Partnering with a specialized pickleball manufacturer is the quickest way for small pickleball brands to scale rapidly while ensuring high performance, durability, and customization. In today’s competitive sports equipment market, a reliable manufacturing partner not only delivers consistent quality but also drives innovation in design and production techniques. This article provides a detailed comparison of manufacturing capabilities and production processes, showcasing how NEX Pickleball can be your ideal OEM1 partner for creating high-performance pickleball paddles.

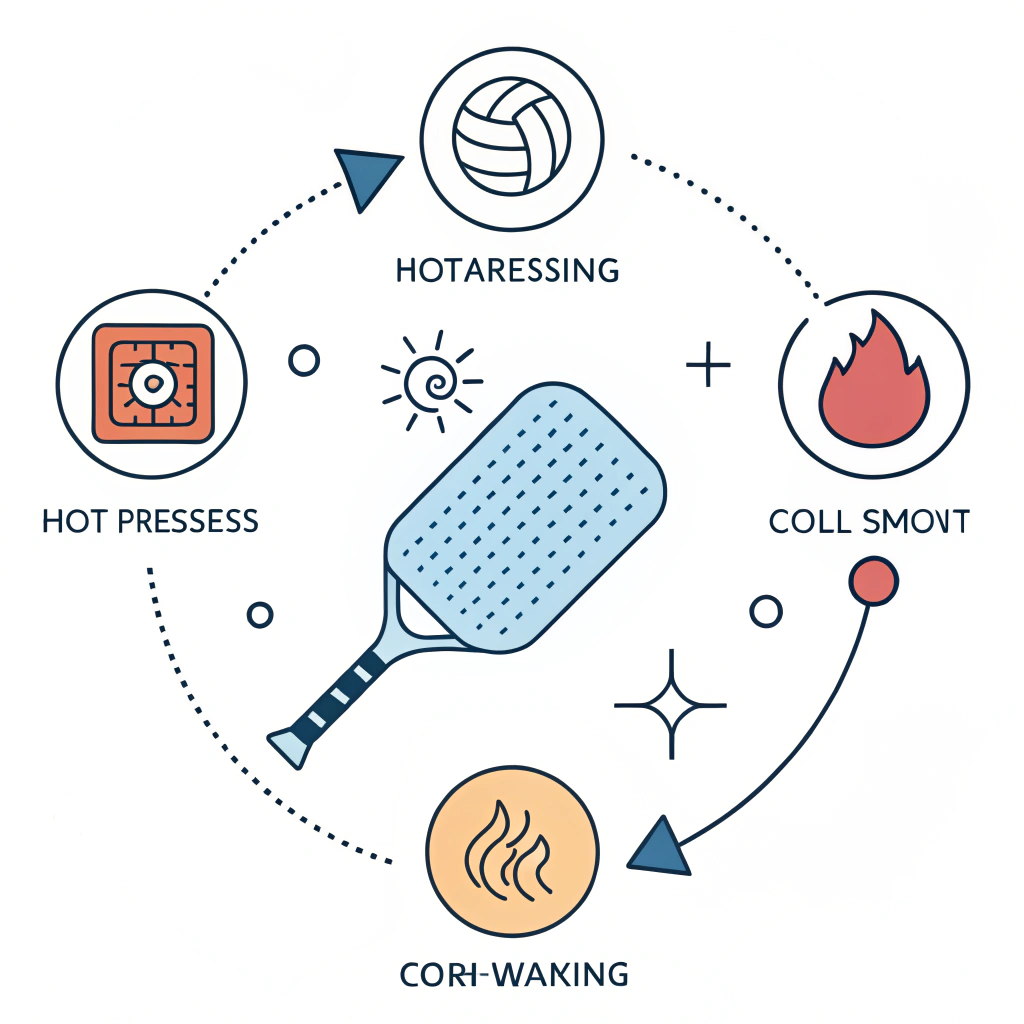

In the dynamic world of pickleball, establishing a strong brand is essential for success. As a decision-maker at a small pickleball brand, you face the challenge of limited manufacturing resources coupled with the need to offer cutting-edge products. You must evaluate potential partners who combine technology, material expertise, and efficient production processes. At NEX Pickleball, we provide a robust solution with advanced production techniques such as hot pressing, cold pressing2 and thermoforming3, along with a diverse range of premium materials like carbon fiber, fiberglass, and composite cores.

Modern pickleball paddles are integral to the player’s performance and overall game experience. As brands look to differentiate themselves, the focus has shifted toward the technical innovations and material choices used in paddle construction. With increasing competition from established names like Joola, Selkirk, and others, partnering with an experienced OEM manufacturer becomes the strategic step forward for small brands aiming to gain a competitive edge.

- Quality Consistency: Ensuring that each paddle performs at the highest level under various playing conditions.

- Production Efficiency: Balancing high-volume production with the ability to customize designs for niche market needs.

- Technological Innovation: Implementing advanced production processes that maintain material integrity and enhance paddle performance.

- Cost-effectiveness: Keeping production costs reasonable without compromising on quality or durability.

For small brands looking to grow, these challenges underscore the importance of selecting a manufacturing partner who can offer not only technical prowess but also strategic insights into market trends and manufacturing innovations.

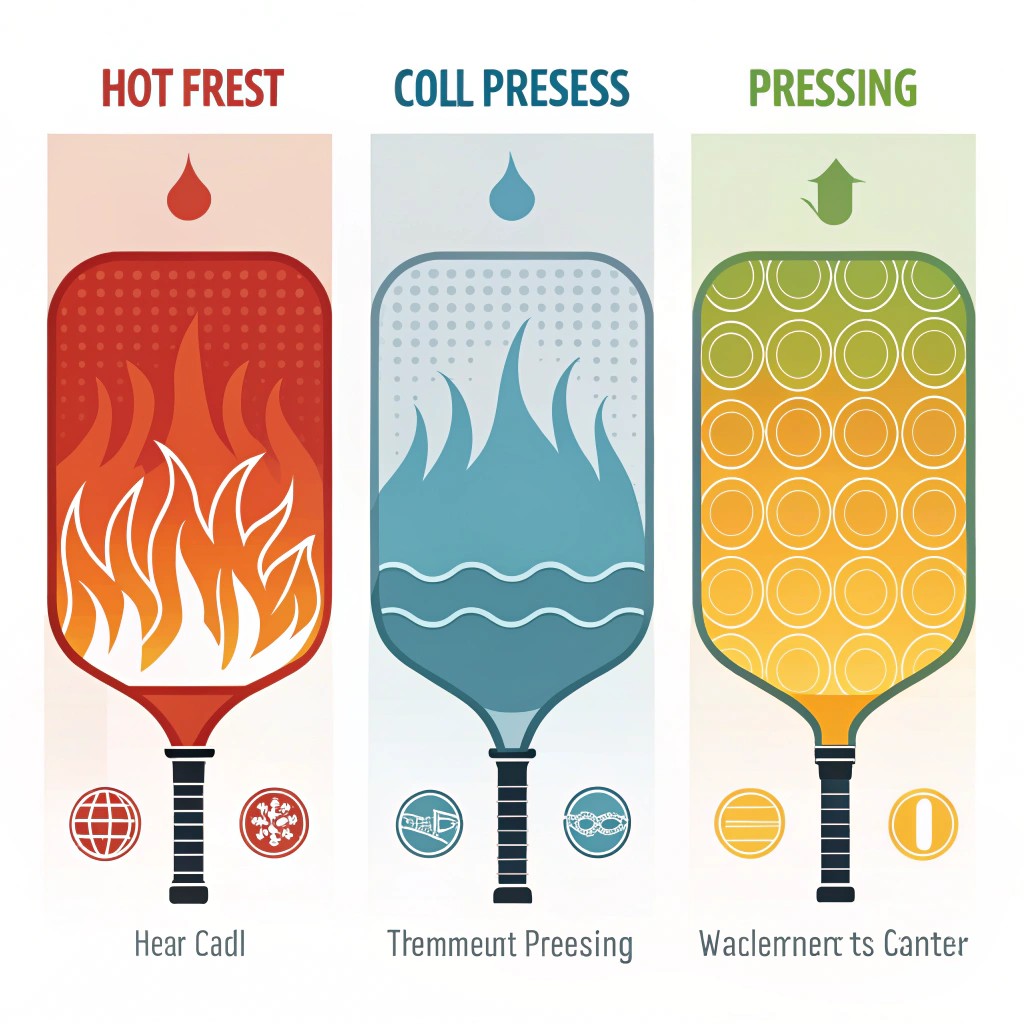

Successful paddle production involves multiple stages where each production process adds distinct advantages. NEX Pickleball employs three main production techniques. Below is a comparative table that details each method and highlights its key features:

| Production Method | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Produces strong and durable paddles - Excellent impact resistance | - Potential alteration of material properties - Requires high investment in specialized equipment |

| Cold Pressing | - Precise control over paddle thickness and structure - Maintains the material’s natural properties - Offers excellent ball feel and responsiveness | - Longer production cycles - Demands high accuracy and quality control equipment |

| Thermoforming | - Ideal for creating complex designs - Ensures uniform material distribution - Enhances paddle stability and performance | - Longer production time - Higher equipment and operational costs |

This table clearly lays out how each method offers distinct advantages depending on your brand’s product positioning and performance requirements. Understanding these differences is vital when selecting a manufacturing partner as it helps align your brand strategy with the technical capabilities needed to deliver quality products.

Alongside production techniques, the choice of raw materials plays a pivotal role in the performance, durability, and overall feel of pickleball paddles. NEX Pickleball leverages a variety of premium materials to cater to different performance needs and playing styles:

Carbon Fiber4 Innovations

- 3K Carbon Fiber: Known for its strength and flexibility, the 3K variant is excellent for paddles that require a high rebound force. It minimizes vibration and offers outstanding durability.

- 12K Carbon Fiber: With a higher thread density, 12K provides a smoother surface and enhanced impact resistance, making it ideal for competitive play.

- T300 Carbon Fiber: This high-performance carbon fiber balances strength with lightweight properties, ensuring optimal performance during fast-paced games.

- E-Glass Fiberglass: Offers excellent elasticity and tensile strength, providing a broad sweet spot and control during play.

- Carbon Fiber and Fiberglass Composite: Combines the advantages of both materials to create paddles that are light yet powerful.

- Bamboo Core Composite & Honeycomb Core: With superior shock absorption and longevity, these core materials provide a clear hitting feel and reduced vibration.

The myriad of material choices allows brands to prioritize either durability, control, or power, depending on their target market. Emphasizing these materials in your product line can make a significant difference in how players perceive and perform with your paddles.

For small brands seeking to scale, customization is key to building a strong market presence. OEM partnerships with manufacturers like NEX Pickleball enable brands to access a wide range of customization options without the burden of in-house production. Custom paddle options include choices in design, weight distribution, balance, and grip sizes, allowing brands to tailor products to specific player needs.

- Speed to Market: Outsourcing manufacturing ensures faster production cycles and streamlined supply chains.

- Brand Differentiation: Customized paddles with exclusive designs and colors help establish a unique brand identity.

- Cost Efficiency: Avoiding high capital expenditure in setting up manufacturing facilities reduces overall costs.

- Quality Assurance: Partnering with an experienced manufacturer guarantees adherence to stringent quality control standards through advanced testing protocols.

OEM partnerships also open up opportunities for on-demand production, ensuring that brands can react rapidly to market trends and customer feedback. This agility translates into a competitive advantage in a market that is continuously evolving.

Consider the success story of a small pickleball brand that partnered with an OEM manufacturer to revamp their product line. Facing stiff competition from established brands, the company focused on delivering high-performance paddles with an emphasis on advanced material composition and precision manufacturing. By switching to a hybrid production technique that combined the advantages of cold pressing with thermoforming, their paddles achieved a superior balance of weight and vibration control.

Key outcomes from this partnership included:

- A significant reduction in production defects due to rigorous quality control.

- Enhanced product performance that led to improved customer satisfaction and brand loyalty.

- The ability to quickly iterate designs based on market feedback, thus staying ahead in product innovation.

- Competitive pricing through efficient large-scale manufacturing, enabling them to invest more in marketing and further brand expansion.

This case proves that strategic OEM partnerships can drive growth and operational excellence, making it clear that technology and innovation in manufacturing are not just add-ons but central to a brand’s success in the competitive landscape of sports equipment.

When evaluating potential manufacturing partners, consider the following guidelines to ensure alignment with your brand’s growth objectives:

-

Assess Production Capabilities:

- Evaluate the manufacturer’s experience with advanced production techniques.

- Look at their ability to reliably use different materials such as carbon fiber and fiberglass.

- Consider the scalability of their production process for long-term brand growth.

-

Review Customization Options:

- Ensure that the manufacturer offers flexible customization to accommodate unique design requirements.

- Check for options related to grip sizes, core materials, and paddle weight adjustments.

- Confirm the availability of on-demand print services for personalized branding.

-

Examine Quality Control Measures:

- Inquire about the rigorous testing protocols they use to maintain consistency.

- Look for certifications and quality awards that demonstrate their commitment to excellence.

- Assess the manufacturer’s responsiveness to customer feedback and quality issues.

-

Consider Cost and Efficiency:

- Analyze the cost-effectiveness of their production processes.

- Evaluate potential trade-offs between production speed and long-term durability.

- Ensure there is transparency in pricing and any additional costs related to customization.

-

Evaluate Industry Expertise:

- Prefer partners with a proven track record of working with well-known brands.

- Review case studies, success stories, or testimonials from current or previous partners.

- Understand their strategic vision and how it aligns with your brand’s goals.

By following these guidelines, you can confidently select a partner who will not only produce high-quality OEM pickleball paddles but also drive your brand’s market presence and profitability.

In summary, selecting the right manufacturing partner is a critical decision for small pickleball brands aiming for rapid growth and competitive differentiation. NEX Pickleball stands out due to its advanced production techniques—including hot pressing, cold pressing, and thermoforming—and its adoption of premium materials such as carbon fiber, fiberglass, and various composite cores5.

Key takeaways for decision-makers:

- Quality and Innovation: Invest in products that emphasize advanced materials and precise production processes.

- Customization and Flexibility: Leverage OEM capabilities for tailored product designs that elevate your brand identity.

- Economies of Scale and Efficiency: Ensure that your partner supports scalable production with robust quality control.

- Strategic Market Positioning: Use detailed manufacturing comparisons and case studies as the backbone for your strategic purchasing decision.

For brands eager to transform their vision into high-performance products while maintaining cost-effectiveness and operational efficiency, partnering with an experienced pickleball manufacturer like NEX Pickleball is a winning strategy. We invite you to explore how our manufacturing capabilities can help propel your brand forward in a highly competitive market.

People Also Ask

Q: What is the marketing strategy of pickleball?

A: Effective pickleball marketing involves a mix of digital advertising strategies, including Google ads to target high-intent audiences and social media platforms like Facebook, Instagram, and YouTube to reach a broad base of enthusiasts.

Q: Which brand is the best for pickleball?

A: While several reputable brands such as Joola, Selkirk, CRBN, and Gearbox offer premium paddles with varying features, the best choice often depends on your specific needs in terms of paddle performance and customization options.

Q: What is the fastest pickleball brand?

A: Some brands focus on speed and performance, with products like the ONIX Dura-Fast 40 pickleballs built specifically for optimized game speed; however, the ideal selection varies according to the player’s style and performance requirements.

-

OEM: Click here to read about Original Equipment Manufacturer partnerships, which explain how leveraging third-party manufacturing can drive scalability, cost efficiency, and access to advanced technology. ↩

-

cold pressing: Click here to learn about the cold pressing process—a manufacturing technique that preserves material integrity while achieving precise control over product dimensions. ↩

-

thermoforming: Click here to explore thermoforming, a process that uses heat to shape materials into complex designs, offering uniformity and enhanced performance in finished products. ↩

-

Carbon Fiber: Click here to understand carbon fiber technology, detailing its benefits such as strength, lightweight properties, and impact resistance essential for high-performance sports equipment. ↩

-

composite cores: Click here to discover composite cores, including insights into their construction, benefits like improved shock absorption, and their role in enhancing product durability and performance. ↩