NEX Pickleball offers high-performance pickleball paddles engineered with advanced materials1. In short, our paddles deliver superior ball control, durability, and power by leveraging state-of-the-art carbon fiber variants, fiberglass, and innovative manufacturing processes like hot pressing, cold pressing, and thermoforming.

In today’s competitive sports equipment market, distributors and retail managers are looking for products with proven performance and technical superiority. NEX Pickleball’s paddles are designed with a focus on maximizing strength, resilience, and playability. Our detailed engineering insights help B2B buyers understand exactly what sets our pickelball paddles apart. This article will explore the materials, production processes, and performance advantages of high-performance pickleball paddles.

One of the key elements that drive superior performance in pickleball paddles is the choice of materials used in their construction. High-performance paddles often include advanced composites that achieve an optimal balance of power, control, and durability.

Carbon fiber is perhaps the most important material in achieving a high-rebound, durable paddle surface. At NEX Pickleball, we use various types:

• 3K Carbon Fiber: Known for its strength and flexibility, it delivers excellent durability with reduced vibration, making it ideal for competitive play.

• 12K Carbon Fiber: Higher thread density means a smoother surface and enhanced hardness. This option provides superior impact resistance, ensuring that paddles maintain their form even under intense use.

• T300 Carbon Fiber: Recognized for outstanding tensile strength, this variant strikes a balance between strength and lightweight performance, offering balanced performance for top-tier players.

These carbon fiber options ensure our paddles provide the optimal “pop” and control during fast-paced games.

Fiberglass paddles are known for their flexibility and wide sweet spot. More specifically:

• E-Glass Fiberglass: Offers excellent elasticity and tensile strength, which translates into a great feel for the ball. Its natural flexibility ensures that control is maintained, even during high-speed exchanges.

The advantage of fiberglass is its ability to combine both power and control, often making it the material of choice for recreational and intermediate players, as well as in hybrid designs.

Integrating carbon fiber with other materials, such as fiberglass or bamboo cores, gives birth to composite paddles2 that encapsulate the strengths of each component. Common composites include:

• Carbon Fiber and Fiberglass Composite: This combination integrates power with superior flexibility, ideal for players who need both speed and precision.

• Bamboo Core Composite: Provides a very lightweight design with high impact resistance, ensuring a clear hitting feel and long-lasting durability.

• Honeycomb Core: Utilizing high-density polymers or pulp, honeycomb cores are excellent for shock absorption, reducing vibration during play, and ultimately extending the paddle’s service life.

Each composite material is chosen based on the desired performance attributes, and by offering these options, NEX Pickleball caters to varied player needs, whether for intense competitive play or casual matchups.

The core of a pickleball paddle is critical in dictating the paddle’s overall performance. NEX Pickleball uses several types of core materials, each with distinct characteristics:

• Nomex Honeycomb Core3: Manufactured from durable polymers, this core provides excellent shock absorption and long-term stability. It is especially popular for players seeking durability in high-impact situations.

• Aluminum Honeycomb Core: Balances weight and power, ensuring that players benefit from both strength and precision in their strokes.

• Polymer Honeycomb Core: Known for its elasticity and vibration reduction, polymer cores offer enhanced comfort, which is particularly appreciated by recreational players and those new to the sport.

The choice of core materials directly influences paddle stiffness, weight, and ball control. Manufacturers can fine-tune these aspects to produce a paddle that meets the specific demands of professional players and team requirements.

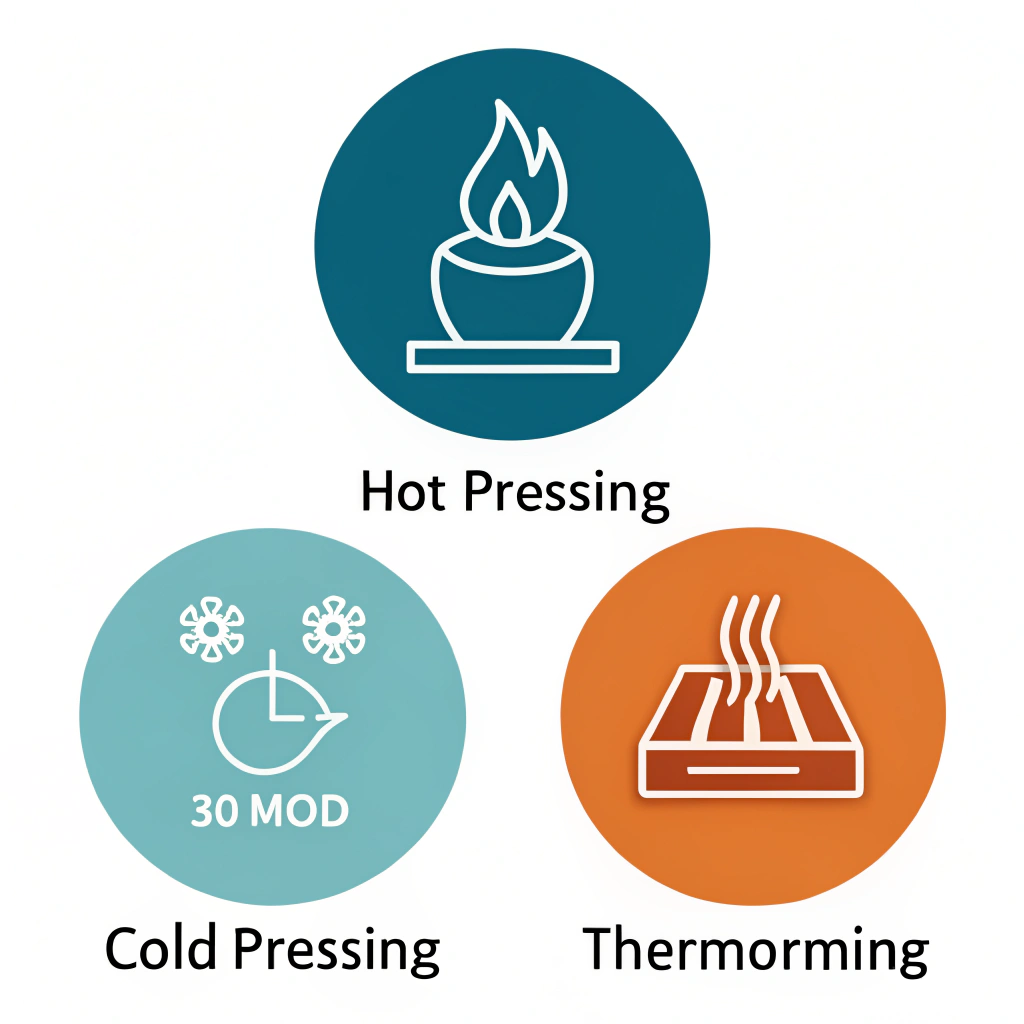

Production Techniques: Hot Pressing, Cold Pressing, and thermoforming4

Achieving excellence in paddle performance also rests on the chosen production processes. NEX Pickleball employs three primary manufacturing techniques to ensure that our paddles meet high standards consistently.

Hot pressing involves heating the material and applying pressure simultaneously to form a strong bond between layers. It is favored for its efficiency and the strong impact resistance it imparts.

• Advantages:

– High production efficiency suitable for large orders.

– Produces paddles with robust structural integrity by effectively bonding materials.

– Enhances impact resistance, ensuring paddles withstand rigorous play.

• Disadvantages:

– The high temperature can sometimes alter material properties, potentially affecting the paddle’s overall feel and response.

– Requires significant investment in specialized equipment for consistent quality control.

Cold pressing is conducted at room temperature using mechanical pressures, which preserves the material’s natural properties.

• Advantages:

– Provides precise control over the paddle’s thickness and structure.

– Retains the original material properties, resulting in better ball feel and responsiveness.

– Ideal for designs that require a delicate balance between flexibility and stiffness.

• Disadvantages:

– Longer production cycles compared to hot pressing, which may affect large-scale manufacturing timelines.

– Demands high-quality pressure control equipment to ensure consistency in each paddle.

Thermoforming uses heat to soften materials before they are molded into shape using precise molds. This process is especially beneficial for producing paddles with complex designs and tailored thickness distributions.

• Advantages:

– Enables intricate designs and ensures uniform material distribution, enhancing overall performance and stability.

– Suitable for premium products that demand a high level of detail in manufacturing.

• Disadvantages:

– The production process is more time-consuming with a need for higher equipment costs.

– Best suited for customized orders or premium product lines rather than high-volume production.

Below is a comparative table of the three production processes used at NEX Pickleball:

| Production Process | Key Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; consistent structural bond | May alter material properties; high equipment investment |

| Cold Pressing | Precise control; retains material feel; excellent responsiveness | Longer production cycle; high precision equipment necessary |

| Thermoforming | Intricate design capabilities; uniform material distribution | Time-consuming; high cost; ideal for premium productions |

To maintain industry-leading quality standards, every paddle from NEX Pickleball undergoes rigorous performance testing. This process includes:

• Structural Integrity Tests: Ensure that each paddle can withstand high levels of impact during play.

• Vibration Analysis: Measures how well the paddle absorbs shock, particularly important for minimizing player fatigue.

• Precision Control Checks: Verify that the paddle offers consistent ball control and accurate response.

These tests are essential in confirming that the advanced materials and production processes result in paddles that not only meet but exceed industry expectations. Consistent testing ensures that each paddle delivers on the promise of high performance, whether it is used in a high-speed competitive environment or a casual match.

Additionally, continuous feedback from professional players and B2B clients aids in refining the design and manufacturing processes. This cycle of constant improvement reinforces our commitment to excellence.

Understanding that different markets have varying needs, NEX Pickleball offers extensive customization options. B2B buyers can specify design elements including weight, balance, grip size, and even surface texture. This flexibility ensures that our paddles can be tailored for:

• Team Branding: Distributors and event organizers can order custom paddle designs featuring team logos and colors.

• Targeted Performance Needs: Adjustments can be made to suit specific play styles, whether the focus is on control, power, or a balanced performance.

• Retail Exclusives: Retail chains can have exclusive designs that cater specifically to local market trends.

The ability to customize not only enhances product appeal but also enables players—from beginner to professional—to find a paddle that fits their unique needs. B2B buyers looking to stock products that stand out in a competitive market have a compelling reason to choose NEX Pickleball’s offerings.

Industry data shows that the trend toward advanced and specialized materials in sports equipment is growing. The adoption of novel carbon fiber technologies and complex composite materials is no longer limited to niche markets. Instead, they are becoming standard in professional-grade equipment. This evolution has significant implications:

• Enhanced Player Performance: Improved materials directly contribute to better control and power, which are critical in competitive matches.

• Durability Considerations: With higher-quality manufacturing processes, products last significantly longer, reducing overall maintenance and replacement costs for retailers and sports organizations.

• Customization and Branding: In a crowded marketplace, the ability to offer bespoke products gives a competitive edge to distributors and retailers.

B2B buyers are increasingly evaluating products not only on performance but also on long-term value and reliability. Data from our quality assurance tests clearly indicates that paddles produced through our optimized manufacturing processes have lower failure rates and superior performance consistency. These factors translate into strong market credibility and customer satisfaction.

For sports equipment distributors, retail managers, and sports event organizers, the decision to invest in high-performance pickleball paddles should be based on a comprehensive evaluation of both material quality and production integrity. Here are some actionable recommendations:

- Evaluate technical specifications such as the type of carbon fiber used and core materials to ensure the paddle meets the performance standards required by professional players.

- Consider the manufacturing process—whether hot pressing, cold pressing, or thermoforming—as this significantly impacts the paddle’s durability and responsiveness.

- Leverage customization options to create exclusive product lines that cater uniquely to your target market, thereby enhancing brand differentiation and customer loyalty.

- Request detailed quality assurance reports or case studies from the manufacturer. These documents can provide additional insights into performance testing and long-term durability, aiding in a more informed purchasing decision.

- Keep an eye on market trends and technological innovations in sports equipment manufacturing to remain ahead of competitors and maintain a robust product lineup.

By following these steps, you can confidently select a product that balances performance, durability, and market relevance—key factors in securing long-term success.

In conclusion, NEX Pickleball’s commitment to advanced materials, precise production techniques, and stringent quality control ensures that our paddles offer unparalleled performance for competitive play. Whether you are looking to enhance your product portfolio with high-performance paddles for pros or seeking customized solutions tailored to your market, our approach integrates technological innovations with proven manufacturing practices. B2B buyers are invited to experience the difference of a paddle engineered to deliver superior ball control, durability, and responsiveness. Make an informed decision by choosing a partner that understands both the art and science behind high-performance sports equipment.

Q: What paddle do most pro pickleball players use?

A: Many professional players favor paddles with advanced carbon fiber options—such as 3K, 12K, or T300—for their durability and performance benefits. Models from leading brands, including those manufactured using our optimized hot pressing and cold pressing techniques, are commonly seen in high-level competitions.

Q: What is the #1 rated pickleball paddle?

A: The top-rated pickleball paddle is often determined by specific performance needs. While several models receive accolades for balance, control, and durability, models incorporating advanced carbon fiber and composite technologies—similar to those available with our production methods—frequently lead the market rankings.

Q: Do pros use 14mm or 16mm pickleball paddles?

A: Professional players typically choose paddle thickness based on their play style. Many prefer 16mm paddles for enhanced power and stability, while some opt for 14mm for improved control and quicker response. The choice largely depends on the player's technique and the performance attributes emphasized in the paddle’s design.

-

advanced materials: Read more to understand how cutting-edge materials enhance product performance by improving strength, durability, and weight efficiency in sports equipment manufacturing. ↩ ↩

-

composite paddles: Discover the advantages of composite paddles that combine multiple materials for optimal power, control, and durability, tailored for various play styles in competitive sports. ↩ ↩

-

Nomex Honeycomb Core: Learn about Nomex Honeycomb Core technology, a high-performance core solution offering exceptional shock absorption and stability critical for high-impact environments. ↩ ↩

-

thermoforming: Click here for an in-depth look at thermoforming—a heat-based molding process that enables precision design and uniform material distribution for superior sports equipment. ↩ ↩ ↩2

-

Quality Assurance: Find out how rigorous quality assurance practices ensure that every product meets high-performance and reliability standards, providing long-term value for B2B clients. ↩ ↩