Quick answer: For OEM buyers choosing paddle faces, E-glass fiberglass1 delivers a cost-effective balance of power, control, and spin with a softer feel and wider playability for recreational to mid-level competitive players, while carbon/composite2 faces (3K/12K/T300 carbon or carbon-fiberglass blends) are stiffer, offer higher power, larger sweet spots, and suit high-performance and competitive segments—choose based on target player profile, margin targets, and your factory’s preferred forming method (hot pressing3 for high-volume stiffness vs cold pressing/thermoforming4 for tuned feel).

Why this decision matters now

- Product managers must match surface material to a target player segment, margin, and manufacturing workflow.

- Face material drives measurable performance (power, spin, sweet spot, vibration), perceived quality, and warranty/durability expectations.

- Production method (hot pressing, cold pressing, thermoforming) changes cost, lead time, and consistent feel across units.

This guide gives you a clear, testable comparison and practical sourcing checklist to decide between fiberglass vs carbon/composite surfaces for OEM paddle lines.

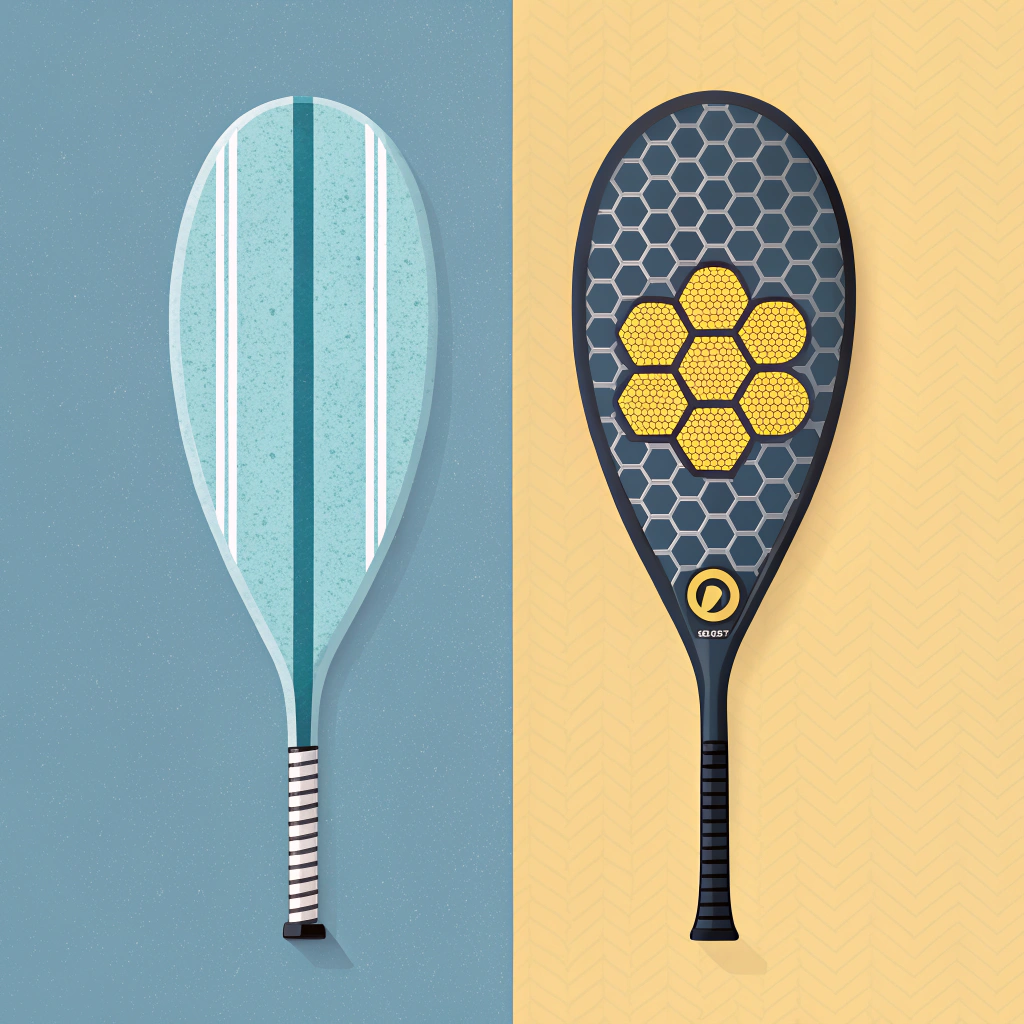

Core difference in one line

- Fiberglass (E-glass): flexible, good ball feel, strong spin and control, lower cost; best for mid/recreational players.

- Carbon/composite: stiff, high rebound (power), consistent sweet spot, premium price; best for competitive players.

Material science & play impact (what you get on-court)

- E-glass fiberglass: a woven glass fiber fabric with good elasticity and tensile strength. It bends more under impact than carbon, so it stores and releases energy differently—this yields more dwell time on the ball, improving touch and spin control. Fiberglass faces often feel "softer" and more forgiving on volleys and dinks.

- Carbon fiber (3K / 12K / T300): much higher stiffness and tensile strength. Carbon returns ball energy faster for more pop and power. 12K offers a harder surface; 3K is slightly more flexible with better feel; T300 is tuned for strength-to-weight optimization.

- Carbon + Fiberglass composites: combine carbon’s power with fiberglass’ feel. Layering strategies (face orientation, weave types) let manufacturers tune sweet spot size, flex profile, and vibration damping.

- Core interacts with face: a polymer honeycomb core gives more elasticity and comfort; Nomex cores increase firmness and durability. The same face material over different cores yields different play profiles.

First time keywords: fiberglass, E-glass, carbon fiber, polymer honeycomb core.

Performance trade-offs (concise)

- Power: Carbon > Carbon-Fiberglass Composite > Fiberglass

- Control / Feel: Fiberglass ≥ Carbon-Fiberglass Composite > Carbon (depends on core)

- Spin: Fiberglass and textured carbon faces can both produce strong spin; fiberglass’s dwell aids spin generation

- Sweet spot: Carbon (larger consistent sweet spot) > Composite > Fiberglass (smaller but more predictable near center)

- Durability: Carbon and high-quality composites > Fiberglass (but depends on epoxy and layup)

- Cost: Fiberglass (lowest) < Composite < Carbon (highest)

Manufacturing implications by process

-

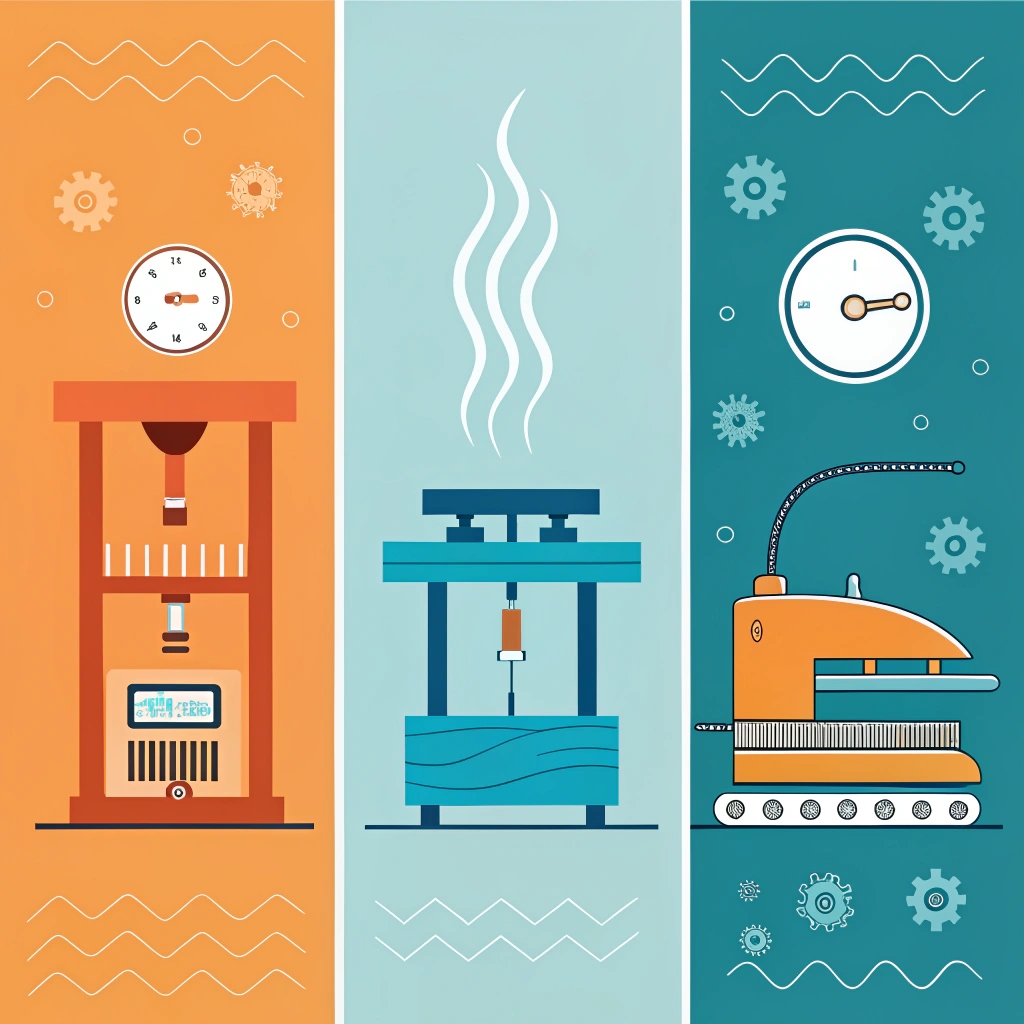

Hot pressing

- Pros: fast cycle, high throughput, robust laminate bonding; good for carbon faces and high-volume OEM runs.

- Cons: can alter polymer matrix properties (firmer feel), higher capital equipment cost.

- Best when: scaling competitive paddle lines where stiffness and tight tolerances are requirements.

-

Cold pressing

- Pros: preserves material properties, allows fine thickness control; better for tuning feel.

- Cons: slower throughput, requires precise pressure control and strong QC.

- Best when: producing fiberglass or blended faces where tactile feel matters.

-

Thermoforming

- Pros: supports complex shapes, precise material distribution; excellent for premium/custom forms.

- Cons: longer cycle, higher cost; high expertise needed.

- Best when: offering differentiated shapes/edges or custom OEM designs.

First time keyword: hot pressing, cold pressing, thermoforming.

Practical sourcing checklist (what to ask suppliers and test)

- Material specs

- Face: weave type (E-glass plain/twill), carbon type (3K/12K/T300), resin system (epoxy type).

- Core: polymer/nomex/aluminum: density, thickness, compression properties.

- Laminate schedule

- Layer sequence, ply angles, face-to-core bonding method.

- Production process

- Which process used (hot/cold/thermoforming) and typical cycle times.

- Consistency controls

- Thickness tolerance (mm), weight tolerance (±g), surface roughness tolerance.

- Physical tests to request (samples)

- Impact resistance (ASTM D2794-style pendulum or custom impact test at specified joules).

- Flexural stiffness (ISO or ASTM flexural test) and deflection at set force.

- Ball rebound/speed test (standardized drop test: initial ball speed post-impact).

- Vibration transfer (accelerometer measurement) and subjective blind play tests.

- Surface hardness (Shore D/A where applicable).

- Delamination and peel strength (face-to-core bond test).

- Lifecycle & durability

- UV and environmental aging tests (500–1000 hours accelerated test).

- Abrasion resistance for surface coatings.

- Commercial KPIs

- MOQ, lead time for samples and production, price per unit at target annual volume tiers, tooling costs.

Include these minimum acceptance criteria in your SOW for prototypes.

Decision matrix (sample table)

| Dimension | Fiberglass (E-glass) | Carbon/Carbon-Composite |

|---|---|---|

| Target segment | Recreational / mid-level | Competitive / premium |

| Feel | Softer, more dwell | Stiffer, faster rebound |

| Power | Medium | High |

| Control / Spin | High (dwell helps) | High (with textured face) |

| Sweet spot | Smaller, focused | Larger, consistent |

| Cost per unit (est.) | Low–Medium | Medium–High |

| Recommended process | Cold pressing / Thermoforming | Hot pressing / Thermoforming |

| Typical lead time | Moderate | Moderate–Long (if custom carbon weave) |

| Durability | Good (depends on epoxy) | Very good |

When to pick fiberglass (recommended use cases)

- You target recreational clubs, multi-paddle retail SKUs, or price-sensitive market segments.

- Your design goal: comfortable feel with control and spin-friendly play.

- You expect moderate margins and want lower material cost and simpler repairability.

- You plan to use a polymer honeycomb core to keep weight down and reduce vibration for amateur players.

When to pick carbon/composite

- You target competitive players, pro lines, or premium retail channels.

- You need greater power, a larger sweet spot, and a consistent, high-end feel across batches.

- You accept higher COGS and want to differentiate by performance claims.

Quality-control and commercial recommendations for OEM contracts

- Define performance tolerances, not just materials (e.g., target ball rebound speed ±5%, stiffness range, and weight tolerance ±7g).

- Require initial pilot run (100–300 units) and blind play tests with a panel of target players.

- Insist on third-party lab reports for impact and aging tests or include factory test protocols that you audit.

- Agree on failure rates (RMA) acceptable for first year—set remediation steps.

- Price negotiation levers: volume tiers, simplified face layup (fewer plies), and shared tooling amortization.

- Sample approval process: prototype → lab tests → blind play → preproduction run → AQL sample checks.

Quick sample spec templates (short)

- Recreational Fiberglass Paddle: E-glass plain weave face, polymer honeycomb core 14 mm, weight 7.8–8.6 oz, hot/cold pressed, surface texture 150–300 grit equivalent, target rebound X m/s.

- Competitive Carbon Paddle: 12K carbon face, polymer or aluminum core 13–14 mm, weight 7.4–8.2 oz, hot-pressed, reinforced edge band, surface micro-texture for spin.

Final recommendation (actionable)

- Define your target player segments clearly (recreational vs competitive) and set retail price points.

- If targeting recreation/mid-market: prioritize E-glass fiberglass for cost and feel; specify polymer honeycomb cores and cold pressing for better feel.

- If targeting performance/premium: specify carbon or carbon-fiberglass composites, hot pressing for consistency, and stricter QC metrics.

- For mixed portfolios: use fiberglass for entry/mid SKUs and carbon for premium SKUs to maximize margin and market coverage.

- Require prototype performance metrics and blind play tests before approving tooling and full production.

People Also Ask

Q: What is the best surface material for a pickleball paddle?

A: There is no single “best” surface—carbon (graphite) faces are widely favored for a premium combination of light weight and touch, giving excellent feel and control, while carbon variants deliver higher power and consistent sweet spots. Choose based on target player: carbon for competitive players who want power and consistency; fiberglass for players who prefer softer feel and versatility.

Q: Is fiberglass surface good for pickleball?

A: Yes. Fiberglass (E-glass) provides a balanced mix of power, control, and spin with a solid ball feel. It often offers more dwell on the ball, which helps with touch shots and spin. Trade-offs: fiberglass can have a smaller sweet spot and may not deliver the same explosive power as stiffer carbon faces, but it is cost-effective and well-suited for recreational and mid-level players.

Q: Why are pickleball paddles made of fiberglass?

A: Fiberglass is used because it is robust, flexible, and offers a pleasing ball feel that enhances control and spin. It’s typically less expensive than high-end carbon, making it ideal for casual and club-level paddles. Manufacturers pair fiberglass faces with different core materials to tune stiffness and comfort for specific player needs.

-

E-glass fiberglass: Read to understand the material’s mechanical properties, cost profile, and how E-glass layups affect dwell, spin, and player feel—helpful for matching product specs to target segments. ↩

-

carbon/composite: Read to learn differences between carbon weaves and carbon-fiberglass blends (3K/12K/T300), how layup and resin choice impact stiffness and sweet spot, and commercial trade-offs for premium SKUs. ↩

-

hot pressing: Read to understand the hot-press process, required tooling/equipment, cycle times, and effects on laminate bonding and perceived paddle stiffness for high-volume production. ↩

-

thermoforming: Read to learn how thermoforming enables complex shapes and material distribution, its tooling and cost implications, and when it’s the right choice for premium/custom OEM designs. ↩