Pickleball’s explosive growth is driven by its addictive gameplay and innovative paddle technology, making it a market opportunity that sports retailers and distributors cannot ignore.

Over the past few years, pickleball has moved from a niche sport to a mainstream phenomenon. Market data shows a marked increase in participation, largely fueled by the sport’s engaging nature and ease of play. At its core, the addictive nature of pickleball stems from its balance of fast-paced action, strategic skill development, and a community-driven experience. Meanwhile, technological innovations in paddle design, such as advanced carbon fiber1, fiberglass2, and composite materials3, have elevated the sport’s performance aspect, attracting both recreational players and competitive athletes.

A significant boost in pickleball’s popularity can be attributed to several underlying trends. First, lifestyle changes and an increasing focus on health and wellness have prompted people to seek out new forms of recreational sports. Pickleball fills that gap with minimal physical strain yet high engagement. Second, the rapid development of paddle technology has made equipment more accessible and performance-oriented, ensuring that every paddle can offer tailored benefits such as enhanced control, increased rebound, and reduced vibration. These factors create a winning proposition for end-users and a compelling value-add for businesses looking to cater to this emerging market.

The addictive dynamics of pickleball are driven by key gameplay factors:

• Engaging Game Mechanics: The sport combines elements of tennis, badminton, and ping pong, appealing to a broad audience with diverse athletic abilities.

• Quick Learning Curve: New players can gain proficiency rapidly, leading to frequent repeated play and a strong word-of-mouth effect.

• Social and Competitive Elements: Whether played in clubs or recreational centers, pickleball fosters social interaction while also offering opportunities for high-level competition.

Simultaneously, advancements in paddle manufacturing have been central to the sport’s growth. Paddle design is deeply intertwined with player performance, influencing aspects such as ball control, dynamism, and overall hitting experience. Manufacturers like NEX Pickleball use cutting-edge production processes to ensure each paddle delivers optimal performance. From the use of multiple types of carbon fiber—like 3K, 12K, and T300—to innovative composite and core materials, every design decision is aimed at enhancing both durability and playability.

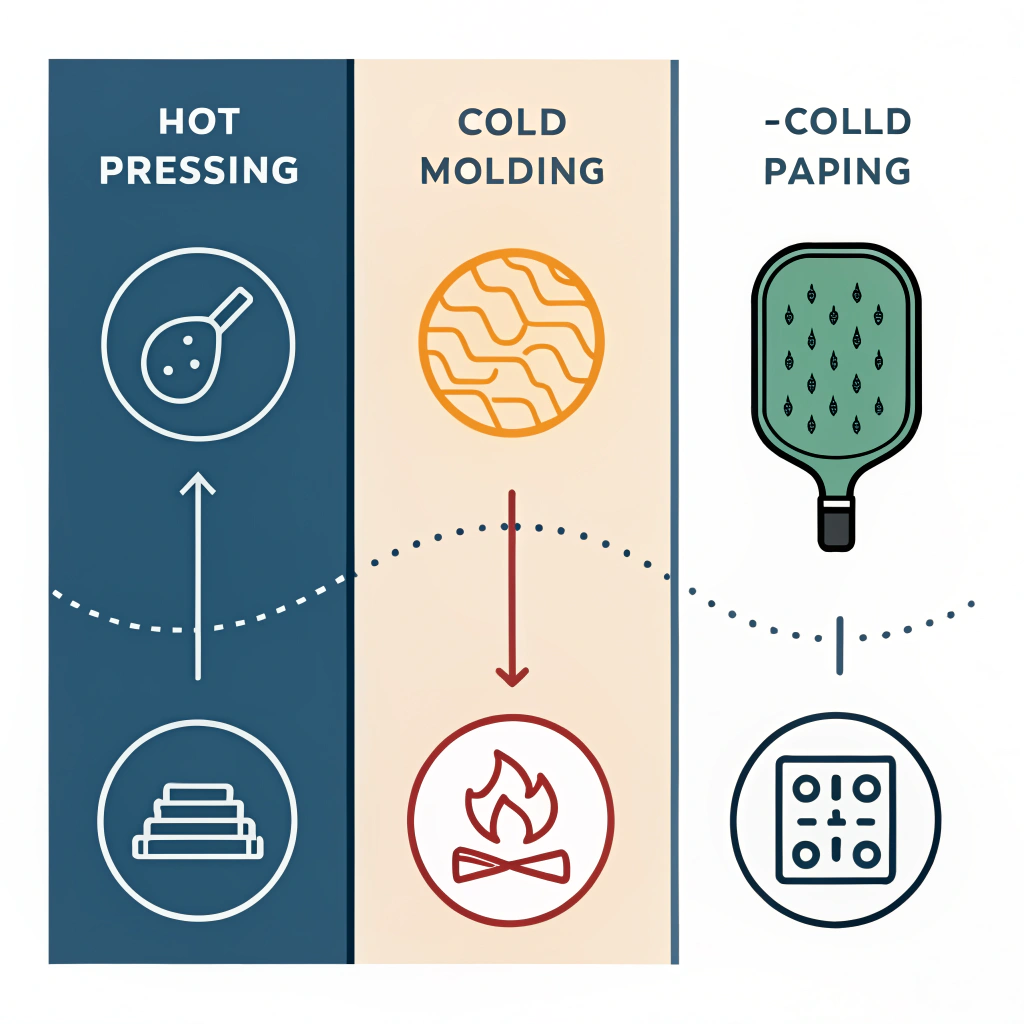

The production methods and material technologies used in pickleball paddle manufacturing are pivotal in achieving high performance and durability. Let’s take a closer look at three primary production processes:

-

Hot Pressing

Hot pressing involves heating the paddle material and applying pressure to create a robust structure. The process guarantees high production efficiency and offers strong impact resistance. However, it may alter some intrinsic material properties which can affect the paddle’s feel. -

Cold Pressing4

Cold pressing shapes paddle materials at room temperature with precise mechanical pressure. This method preserves the material’s natural qualities, offering better control and flexibility. The trade-off lies in its longer production cycle, which could impact efficiency for large-scale orders. -

Thermoforming5

Thermoforming heats materials to a softening point before molding them into precise shapes. This allows for intricate designs that maintain balanced material distribution, ideal for premium and custom products. Despite its benefits, thermoforming demands higher equipment costs and longer production times.

The following table summarizes the advantages and disadvantages of each production process:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, consistent structural integrity | May alter material feel, requires significant investment in equipment |

| Cold Pressing | Superior control, preserves material properties, excellent ball feel | Longer production cycles, demands precise pressure control |

| Thermoforming | Intricate design potential, balanced material distribution, ideal for premium products | Higher costs, longer production time |

Understanding these processes is vital for buyers who are assessing supplier capabilities. With sophisticated techniques in place, manufacturers are well-positioned to produce paddles that meet the rigorous demands of competitive play. This manufacturing prowess not only assures end-users of top-tier performance but also provides B2B partners with a reliable, high-quality product portfolio to offer their customers.

Looking deeper into industry trends, several market dynamics are influencing the growing demand for advanced pickleball paddles:

• Evolving Consumer Preferences – As players become more discerning, there is a rising demand for premium-quality paddles designed to enhance both power and control. This has led to a diversification of materials used, with carbon fiber options offering high strength and exceptional rebound, while fiberglass provides a larger sweet spot and improved tactile feedback.

• Innovation in Composite Materials – The integration of carbon fiber and fiberglass in composite paddles is delivering a balanced performance that meets the needs of both recreational and competitive players. Additionally, innovative core materials such as Nomex, aluminum, and polymer honeycomb cores allow for customization in weight distribution and vibration dampening—a critical factor for player comfort.

• Customization and Branding – With options to tailor paddle designs, weight, and grip sizes, manufacturers can cater to branded team requirements or special events. This level of customization opens up unique marketing strategies for B2B retailers aiming to differentiate their product lines in a competitive market.

These innovations and market trends signal robust growth potential for pickleball, making it imperative for industry professionals to capitalize on these developments. For sports retail executives, club managers, and distributors, the key takeaway is that the right equipment, underpinned by cutting-edge production technologies and material science, can drive not only consumer satisfaction but also significant market differentiation.

For decision-makers in the sports retail and distribution sectors, several strategic actions are recommended:

-

Leverage the Trend: Embrace the rising pickleball trend by integrating a diverse range of high-performance paddles into your product portfolio. Tailoring your offerings with options ranging from high-strength carbon fiber paddles to user-friendly fiberglass variants will address a broad spectrum of player needs.

-

Prioritize Customization: The modern consumer is looking for products that align with personal preference and performance standards. Investing in custom paddle solutions—whether for team branding, personalized ergonomics, or enhanced tactile feedback—can set your inventory apart.

-

Build Data-Driven Strategies: Use market insights and performance data to guide procurement decisions. Understanding the benefits and trade-offs of various production processes (hot pressing vs cold pressing vs thermoforming) will ensure that you select products with the optimal balance of durability and performance for different market segments.

-

Assess Supplier Capabilities: Partner with manufacturers who demonstrate rigorous quality control and advanced production methods. This not only guarantees product consistency but also underscores a commitment to innovation which resonates well with premium buyers.

-

Educate End-Users: Equip your sales teams with insights into how production processes and material choices directly impact gameplay. This knowledge builds trust and assists in the upselling of products by clearly conveying their technological and performance advantages.

In summary, the surge in pickleball’s popularity is more than a passing trend—it reflects a deep-seated shift in consumer preferences towards sports that are simultaneously accessible and technically demanding. The sport’s addictive nature, combined with ongoing innovations in paddle construction, presents a unique opportunity for B2B partners in the sports industry. By understanding the game’s evolving dynamics and leveraging advanced paddle technologies, stakeholders can make informed purchasing decisions that not only meet current market demands but also anticipate future growth trends.

Taking decisive action now means securing a competitive edge in a market poised for exponential growth. Whether you are looking to diversify your product offerings, deepen customer engagement, or enhance your brand reputation, investing in high-performance pickleball paddles—with their superior material composition and precision manufacturing—is a pathway to success.

People Also Ask

Q: What factors make pickleball addictive for players?

A: Pickleball’s addictive nature stems from its engaging blend of fast-paced action, simple rules, and the ease with which new players can improve their skills. Its social and competitive aspects further encourage repeat play, making it a compelling sport for a wide range of participants.

Q: How does advanced paddle technology improve performance in pickleball?

A: Advanced paddle technology enhances performance by optimizing weight distribution, grip, and surface texture. Innovations using materials like diverse carbon fiber types and composite constructions ensure paddles offer excellent power, control, and reduced vibration, which are critical for both recreational and competitive play.

Q: What are the differences between hot pressing, cold pressing, and thermoforming processes in paddle manufacturing?

A: Hot pressing provides high efficiency and robust impact resistance but may alter material feel. Cold Pressing4 preserves the material’s natural characteristics for better control, though it requires longer production cycles. Thermoforming5 allows for intricate design and precise material distribution, ideal for premium paddles, yet it comes with higher costs and extended production times.

-

Carbon Fiber: Read this article to understand the advanced properties, manufacturing techniques, and performance benefits of carbon fiber in enhancing sports equipment durability and playability. ↩ ↩

-

Fiberglass: Click here to explore how fiberglass is utilized in sports gear, offering a balance of flexibility and strength, which is essential for optimal paddle performance. ↩ ↩

-

Composite Materials: Discover the world of composite materials and learn how the integration of different fibers and resins creates lightweight, high-performance sporting equipment. ↩ ↩

-

Cold Pressing: This article explains the cold pressing process, a method that preserves the natural qualities of materials to enhance product control and flexibility, ideal for high-performance paddles. ↩ ↩ ↩2

-

Thermoforming: Learn about thermoforming, a manufacturing process involving heating and molding materials to achieve intricate designs and balanced material distribution, crucial for premium, custom sports products. ↩ ↩ ↩2