High-performance pickleball paddles rely on advanced production techniques and premium materials – ensuring durability, precision, and consistent performance for competitive markets. This article explains the technical details and manufacturing processes behind our carbon fiber paddles1, helping retail buyers make an informed decision when sourcing wholesale pickleball equipment.

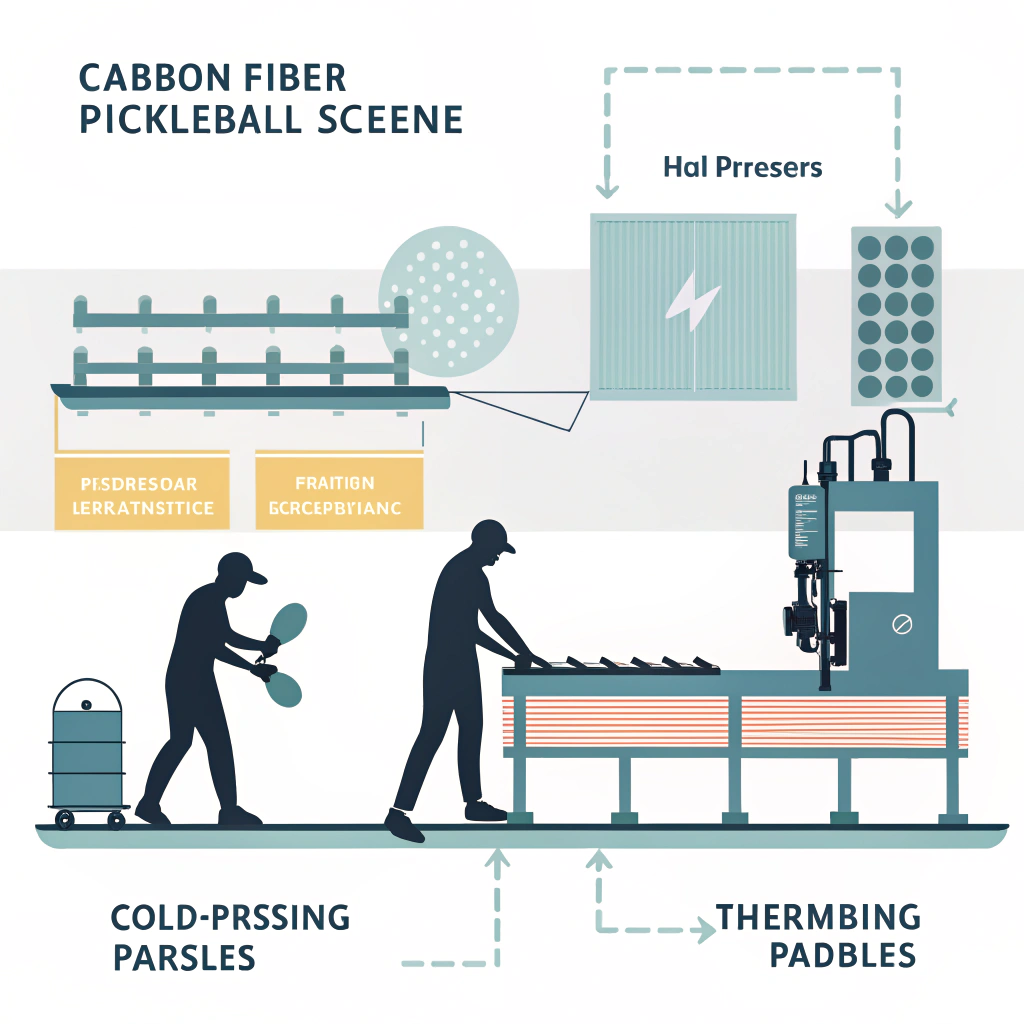

In today’s competitive sports equipment market, retail buyers need products that not only meet high-performance standards but also provide a competitive edge through durability and technical innovation. At NEX Pickleball, our advanced manufacturing processes—hot pressing2, cold pressing3, and thermoforming4—combined with premium materials like various grades of carbon fiber, enable us to deliver products that balance power, control, and longevity. In this article, we dive deep into the production techniques and material selections that distinguish our paddles, explaining the benefits and trade-offs of each method, and offering actionable insights for B2B clients.

Retail buyers and store managers often face several challenges when selecting a supplier for sports equipment:

• Ensuring that products meet a high level of performance without compromising on durability

• Evaluating technical parameters that influence product quality (weight distribution, grip design, surface texture)

• Comparing suppliers on the basis of production processes and material quality

• Balancing cost-efficiency with advanced manufacturing capabilities

When choosing a supplier for wholesale pickleball paddles, it is crucial to understand not only the raw materials but also the production processes that affect paddle performance. For example, while carbon fiber paddles are widely recognized for their strength and responsiveness, the manufacturing process used can alter key characteristics such as rebound force, vibration dampening, and overall feel. Our deep technical overview below provides clarity on how we use each process to tailor paddles to diverse playing styles and market needs.

Our production methods are a cornerstone of our product excellence, each offering unique benefits and considerations. Here’s a breakdown of our three core techniques:

Hot pressing involves heating and applying pressure to the paddle materials to create a structurally strong product.

- Key Advantages:

• High production efficiency, ideal for large-scale orders

• Enhanced impact resistance and structural integrity

• Suitable for high-performance play where durability is critical - Drawbacks:

• Potential alteration of intrinsic material properties, which might affect the delicate feel of the paddle

• Higher equipment investment and operational complexity

Cold pressing shapes the paddle material at room temperature using controlled mechanical pressure, maintaining the natural properties of the materials.

- Key Advantages:

• Precise control over the paddle’s thickness and internal structure

• Preservation of material elasticity for excellent ball control and responsiveness

• Ideal for designs prioritizing touch and finesse - Drawbacks:

• Production cycles are typically longer

• Requires precision equipment to ensure consistency, which may affect scalability

Thermoforming is used for creating paddles with complex shapes by heating the material to a softening state and then molding it.

- Key Advantages:

• Ability to produce intricately designed paddles with optimized material distribution

• Enhanced stability and improved performance through precise shaping

• Adaptable to various high-performance, custom-made designs - Drawbacks:

• Longer production times and higher processing costs

• Best suited for premium or custom orders rather than high-volume production

To further clarify the differences, consider the following table summarizing our production processes:

| Production Method | Key Advantages | Limitations |

|---|---|---|

| Hot Pressing | Fast production, high strength, strong impact resistance | Potential material alteration; higher equipment cost |

| Cold Pressing | Precise control, better ball feel and elasticity | Longer cycle times; requires precise pressure management |

| Thermoforming | Complex designs, optimized material distribution, high stability | Longer production time; higher processing cost |

Each of these techniques is selected based on the desired performance characteristics and customization needs of the paddles. For wholesale buyers, understanding these processes is essential to ensuring that the chosen supplier aligns with their quality and supply chain requirements.

Beyond production processes, the choice of raw materials significantly determines the final product’s performance. Our carbon fiber paddles utilize several high-grade carbon fibers, each optimized for distinct performance aspects:

• 3K Carbon Fiber: Designed for high rebound force, it offers strength and flexibility, and is excellent for reducing paddle vibration. This material suits players who demand power combined with durability.

• 12K Carbon Fiber: With a higher thread density, 12K carbon fiber paddles have a smoother and harder surface. They provide exceptional impact resistance, making them ideal for competitive play where extreme strength is necessary.

• T300 Carbon Fiber: Known for its outstanding tensile strength, T300 is balanced in terms of weight and power, delivering precision performance for players who require a blend of speed and control.

While our carbon fiber variants lead the market in terms of performance, we also utilize high-quality fiberglass for paddles that demand enhanced ball control and a wider sweet spot. Additionally, composite materials such as carbon fiber-fiberglass amalgams and bamboo core composites broaden our product portfolio, catering to various playing styles and market segments.

The combination of advanced materials and production processes gives us the flexibility to offer customization. Clients can select from multiple core materials such as Nomex5, aluminum, or polymer honeycomb cores, each affecting the paddle’s hardness, balance, and vibration absorption. This level of control is particularly valuable for B2B partners who need to cater to diverse customer demands and competitive market standards.

In today’s B2B landscape, retail buyers value suppliers who not only supply quality products but also offer the ability to customize orders to match specific customer needs. At NEX Pickleball, our on-demand print services and customizable options mean that you can tailor your order based on design preferences, grip sizes, weight distribution, and surface textures. Such customization ensures that the finished product resonates with your target market, enhancing your store’s competitive advantage.

Custom options provided include:

• Choice of carbon fiber type for tailored performance

• Variety of core materials for optimal balance and shock absorption

• Ergonomic grip designs adjusted to regional and market-specific requirements

• Personalized printing options for team branding or retail aesthetics

Retail buyers can leverage our flexibility to secure bulk order discounts without compromising on quality. Our streamlined production processes ensure timely delivery and consistency—critical factors when managing seasonal stock or meeting retailer demands amid competitive inventory cycles.

For retail buyers considering a supplier for high-performance pickleball paddles, here are several best practices to ensure a successful procurement process:

- Technical Evaluation: Verify that the supplier can deliver technical specifications that match market expectations. Ask for detailed comparisons of production techniques and material quality.

- Production Reliability: Choose suppliers with robust quality control measures. Understanding the nuances of production processes like hot pressing and thermoforming can indicate the consistency and durability of the products.

- Customization Capability: Look for manufacturers that allow customization. A supplier who can adjust paddle properties to meet local market preferences offers significant added value.

- Cost-Efficiency Analysis: Evaluate the overall cost-to-performance ratio. Advanced production processes might come at a premium, but efficiencies gained through customization and durability can lead to long-term savings.

- Supply Chain Transparency: Confirm that the manufacturer adheres to stringent quality standards. Trust and reliability in the supply chain minimize risk and enhance buyer confidence in bulk transactions.

The decision-making process in selecting the right supplier is complex, but a detailed technical evaluation will help you choose a partner whose production methods align with your retail strategies.

Recent industry data highlights that consumers increasingly demand premium materials in sports equipment. For example, a survey of competitive pickleball players revealed that over 70% prefer paddles with advanced carbon fiber construction due to their enhanced power and control. This trend has encouraged many retailers to stock products that boast both technical advantages and customizable designs.

A case study from a leading sports distributor demonstrated that incorporating high-quality, custom-designed carbon fiber paddles into their portfolio led to a 25% increase in repeat orders. The distributor attributed this success to the product’s superior performance and the ability to meet diverse market demands through customization. These insights reinforce the importance of leveraging advanced manufacturing processes for sustained market relevance.

In summary, wholesale pickleball paddle buyers can significantly benefit from partnering with manufacturers that employ advanced production techniques and premium materials. Understanding the intricacies of hot pressing, cold pressing, and thermoforming—and how these processes affect product performance—enables you to make well-informed purchasing decisions. Our diverse range of high-performance materials, including multiple grades of carbon fiber, along with customization options, ensures that your inventory meets both competitive standards and consumer expectations.

Actionable recommendations for B2B buyers:

• Request technical specifications and production process details from potential suppliers.

• Consider the balance between production efficiency and product customization to suit market needs.

• Utilize data-backed insights to guide bulk order decisions and negotiate competitive pricing.

• Engage with suppliers who offer transparent quality control procedures for consistent product performance.

• Evaluate customization capabilities that allow for personalized print services and design modifications to enhance market appeal.

By carefully weighing these factors, you can confidently choose a supplier that aligns with your business objectives, ensuring that your store offers premium, durable, and performance-enhancing pickleball paddles that resonate with a competitive customer base.

Q: What are the advantages of hot pressing compared to other production methods?

A: Hot pressing offers high production efficiency and creates strong, impact-resistant paddles ideal for large-scale orders, though it may slightly alter material properties compared to cold pressing or thermoforming.

Q: How does using carbon fiber enhance paddle performance?

A: Carbon fiber, especially types like 3K, 12K, and T300, provides excellent strength, durability, and controlled flexibility, resulting in paddles with superior rebound force, reduced vibration, and balanced performance.

Q: What customization options does NEX Pickleball offer for wholesale orders?

A: NEX Pickleball provides various customization options, including selection of carbon fiber type, core material customization (Nomex, aluminum, polymer honeycomb), grip design adjustments, and on-demand print services to meet specific retailer requirements.

-

carbon fiber paddles: Click here to learn more about the advanced composite properties and design considerations that make carbon fiber paddles a top choice for high-performance sports equipment. ↩ ↩

-

hot pressing: Click here to explore how hot pressing applies heat and pressure to enhance material strength and impact resistance in paddle manufacturing. ↩ ↩

-

cold pressing: Click here to understand how cold pressing preserves the material’s natural properties while ensuring precision in thickness and elasticity for optimal paddle performance. ↩ ↩

-

thermoforming: Click here to read about the thermoforming process, which enables the creation of complex paddle shapes through controlled heating and molding techniques. ↩ ↩

-

Nomex: Click here to discover more about Nomex, a high-performance, fire-resistant material used in composite cores to enhance durability and performance in sports equipment. ↩ ↩