The surge in pickleball popularity is driven by a combination of accessible gameplay, advanced manufacturing techniques, and evolving material choices. In response to the booming demand, manufacturers are refining production processes and material formulations to create paddles that maximize performance, durability, and comfort. This article outlines the key challenges in today’s pickleball paddle production, analyzes the underlying reasons, presents solution strategies, and offers actionable recommendations for B2B buyers in the sports equipment industry.

The pickleball boom has taken North America and other regions by storm, leading to heightened demand for high-performance paddles. Unlike traditional racquet sports, pickleball offers an accessible entry point for players of all ages, which has led to a rapidly expanding market. As a result, manufacturers must reassess their production techniques and material choices to ensure their products meet higher performance standards without sacrificing cost efficiency.

Industry professionals, such as supply chain managers and B2B procurement specialists, face the challenge of balancing quality with production scalability. With competitors constantly pushing the envelope on technology and materials, companies must adopt cutting-edge processes like hot pressing1, cold pressing2 and thermoforming3 to maintain an edge in a market characterized by increasing competition and rapidly changing consumer expectations.

The contemporary consumer is not only driven by affordability but also by performance. The dual challenge of cost and quality is particularly apparent in the competitive pickleball market. Paddles must deliver consistent performance for competitive play and provide enhanced durability, leading to the adoption of premium materials such as various forms of carbon fiber, fiberglass, and composite materials. For instance, the evolution from basic materials to sophisticated composites has allowed manufacturers to reduce vibration, enhance control, and increase impact resistance.

Modern manufacturing relies heavily on advanced materials. High-end paddles are now engineered using materials like 3K Carbon Fiber, 12K Carbon Fiber4 and T300 Carbon Fiber which offer tailored benefits in terms of strength, flexibility, and vibration reduction. Additionally, composites that blend carbon fiber with fiberglass offer a balanced solution for both power and control. Core materials like Nomex Honeycomb5, Aluminum Honeycomb, and Polymer Honeycomb are also being refined to provide improved shock absorption and durability; these innovations address both performance and longevity.

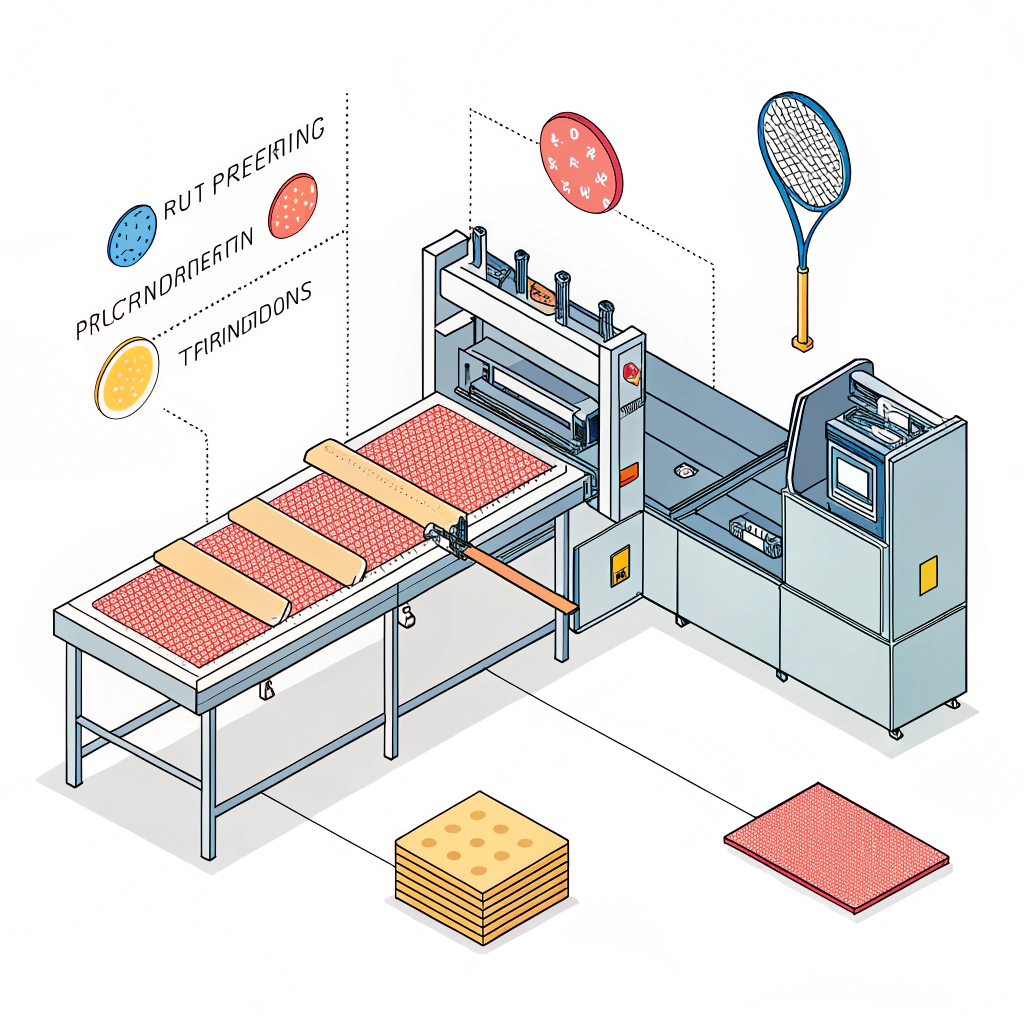

The way paddles are produced has seen significant innovation due to demands for higher precision and customization. Techniques such as hot pressing, cold pressing, and thermoforming each play distinct roles in achieving desired properties:

- Hot Pressing: This process applies heat and pressure simultaneously to form strong, durable paddles rapidly. Although it risks altering some material properties, it is highly efficient for large-scale production.

- Cold Pressing: Ideal for designs that require precise control, cold pressing maintains the intrinsic properties of materials, offering a superior ball feel and refined control. However, longer production cycles may affect scalability.

- Thermoforming: By heating materials to a softening point and molding them, thermoforming enables manufacturers to create paddles with complex geometries and enhanced material distribution, albeit at the expense of longer production times.

These processes not only shape the physical properties of the paddles but also influence manufacturing costs, production cycles, and overall product performance.

To address these challenges, manufacturers are adopting a clear, three-pronged approach:

-

Material Selection Optimization

- Evaluate the performance benefits of different carbon fiber types (3K, 12K, T300) based on the intended paddle use.

- Consider composite options that combine the strengths of multiple materials (e.g., carbon fiber with fiberglass) to meet varying performance needs.

- Choose core materials that balance shock absorption with overall paddle stability.

-

Process Selection Alignment

- Assess production needs: High-speed mass production may favor hot pressing, whereas precision-oriented projects may benefit from cold pressing.

- Consider thermoforming for custom orders or premium paddle lines that require intricate design features.

-

Quality Control and Performance Testing

- Implement rigorous testing protocols to ensure that each paddle meets the highest standards of impact resistance, vibration reduction, and ergonomic design.

- Emphasize iterative testing and customer feedback to refine material compositions and production methods.

The following table summarizes the advantages, disadvantages, and ideal use cases for each production process:

| Production Process | Advantages | Disadvantages | Ideal Use Case |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Strong impact resistance | - Can alter material properties - High equipment cost | Large-scale production of durable paddles |

| Cold Pressing | - Maintains material properties - Superior ball feel | - Longer production cycles - Requires high precision | Custom paddle designs requiring precision |

| Thermoforming | - Intricate design possibilities - Precise material distribution | - Lengthier process - Increased production cost | Premium or custom-made paddles |

This table allows B2B buyers to quickly assess which manufacturing process aligns best with their production strategies and market demands.

While advances in production techniques have opened new avenues for achieving competitive advantage, several factors require careful consideration:

- Cost Implications: Premium manufacturing processes like thermoforming may increase production costs. Buyers should evaluate the return on investment based on the target market segment.

- Production Scalability: Methods like cold pressing, though delivering superior control, may not be ideal for large-scale production due to longer cycles. Ensuring that production methods match demand volume is critical.

- Technical Complexity and Equipment: Modern production techniques require sophisticated machinery and skilled operators. Investments in technology and personnel training become essential components of sustaining high-quality output.

- Quality Control: Maintaining consistent quality standards across different production batches demands robust testing procedures. Continuous monitoring of process parameters is necessary to avoid variability in paddle performance.

- Customization Needs: B2B buyers often seek custom solutions—for example, specific paddle weight, balance, or grip dimensions. Manufacturers need to balance bespoke customer requirements with standardized production practices to achieve both customization and efficiency.

Several industry case studies underline the crucial role of advanced manufacturing techniques:

-

Case Study: NEX Pickleball’s Manufacturing Excellence

NEX Pickleball, a leading manufacturer in Jiaxing, Zhejiang, leverages advanced processes such as cold pressing and thermoforming to deliver paddles that meet the strict demands of competitive play. By selecting high-performance materials like T300 Carbon Fiber and combining it with state-of-the-art Nomex Honeycomb Core technology, NEX Pickleball has achieved an optimal balance between performance and durability. Their iterative approach—emphasizing research, development, and quality testing—provides a blueprint for aligning production techniques with market expectations. -

Market Trends Data

Recent market studies indicate that the pickleball boom is largely driven by increased accessibility and the sport’s low barrier to entry. This growth trend is especially pronounced in North America, where community centers, schools, and sports clubs are actively adopting the sport. Manufacturers that embrace advanced production techniques are ideally positioned to capitalize on this demand surge, provided they balance cost, scalability, and performance. -

Data on Material Performance

Comparative trials have demonstrated that paddles manufactured from 12K Carbon Fiber display superior hardness and impact resistance compared to those made with traditional fiberglass. The ability to reduce vibration without compromising the ball control experience is a significant selling point for competitive players. Such empirical evidence has pushed manufacturers to innovate further, ensuring that each paddle is not just a piece of equipment but a performance enhancer.

These examples illustrate that integrating technology with production processes directly contributes to market success. For businesses making procurement decisions, understanding these industry cases is critical—they highlight the importance of aligning manufacturing innovations with strategic business objectives.

In summary, the surge in pickleball popularity is not merely a consumer trend but a call for innovation among manufacturers. To stay competitive, companies must focus on:

- Optimizing Material Selection: Embrace high-performance materials such as advanced carbon fiber variants and composite blends to enhance game performance.

- Aligning Production Processes: Choose production methods that match your volume needs—from hot pressing for mass production to cold pressing and thermoforming for custom, high-precision products.

- Investing in Quality Control: Implement stringent testing and quality assurance protocols to ensure consistency in performance and durability.

- Balancing Cost and Performance: Understand that while premium processes may increase costs, the improved performance and durability can result in higher market acceptance and customer satisfaction.

For B2B procurement specialists and supply chain managers, these insights provide a clear framework for evaluating potential manufacturing partners. By considering the material and process innovations outlined in this article, you can make informed decisions that meet both current market trends and future demands.

Moving forward, it is advisable to conduct detailed cost-benefit analyses when selecting production processes. Engage with manufacturers who demonstrate a strong track record of innovation and quality control. Additionally, consider pilot projects to test product performance and customer acceptance before committing to large-scale orders. This proactive strategy will ensure that your investment in advanced pickleball paddles not only meets today’s standards but is also adaptable to the dynamic sports equipment market.

Why is pickleball so popular in the US?

Pickleball’s popularity in the United States stems from its high accessibility and low setup requirements. Unlike sports such as tennis, pickleball can be played in various settings—even makeshift courts on driveways or local parks. Affordable equipment, including paddles and balls, combined with a slower pace and simpler rules, makes it easy for individuals of all ages and skill levels to enjoy the sport.

What are the key factors contributing to the rise in popularity of pickleball in the United States, Australia, and other regions globally?

The rapid rise in pickleball’s popularity globally is largely due to its accessible nature. The sport offers an inclusive environment where beginners and experienced players compete on a level playing field. Its ease of learning, minimal equipment requirements, and flexibility in playing location contribute significantly to the sport’s expanding appeal, driving both recreational interest and competitive play worldwide.

-

Hot Pressing: Click to learn more about how hot pressing uses heat and pressure simultaneously to form durable, high-performance components in large-scale manufacturing. ↩

-

Cold Pressing: Click to learn more about how cold pressing maintains the intrinsic properties of materials, offering precise control and an enhanced ball feel in custom production. ↩

-

Thermoforming: Click to learn more about the thermoforming process, which involves heating materials to a malleable state to mold complex geometries and improve material distribution. ↩

-

12K Carbon Fiber: Click to learn more about 12K Carbon Fiber and its role in enhancing paddle hardness and impact resistance through advanced composite manufacturing. ↩

-

Nomex Honeycomb: Click to learn more about Nomex Honeycomb technology, a lightweight yet strong core material that improves shock absorption and overall product durability. ↩