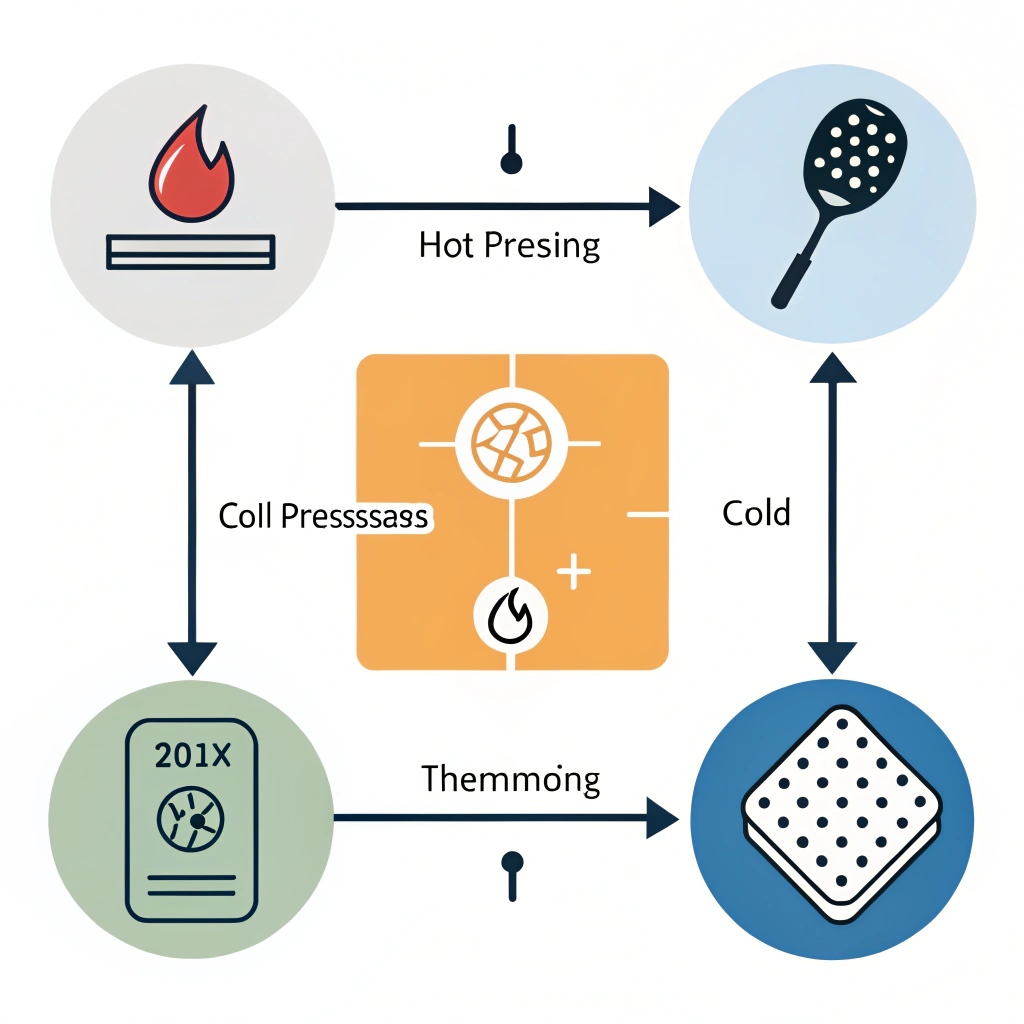

At NEX Pickleball, incorporating advanced surface treatments into the manufacturing process is standard practice, ensuring that each paddle delivers optimal performance under varying environmental conditions. The integration of UV-resistant coatings is carefully aligned with our precise production techniques:

- Advantages:

• High production efficiency

• Strong impact resistance

• Structural integrity maintained through heat treatment - Disadvantages:

• The heat may alter some sensitive material properties

• Requires significant equipment investment

Hot pressing can be optimized by first applying a UV-resistant coating prior to the pressing stage. The coating is designed to withstand the high temperatures, ensuring that the paddle retains both its enhanced durability and precise performance feel.

- Advantages:

• More precise control over paddle thickness

• Preservation of the original material properties

• Superior ball feel and responsiveness - Disadvantages:

• Longer production cycles

• Demands high-quality pressure control equipment

Cold pressing is ideal when the objective is to maintain the pristine characteristics of the base materials. In this process, the UV-resistant coating is tailored to bond effectively at room temperature, ensuring that the paddle’s core and composite layers remain protected without compromising the tactile feel.

- Advantages:

• Allows for intricate design and precise material distribution

• Enhances product stability through controlled shaping

• Suitable for premium, custom-made paddles - Disadvantages:

• Longer production times increase cost

• Requires higher equipment investments

Thermoformed paddles benefit from UV coatings that are applied post-formation. This ensures that any surface imperfections or areas prone to UV damage receive an extra layer of protection, thereby extending the paddle’s overall life.

Below is a table that summarizes the advantages and disadvantages of these processes when integrated with UV-resistant coatings:

| Production Process | Advantages with UV Coatings | Disadvantages |

|---|---|---|

| Hot Pressing | Efficient coating application, maintains stability | High temperature may affect coating integrity |

| Cold Pressing | Preserves natural material properties, enhanced control | Longer cycle times, precision equipment needed |

| Thermoforming | Perfect for complex designs, excellent for custom UV protection | Longer production time, higher costs |

When selecting or developing a UV-resistant coating, a few technical attributes are considered:

- Adhesion Quality: The coating must bond well with various substrate materials such as carbon fiber, fiberglass, or composite compounds.

- Elasticity and Flexibility: An effective UV coating should adapt to slight structural changes without cracking or peeling.

- Thickness and Coverage: Optimal thickness ensures consistent coverage without adding excessive weight, which could affect paddle balance.

- Environmental Durability: The coating must resist not only UV rays but also other weather elements like rain, humidity, and temperature fluctuations.

- Production Compatibility: The chosen coating should integrate seamlessly with existing processes (hot pressing, cold pressing, thermoforming) to minimize production delays.

Proper engineering of these parameters significantly improves the paddle's performance and lifespan, thereby providing manufacturers with a competitive edge in the sports equipment market.

Implementing UV-resistant coatings in manufacturing offers several tangible benefits:

- Long-Term Cost Savings: Reduced need for replacements and lower maintenance costs contribute to overall cost-effectiveness.

- Enhanced Player Experience: Consistent performance and reliability mean players can trust their equipment under various outdoor conditions.

- Brand Integrity: For manufacturers and retailers, longevity and consistent aesthetics uphold the brand’s reputation and customer confidence.

- Customization Capabilities: Today’s coatings can be customized to offer additional benefits, such as antibacterial properties or enhanced tactile grip, further enhancing product differentiation.

- Environmental Impact: Durable products reduce waste and support sustainable production practices by lowering the overall frequency of product disposal and remanufacturing.

Industry data consistently show that products treated with advanced UV coatings report fewer customer complaints related to weather-induced wear and tear. This insight is particularly crucial for procurement managers looking to invest in reliable, high-performance equipment.

For businesses considering the adoption of UV-resistant coatings, the following guidelines can help maximize the benefits:

- Select the Right Coating Formula: Partner with experienced manufacturers who understand the specific demands of outdoor sports equipment. Ensure the UV coating is compatible with the chosen core and composite materials.

- Optimize Production Processes: Integrate the coating step into your chosen production process to maintain efficiency. For instance, if using thermoforming, apply the coating post-formation to ensure full coverage without compromising design details.

- Regular Quality Testing: Implement rigorous testing protocols to assess the coating’s performance under simulated outdoor conditions. Evaluate parameters such as adhesion, elasticity, and color retention.

- Educate End Users: Provide detailed care instructions for end users to minimize potential UV exposure. For example, advising players to avoid leaving paddles in direct sunlight during extended periods can significantly extend product life.

- Monitor Market Trends: Stay updated on advancements in coating technologies. Continuous improvements in formulation can offer additional benefits such as enhanced scratch resistance or improved ergonomic feel.

These steps, when followed diligently, can result in superior product durability and an improved competitive edge in the sports equipment market.

At NEX Pickleball, our dedication to innovation is at the forefront of our manufacturing process. Our advanced UV-resistant coatings are a direct response to the technical challenges posed by outdoor usage. By blending traditional manufacturing techniques such as hot pressing, cold pressing, and thermoforming with state-of-the-art surface treatment technologies, we ensure that every paddle offers exceptional performance under diverse weather conditions.

Our manufacturing team constantly refines production parameters to ensure:

- Maximum UV stability without compromising the paddle’s lightweight and responsive design.

- Uniform coating application that guarantees full coverage across all paddle surfaces.

- Sustainable practices that reduce material waste and conserve resources.

The result is a product that not only meets but exceeds global standards for outdoor durability. Our commitment has earned us partnerships with industry leaders like Joola and Selkirk, and continues to drive our reputation as a trusted partner in high-performance pickleball paddle manufacturing.

To sum up, integrating UV-resistant coatings in the manufacturing of outdoor pickleball paddles is a strategic investment that enhances product durability, maintains consistent performance, and improves overall customer satisfaction. By understanding the underlying causes of UV degradation and how advanced production techniques can mitigate these effects, procurement and product development managers can confidently select the right manufacturing partner for their needs.

As outdoor sports equipment continues to face harsh environmental conditions, prioritizing advanced UV protection measures is not just a luxury but a necessity for maintaining competitive advantage in the market. We encourage you to consider these technical insights when evaluating potential suppliers or upgrading your product lines to ensure that your equipment stands up to the challenges of everyday play.

Q: Is it bad to leave my pickleball paddle in the sun?

A: Prolonged exposure to direct sunlight can cause expansion and contraction in paddle materials, leading to potential micro-cracks and degraded performance. Manufacturers generally advise keeping paddles out of extreme temperatures when possible.

Q: How long do thermoformed pickleball paddles last?

A: With proper care and regular maintenance, thermoformed pickleball paddles can last several years due to their robust construction and advanced material distribution techniques.

Q: Which material is better for pickleball paddles?

A: The best material depends on the desired playing style. Graphite (or high-performance carbon fiber) typically offers superb handling and feel, whereas fiberglass often provides greater power due to its flexibility.

-

UV-resistant coatings: Read this article to learn how specialized coatings protect outdoor equipment from harmful UV light, extending product life and reducing maintenance costs. Back to UV-resistant coatings ↩

-

Photodegradation: Click here to understand the UV-induced chemical breakdown processes that compromise material durability and affect product performance. Back to Photodegradation ↩

-

Surface Treatments: Discover how advanced surface treatments enhance material properties, improve grip, and provide resistance against environmental wear. Back to Surface Treatments ↩

-

Hot Pressing: Learn about the hot pressing process that uses heat and pressure to shape and stabilize materials efficiently in manufacturing. Back to Hot Pressing ↩

-

Thermoforming: Explore the thermoforming process and its benefits in molding composite materials for custom and complex product designs. Back to Thermoforming ↩