Grip circumference is a key factor in maximizing player comfort and performance in pickleball, as it directly influences ergonomics and control, reducing strain and enhancing shot accuracy.

In today’s competitive sports equipment market, a common challenge for procurement specialists lies in selecting pickleball paddles that offer the perfect balance of durability, performance, and ergonomic design. A poorly sized grip can lead to unnecessary tension and even long-term strain injuries. Specifically, an improperly sized grip—whether too small or too big—compromises a player’s control and comfort, potentially diminishing overall performance on the court.

The ergonomic design of a paddle grip is not merely about comfort; it is also about optimizing the energy transfer from the player’s hand to the paddle, thereby enhancing power and precision in every shot. For B2B procurement managers, understanding the technical basis behind grip circumference is essential. A deep dive into the engineering principles, material choices, and manufacturing processes will aid in evaluating product quality and suitability for various player demographics.

Several factors affect how grip circumference impacts player performance:

- Excessive Strain: If the grip is too small, players tend to compensate by gripping tighter, which can lead to fatigue and even repetitive stress injuries over time.

- Loss of Control: An oversized grip forces players to stretch their fingers more than is comfortable, reducing the sensitivity and precision required for high-performance gameplay.

- Material Interaction: The materials used in paddle construction, such as carbon fiber1, fiberglass2, and various composites, interact differently with grip designs. The choice of core materials (such as Nomex or polymer honeycomb) directly influences the weight distribution and shock absorption of the paddle, further affecting the grip’s effectiveness.

Thus, any decision on grip size must consider player biomechanics, material properties, and the intended use scenario—whether for high-speed competitive play or casual recreational games.

To address these challenges, manufacturers and procurement specialists can adopt several strategies based on advanced production techniques and ergonomic studies. Below is a table highlighting key solutions:

| Approach | Advantage | Consideration |

|---|---|---|

| Accurate Grip Measurement & Customization | Ensures the paddle fits the player's hand perfectly | May increase customization lead times |

| Integrated Material Evaluation | Combines benefits of carbon fiber1 and composites for enhanced control | Requires expert analysis on material behavior |

| Advanced Production Techniques | Processes like hot pressing3, cold pressing4, and thermoforming5 ensure consistency in grip dimensions | Each method has its trade-offs in cost and production speed |

This table provides a quick reference for procurement managers to weigh the benefits and limitations of different manufacturing approaches when evaluating pickleball paddles.

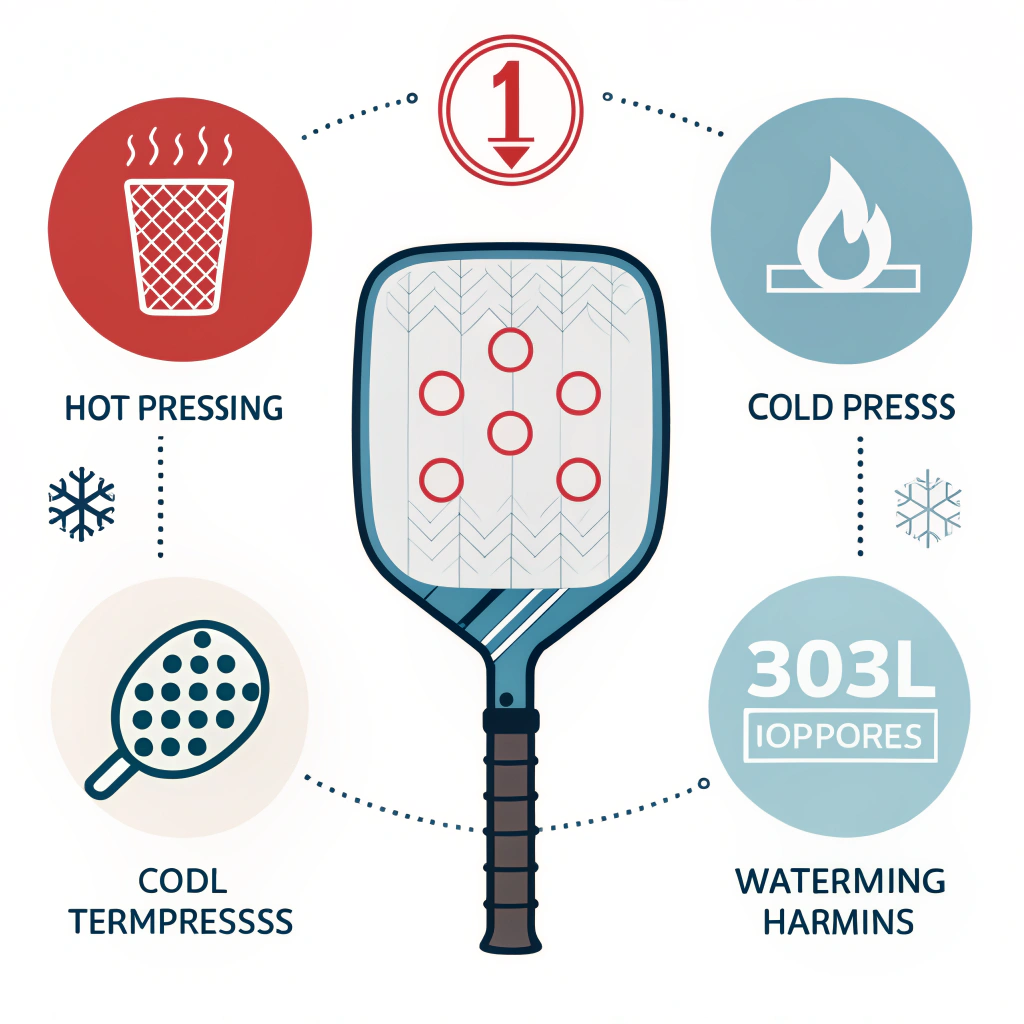

A deep understanding of manufacturing processes is essential in ensuring that the grip circumference is both consistent and optimized for performance. At NEX Pickleball, we incorporate three primary production techniques:

This method involves applying heat and pressure simultaneously to mold the paddle.

- Advantages:

- High efficiency and strong bonding for material integrity.

- Produces paddles with excellent impact resistance.

- Disadvantages:

- There is a risk of altering some of the inherent material properties, which could slightly affect the feel of the grip.

Cold pressing shapes the paddle without additional heat, preserving the materials’ natural properties.

- Advantages:

- Maintains the intrinsic qualities of the core and surface materials, resulting in better tactile feedback.

- Offers a more precise control over the paddle’s dimensions.

- Disadvantages:

- The process is slower, which may impact production scalability.

By heating the material until it softens and then forming it under controlled conditions, thermoforming allows for intricate design features.

- Advantages:

- Supports complex geometries and precise material distribution for a more ergonomic grip.

- Helps maintain overall paddle performance even in customized builds.

- Disadvantages:

- Higher costs and longer production cycles are typical.

The choice between these production methods depends on the intended market and performance expectations. For example, while hot pressing3 might be ideal for high-volume manufacturing, thermoforming5 is often preferred for premium paddles where customization is a significant advantage.

The performance and durability of a pickleball paddle are not solely determined by production methods. The materials used play a critical role in the overall grip and feel. Here are some impactful materials employed in our manufacturing process:

-

- 3K Carbon Fiber: Balances strength and flexibility, suitable for paddles that require high rebound forces.

- 12K Carbon Fiber: Offers a smoother surface and greater hardness, ideal for competitive play due to its superior durability.

- T300 Carbon Fiber: Known for its remarkable tensile strength, helping create a lightweight yet robust paddle.

-

- E-Glass Fiberglass: Provides excellent elasticity and control, ensuring a wider sweet spot in the grip area.

-

Composite Materials:

- Carbon Fiber and Fiberglass composites marry the best of both worlds, offering high power while retaining control.

- Bamboo Core and Honeycomb Cores enhance shock absorption and overall paddle longevity, ensuring that the grip area remains stable under high-impact conditions.

The integration of these materials not only advances performance but also contributes to a paddle’s ergonomic design by ensuring that the grip remains comfortable and effective throughout extensive use. Using precise engineering calculations to determine the optimal grip circumference, our manufacturing processes are aligned with the best practices in sports ergonomics.

A critical part of optimizing grip circumference is testing. Quality assurance protocols that assess grip performance under various stress conditions are indispensable.

-

Biomechanical Evaluation:

Trainers and engineers collaborate to simulate gameplay scenarios, measuring the stress placed on players’ hands with different grip sizes. -

Wear and Tear Assessments:

Paddles undergo repeated impact tests to determine how grip material and design endure over time. -

Player Feedback Integration:

Real-world testing in clubs and competitive environments helps refine the ergonomic grip design continuously.

A structured testing approach helps identify any ergonomic deficiencies, ensuring that every paddle delivered meets high standards of performance and player comfort.

For sports equipment sourcing managers, selecting the right pickleball paddle becomes less daunting when equipped with technical knowledge about grip circumference and its impact. Here are some best practices:

-

Detailed Specifications Review:

Always examine the manufacturing process details and material specifications. Understand which production technique (hot pressing, cold pressing, or thermoforming) is best suited for your player demographic. -

Customization Options:

Prioritize manufacturers that offer tailored options, such as adjustable grip sizes. This customization can facilitate a better match for players with varying hand sizes, ensuring improved comfort and performance. -

Post-Production Testing:

Ensure that the supplier has stringent quality control measures. Request performance data or case studies reflecting the ergonomic benefits of their grip designs. -

Comparative Analysis:

Use side-by-side comparisons of similar products to compare design elements, production processes, and material choices. A detailed comparison table can help illustrate how different features affect the ergonomic performance. -

Regulatory and Industry Standards Adherence:

Ensure that the products comply with international sports equipment standards. This not only guarantees safety but also enhances the reliability of the procurement decision.

Consider the case of a regional sports equipment distributor that recently integrated paddles optimized for ergonomic grip design into their product line. The distributor noticed a substantial decrease in player complaints regarding hand fatigue and an increase in overall satisfaction during extended gameplay sessions. By collaborating closely with manufacturers specializing in advanced production techniques and material innovation, the distributor was able to:

- Achieve a consistent grip size across batches.

- Reduce the incidence of hand strain in players, thereby extending the life of the paddle.

- Enhance overall player performance, which in turn, improved the paddle’s market reputation.

This case underlines a direct correlation between precise engineering of grip circumference and improved ergonomic outcomes for players. For procurement specialists, investing in products that offer such optimized design characteristics is not only a technical win but also a smart business strategy, enhancing customer satisfaction and ultimately driving higher sales conversions.

In summary, grip circumference is a pivotal aspect of pickleball paddle design that affects player comfort, control, and long-term performance. Understanding the interplay between production processes, material choices, and ergonomic design principles equips sourcing managers with the insights needed to make informed procurement decisions.

Key takeaways for procurement specialists include:

- Recognize that improper grip size can lead to repetitive strain and compromised play quality.

- Evaluate manufacturing processes—whether hot pressing, cold pressing, or thermoforming—to determine which method aligns best with the desired product performance.

- Place emphasis on material selection and quality assurance tests that guarantee a reliable and comfortable grip.

- Use quantitative data and real-world case studies as validation to support your procurement decision.

For those looking to enhance their product lines, adopting these engineering best practices can lead to improved player satisfaction, reduced injury risks, and a stronger market position.

Q: Does grip size matter in pickleball?

A: Yes, grip size is critical in pickleball because an improperly sized grip can lead players to hold the paddle too tightly or too loosely, increasing hand fatigue and reducing shot control over time.

Q: Do pickleball pros use 14mm or 16mm paddles?

A: Generally, a 14mm paddle tends to provide more power, spin, and speed, while a 16mm paddle offers more control. Advanced players often prefer paddles within the 10-14mm range for enhanced performance, whereas beginners and intermediate players may benefit from the control offered by 16mm paddles.

Q: What is the best length grip for pickleball?

A: The best grip size for pickleball is determined by measuring the distance from the bottom lateral crease up to the tip of the ring finger, typically falling between 4 and 5 inches. This measurement generally provides an optimal balance of comfort and control for most players.

-

Carbon Fiber: Reading this article will help you understand how carbon fiber technology enhances durability and weight reduction in advanced manufacturing, crucial for high-performance sports equipment. ↩ ↩ ↩2 ↩3

-

Fiberglass: Discover insights on fiberglass’s role in reinforcing materials, improving elasticity and control in sporting goods applications. ↩ ↩ ↩2

-

Hot Pressing: Learn about hot pressing as a manufacturing method that uses heat and pressure to achieve strong material bonds and improve product performance. ↩ ↩ ↩2

-

Cold Pressing: This explanation details how cold pressing preserves intrinsic material properties, providing enhanced tactile feedback and precision in component manufacturing. ↩ ↩

-

Thermoforming: Explore the benefits of thermoforming in creating intricate, ergonomic designs through the careful application of heat, fostering product customization and innovation. ↩ ↩ ↩2