Providing a high-performance pickleball paddle that enhances spin control starts with a careful combination of advanced materials1 and optimized production processes2. In today’s competitive sports equipment market, understanding the interplay among paddle materials—such as various types of carbon fiber, fiberglass, and composite cores—and manufacturing techniques like hot pressing, cold pressing, and thermoforming is essential. This article dives into these elements to help you make informed procurement decisions that combine durability, precise spin control, and overall high performance.

In recent years, the demand for superior spin control in pickleball paddles has grown as player strategies become more advanced. For businesses in the sports equipment industry, investing in paddles that optimize spin control means not only improving player performance but also delivering a competitive edge to retailers and manufacturers. The blend of material science3 and specialized production methods forms the backbone of a paddle’s performance characteristics.

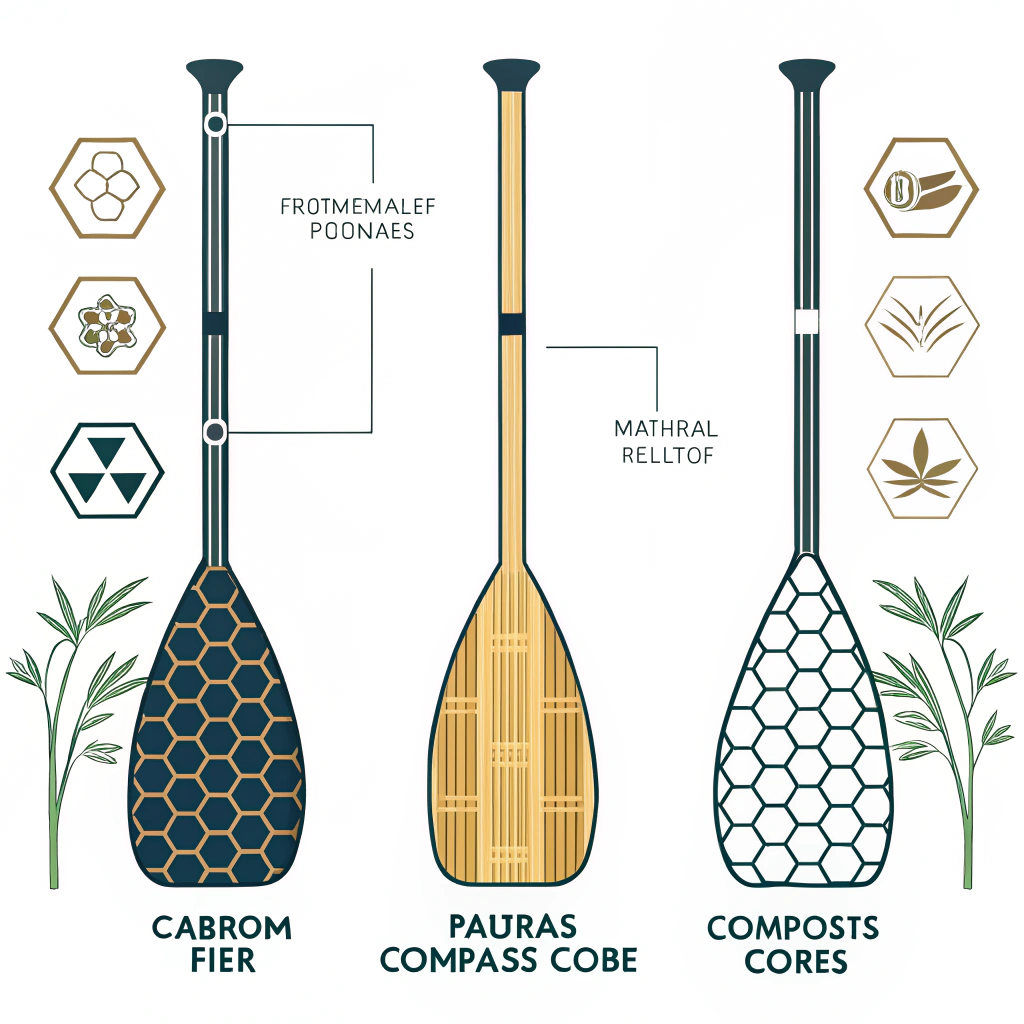

One of the primary aspects of paddle design is the selection of high-quality materials. At NEX Pickleball, a variety of premium materials are used, each offering distinct advantages:

-

Carbon Fiber: Utilizing types such as 3K, 12K, and T300, carbon fiber is known for providing excellent strength, durability, and control.

- 3K Carbon Fiber is prized for its balance of strength and flexibility, reducing vibration while delivering a high rebound force—ideal for dynamic spin control.

- 12K Carbon Fiber offers a smoother surface texture and greater hardness, enhancing the paddle’s ability to generate precise spin.

- T300 Carbon Fiber brings a balance between strength and lightweight characteristics, ensuring that spin is executed with fast responsiveness.

-

Fiberglass: Known for its excellent elasticity, fiberglass paddles offer a wider sweet spot. Its inherent flexibility contributes to enhanced ball control, making it a popular choice for players at various performance levels.

-

Composite Materials: Combining carbon fiber with fiberglass or using bamboo core composites creates paddles that deliver optimal power and control. These composites allow manufacturers to fine-tune the paddle’s balance and responsiveness, which are critical factors for effective spin control.

-

Core Materials: The core, often made from Nomex or honeycomb structures (aluminum or polymer), has a significant influence on the paddle's performance. A Nomex Honeycomb Core4 provides excellent shock absorption, while an Aluminum Honeycomb Core or Polymer Honeycomb Core brings a balance between weight and stability, contributing directly to the paddle’s ability to generate and control spin.

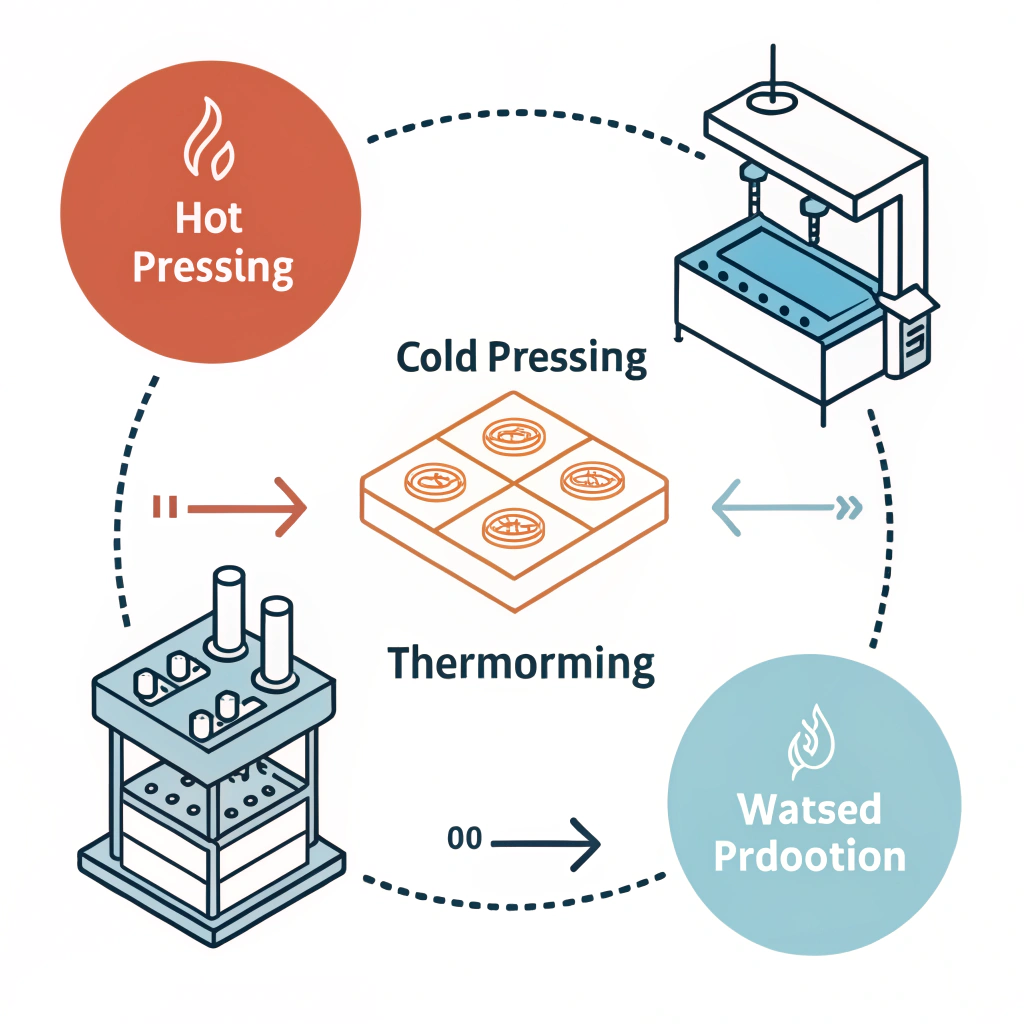

Production Processes: Hot Pressing, Cold Pressing, and Thermoforming5

The method by which a paddle is manufactured plays a vital role in its performance. Each production technique impacts the paddle’s weight, strength, and feel—all factors that can control the amount and precision of spin delivered during play. Let’s examine the three major production processes:

-

Hot Pressing:

This process involves applying heat and pressure simultaneously to form the paddle. It is primarily used for robust and durable designs.- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Creates strong paddles with excellent impact resistance.

- Enhances structural integrity for high-speed spin scenarios.

- Disadvantages:

- The heating process can slightly alter the feel of the paddle.

- Requires significant investment in specialized equipment.

- Advantages:

-

Cold Pressing:

In this process, mechanical pressure is applied at room temperature, preserving the inherent properties of the material.- Advantages:

- Maintains the natural elasticity and feel of the material, which translates into better control and precision in spin execution.

- Allows for more precise control over the paddle’s thickness and internal structure.

- Disadvantages:

- Longer production cycles may affect output efficiency.

- Requires precision pressure control, often necessitating higher-quality equipment.

- Advantages:

-

Thermoforming:

Thermoforming heats materials to soften them before molding into a desired shape, ideal for complex designs.- Advantages:

- Enables the creation of paddles with intricate designs that balance weight and aerodynamic properties.

- Helps maintain material distribution for consistent performance, directly affecting spin control.

- Disadvantages:

- Longer production time and higher equipment costs.

- Best suited for premium or custom-made paddles where performance is paramount.

- Advantages:

Below is a comparative table summarizing key aspects of these production methods:

| Production Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance; strong paddles | Alters material feel; high equipment cost | Mass production, durability |

| Cold Pressing | Maintains material properties; precise control; excellent feel | Longer cycle time; needs precise equipment | Precision control, spin focus |

| Thermoforming | Intricate design; balanced weight distribution; stable performance | Longer production time; higher cost | Premium/custom designs |

Achieving optimal spin control in pickleball hinges on bridging material science with manufacturing precision. Here are some key considerations:

-

Surface Texture and Flexibility:

A paddle’s surface directly affects how much spin a player can impart on the ball. Carbon fiber paddles, particularly those with a higher thread density like 12K, create a textile-like surface that interacts with the ball surface uniquely, enhancing friction and allowing players to generate more spin. Additionally, the elasticity provided by fiberglass or specific composite mixes allows a slight deformation on impact, which can lead to a “snap-back” effect that boosts spin. -

Weight Distribution and Balance:

Proper weight distribution is critical. Paddles manufactured through cold pressing are able to maintain a precise internal structure, ensuring that the weight is evenly distributed. This enhances the player’s ability to control the paddle during rapid plays and when executing spin moves. Thermoformed paddles, meanwhile, can be tailored to have a balanced profile that does not sacrifice control for power. -

Vibration Damping:

High-performance paddles incorporate materials and cores that reduce vibration upon ball impact. The incorporation of Nomex Honeycomb Cores or polymer-based cores absorbs shock, preventing energy loss and ensuring that more energy is transferred into spin. Reduced vibration also minimizes player fatigue, allowing for sustained performance during long matches. -

Advanced Composite Structures:

Composites, which strategically combine elements of carbon fiber and fiberglass, capitalize on the strengths of both materials. For instance, a Carbon Fiber and Fiberglass Composite paddle leverages the rigidity of carbon fiber and the elasticity of fiberglass, offering a paddle that is simultaneously strong, responsive, and exceptionally capable of controlling spin dynamics.

Several case studies and performance data from high-end competitive play support the efficacy of these advanced paddle designs:

-

Case Study Example:

A leading distributor of pickleball equipment reported a 20% increase in player satisfaction when switching to paddles designed with a lower vibration core and a composite surface engineered for spin enhancement. The paddles, manufactured using a combination of cold pressing and thermoforming processes, offered both precise control and robust durability, directly contributing to better spin performance. -

Player Feedback:

Top competitive players have noted that paddles incorporating a blend of carbon fiber and fiberglass composites enabled them to add more spin during serves and returns without compromising control. In interviews, these players emphasized the importance of consistent material properties and optimal production processes in achieving a competitive edge. -

Industry Trend Analysis:

The sports equipment manufacturing sector increasingly values technical innovation. Manufacturers like NEX Pickleball are at the forefront by integrating advanced materials with state-of-the-art production processes. This commitment to innovation has resulted in products that not only meet but exceed the performance expectations of both recreational and competitive players.

For product managers and procurement specialists, selecting the right pickleball paddle design involves weighing technical specifications, production capabilities, and cost considerations. Here are some actionable steps:

-

Evaluate Material Specifications:

Compare the advantages of different materials, such as the strength and rebound force of various carbon fibers versus the elasticity offered by fiberglass. Factor in how these properties directly impact spin control and overall paddle performance. -

Assess Production Process Capabilities:

Ensure that manufacturing partners can provide consistent quality. Look for control over production parameters related to cold pressing or thermoforming, especially if the final product needs to emphasize precision and responsiveness. -

Review Long-Term Durability and Performance Data:

Request performance data and case studies from suppliers. Paddles that deliver consistent performance in high-impact environments are likely built with careful selection of both materials and processes, reducing replacement cycles and improving overall customer satisfaction. -

Consider Customization Options:

For businesses aiming to target niche markets, the ability to customize paddles—adjusting aspects such as weight distribution, grip design, and material combination—can be a significant differentiator. Custom paddle options allow you to meet unique market requirements or brand-specific standards.

In summary, a superior pickleball paddle engineered for enhanced spin control is a product of carefully selected premium materials and finely tuned manufacturing processes. By leveraging advanced carbon fibers, fiberglass, and composite materials along with processes like hot pressing, cold pressing, and thermoforming, manufacturers can produce paddles that offer improved spin, durability, and overall game performance.

For decision-makers in the sports equipment sector, consider the following actionable recommendations:

- Conduct thorough comparative analyses of paddle materials and production techniques.

- Request detailed production process documentation from suppliers.

- Utilize real-world performance data to guide procurement decisions.

- Explore customization opportunities that can cater to both niche and broad market segments.

Taking these steps will ensure that your product portfolio remains competitive, delivering both excellent spin control and the endurance required for competitive play.

People Also Ask

Q: What is the best material for maximizing spin control in pickleball paddles?

A: High thread density carbon fiber, such as 12K or T300, is typically favored because it creates a smoother, more frictional surface and offers enhanced durability, which improves spin control during play.

Q: How do production techniques like cold pressing enhance paddle performance?

A: Cold pressing preserves the inherent elasticity of the paddle’s materials and allows precise control over the paddle’s structure. This results in a more balanced weight distribution and better responsiveness during rapid spin moves.

Q: How does the combination of composite materials affect paddle durability and spin control?

A: Using composites, such as a mix of carbon fiber and fiberglass, optimizes the benefits of both materials. This results in superior strength, shock absorption, and enhanced surface characteristics, directly contributing to improved spin control and longer durability.

-

advanced materials: Click this link to explore an in-depth analysis of innovative materials engineered for high-performance sports equipment, including their properties and benefits for enhanced durability and spin control. [^return] ↩

-

optimized production processes: Click to read about modern manufacturing techniques that improve efficiency and quality in sports equipment production, ensuring consistent performance and precision. [^return] ↩

-

material science: Click here for a comprehensive overview of material science principles applied in paddle manufacturing, detailing how material composition affects performance and longevity. [^return] ↩

-

Nomex Honeycomb Core: Click this link for insights into the use of Nomex honeycomb structures in paddles, explaining its shock absorption properties and contribution to vibration damping and stability. [^return] ↩

-

Thermoforming: Click here to understand the thermoforming process, a key manufacturing technique that softens and molds materials to create intricate, performance-enhancing paddle designs. [^return] ↩