Quick Answer: Both padel and pickleball manufacturing and playing experiences focus on precision and performance, yet they differ in court design, ball selection, and production methods. By comparing cross-industry innovations, manufacturers can enhance product performance and brand strategy while addressing the distinct demands of each sport.

In today’s fast-paced sports equipment industry, manufacturers and strategic decision-makers need to understand the nuances between padel and pickleball equipment to drive product differentiation and market competitiveness. This article provides a comprehensive comparison between the two sports from a manufacturing perspective. We explore materials, production processes, and design philosophies that define high-performance paddles and how cross-industry insights can translate into innovative product strategies.

Both padel and pickleball have experienced rapid growth, driven by increased consumer interest in fast-paced, accessible racket sports. However, the target audiences and operational nuances between the two sports differ significantly.

- Padel is predominantly popular in Europe and parts of Latin America. It features courts that are slightly larger than pickleball courts, with enclosed glass walls and wire mesh, creating a dynamic gameplay environment.

- Pickleball has garnered widespread attention in North America and beyond. Its courts are more compact, and the game requires a delicate balance of power, control, and precision when interacting with a plastic ball that has specific design parameters.

For product managers and brand strategists, these differences open avenues to explore cross-industry manufacturing innovations to enhance both paddle design and performance.

At the core of our innovation is material performance. High-quality carbon fiber, fiberglass, and composite materials1 not only define the look of a paddle but also its power, durability, and control characteristics.

-

Carbon Fiber Varieties:

- 3K Carbon Fiber: Offers high rebound force and flexibility, ideal for paddles needing rapid recovery and high durability.

- 12K Carbon Fiber: Provides a smoother surface with greater hardness, making it highly suitable for intense competitive play.

- T300 Carbon Fiber: Balances strength with lightweight, offering superior tensile performance.

-

Fiberglass: Utilized in paddles to ensure a broader sweet spot and balanced playability, it provides excellent elasticity and enhanced ball control.

-

Composite Materials: The combination of carbon fiber and fiberglass can yield exceptional results, merging strength with lightweight properties. Additionally, materials such as bamboo core, honeycomb, and polymer cores adjust the paddle’s weight distribution and vibration damping, essential for a competitive edge.

By leveraging these materials, companies like NEX Pickleball can deliver products that cater to both recreational and professional players. The selection of these materials is essential when designing paddles that perform consistently across different game styles.

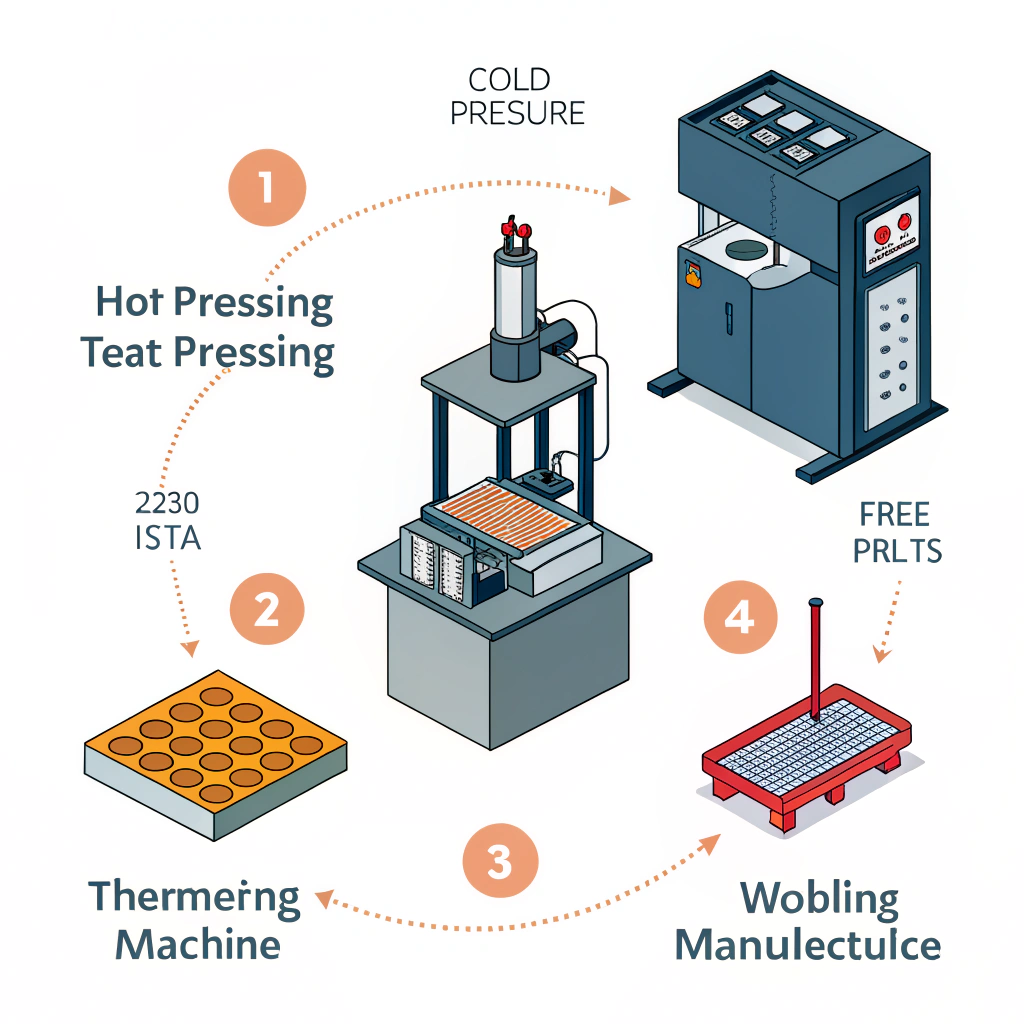

Different production techniques impact the final product's performance and durability. Our analysis highlights three primary processes that producers employ:

Hot Pressing uses heat combined with pressure to form the paddle.

- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Results in strong paddles with excellent impact resistance.

- Maintains a robust structural integrity.

- Disadvantages:

- May alter some intrinsic material properties.

- Requires significant investment in equipment.

Cold Pressing shapes the paddle material at room temperature, offering precise control over thickness and structure.

- Advantages:

- Preserves the natural material properties for better control.

- Delivers a superior tactile feel and responsiveness during play.

- Disadvantages:

- Production cycles are generally longer.

- Demands high-quality equipment for precise pressure control.

Thermoforming heats the material to a workable point before molding into shape, allowing for complex designs and precise material distribution.

- Advantages:

- Suitable for intricate and premium paddle designs.

- Enhances performance stability with carefully crafted material distribution.

- Disadvantages:

- Involves longer production times.

- Requires higher equipment costs, making it ideal for premium product lines.

These processes are chosen based on the intended market and specific product requirements. For competitive paddle manufacturing, selecting the right process can mean the difference between a product that feels great on the court and one that falls short in performance.

To aid in decision-making, let’s examine the key differences and similarities between the manufacturing criteria for both sports:

| Aspect | Padel | Pickleball |

|---|---|---|

| Court Size & Design | Larger courts with glass walls & mesh | Smaller, with lower nets and defined boundaries |

| Ball Specifications | Depressurized tennis balls, lower bounce | Plastic balls with holes to limit bounce |

| Paddle Material Usage | Often uses high-performance composites with high rebound requirements | Designed for balance between control and power often using composite materials or polymer cores |

| Production Process Focus | Emphasizes impact resistance and structural integrity | Prioritizes precision in control and vibration reduction |

| Player Experience Focus | Dynamic interplay with glass and extra court space calls for robust paddles | Compact playing area emphasizes maneuverability and responsive ball control |

| Market Distribution | Popular in European and Latin American markets | Thriving market in North America and increasingly worldwide |

This table illustrates that while both sports require high-quality manufacturing, the specific attributes of the paddles often differ to match the play style and court structure. For example, a padel paddle might be optimized for durability and a hard-hitting game, while a pickleball paddle focuses more on axial control and rebound consistency.

For senior product managers and strategic executives, these manufacturing comparisons represent opportunities to apply cross-industry learning. Consider the following strategies:

-

Adopting Mixed Material Technologies:

Leveraging the benefits of both carbon fiber and fiberglass can create a hybrid paddle that offers durability without sacrificing control. The idea of using a composite material can pave the way for custom paddle solutions tailored to market needs, ensuring competitive edge in both padel and pickleball markets. -

Precision Through Process Optimization:

Selecting the optimal production process—whether hot pressing for strength or cold pressing for control—should align with the target player’s needs. Establishing a balance between production efficiency and product performance is key to maintaining brand reputation and market share. -

Focusing on Ergonomics and Customization:

Modern players are looking for a personalized playing experience. Customizable options in grip size, weight distribution, and balance allow for tailored performance enhancements. Not only does this cater to a larger market segment, but it also provides an avenue for brand loyalty. -

Continuous Quality Assurance:

Using advanced technology for precision and robust testing ensures that each paddle consistently meets the highest standards of performance. At NEX Pickleball, every paddle undergoes rigorous quality control, a practice that can be extended across both sports to bolster customer trust. -

Leveraging Data-driven Decisions:

Integrating market feedback with manufacturing outcomes—such as product durability tests or usage analytics—can help refine production processes over time. Data-backed insights are invaluable for iterative improvements and for validating product features that resonate most with players.

Consider the case of a leading padel brand that transitioned from traditional manufacturing methods to a combination of thermoforming and cold pressing. The strategic pivot not only improved the paddle’s durability but also minimized vibration, leading to a better on-court performance. Similarly, in the pickleball space, innovation in composite core materials like Nomex Honeycomb4 has been a game-changer for long-lasting performance and player comfort.

- Enhanced Player Performance: Lightweight yet strong paddles allow players to execute quicker reactions and maintain precision during long rallies.

- Reduced Manufacturing Costs: Process optimization can lead to lower production costs, freeing up budget for R&D or marketing efforts.

- Market Leadership: Embracing advanced materials and production methods positions a brand as an industry innovator, strengthening market presence internationally.

These examples underline the importance of continuous innovation and the adoption of cross-industry best practices to not only meet but exceed market expectations.

Technology continues to evolve, and so do player expectations. Here are some trends to watch for:

- Smart Manufacturing5: The integration of IoT and AI-driven quality control systems promises enhanced precision and reduced error rates in paddle production.

- Sustainable Materials: There is growing demand for eco-friendly manufacturing processes and materials. Embracing sustainable composites could become a trademark for forward-thinking brands.

- Customization at Scale: Advances in on-demand print technology and customizable design options will empower brands to cater to niche markets without incurring significant cost increases.

- Cross-Sport Innovations: Bridging innovations from padel to pickleball (and vice versa) will continue to inspire improvements in paddle performance, ensuring continuous evolution in game dynamics.

For brands poised to lead the market, these trends offer a glimpse into a future where high-performance, customized sports equipment becomes the norm.

In summary, while padel and pickleball have distinct manufacturing and gameplay features, the opportunities for cross-industry innovation are abundant. Here’s what product managers and brand strategists should consider:

- Embrace Advanced Materials: Leverage both traditional and composite materials to build paddles that offer superior performance.

- Optimize Production Techniques: Choose the right process (hot pressing, cold pressing, or thermoforming) that aligns with your product’s intended functionality and market needs.

- Invest in Customization: Enhance ergonomics and player-specific customization to drive customer satisfaction and brand loyalty.

- Monitor Industry Trends: Stay attuned to emerging trends in smart manufacturing and sustainability to maintain a competitive edge.

By integrating these insights into product development strategies, brands can not only refine their manufacturing processes but also differentiate themselves in a crowded market. For those in the decision comparison phase, these actionable strategies provide a roadmap to optimize paddle performance, drive innovation, and ultimately achieve market leadership.

Q1: How does padel compare to pickleball?

A: Padel is played on larger courts enclosed by glass walls with wire mesh and uses a depressurized tennis ball that has a lower bounce, while pickleball utilizes smaller courts with a lower net and specific boundary lines, and is played with a specially designed plastic ball that limits bounce.

Q2: Does pickleball paddle brand matter?

A: Yes, the brand matters as there are numerous differences between pickleball paddles. Factors such as the materials used, paddle weight, shape, craftsmanship, and innovation all play significant roles in performance, making the choice of brand critical for both playing experience and durability.

Q3: What game is similar to padel?

A: Padel shares similarities with tennis in terms of ball play, but differs notably in the use of a less pressurized ball and the unique enclosed playing environment. Alternatively, pickleball also uses paddles like padel, though it features a plastic ball with holes to reduce bounce, catering to its smaller court dimensions.

-

composite materials: Click to learn how combining different materials such as carbon fiber and fiberglass can optimize product durability and performance through enhanced strength-to-weight ratios. ↩

-

Cold Pressing: Click to discover how cold pressing shapes materials at room temperature, preserving natural properties and delivering superior control in product manufacturing. ↩

-

Thermoforming: Click to explore the process of thermoforming, which heats materials for molding into complex shapes, thereby allowing precision in design and premium product features. ↩

-

Nomex Honeycomb: Click to understand the advantages of Nomex Honeycomb technology in enhancing structural strength and vibration damping in competitive paddle design. ↩

-

Smart Manufacturing: Click to read about how IoT and AI-driven solutions are revolutionizing production processes with increased precision, efficiency, and predictive maintenance capabilities. ↩