Customized pickleball paddle production offers a quick answer: using a blend of advanced materials1 such as carbon fiber and fiberglass, combined with production processes like hot pressing, cold pressing, and thermoforming2, enables manufacturers to create high-performance, durable paddles tailored for both competitive and recreational play. This article explains the critical customization options available, the benefits and tradeoffs of each production method, and practical guidance for selecting the right manufacturing partner.

Procurement managers and sports equipment distributors often face a multifaceted challenge when sourcing paddles: balancing durability, performance, and cost while achieving a product tailored exquisitely to market needs. The demand for customized pickleball paddles involves careful selection of premium materials3—from different types of carbon fiber and fiberglass to hybrid composites—and the meticulous application of various production methods. As play styles range from recreational to high-intensity competitive scenarios, the need to fine-tune paddle features like weight, grip, balance, and hitting feel becomes critical.

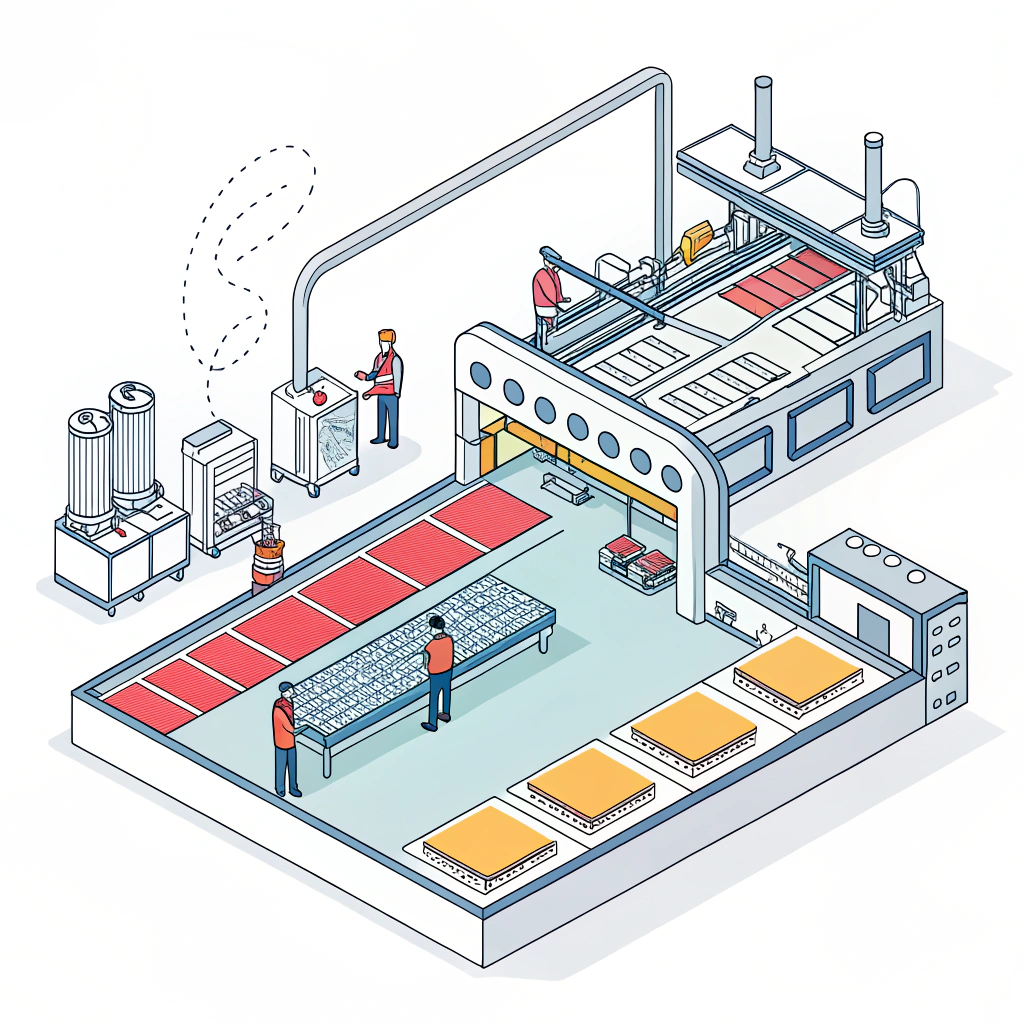

Manufacturers, like us at NEX Pickleball, invest heavily in advanced production techniques. Our facility in Jiaxing, Zhejiang, China, leverages technologies such as hot pressing, cold pressing, and thermoforming. Each process has its own advantages and disadvantages, affecting the paddle’s overall performance. In addition, the selection of core materials like Nomex honeycomb4 or polymer honeycomb further refines the playing experience, offering benefits such as reduced vibration and enhanced shock absorption.

To meet the needs of professional players and market expectations, every manufacturing step must maintain strict quality control. Let’s break down the key production processes:

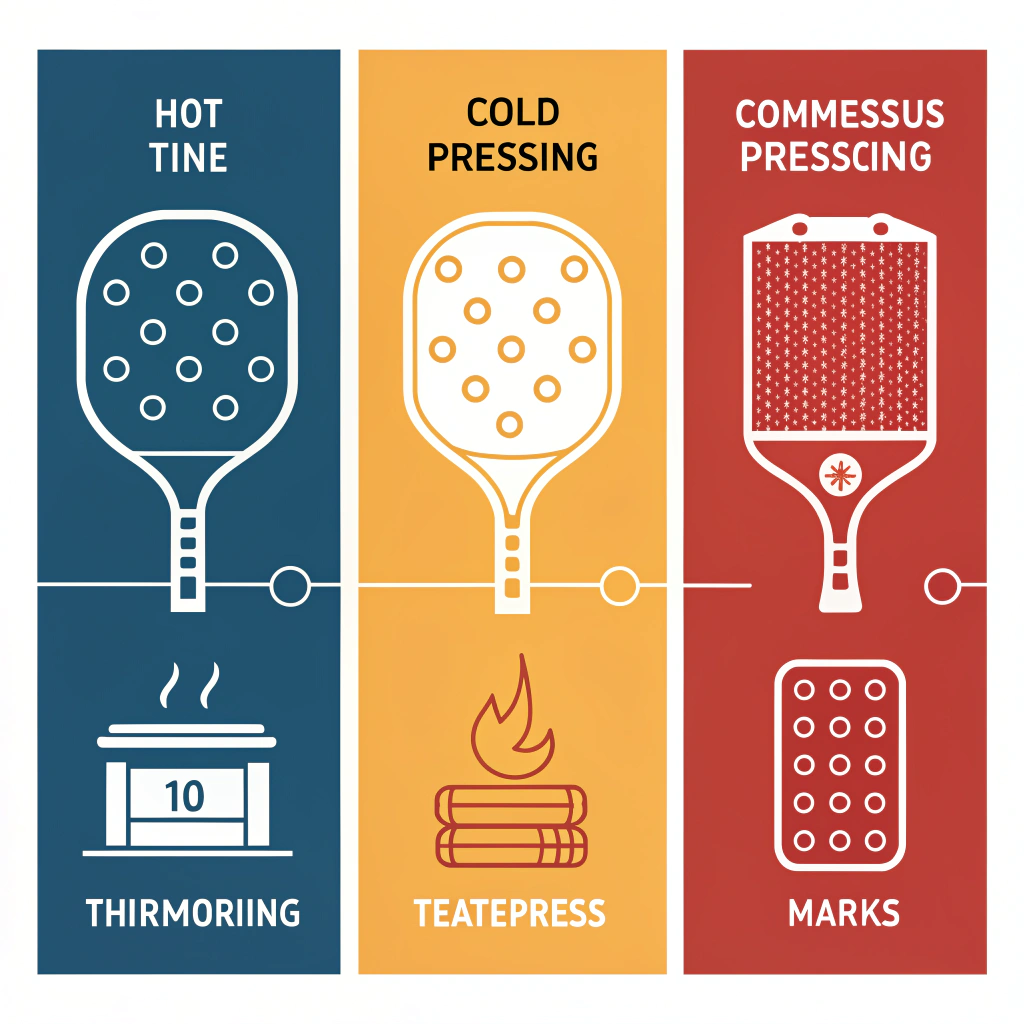

Hot pressing involves heating materials and applying pressure to form the paddle structure. This method is widely used due to its high efficiency in large-scale production.

- Advantages:

- Enhanced structural integrity and high impact resistance.

- Efficient production suitable for high volume.

- Disadvantages:

- Potential alteration of material properties that can affect the paddle feel.

- Requires significant investment in specialized equipment.

Cold pressing shapes the paddle material at room temperature using mechanical pressure. This process is ideal for designs that require precise control over thickness and structural properties.

- Advantages:

- Superior control over material thickness.

- Maintains inherent material properties, leading to enhanced ball feel and responsiveness.

- Disadvantages:

- Longer production cycles, which may limit throughput.

- Demands high-quality pressure control mechanisms.

Thermoforming heats the material to a softening point before molding it into the required shape. This technique is perfect for creating paddles with intricate designs, ensuring exact material distribution for optimal performance.

- Advantages:

- Ability to create paddles with complex and precise designs.

- Maintains the paddle’s stability under various play conditions.

- Disadvantages:

- Higher equipment costs and longer production times.

- Better suited for premium or custom-made products rather than bulk production.

To assist in decision making, here is a comparative table that highlights the core differences among the three processes:

| Production Process | Strengths | Weaknesses | Best Used For |

|---|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, robust structure | May alter material feel, high equipment cost | High-volume manufacturing, durable paddles |

| Cold Pressing | Precise control over thickness, maintains original material properties, better responsiveness | Longer cycle times, precision equipment needed | Custom designs requiring optimal ball feel |

| Thermoforming | Complex design capability, precise material distribution | High cost, longer production process | Premium and custom-made paddles |

This table serves as a quick decision guide for procurement managers evaluating the manufacturing approach that best meets their product quality and business goals.

A critical element of paddle manufacturing is selecting the right materials. At NEX Pickleball, we offer a variety of premium materials, ensuring that every paddle is designed to meet specific performance criteria. The key materials include:

- 3K Carbon Fiber: Known for its excellent strength and flexibility. It improves rebound force and dampens vibration—ideal for paddles demanding robust performance.

- 12K Carbon Fiber: With a higher thread density, this fiber offers a smoother surface and superior durability. It is designed for competitive play, providing both extreme strength and resistance to impact.

- T300 Carbon Fiber: This high-performance fiber balances light weight with remarkable tensile strength, ensuring a paddle that is both agile and durable.

- E-Glass Fiberglass: This material delivers a balance between power and control with enhanced flexibility. Its wider sweet spot improves ball control, making it particularly attractive for players who appreciate precision.

The fusion of multiple materials can yield superior properties. Some popular combinations include:

- Carbon Fiber and Fiberglass Composite: Harnesses the strengths of both materials, ensuring a balance of hardness, light weight, and responsive control.

- Bamboo Core Composite: Offers an exceptionally lightweight paddle with high impact resistance. It contributes to a well-defined hitting feel for long-lasting play.

- Honeycomb Core: Made from high-density polymer or pulp, this core delivers premium shock absorption and reduces vibrations significantly.

- Nomex Honeycomb Core: Excellent for absorbing shocks while delivering a consistent performance even in long matches.

- Aluminum Honeycomb Core: A balanced choice that offers both power and precision, ideal for manufacturers looking to produce paddles appealing to a broad market.

- Polymer Honeycomb Core: This option emphasizes elasticity and vibration reduction, providing a softer touch and greater comfort for recreational players or beginners.

Together, these materials and composite options enable manufacturers and distributors to meet varied market demands by tailoring paddles to specific performance requirements.

Quality control is paramount. At NEX Pickleball, each paddle undergoes rigorous testing to ensure that the delicate balance between durability, performance, and comfort is maintained. Here are some critical checkpoints for ensuring quality:

- Material Inspection: Conducting regular checks on carbon fiber batches, fiberglass consistency, and composite quality before production.

- Process Monitoring: Ensuring precise control during hot pressing, cold pressing, and thermoforming stages to maintain design specifications.

- Post-Production Testing: Every paddle is rigorously tested for weight distribution, ergonomic grip, and surface treatment to confirm that it meets the highest standards.

- Custom Orders: For customized paddle orders, additional design reviews and testing phases are implemented. This guarantees that the final product aligns with unique requirements, whether for team branding, retail distribution, or personal use.

Implementing a rigorous quality control protocol not only maintains the integrity of the manufacturing process but also builds trust with procurement managers and distributors.

For procurement managers seeking to partner with a reliable manufacturing provider, consider the following steps:

- Define Product Requirements: Clearly outline the desired paddle characteristics—weight, balance, grip size, and material specifications.

- Evaluate Production Processes: Understand the strengths and trade-offs of hot pressing, cold pressing, and thermoforming. Choose a process that aligns with production volume and product performance requirements.

- Assess Material Options: Examine the benefits of different materials. Make use of the comparative table provided to match your product requirements with the appropriate materials.

- Prioritize Quality Control: Ensure that the manufacturing partner has robust quality control measures. Request detailed reports on material testing and process consistency.

- Plan for Future Customization: Consider scalability and the potential for future innovation, including on-demand printing services. This ensures your products remain competitive as market demands evolve.

By taking these steps, companies can minimize the risk of product performance issues and maximize customer satisfaction in their target markets.

Customizing pickleball paddles for the competitive and recreational markets requires an in-depth understanding of both materials and production processes. By leveraging advanced manufacturing techniques and premium materials like various types of carbon fiber, fiberglass, and composite cores, manufacturers can deliver paddles that meet exacting performance standards. Quality control, process optimization, and continuous innovation are critical factors that drive success in a competitive market.

For procurement managers and distributors, partnering with a manufacturer that offers transparent production processes, rigorous quality checks, and a wide array of customization options is essential. Making informed decisions based on the detailed comparisons and actionable recommendations outlined above can pave the way towards optimized production efficiency and superior product performance.

People Also Ask

Q1: What are the benefits of using carbon fiber in pickleball paddles?

A1: Carbon fiber offers high tensile strength, excellent rebound, and reduced vibration, making paddles both durable and high-performing for competitive play.

Q2: How do different production processes affect paddle quality?

A2: Production methods such as hot pressing, cold pressing, and thermoforming each have unique impacts—hot pressing enhances durability for high-volume production, cold pressing maintains material properties for better ball feel, and thermoforming allows intricate designs with stable performance.

Q3: What customization options are available for paddle manufacturing?

A3: Customization includes material selection (e.g., various carbon fiber types, fiberglass, composites), core material choices, and adjustable features such as weight distribution and ergonomic grip design, along with options like on-demand printing for personalized branding.

-

advanced materials: Read the article to learn how cutting-edge materials like carbon fiber and fiberglass enhance product performance and durability in manufacturing. ↩

-

thermoforming: Read the article to gain insights into the thermoforming process, including its ability to shape materials into complex designs and its role in precision manufacturing. ↩

-

premium materials: Read the article to understand the benefits of using high-grade materials that deliver superior quality and optimal performance under rigorous conditions. ↩

-

Nomex honeycomb: Read the article to understand how Nomex honeycomb structures improve shock absorption and performance by providing a lightweight yet resilient core. ↩