A high-performance pickleball paddle is defined by its advanced materials and precision manufacturing processes. For professional players and B2B procurement managers, NEX Pickleball offers paddles that combine superior carbon fiber1 strength, refined fiberglass2 control, and innovative composite solutions, all produced through meticulously optimized production techniques.

Professional pickleball paddles require a delicate balance of power, control, and durability. At NEX Pickleball, we employ a range of premium materials that set our paddles apart. Our selection includes different types of carbon fiber—namely 3K, 12K, and T300—each offering unique performance benefits:

- 3K Carbon Fiber: Known for its excellent strength and flexibility, this fiber provides high rebound force and reduces vibration. Its durability makes it a solid choice for players who need a paddle that can withstand frequent, high-impact play.

- 12K Carbon Fiber: With a denser thread structure, 12K offers a smoother surface and superior hardness. Ideal for competitive play, it provides higher impact resistance and ensures longevity.

- T300 Carbon Fiber: This high-performance carbon fiber is celebrated for its outstanding tensile strength and lightweight properties, allowing for balanced performance that supports both agility and power.

In addition to carbon fiber, our paddles incorporate fiberglass technologies. Fiberglass paddles, particularly those made from E-Glass, offer a wider sweet spot and improved ball control through enhanced elasticity and tensile strength. This balance between power and finesse is crucial for professional-level play where precision and consistency are paramount.

We also combine materials in composite designs. For example, our Carbon Fiber and Fiberglass Composite paddles bring together the strength of carbon fiber and the control of fiberglass, catering to players who demand excellence in both areas. Alternatives like Bamboo Core Composite and Honeycomb Core Composite provide unique benefits such as impact resistance and reduced paddle vibration, ensuring a clear, responsive hitting experience.

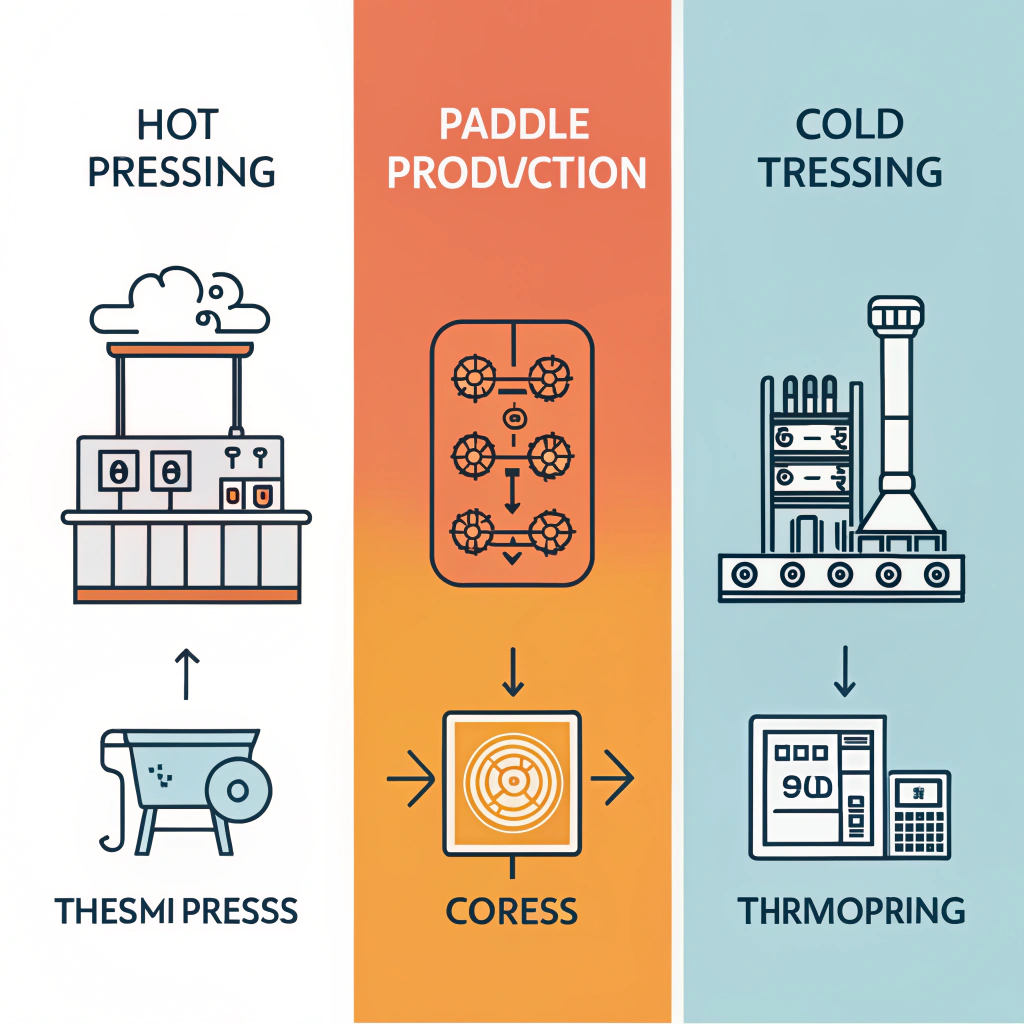

The performance of a pickleball paddle does not solely depend on its material—you must also consider how it is manufactured. NEX Pickleball utilizes three distinct production processes, each with unique advantages and constraints:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing3 | - High production efficiency - Produces robust, high-strength paddles - Excellent impact resistance | - May alter some material properties - Requires significant equipment investment |

| Cold Pressing4 | - Precise control over thickness and paddle structure - Maintains natural material properties - Provides a superior ball feel | - Slower production cycles - Demands precise pressure control with high-quality machinery |

| Thermoforming5 | - Ideal for complex shapes and precise material distribution - Enhances paddle stability and performance - Suitable for premium and custom products | - Extended production time - Higher equipment costs |

Each process is selected based on the target performance attributes and production requirements. Hot pressing is often favored for mass production and durability, whereas cold pressing preserves the innate qualities of the material, crucial for optimal ball control. Meanwhile, thermoforming allows our engineers to design paddles with intricate shapes that perfectly balance weight distribution and gripping comfort.

For competitive players, the paddle’s core material is as vital as its external construction. NEX Pickleball offers a range of core options to meet diverse playing styles:

- Nomex Honeycomb Core: This polymer-based material is prized for its excellent shock absorption. It provides lasting durability and stability, making it the go-to option for professionals who engage in high-intensity matches.

- Aluminum Honeycomb Core: Offering balanced weight distribution, aluminum cores deliver a blend of power, control, and precision. They are favored when a mix of strength and finesse is required.

- Polymer Honeycomb Core: Known for its elasticity and vibration damping, polymer cores are preferred by players who prioritize comfort and a softer touch during play.

In B2B procurement, the option to customize paddle core materials and construction allows distributors to tailor products to the needs of various market segments—from high-performance competitive equipment to recreational paddles. Our custom paddle service lets you specify design elements such as grip size, weight balance, and surface texture. This flexibility not only meets the specific requirements of professional players but also provides a competitive edge for sports equipment distributors seeking unique product offerings.

Additionally, our quality assurance protocols ensure that every paddle undergoes rigorous testing. Parameters like structural integrity, vibration levels, and rebound force are measured to guarantee that our products meet the highest industry standards. This commitment to innovation and durability has made NEX Pickleball a trusted name among major brands like Joola and Selkirk.

The market for professional pickleball paddles is evolving rapidly, with a growing demand for equipment that leverages advanced materials and precise manufacturing techniques. Recent trends indicate that the choice of paddle is increasingly influenced by:

- Material Innovation: Advances in carbon fiber and composite materials continue to redefine performance parameters. Competitive players look for paddles that reduce vibration while offering exceptional power and control.

- Production Method Optimization: Manufacturers are investing heavily in processes such as cold pressing and thermoforming to create paddles that maximize both craftsmanship and athletic performance.

- Customization Capabilities: The ability to tailor products to players' unique ergonomic and performance needs is a significant selling point. Custom paddle options allow for a better fit, enhanced performance, and brand differentiation in the competitive market.

Our experience in B2B sports equipment procurement emphasizes that understanding these trends is crucial. For example, industry data shows that paddles with 16mm thickness are increasingly popular among top-tier professionals, balancing a solid hitting surface with ideal responsiveness. However, some players still prefer a 14mm option for a more delicate touch, highlighting the importance of offering multiple product variants.

Consider the strategic overhaul implemented by NEX Pickleball when refining its manufacturing technologies to support competitive play. Our advanced production techniques have allowed us to significantly boost production efficiency while simultaneously improving paddle performance. Here’s a brief overview of our approach:

- Advanced Material Sourcing: With a dedicated focus on high-grade carbon fiber and innovative composites, we ensure that every paddle performs at peak levels. By leveraging different carbon fibers (3K, 12K, T300), we create products tailored for various performance needs.

- Precision Production Processes: The selection of hot pressing, cold pressing, or thermoforming is based on the desired paddle characteristics. Our use of cold pressing preserves the natural structure of the material, enhancing finesse and control—qualities essential for competitive play.

- Quality Control and Testing: Each paddle is rigorously tested for strength, durability, and playability. This quality control process not only verifies the manufacturing consistency but also aligns our products with the exacting standards required by top professional players.

- Customization Options: By offering fully customizable designs, we meet the specific needs of B2B partners. Whether a distributor needs paddles that match their clientele's ergonomic preferences or require branding enhancements, our flexible production system can accommodate these demands.

This comprehensive approach has led our customers to experience reduced defect rates, improved equipment performance, and enhanced market competitiveness. Our continuous innovation and strict adherence to technical standards ensure that every paddle is a market leader in both durability and performance.

When selecting professional pickleball paddles for competitive play, it is essential to look beyond just the superficial design. The performance of a paddle is deeply influenced by the materials used, the manufacturing process, and the level of customization offered by the manufacturer. Here are some key takeaways for B2B procurement managers:

- Material Quality Matters: Choose paddles that utilize advanced materials such as various grades of carbon fiber, high-grade fiberglass, and specialized composites. These materials are proven to enhance both power and control.

- Process Precision is Key: Understand the differences between production processes—hot pressing for mass durability, cold pressing for refined control, and thermoforming for intricate design and performance stability.

- Customization as a Differentiator: Opt for manufacturers who offer customizable paddle options. The ability to tailor core materials, grip sizes, and weight distribution not only meets specific player needs but also differentiates your product offerings in a competitive market.

- Rigorous Quality Control: Ensure that the manufacturer follows strict quality control measures, including rigorous testing for structural integrity and performance consistency.

In short, investing in paddle technology that emphasizes advanced material integration and precise manufacturing processes is critical for staying competitive in the rapidly evolving sports equipment landscape. Double-check your supplier’s expertise, and be sure to align your product specifications with market demands to secure a competitive edge in professional pickleball equipment.

Q: What paddle do most pro pickleball players use?

A: Professional players typically favor paddles crafted from advanced materials like high-grade carbon fiber and specialized composites. Top models from brands such as JOOLA, Selkirk, and Paddletek leverage production techniques that enhance power, control, and durability—qualities that are crucial for competitive play.

Q: What is the #1 rated pickleball paddle?

A: Although ratings can vary, leading products incorporate state-of-the-art materials and refined production processes. Top-rated paddles often include innovative designs such as the JOOLA Ben Johns Perseus Pro IV, which exemplify the balance between strength, control, and ergonomic design that professionals seek.

Q: Do pros use 14mm or 16mm pickleball paddles?

A: Many professionals prefer 16mm paddles for their superior hitting surface and enhanced durability, though some players opt for 14mm models if they desire a lighter touch. Ultimately, paddle thickness is chosen based on individual play style and performance requirements.

-

carbon fiber: Reading about carbon fiber will provide insights into its high strength-to-weight ratio, its role in enhancing performance, and its applications in high-performance sports equipment. ↩ ↩

-

fiberglass: Explore fiberglass to understand its benefits in delivering precise control and improved elasticity in sports gear manufacturing. ↩ ↩

-

Hot Pressing: Learn about the hot pressing manufacturing technique, which is used to consolidate materials under heat and pressure for optimal durability and strength. ↩ ↩

-

Cold Pressing: Discover how cold pressing preserves natural material properties while achieving precise control over product specifications, enhancing performance consistency. ↩ ↩

-

Thermoforming: Delve into thermoforming to see how this process creates complex shapes and distributes materials accurately, resulting in tailored design and improved stability for high-performance equipment. ↩ ↩