Custom OEM production1 for pickleball paddles offers enhanced customization, quality control, and brand differentiation compared to dropshipping2, delivering long‐term value and cost efficiency for B2B decision-makers. This article explains the challenges of the dropshipping model, highlights the advantages of transitioning to custom OEM, and provides detailed guidelines on implementing a successful transition strategy.

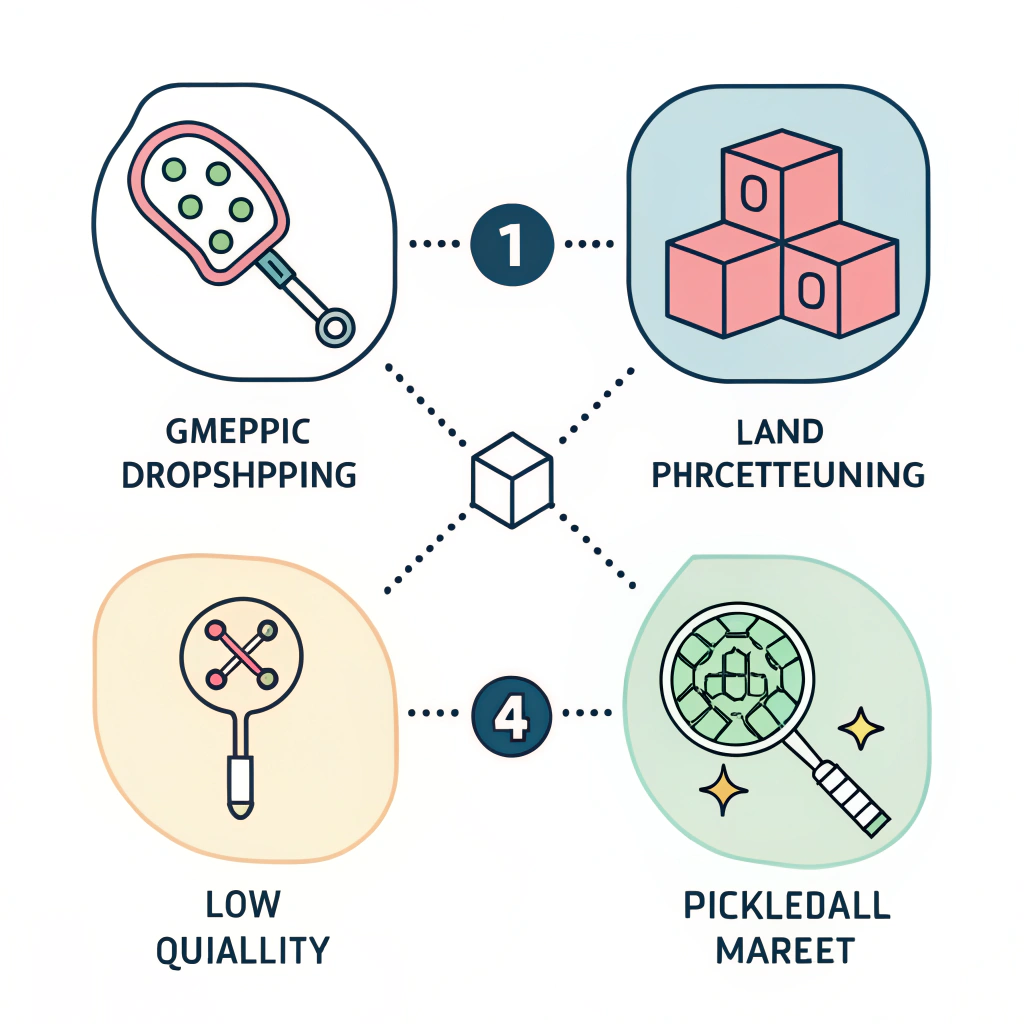

For many B2B entrepreneurs in the sports equipment industry, dropshipping has been an accessible model. However, as markets grow competitive and brand value becomes crucial, the dropshipping model may no longer support scalability or differentiation. Key challenges with dropshipping include:

- Limited Customization: Dropshipped products often come as-is, leaving little room for exclusive features or branding.

- Lower Perceived Value: Products that are widely distributed may compete primarily on price, which can sometimes compromise quality or performance.

- Supply Chain Dependency: With dropshipping, you rely on third parties for inventory, fulfillment, and quality control, which can introduce variability in production standards.

- Reduced Control Over Materials and Processes: When you are not directly involved in manufacturing, ensuring premium materials such as 3K Carbon Fiber, 12K Carbon Fiber, or specialized composites becomes difficult.

Transitioning from dropshipping to a custom OEM approach can address the above challenges while opening new avenues for market differentiation. Here’s why custom OEM production, especially with an expert manufacturing partner like NEX Pickleball, is worth considering:

Custom OEM allows you to design paddles that reflect your brand’s identity. Rather than offering generic paddles, you can integrate unique elements such as color schemes, logos, or custom grip designs that resonate with your target audience.

By partnering directly with manufacturers who specialize in advanced production techniques—including hot pressing, cold pressing, and thermoforming3—you secure a level of quality that elevates customer satisfaction. Utilizing premium materials such as various types of Carbon Fiber and Fiberglass ensures that your paddles perform exceptionally and last longer.

Although custom OEM might seem like a larger upfront investment compared to dropshipping, the long-term benefits include:

- Improved Manufacturing Efficiency: By eliminating intermediaries, you can achieve significant cost savings over time.

- Tailored Inventory Management: Control over production volumes helps reduce excess inventory while ensuring supply meets demand.

- Strategic Pricing Flexibility: With a premium custom product, you can command higher price points and improve your profit margins.

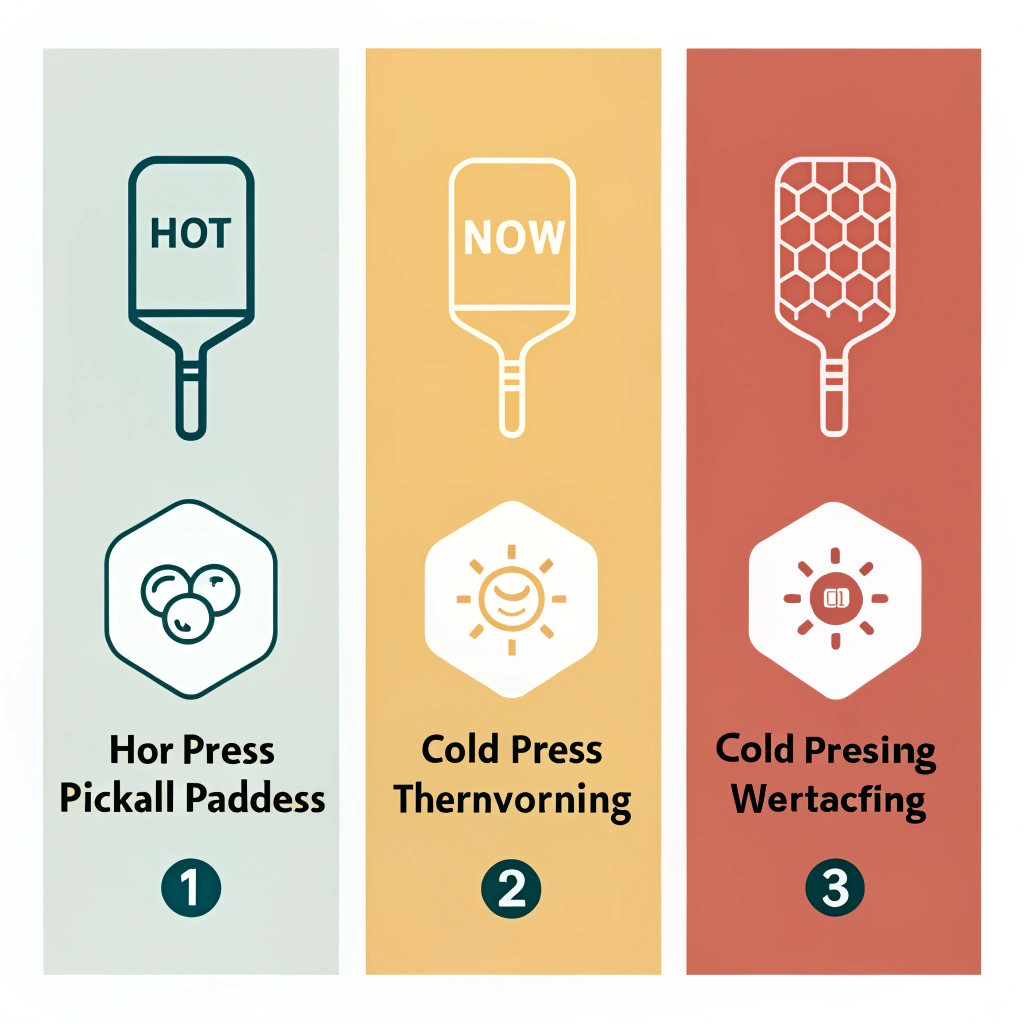

A critical component of the OEM production process is the selection of manufacturing techniques. NEX Pickleball employs three primary production methods that allow for precision and durability. Understanding these can help clarify which production technique is most aligned with your brand’s needs.

Below is a table comparing the pros and cons of the three main production processes:

| Production Process | Advantages | Disadvantages | Ideal Use Case |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Strong impact resistance - Excellent structural integrity | - May alter material properties affecting feel - Requires high investment in equipment | High-performance paddles for competitive play |

| Cold Pressing | - Precise control over thickness - Maintains material properties - Excellent ball feel | - Longer production cycles - Demands high-quality equipment for pressure control | Designs requiring superior control and a refined touch |

| Thermoforming | - Enables intricate designs - Precise material distribution - Maintains paddle stability | - Longer production time - Higher equipment cost | Premium products or custom-made paddles with complex shapes |

These processes not only ensure that paddles are made to exacting standards but also allow for customizations that align with your brand’s identity, which dropshipping rarely supports.

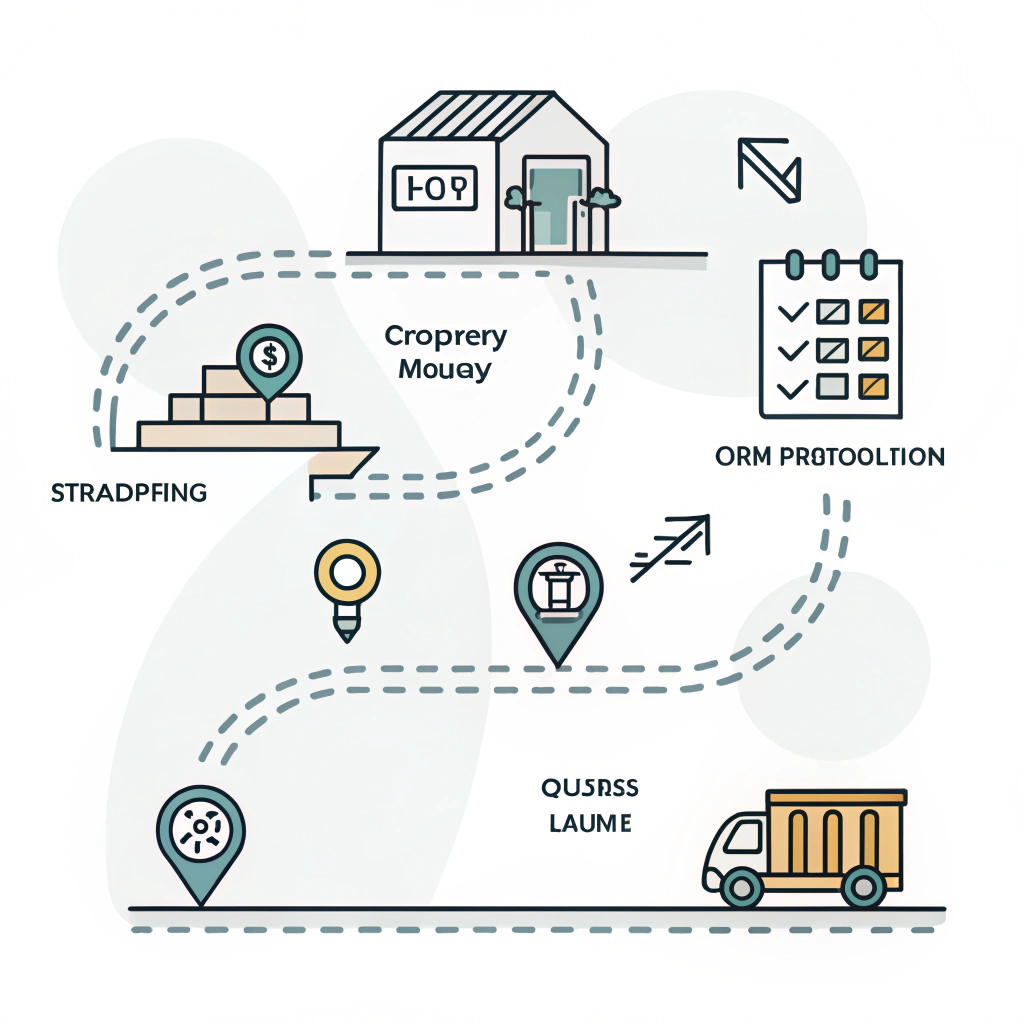

Transitioning your business model requires strategic planning and collaboration with a trusted manufacturing partner. Here’s a step-by-step guide to help you make a smooth transition:

- Identify Market Gaps: Evaluate your current product portfolio and identify areas where customization could enhance value.

- Determine Customer Preferences: Conduct surveys or focus groups to understand what your customers value—be it paddle durability, performance, or custom design aesthetics.

- Expertise in Pickleball Paddles: Choose a partner with a proven track record, such as NEX Pickleball, who offers advanced production techniques and diverse material options.

- Quality Control Standards: Ensure that the manufacturer adheres to rigorous testing and quality controls to guarantee that every paddle meets high-performance benchmarks.

- Customization Capabilities: Look for a partner that offers multiple options for core materials (like Nomex Honeycomb4, Aluminum Honeycomb, and Polymer Honeycomb) and surface materials (e.g., carbon fiber, fiberglass).

- Collaborative Design Process: Work with your OEM partner to develop a design that meets both your branding requirements and performance standards.

- Material Selection: Choose among premium materials such as 3K Carbon Fiber for enhanced rebound force or Bamboo Core Composite5 for a lightweight, impact-resistant structure.

- Prototype Testing: Before mass production, create prototypes for testing to ensure the design meets all expected quality and performance criteria.

- Upfront Costs vs. Long-Term Savings: Compare the investment required for OEM production against the benefits of custom branding and potential higher retail margins.

- Scalability Considerations: Evaluate if your chosen OEM partner can scale production efficiently as your business grows.

- Return on Investment (ROI): Consider how premium custom paddles can improve your brand reputation and allow you to charge a competitive price.

A simple table outlining cost-benefit considerations may help summarize these points:

| Consideration | Dropshipping Model | Custom OEM Production |

|---|---|---|

| Initial Investment | Low | Moderate to High |

| Customization Opportunity | Minimal | Extensive |

| Brand Differentiation | Low | High |

| Quality and Performance Control | Dependent on third party | High (direct quality control) |

| Scalability | Quick setup but limited flexibility | Requires planning, but scalable |

| Long-Term Cost Efficiency | Lower margins | Higher margins and brand value |

- Structured Rollout: Plan a phased rollout of your custom products, starting with limited editions to gather customer feedback.

- Marketing and Branding: Leverage the unique selling points of your OEM paddles—such as superior quality, custom design, and innovative materials—in your marketing campaigns.

- Monitor and Optimize: Collect data on market response and adjust production based on performance feedback and customer satisfaction metrics.

NEX Pickleball stands as a prime example of how custom OEM production can empower a brand. As a leading manufacturer of high-performance pickleball paddles in Jiaxing, Zhejiang, China, they specialize in:

- Utilizing advanced production methodologies like hot pressing, cold pressing, and thermoforming.

- Offering a diverse range of premium materials—from various grades of carbon fiber to state-of-the-art composite cores.

- Providing custom paddle options to suit varying player needs, whether for competitive tournaments or recreational play.

- Delivering a commitment to quality with rigorous testing and quality control, ensuring that every paddle meets high industry standards.

Their ability to produce paddles tailored to specific performance metrics has helped many B2B partners differentiate their brands in competitive markets. For companies looking to transition from a basic dropshipping model to a custom OEM strategy, partnering with an experienced manufacturer like NEX Pickleball can provide the expertise and innovation necessary for long-term business success.

When planning a transition, consider these best practices to streamline your process and maximize benefits:

- Start Small: Begin with a limited product run to test the market response before committing to full-scale production.

- Focus on Quality Assurance: Ensure that the OEM partner implements a robust testing process to maintain consistent quality.

- Maintain Open Communication: Establish clear channels with your manufacturer to discuss design modifications, production timelines, and any issues that arise.

- Invest in Design Innovation: Encourage creative designs that not only look good but also enhance performance metrics such as ball control, durability, and user comfort.

- Plan for Scalability: Confirm that your chosen OEM partner has the capacity to scale production as your business grows without sacrificing quality.

Transitioning from a dropshipping model to a custom OEM strategy for pickleball paddles is a strategic move designed to drive long-term success. By embracing custom production, you gain full control over product quality, design, and branding, which can translate into higher profit margins and improved customer loyalty.

Our analysis shows that while dropshipping offers a low entry cost, the custom OEM route allows businesses to establish a strong market presence through superior product quality and innovative design. With the advanced production techniques and expertise available at NEX Pickleball, you can confidently offer paddles that meet the high expectations of today’s competitive sports equipment market.

If you’re looking to elevate your brand and deliver products that truly resonate with your audience, a strategic shift to custom OEM production is the next step forward. Evaluate your business goals, review your current product offerings, and consider partnering with an experienced manufacturer who can help you achieve your strategic objectives. Your brand deserves a product that stands out in performance, design, and quality.

Take the next step today—explore the benefits of custom OEM production and set your brand apart in the rapidly growing pickleball market.

What is the best budget pickleball paddle?

While many budget options exist, such as those priced below $50, custom OEM production focuses on quality and performance rather than offering a low-cost solution. Budget paddle lists highlight models with basic performance characteristics; however, investing in a premium, custom-designed paddle through OEM can deliver superior longevity, enhanced playability, and better brand differentiation, which may offer greater long-term value for your business.

-

OEM production: Click to read about the strategic benefits of manufacturing products under your own brand, which can drive differentiated quality and long-term value. ↩

-

Dropshipping: Click to explore an in-depth guide on the dropshipping model and its challenges in competitive markets, especially for B2B operations. ↩

-

Thermoforming: Click to understand how thermoforming works and its advantages in producing intricate, high-quality custom products. ↩

-

Nomex Honeycomb: Click to learn about the properties of Nomex Honeycomb material and why it's a preferred choice for high-performance manufacturing. ↩

-

Bamboo Core Composite: Click to discover the benefits of using Bamboo Core Composite for creating lightweight and impact-resistant products, enhancing overall performance. ↩