Custom printed pickleball paddles can significantly enhance your brand’s appeal while offering high-performance, durable equipment perfectly tailored to your business needs. By leveraging advanced manufacturing processes and high-quality materials, partnering with a reliable OEM1 like NEX Pickleball ensures you receive custom solutions that balance performance, innovation, and cost-efficiency.

With the rapid growth of pickleball as a sport, many retailers, distributors, and branding managers are looking for suppliers who can deliver unique, high-quality, and customizable paddle solutions. Decision-makers face several challenges:

• Ensuring production quality and consistency across large orders

• Meeting strict branding requirements with custom prints and design modifications

• Balancing production costs with high-performance materials and advanced manufacturing processes

• Adapting to shifting market trends while maintaining competitive pricing

Companies that seek to stand out in the sports equipment market require partners who not only excel at quality manufacturing but also provide flexibility in design and customization options. This is where NEX Pickleball comes into play.

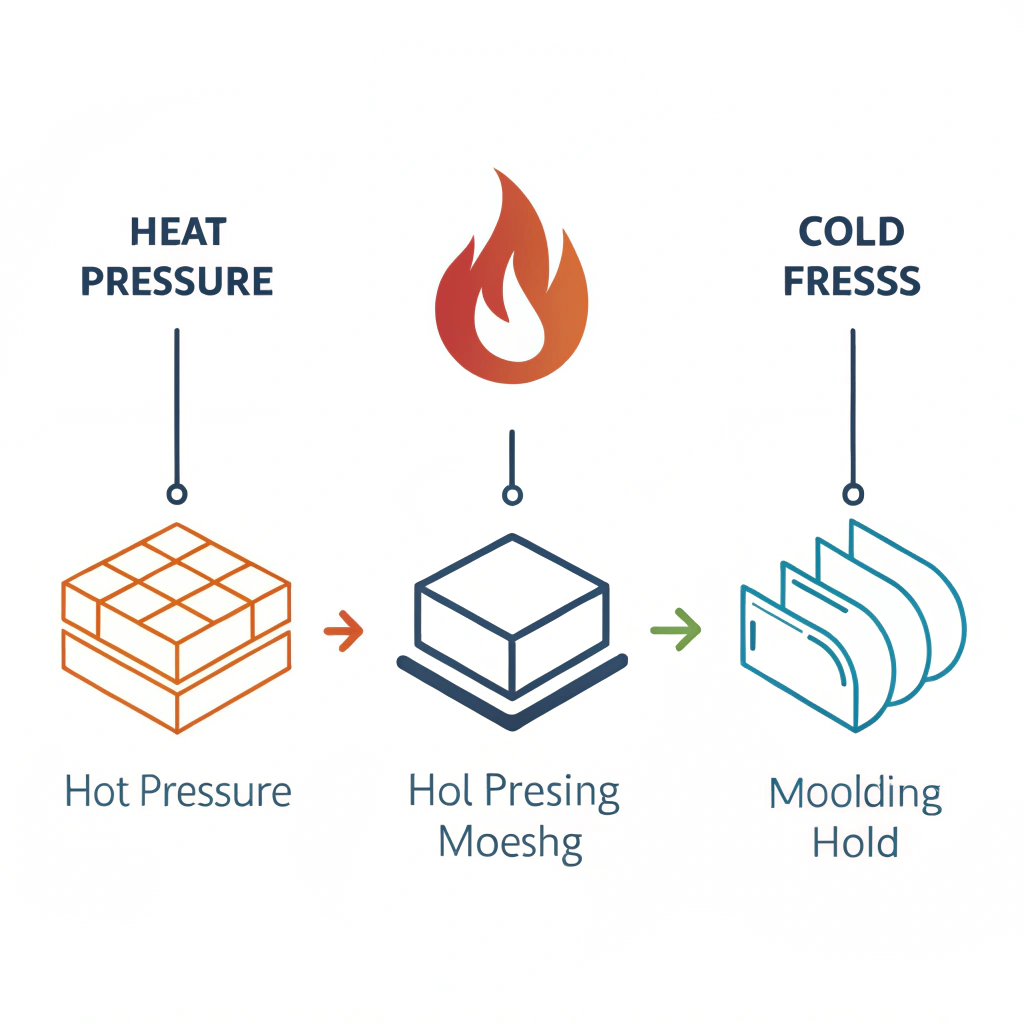

At NEX Pickleball, our competitive edge is built upon a deep commitment to quality control and innovation in production. We specialize in three main manufacturing processes: hot pressing2, cold pressing, and thermoforming3. Each process is optimized to meet different performance needs and design specifications.

This method involves heating the materials and applying high pressure to form a robust paddle structure.

- Advantages:

• High production efficiency makes it suitable for bulk manufacturing.

• Results in paddles with excellent impact resistance and structural integrity.

• Ideal for high-performance paddles designed for competitive play. - Disadvantages:

• High equipment investments are required.

• Intensive heat may alter certain material properties, potentially affecting the paddle’s feel.

Cold pressing shapes the paddle material at room temperature through mechanical pressure.

- Advantages:

• Precise control over paddle thickness and structure, ensuring a stable feel.

• Preservation of the natural material properties leads to superior ball control and responsiveness. - Disadvantages:

• Longer production cycles can limit overall efficiency.

• The process demands precise equipment calibration to achieve consistent quality.

This process softens the material through controlled heating and then molds it into the desired shape using predefined molds.

- Advantages:

• Allows for complex and precise paddle designs with controlled material distribution.

• Enhances paddle stability and performance characteristics especially in premium product lines. - Disadvantages:

• Involves longer production times.

• Higher equipment costs make it best suited for custom-made or premium paddles.

Below is a comparative table summarizing the three production processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, robust structural integrity | High investment cost, potential alteration of material properties |

| Cold Pressing | Precise thickness control, maintains natural material properties, superior responsiveness | Longer production cycles, requires high precision equipment |

| Thermoforming | Allows intricate designs, maintains stability, suitable for premium paddles | Longer production time, higher equipment costs |

Material selection is critical when manufacturing high-performance, custom printed paddles. NEX Pickleball uses a variety of premium materials aimed at meeting different play styles and performance standards.

Carbon Fiber4 is favored for its strength-to-weight ratio, durability, and impact absorption. We offer:

• 3K Carbon Fiber:

Ideal for paddles requiring high rebound force and flexibility. It provides excellent durability while reducing vibration, making it suitable for both recreational and competitive play.

• 12K Carbon Fiber:

With a higher thread density, this material provides a smoother surface finish, enhanced hardness, and better durability. It is perfect for competitive players seeking extreme performance.

• T300 Carbon Fiber:

Known for its balanced performance, T300 offers outstanding tensile strength while keeping the paddle lightweight, making it optimal for agile gameplay and power control.

Fiberglass5 is used for paddles that prioritize striking a balance between power and control, thanks to its flexibility and excellent ball feel.

• E-Glass Fiberglass:

Provides excellent elasticity and control, making it a popular choice for paddles targeting a wider sweet spot.

• Carbon Fiber and Fiberglass Composite:

These composites combine the rigidity of carbon fiber with the flexibility of fiberglass, ensuring that the paddle delivers both explosive power and nuanced control.

• Bamboo Core Composite:

Offers an eco-friendly, lightweight solution with impressive impact resistance and a distinct, crisp hitting feel.

• Honeycomb Core:

Engineered with high-density polymers or pulp, these cores provide superior shock absorption, enhancing durability while reducing vibration.

The core of the paddle is central to its performance, dictating the balance of control, hardness, and overall hitting feel. Our core materials include:

• Nomex Honeycomb Core:

Known for its durability and excellent shock absorption, it offers stability for high-performance play.

• Aluminum Honeycomb Core:

Balances weight evenly, offering both power and precise control—ideal for players seeking versatility.

• Polymer Honeycomb Core:

Provides improved elasticity and reduces vibration, making it a favorite among recreational players and beginners seeking comfort during play.

For B2B buyers, the ability to customize is key to differentiating your brand in a competitive market. Our custom printing services allow you to imprint your logo, colors, and unique design elements directly onto the paddle. Here’s why customization matters:

Custom printed paddles offer your brand a unique identity and premium image. Not only do they serve as a functional sports tool, but they also double as a marketing asset:

• Brand Recognition:

With every strike on the court, your brand’s logo is on display, reinforcing your market presence.

• Consistent Brand Messaging:

Consistency in design across your sports merchandise builds credibility and customer trust.

• Tailored Solutions:

Whether you’re looking to outfit a team, create limited-edition items, or enhance your store’s product line, our customization options allow for tailored designs that meet your specific requirements.

Our process is designed to be hassle-free and efficient:

-

Design Consultation:

We work closely with your team to understand your branding needs and design preferences. -

Material and Process Selection:

Based on the required performance and design, we select the optimal materials (e.g., carbon fiber, fiberglass) and production processes (hot pressing, cold pressing, or thermoforming). -

Precision Printing:

Our advanced printing technology ensures that every paddle meets the highest quality standards while providing vibrant, long-lasting branding.

This deep customization aligns with our overall commitment to providing a complete OEM solution that merges high-performance sports equipment with effective branding strategies.

When selecting an OEM partner, decision-makers must evaluate not only the product quality but also production efficiency and after-sales support. Here’s how NEX Pickleball stands out:

Every paddle produced undergoes rigorous testing to ensure it meets stringent quality standards. Our quality control protocol covers:

• Material Integrity Testing:

Verifying that materials like carbon fiber and fiberglass meet durability and performance benchmarks.

• Production Process Monitoring:

Ensuring that hot pressing, cold pressing, and thermoforming steps are optimized for consistent product quality.

• Performance Validation:

Testing paddles under various controlled environments to assess shock absorption, weight distribution, and ergonomic grip.

This comprehensive approach minimizes waste, reduces defect rates, and maintains a high quality consistency critical for B2B partners seeking reliability.

Our state-of-the-art manufacturing facilities in Jiaxing, Zhejiang, allow us to scale production quickly without compromising quality. By implementing lean manufacturing practices and advanced production technology, we ensure:

• On-Time Delivery:

Efficiency in production cycles means you receive your orders as scheduled.

• Cost-Effective Solutions:

Bulk production and optimized processes make our custom printed paddles competitively priced, ensuring excellent ROI.

• Flexibility in Order Volume:

Whether you need a large batch for retail distribution or a smaller, custom run for a special event, our systems are designed to accommodate your requirements seamlessly.

Choosing a manufacturing partner for custom printed pickleball paddles is a strategic decision that can significantly impact your brand’s market performance. Here are the main points to consider:

-

Advanced Production Processes:

Our deep integration of hot pressing, cold pressing, and thermoforming methods ensures that every paddle is manufactured to perfection. -

Superior Material Options:

With premium materials such as various grades of carbon fiber, fiberglass, and innovative composite cores, our paddles offer unmatched performance and durability. -

Customization and Branding:

Tailor-made paddle designs elevate brand identity and offer an impactful way to engage with your target audience. -

Consistent Quality Control and Efficiency:

With rigorous testing protocols and scalable production, you get reliable products delivered on time every time.

Based on our factory experience and market insights, partnering with NEX Pickleball not only elevates your product line but also positions your brand as a leader in innovative sports equipment. We invite you to explore our custom printed paddle solutions and experience the benefits of working with an OEM partner who truly understands performance, customization, and market demands.

-

What are the advantages of custom printed pickleball paddles?

Custom printed pickleball paddles offer enhanced branding opportunities, enabling your company to stand out by showcasing your logo and design on high-performance sports equipment. The customization ensures that every paddle reflects your brand’s identity while delivering reliable performance with precise control and durability. -

How do different production processes affect the paddle quality?

Different production processes impact paddle quality in various ways. Hot pressing increases production efficiency and results in strong, durable paddles, while cold pressing provides precise control over thickness and enhances responsiveness. Thermoforming allows for intricate designs and optimal material distribution, catering to premium, custom-made paddle requirements. -

Why is material selection important in pickleball paddle manufacturing?

Material selection is crucial because it directly impacts the paddle’s performance, durability, and playability. Premium materials such as various grades of carbon fiber, fiberglass, and composite core materials ensure that each paddle can provide the right balance of strength, light weight, and impact absorption. This selection process is key to meeting both competitive performance standards and customization demands for effective branding.

-

OEM: Click to learn about Original Equipment Manufacturers, including their role in design, production, and supply chain dynamics to enhance product branding and efficiency. ↩

-

hot pressing: Click to explore the hot pressing process, which uses heat and pressure for rapid, high-volume manufacturing while ensuring structural integrity. ↩

-

thermoforming: Click to understand thermoforming—a process involving controlled heating and molding for creating detailed, custom product shapes with consistent quality. ↩

-

Carbon Fiber: Click to discover the benefits of carbon fiber, renowned for its strength-to-weight ratio and durability, making it ideal for high-performance sports equipment. ↩

-

Fiberglass: Click to learn about fiberglass, a versatile material used for its excellent balance of flexibility and strength in enhancing product performance. ↩