In today’s competitive global market, choosing China as your manufacturing partner for pickleball paddles provides access to advanced production technology, rigorous quality control, and significant cost efficiency. This article details how innovative techniques like hot pressing1, cold pressing2, and thermoforming3 contribute to producing high-performance paddles. It also compares production processes and outlines why a reliable partner like NEX Pickleball—a trusted OEM4 for brands such as Joola and Selkirk—is positioned to meet your B2B sourcing needs.

Our industry faces a dual challenge: meeting the demand for state-of-the-art pickleball equipment while keeping production costs sustainable. As a senior procurement or product sourcing manager, you understand that combining innovation with reliability is essential. Manufacturers in China leverage advanced production techniques to offer the performance, durability, and customization needed to support leading pickleball brands. This article unpacks the reasons behind China’s manufacturing leadership and provides an in-depth look at the advanced processes shaping the industry.

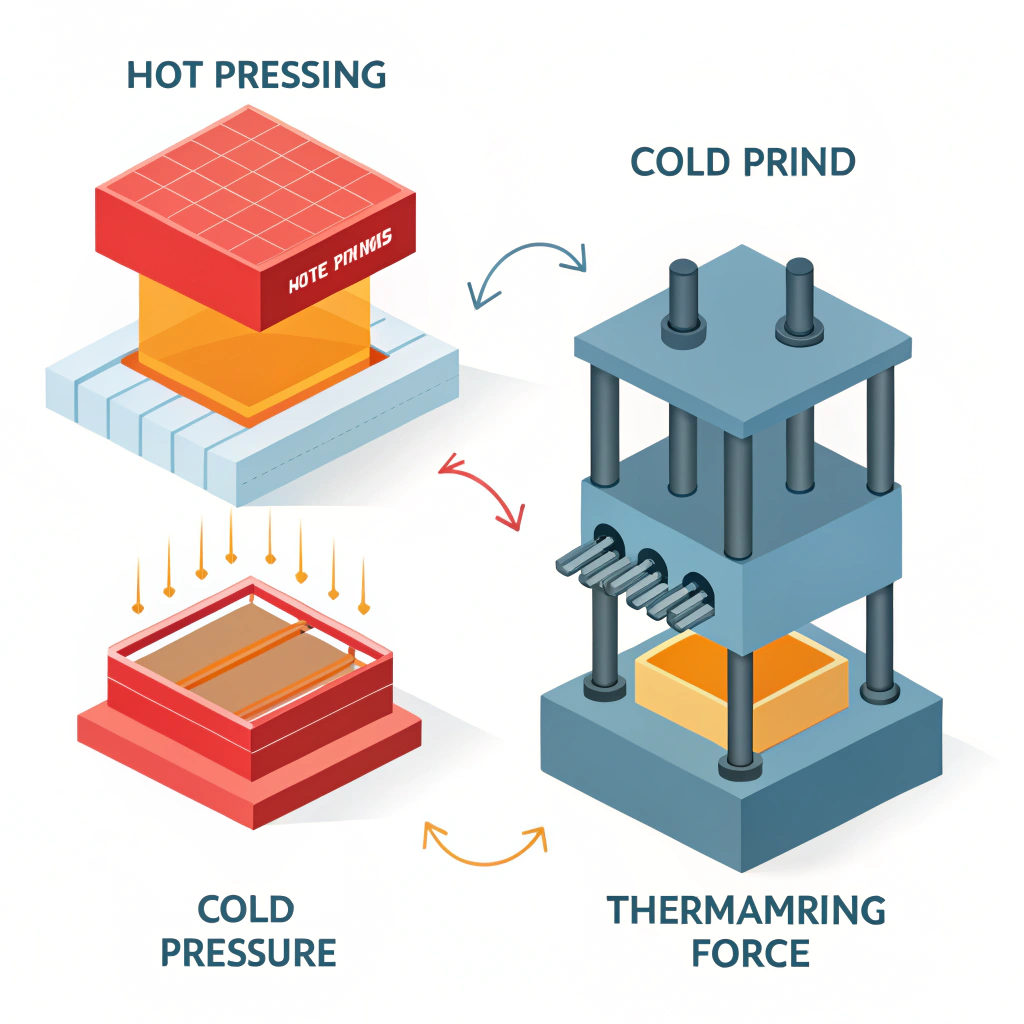

Three core manufacturing processes underpin the high-quality production of pickleball paddles at NEX Pickleball: hot pressing1, cold pressing2, and thermoforming3. Each process has its unique advantages and limitations, which collectively ensure that every paddle performs across different playing levels.

Hot pressing involves heating materials to a controlled temperature and applying pressure to form the paddle. This process is widely recognized for producing durable paddle faces with superior impact resistance.

• Advantages:

- High production efficiency ideal for large-scale manufacturing

- Creates strong, durable paddles with excellent shock absorption

- Maintains structural integrity through uniform heat application

• Disadvantages:

- Can alter some material properties, slightly changing the paddle’s feel

- Requires significant investment in high-end equipment

Cold pressing utilizes mechanical pressure at room temperature, enabling manufacturers to retain the natural properties of the materials used in paddle construction. This method allows for precise control over thickness and structure, essential for producing paddles with enhanced control and responsiveness.

• Advantages:

- Provides precise control over paddle dimensions and properties

- Maintains optimal material characteristics for improved responsiveness

- Yields paddles with excellent ball feel and ergonomic grip

• Disadvantages:

- Longer production cycles compared to hot pressing

- Requires high-precision equipment to ensure consistency

Thermoforming involves heating the material until it softens and then shaping it within a mold. This process is ideal for paddles with intricate design patterns and advanced customizations. It allows for optimal material distribution, which enhances paddle stability and performance.

• Advantages:

- Enables the creation of paddles with complex designs and precise material layering

- Improves product stability while maintaining lightweight construction

- Suitable for a wide range of high-performance materials

• Disadvantages:

- Longer production times can increase overall manufacturing costs

- Higher dependency on sophisticated machinery for quality control

To help you quickly compare these processes, the following table highlights their key pros and cons:

| Production Process | Key Advantages | Main Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong structure, excellent impact resistance | Potential alteration of material feel; high equipment cost |

| Cold Pressing | Precise control, retains material’s natural properties, superior ball feel | Longer production cycle; requires precision equipment |

| Thermoforming | Enables complex designs; optimal material distribution; high stability | Extended production times; increased equipment investment |

A key factor when considering manufacturing partnerships is quality control. NEX Pickleball employs stringent testing protocols to verify that every paddle meets the highest industry standards. These quality checks not only confirm optimum durability and performance but also ensure consistency across large production volumes—a critical factor for global brands.

Customization is another significant advantage offered by our production processes. Clients can specify design parameters such as paddle weight, balance, grip size, and even surface texture. With custom production options, your brand can:

• Tailor paddles to specific player needs and performance requirements

• Enhance player comfort and control through ergonomic design options

• Differentiate your product offerings in a competitive marketplace

This level of customization is essential if your brand aims to address both recreational players and elite athletes. Moreover, combining multiple advanced materials—such as 3K, 12K, and T300 carbon fiber, fiberglass, and composite materials—allows for a finely tuned balance between power and control.

One of the prime reasons for sourcing manufacturing from China is the inherent scalability5 that Chinese manufacturers offer. With industry-leading facilities and a robust supply chain, partners like NEX Pickleball can scale production rapidly while maintaining quality. This scalability is particularly crucial when market demand surges, allowing brands to efficiently manage inventory without sacrificing performance.

The cost benefits of using advanced production techniques in China cannot be overstated. Efficient processes such as hot pressing deliver high volumes at lower unit costs. Furthermore, the combination of cost-effective labor, access to high-quality raw materials, and advanced production facilities leads to a favorable cost-benefit ratio. Decision-makers can thus enjoy reduced overheads while still delivering high-performance equipment to end-users.

The selection of materials is a cornerstone of paddle performance. At NEX Pickleball, we utilize several premium materials to ensure that every paddle delivers exceptional gameplay experience:

-

Carbon Fiber Varieties:

- 3K Carbon Fiber: Strikes an ideal balance between strength and flexibility, perfect for high rebound force and reduced vibration.

- 12K Carbon Fiber: High thread density translates to superior hardness and durability, especially suitable for competitive play.

- T300 Carbon Fiber: Offers excellent tensile strength with balanced performance and light weight. -

Fiberglass:

- E-Glass Fiberglass: Provides elasticity and superior ball control, making it a popular choice for paddles requiring a wider sweet spot. -

Composite Materials:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials for balanced performance.

- Bamboo Core Composite: Lightweight and impact-resistant, it offers a clear hitting feel.

- Honeycomb Core: Utilizes high-density polymers or pulp to absorb shocks and diminish vibrations. -

Core Materials:

- Nomex Honeycomb Core: Known for its durability and shock absorption.

- Aluminum Honeycomb Core: Balances weight while offering both power and control.

- Polymer Honeycomb Core: Provides elasticity and reduced vibrations, ensuring a more comfortable playing experience.

Emphasizing these materials in your product specifications can help you create a unique value proposition, whether you are targeting elite professionals or recreational users. The right material and production process can significantly enhance ball control, power, and overall playability.

Efficient manufacturing processes are underpinned by continuous process optimization. In our facilities, precision and consistency are maintained through advanced techniques and rigorous quality management systems. Our commitment to excellence includes:

• Regular calibration of machinery to maintain strict tolerance levels

• Detailed inspection protocols at every production stage

• Incorporation of innovative materials that meet evolving market demands

A strategic approach to process optimization not only reduces production errors but also minimizes waste, thereby driving down costs and improving overall product quality. For procurement managers, these efficiencies translate into predictable production timelines and lower risk, which are highly valuable in large-scale rollouts.

Consider a scenario where a well-known pickleball brand sought to expand its product line into high-performance paddles designed for competitive play. The brand struggled with meeting increasing market demands while maintaining high-quality standards. By partnering with a Chinese OEM that utilized advanced production techniques, the brand was able to:

- Scale production through efficient hot pressing methods while maintaining material integrity.

- Enhance paddle ergonomics and player control using cold pressing, leading to a noticeable improvement in gameplay performance.

- Introduce complex paddle designs through thermoforming, achieving a distinct market differentiation.

The brand reported a reduction in production costs by 15% and an increase in product consistency, which bolstered consumer trust and brand reputation. Such success stories underline the importance of selecting the right manufacturing partner who understands both advanced production processes and the nuances of the pickleball market.

As you evaluate sourcing options for pickleball equipment, here are some actionable steps to guide your decision-making process:

-

Assess Production Capabilities:

- Request detailed process flow charts and quality control certifications from potential manufacturers.

- Verify the manufacturer’s ability to handle large-scale production through robust supply chain logistics. -

Evaluate Material Quality and Customization Options:

- Ensure the manufacturer offers a variety of high-quality materials including latest carbon fiber variants, fiberglass, and composites.

- Determine if customization options align with your product requirements for ergonomic design and specific performance criteria. -

Compare Cost-Efficiency and Scalability:

- Analyze the cost breakdown for different production processes.

- Prioritize manufacturers with flexible and scalable operations that can quickly adapt to changes in market demand. -

Review Quality Assurance Protocols:

- Confirm that the manufacturer adheres to international quality standards.

- Look for evidence of continuous process improvement and regular product testing. -

Consider Long-Term Partnership Potential:

- Evaluate the manufacturer’s track record in achieving timely deliveries and consistent quality.

- Prioritize OEM partners with a strong reputation in the global pickleball market.

Choosing a manufacturing partner in China for pickleball paddles offers a strategic advantage through advanced production techniques, premium material selection, and an unwavering commitment to quality. Whether you lean towards hot pressing for efficient mass production, cold pressing for precision, or thermoforming for sophisticated designs, reliable partners like NEX Pickleball have the expertise to support your brand’s growth. With scalable operations, cost-effective processes, and customizable production options, aligning with leading Chinese manufacturers will not only meet current market demands but also set the stage for future innovation in pickleball equipment.

By following the actionable recommendations detailed above, your sourcing decisions will be bolstered by a deep understanding of manufacturing processes and a clear insight into cost-benefit dynamics. This strategic approach will ensure that your brand continues to deliver high-performance products, ultimately translating into elevated market competitiveness and consumer satisfaction.

People Also Ask

Q: What is the best Chinese pickleball brand?

A: While there are several reputable brands, DinkPickleball is often cited as a leading Chinese manufacturer known for its high-quality materials, durability, and performance, making it a trusted choice among top players and sports organizations.

Q: Are most pickleball paddles made in China?

A: Yes, the majority of pickleball paddles are manufactured in China because the country offers a robust supply chain, advanced manufacturing techniques, and cost-effective production processes that support a wide range of paddle brands.

Q: What is the best pickleball paddle manufacturer?

A: Leading manufacturers in the global market include brands like Joola, Selkirk, CRBN, and Gearbox. These companies offer premium paddles designed with a variety of shapes, sizes, and materials to suit both competitive players and recreational enthusiasts.

-

hot pressing: Reading this article will help you understand the hot pressing process—a manufacturing technique that utilizes heat and pressure to form strong, durable components while optimizing production efficiency. ↩ ↩ ↩2

-

cold pressing: Reading this article will help you grasp the cold pressing process—a method performed at room temperature to preserve material properties and enable precise dimensional control for enhanced product performance. ↩ ↩ ↩2

-

thermoforming: Reading this article will help you explore the thermoforming process—a technique where materials are heated to soften and then molded into complex, customized designs that enhance product functionality. ↩ ↩ ↩2

-

OEM: Reading this article will help you understand the role of an Original Equipment Manufacturer (OEM) in providing high-quality, reliable production services that meet specific industry standards and brand expectations. ↩ ↩

-

scalability: Reading this article will help you comprehend scalability in manufacturing—a key factor that allows production processes to adjust quickly to market demands while maintaining efficiency and quality. ↩ ↩