The honeycomb core in pickleball paddles delivers superior shock absorption, enhanced durability, and reduced vibration—critical qualities that make it an optimal choice for competitive and recreational play alike.

In today’s fast-paced pickleball market, B2B procurement managers and sports equipment distributors are constantly on the lookout for the best technological advancements that enhance paddle performance while maintaining reliable manufacturing efficiency. Honeycomb core1 have emerged as one of the favored design choices because of their unique blend of lightweight impact resistance and excellent shock absorption. This article examines the technical aspects of various paddle core options, compares their performance characteristics, and explains how our advanced manufacturing methods at NEX Pickleball have set new benchmarks in the industry.

At the heart of every pickleball paddle, the core material determines the balance of power, control, and durability. With diverse options available—such as Nomex2, Polymer, Aluminum, and specially engineered honeycomb cores—choosing the right core is both a technical and strategic decision. The honeycomb core specifically offers:

• Superior shock absorption that reduces vibration during play

• Enhanced durability which supports long-lasting performance

• A lightweight structure that optimizes power and control

Given these attributes, many procurement managers ask: “How does a honeycomb core stand against other materials, and is it worth the production investment?” The following sections break down the science behind these materials and the production methods that ensure consistent, high-performance output.

A detailed comparison of various core materials provides clarity on why the honeycomb core is a compelling choice for high-performance pickleball paddles. Consider the table below, which summarizes key attributes of different core options:

| Core Material | Shock Absorption | Durability | Weight | Vibration Reduction | Production Precision |

|---|---|---|---|---|---|

| Honeycomb Core | Excellent | High | Very Light | Excellent | High |

| Nomex Honeycomb Core | High | Very High | Light | Moderate | Consistent |

| Aluminum Honeycomb Core | Moderate | High | Moderate | Moderate | Balanced |

| Polymer Honeycomb Core | Good | Moderate | Light | Excellent | Excellent |

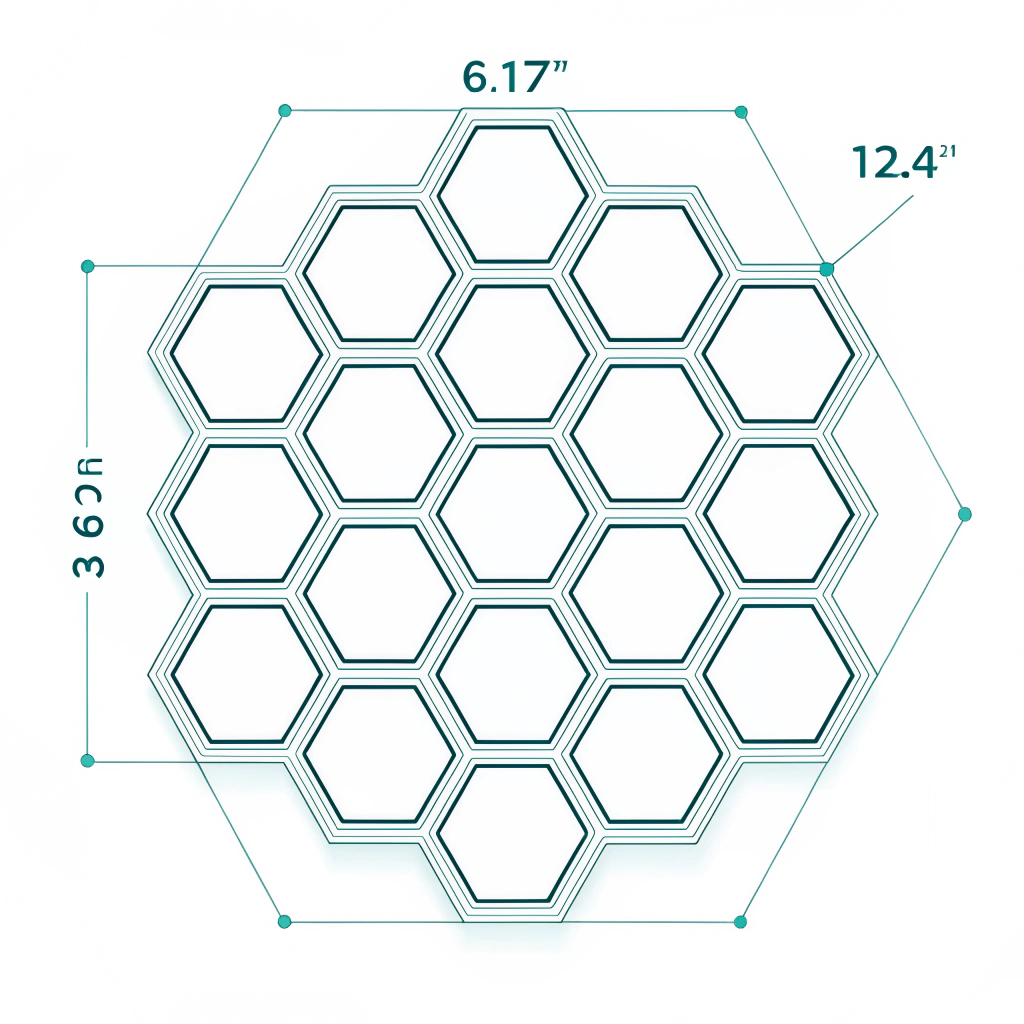

Honeycomb cores are made from high-density polymers or pulp, structured in a way that resembles a beehive. This design achieves a high strength-to-weight ratio, meaning that paddles can be both light and highly resistant to shock. The uniform cell structure not only absorbs energy from impact but also minimizes the propagation of vibrations, which is critical for maintaining control during fast-paced play.

Key benefits include:

• Shock Absorption: The cellular structure helps in dissipating impact forces, thereby reducing the risk of paddle damage over time.

• Durability: The interlocking cells distribute stress evenly, making the paddle more robust and long-lasting.

• Vibration Reduction: Less vibration means a more comfortable playing experience for the user, reducing the risk of repetitive strain.

Many distributors have reported that paddles with honeycomb cores tend to have a more consistent performance throughout their lifecycle, contributing to enhanced player confidence and improved market reputation.

Alongside material choice, the manufacturing process plays a pivotal role in ensuring the final paddle meets quality standards. At NEX Pickleball, we employ three primary production processes—each with its benefits and limitations—which affect the final performance and cost-efficiency of our paddles.

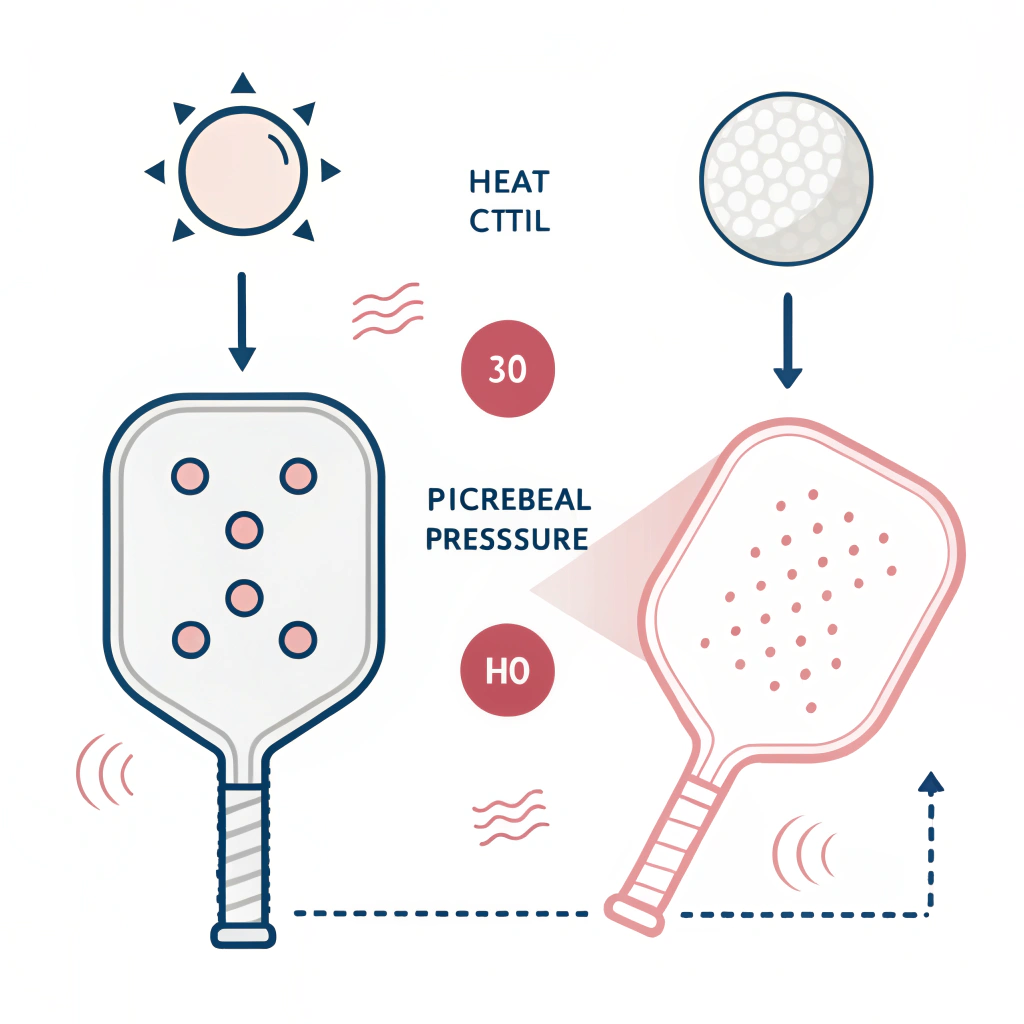

Hot pressing involves heating the paddle material and applying pressure simultaneously. This method is generally used to produce paddles that exhibit both high strength and endurance against impacts.

• Advantages:

– High production throughput suitable for large-scale manufacturing.

– Results in paddles with exceptional impact resistance.

– Guarantees structural integrity for high-performance play.

• Disadvantages:

– Can slightly alter some material properties affecting the play feel.

– Requires significant investment in specialized equipment.

Using cold pressing, the paddle material is formed at room temperature under mechanical pressure. This process allows for superior precision, making it ideal for designs that prioritize control and optimal weight distribution.

• Advantages:

– Maintains the intrinsic properties of the materials, enhancing responsiveness.

– Delivers consistent thickness and finely tuned control features.

• Disadvantages:

– Longer production cycles compared to hot pressing.

– Higher precision demands mean more sophisticated equipment maintenance.

In thermoforming, the paddle material is heated until it softens and then molded into shape. This is particularly effective for paddles requiring complex designs or intricate material distribution, such as those incorporating a honeycomb core.

• Advantages:

– Supports innovative design and material precision.

– Enhances paddle stability for competitive performance.

• Disadvantages:

– Generally more time-consuming and expensive.

– Best suited for high-end or custom paddle products.

The choice of production process is often influenced by the target market and cost considerations. For clients looking for a versatile paddle that combines control with durability, the thermoforming process can be particularly beneficial when paired with a honeycomb core design.

In response to the diverse requirements of today's pickleball players, many manufacturers—including NEX Pickleball—blend various materials to harness combined benefits. By integrating multiple materials in one paddle, we can create a composite that exhibits enhanced performance characteristics. For instance, a composite blend of carbon fiber4 and fiberglass offers a harmonious balance between power and control:

• Carbon Fiber: Provides strength, rigidity, and quick rebound characteristics.

• Fiberglass: Offers a wider sweet spot and improved ball control due to its inherent flexibility.

Another compelling composite is the bamboo core composite. Bamboo cores are known for their lightweight yet impact-resistant properties, delivering an authentic feel that is both powerful and precise for extended gameplay. These composites are often structured around a honeycomb framework, allowing for a design that maximizes durability while minimizing vibration and shock.

Such composites prove invaluable in meeting the rigorous demands of professional play, while also appealing to enthusiastic players who demand consistently high performance from their equipment.

Ergonomic design5 and Weight Distribution

Beyond the material composition and production processes, the ergonomic design of the paddle is crucial. An intelligently engineered paddle not only features advanced core materials but also emphasizes optimal weight distribution. This balance is essential to maximize maneuverability and reduce user fatigue, particularly during extended play sessions.

Key considerations include:

• Grip Design: Ensuring that the paddle is comfortable to hold with minimal slip during high-intensity matches.

• Balance: A well-balanced paddle enhances control, enabling players to deliver powerful yet precise strokes.

• Surface Texture: A specially treated surface improves the paddle’s grip on the ball, which is instrumental in generating spin and accuracy.

These design elements are meticulously integrated with core choices such as the honeycomb structure, which inherently supports superior vibration dampening. The cumulative effect is a paddle that not only excels in technical performance but also enhances the overall user experience.

Achieving consistency in the production process is key to maintaining high standards across a product line. At NEX Pickleball, each paddle undergoes a rigorous series of tests to verify that it meets our quality benchmarks in terms of strength, flexibility, and performance. This deliberate focus on quality control is reflected in several areas:

- Material Testing: Every batch of core materials, whether honeycomb, Nomex, or polymer composites, is subjected to strict durability and impact absorption tests.

- Precision Engineering: Our state-of-the-art production lines ensure that each paddle features consistent weight distribution and ergonomic design.

- Performance Trials: Extensive playtesting in various conditions verifies that each paddle performs reliably, regardless of intensity or environment.

- Customer Feedback: We regularly review feedback from distributors and players, which helps in fine-tuning our production methods and material choices.

This systematic approach to quality control not only reinforces the reliability of our paddles but also builds long-term trust with our B2B partners, ensuring they can confidently supply top-tier products to their end customers.

For procurement managers seeking to expand their product portfolios with high-performance pickleball paddles, the key lies in understanding both the materials and manufacturing techniques that drive paddle performance. Here are several strategic recommendations:

- Evaluate Core Options: Compare the benefits of honeycomb cores against other materials like Nomex or polymer cores. Look into performance data regarding shock absorption and durability.

- Consider Production Processes: Understand the impact of different manufacturing methods (hot pressing, cold pressing, thermoforming) on the final product. This insight helps in estimating production costs and lead times.

- Demand Quality Control: Ensure your suppliers utilize rigorous quality control measures to maintain consistent product performance.

- Focus on Customization: Consider products that offer adjustable grip sizes, weight distributions, and ergonomic designs. Customization can be a significant differentiator in competitive markets.

- Monitor Market Feedback: Use real-world performance data and player reviews to continuously assess and improve product offerings, ensuring that they meet the evolving needs of competitive players and recreational enthusiasts alike.

Summarily, the combination of a honeycomb core with advanced production technologies not only enhances performance but also solidifies the manufacturer’s reputation, making it a prudent choice for businesses aiming to thrive in the competitive pickleball equipment market.

• What are the benefits of a honeycomb core in pickleball paddles?

Honeycomb cores offer excellent shock absorption, reduce vibration, and provide a lightweight yet durable structure, making them ideal for both competitive and recreational play.

• How does a honeycomb core compare to other paddle core materials?

Compared to alternatives like Nomex, aluminum, and polymer cores, honeycomb cores strike an optimal balance between durability, weight, and performance, particularly in reducing vibration and enhancing impact resistance.

• What manufacturing process is best for producing paddles with a honeycomb core?

Thermoforming is particularly effective for honeycomb cores as it allows for intricate shaping and precise material distribution, though the choice ultimately depends on production scale, cost, and desired paddle performance.

-

Honeycomb core: Click to learn more about how the unique cellular structure of honeycomb cores delivers superior shock absorption and durability in sports equipment manufacturing. ↩

-

Nomex: Click to explore detailed insights into Nomex, a high-performance material known for its strength and thermal stability in advanced industrial and sports applications. ↩

-

Thermoforming: Click to read about the thermoforming process, a manufacturing technique that heats and molds materials for precision shaping in high-end product designs. ↩

-

Carbon fiber: Click to understand the benefits of carbon fiber, a composite material celebrated for its strength-to-weight ratio and performance-enhancing properties in sports equipment. ↩

-

Ergonomic design: Click to discover how ergonomic design principles optimize comfort, control, and balance in equipment, reducing user fatigue and enhancing performance. ↩