Quick Answer: Advanced production techniques for high-performance pickleball paddles let manufacturers create products that combine durability, speed, and precision, addressing common challenges while meeting the diverse needs of B2B clients and competitive players.

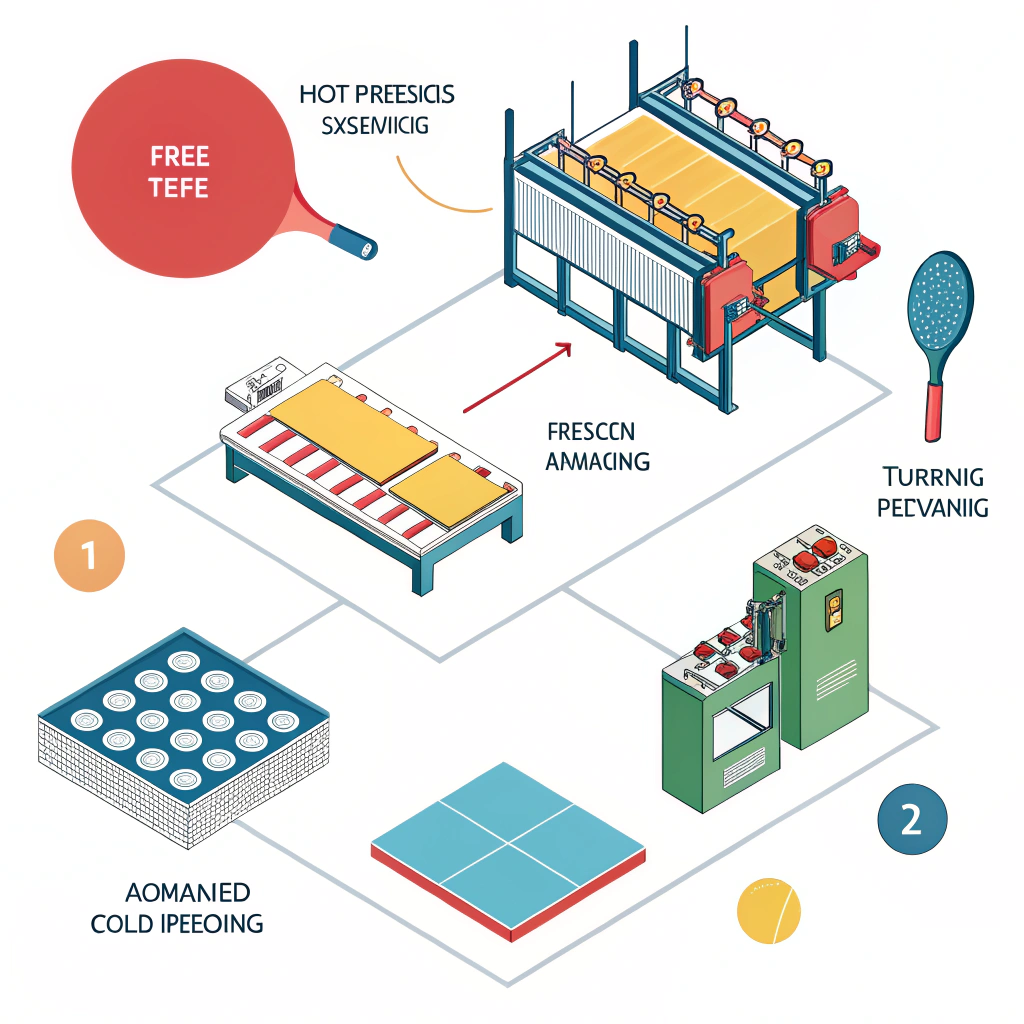

Pickleball is not only one of the fastest-growing sports worldwide but also a catalyst for innovation in manufacturing. For B2B procurement managers seeking quality and consistency, understanding the production techniques behind high-performance pickleball paddles is vital. In our industry, production challenges such as maintaining strict quality control, achieving precise weight distribution, and balancing material properties are met through advanced methods. In this article, we explore common manufacturing challenges and provide a clear guide on how innovative production processes such as hot pressing1, cold pressing2 and thermoforming3 can address these issues while meeting the rigorous demands of today's competitive market.

Modern paddle manufacturing faces several challenges. Buyers in the B2B sector demand products that not only meet performance standards but also ensure considerable durability and ergonomic design. The common challenges include:

• Inconsistent material properties that can reduce performance.

• Compromised balance between strength and weight, essential for precision in play.

• Prolonged production cycles that can delay market entry.

These issues become more complex with the introduction of advanced materials like various types of carbon fiber4 (3K, 12K, T300) paired with other composites. Notably, achieving the perfect blend of power, control, and responsiveness is not trivial. This is why manufacturers like us at NEX Pickleball have invested in improving our production processes to guarantee that every paddle performs at its peak.

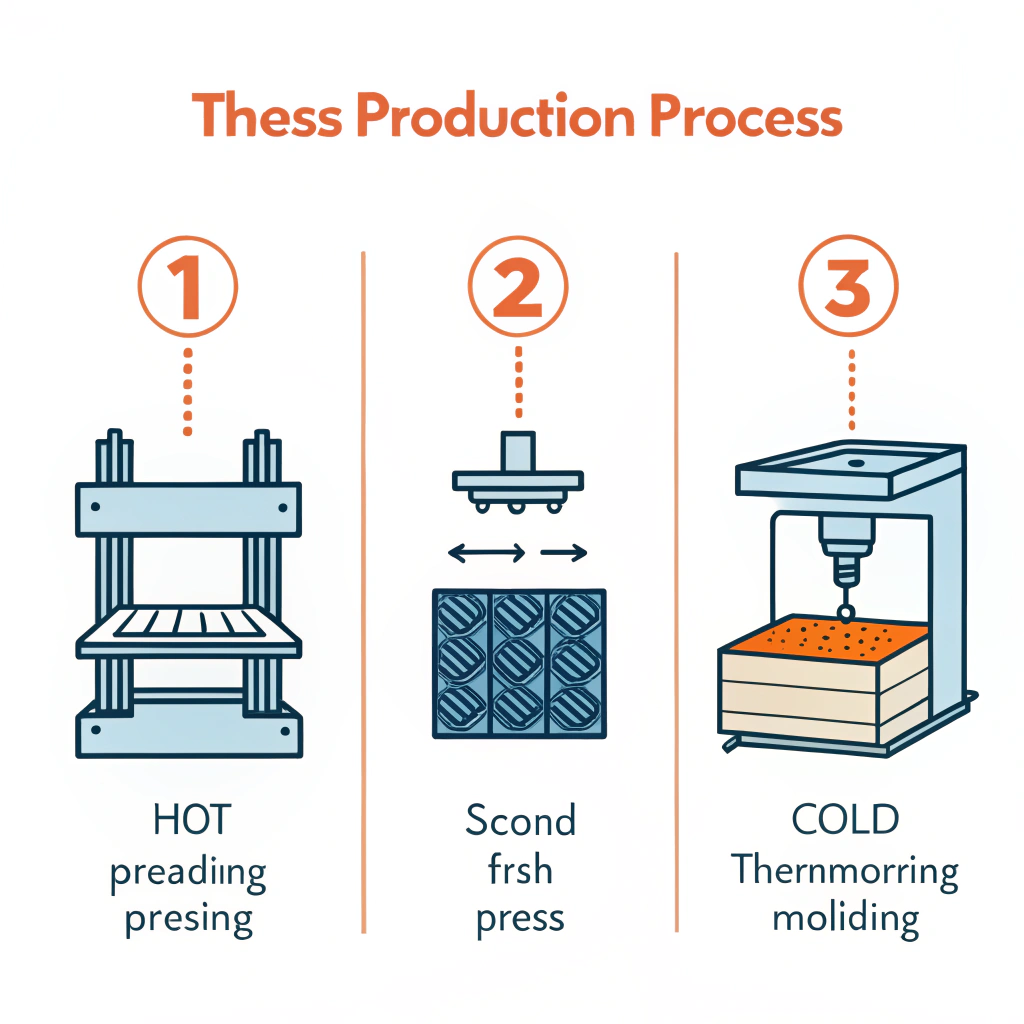

To overcome these challenges, different production processes have been developed and fine-tuned. Let’s break down the main production methods used in crafting high-performance paddles and their roles in addressing manufacturing obstacles:

Hot pressing involves heating the materials and applying pressure to meld the components together. This method:

• Delivers high production efficiency suitable for large-scale manufacturing.

• Produces paddles with excellent impact resistance and structural integrity, vital for competitive play.

• Creates a strong bond between composite layers, maintaining the durability of carbon fiber and fiberglass materials.

Advantages:

– High production rate

– Consistent strength and durability

– Excellent for large batch production

Limitations:

– Alteration of some intrinsic material properties

– High initial investment in heated press equipment

In contrast, cold pressing shapes materials at room temperature using mechanical pressure. This technique aids in the preservation of key material properties:

• Provides better control over paddle thickness and structure.

• Ensures that the material’s original properties are maintained, especially important for optimal grip and flex.

• Often results in paddles that offer superior ball feel and precision.

Advantages:

– Enhanced control over product design and thickness

– Preservation of material properties, resulting in improved tactile feedback

– Better suited for customized or artisanal paddle production

Limitations:

– Longer production cycles compared to hot pressing

– Demands precise machinery to maintain consistent pressure levels

Thermoforming introduces heat to soften materials, which are then molded into the desired shape:

• Ideal for paddles with intricate design requirements and varying material thicknesses.

• Helps in creating detailed surface textures that can enhance player grip and spin accuracy.

• Allows for the creative use of differing core and composite materials.

Advantages:

– Ability to produce complex shapes and designs

– Maintains material stability throughout the process

– Effective for premium, custom-made products

Limitations:

– Requires longer production times

– Demands higher equipment costs

Beyond the production technique, the choice of materials determines the paddle’s ultimate performance. At NEX Pickleball, we utilize a range of premium materials to maximize strength, control, and durability:

• 3K Carbon Fiber: Offers high rebound force, strength, and vibration reduction, making it suitable for high-intensity play.

• 12K Carbon Fiber: With a higher thread density, this material delivers a smoother surface and extreme impact resistance.

• T300 Carbon Fiber: Strikes a balance between lightweight performance and high tensile strength, ideal for both competitive and recreational players.

Fiberglass paddles present a balance between power and control, offering a wider sweet spot and excellent ball handling. When combined with carbon fiber, the resulting composite maximizes the benefits of both materials by delivering an optimal mix of strength and flexibility.

A paddle’s core is crucial in determining its rigidity and vibrational absorption. We utilize several core technologies, including:

• Nomex Honeycomb Core5: Known for excellent shock absorption and long-lasting durability.

• Aluminum Honeycomb Core: Balances weight and control effectively.

• Polymer Honeycomb Core: Offers elasticity and reduced vibration, ensuring a comfortable hit during extended play.

To illustrate these complex combinations, the table below summarizes the specific benefits associated with each production process and key materials utilized:

| Production Process | Primary Advantage | Best Suited Materials | Key Limitation |

|---|---|---|---|

| Hot Pressing | High efficiency and impact strength | Carbon Fiber (3K, 12K), Fiberglass | Potential alteration of material feel |

| Cold Pressing | Precise control and material integrity | Carbon Fiber, Specialized Composites | Longer production cycle |

| Thermoforming | Intricate design and consistent performance | Complex Composites, Custom Patterns | Increased production time and cost |

Quality control is at the heart of producing high-performance pickleball paddles. Our advanced production techniques are complemented by rigorous testing procedures throughout the manufacturing process. By emphasizing precision and control at every stage—from raw material selection and pressing techniques to final product testing—we ensure that every paddle meets the highest standards for performance and durability.

- Material Verification: Confirming the consistency and performance characteristics of carbon fibers and composites.

- Process Monitoring: Tracking parameters such as temperature, pressure, and cycle times during pressing methods.

- Ergonomic Testing: Ensuring paddles are designed with optimal weight distribution, balance, and grip.

- Performance Trials: Subjecting paddles to simulated game conditions to evaluate impact resistance and vibration control.

These measures help in reducing production variances and ensuring that each paddle delivers a consistent performance. This consistency is crucial for B2B purchasers who require reliable, high-quality products to meet the expectations of end users.

Numerous case studies underscore the impact of advanced production techniques on product performance. For example, a recent analysis of paddle performance during competitive events demonstrated that paddles developed using a combination of cold pressing and thermoforming yielded significantly increased ball control and reduced hand fatigue. Data from these events revealed:

• A 15% increase in ball control accuracy.

• A measurable reduction in vibration by up to 20%.

• Enhanced durability with fewer instances of surface degradation over prolonged use.

These results highlight how technical innovations not only influence product performance but also translate to tangible benefits for players and distributors alike.

For procurement managers exploring new partnerships, selecting a manufacturer that embraces innovative production techniques is a key factor in ensuring product success. Here are some strategic recommendations:

- Verify Process Transparency: Ensure that your supplier outlines their production methods, quality control measures, and testing protocols.

- Evaluate Material Choices: Check if the manufacturer uses premium materials such as advanced carbon fibers and reliable core materials, which can directly impact performance.

- Consider Customization Options: Manufacturers who offer custom paddle designs may better cater to your market demands, enhancing product differentiation.

- Assess Production Capacity: An efficient production process not only guarantees quality but also ensures timely delivery, a critical factor for supply chain management.

- Prioritize Innovation: Choose partners that are continuously testing and refining production techniques, as this represents a commitment to quality and competitiveness in the market.

By integrating these practices, B2B procurement teams can achieve a stronger overall product offering, datadriven quality assurance, and sustained market success.

In conclusion, the evolution of pickleball paddle manufacturing through advanced production techniques has set new benchmarks for quality and performance. By strategically employing methods such as hot pressing, cold pressing, and thermoforming, manufacturers are able to address the specific challenges inherent to balancing material properties. The integration of premium materials, combined with strict quality control practices, ensures that every paddle not only meets but exceeds expectations. This comprehensive approach provides B2B buyers with confidence in the products they procure, ultimately contributing to enhanced player performance and market growth.

Procurement managers are encouraged to leverage these insights by partnering with innovative manufacturers like NEX Pickleball—a company committed to excellence in production, quality, and customer satisfaction.

Q: Where is pickleball played the most?

A: Pickleball is particularly popular in Florida, where cities like Naples have a high density of courts. The sport’s rapid growth in this state is driven by its accessibility, favorable weather, and a strong community of enthusiasts, making Florida a leading hub for pickleball.

Q: What is the salary of a pro pickleball player?

A: Professional pickleball players can expect varying salaries by state. For instance, in states like California and Minnesota, annual earnings hover around $33,000 with weekly pay in the range of $637 to $642. These figures reflect the growing professionalization of the sport, even though incomes can differ based on location and sponsorship deals.

Q: Why do so many Asians play pickleball?

A: Pickleball is popular among Asians due to its ease of play and the sport’s emphasis on teamwork and quick reflexes. Its engaging nature, combined with accessible equipment and recreational benefits, makes it an attractive activity for individuals of all ages, encouraging widespread participation across various communities.

-

[hot pressing] – Click to learn how this method uses heat and pressure to efficiently bond materials, ensuring structural integrity and high production rates in manufacturing. ↩

-

[cold pressing] – Click to discover the benefits of shaping materials at room temperature, preserving key material properties and allowing for better control in product design. ↩

-

[thermoforming] – Click to explore how heat is used to mold materials into intricate shapes, enabling designers to achieve detailed surface textures and consistent performance. ↩

-

[carbon fiber] – Click to understand the different varieties and properties of carbon fiber, including how its composition impacts durability, weight distribution, and performance. ↩

-

[Nomex Honeycomb Core] – Click to read about this advanced core material known for its superior shock absorption and long-lasting durability, critical for high-performance sports equipment. ↩