Thermoforming is a versatile heat-based manufacturing process that uses heated thermoplastic sheets to produce complex, high-performance products with cost-effective and efficient production methods. In this article, we explore Thermoforming1 in depth—its principles, benefits, limitations, and applications in industries like high-performance paddle manufacturing.

In modern B2B manufacturing, companies constantly seek production techniques that combine quality, precision, and economic feasibility. Thermoforming has emerged as a critical process in advanced manufacturing because it enables the creation of intricate shapes and designs while maintaining excellent material properties. This article will walk you through the thermoforming process, compare it with other manufacturing techniques, and explain why it plays a key role in producing products such as high-performance pickleball paddles.

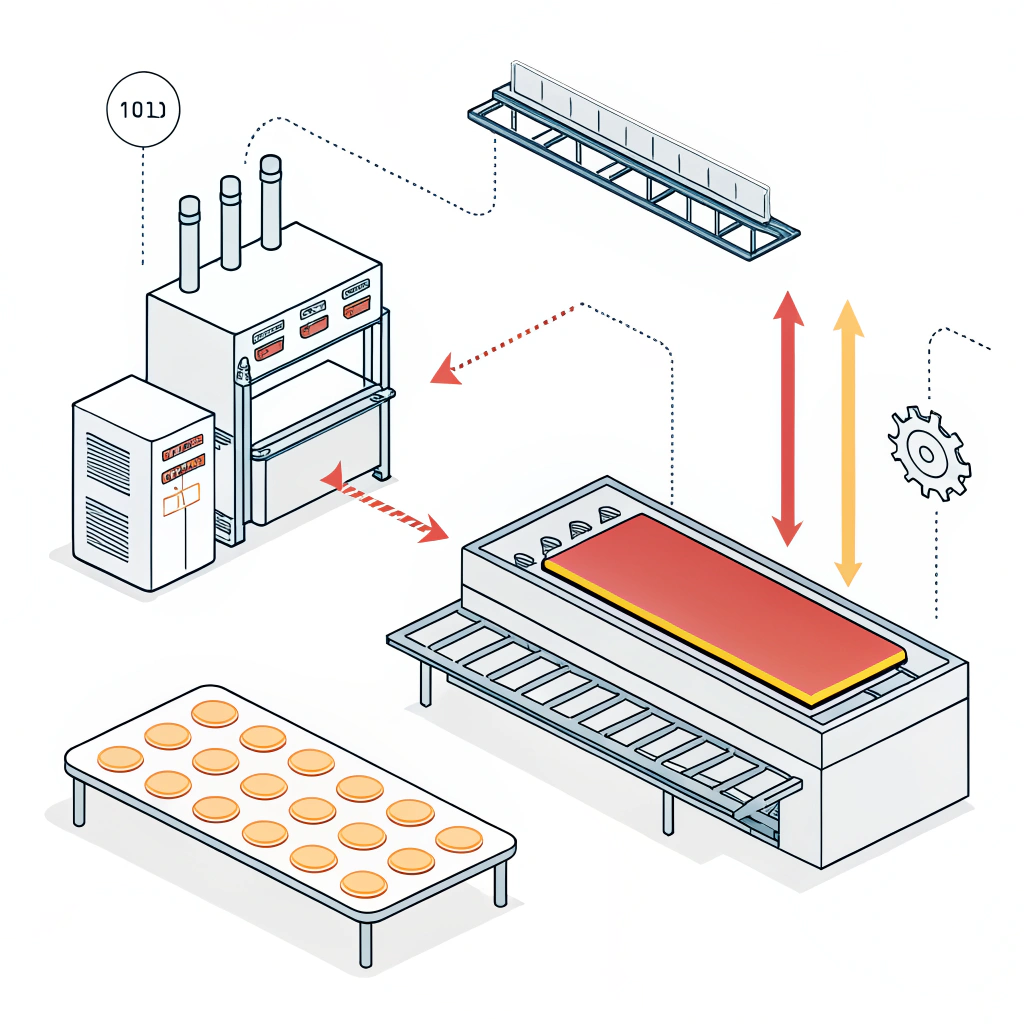

Thermoforming is a plastic molding process that involves several key steps:

- Heating: A thermoplastic sheet is uniformly heated until it reaches a pliable state.

- Forming: The softened sheet is then pressed or vacuumed over a mold, allowing it to take on the shape of the mold.

- Cooling: Once the material conforms to the mold, it is rapidly cooled to set its new shape.

- Trimming: The final step is trimming the excess material to obtain the finished part.

This process can produce complex three-dimensional parts with relatively low tooling costs compared to other manufacturing techniques. Moreover, by using methods such as vacuum forming2, pressure forming, and even twin sheet forming, manufacturers can tailor the process based on product requirements.

For manufacturers, especially those working with composite materials3 and high-performance sports equipment, traditional manufacturing methods may pose challenges such as:

• High tooling costs for intricate designs

• Inefficient material usage leading to increased waste

• Limited ability to produce complex geometries quickly

• Inconsistent quality for products demanding high durability and precision

These challenges often force companies to look for production processes that can deliver both quality and cost advantages. Thermoforming addresses these issues by providing:

• Cost-effectiveness: Low tooling costs that make it accessible for small to medium-sized enterprises.

• Material efficiency: Minimal waste through optimal use of thermoplastic sheets.

• Precision forming: Capability to produce parts with detailed features and high dimensional accuracy.

• Flexibility: Compatibility with a wide range of materials which supports various performance requirements.

Manufacturers in the sports equipment industry, for example, require products like pickleball paddles that must combine lightweight features with high-impact resistance. Thermoforming offers the necessary control over design, material distribution, and surface thickness, making it an ideal choice for such applications.

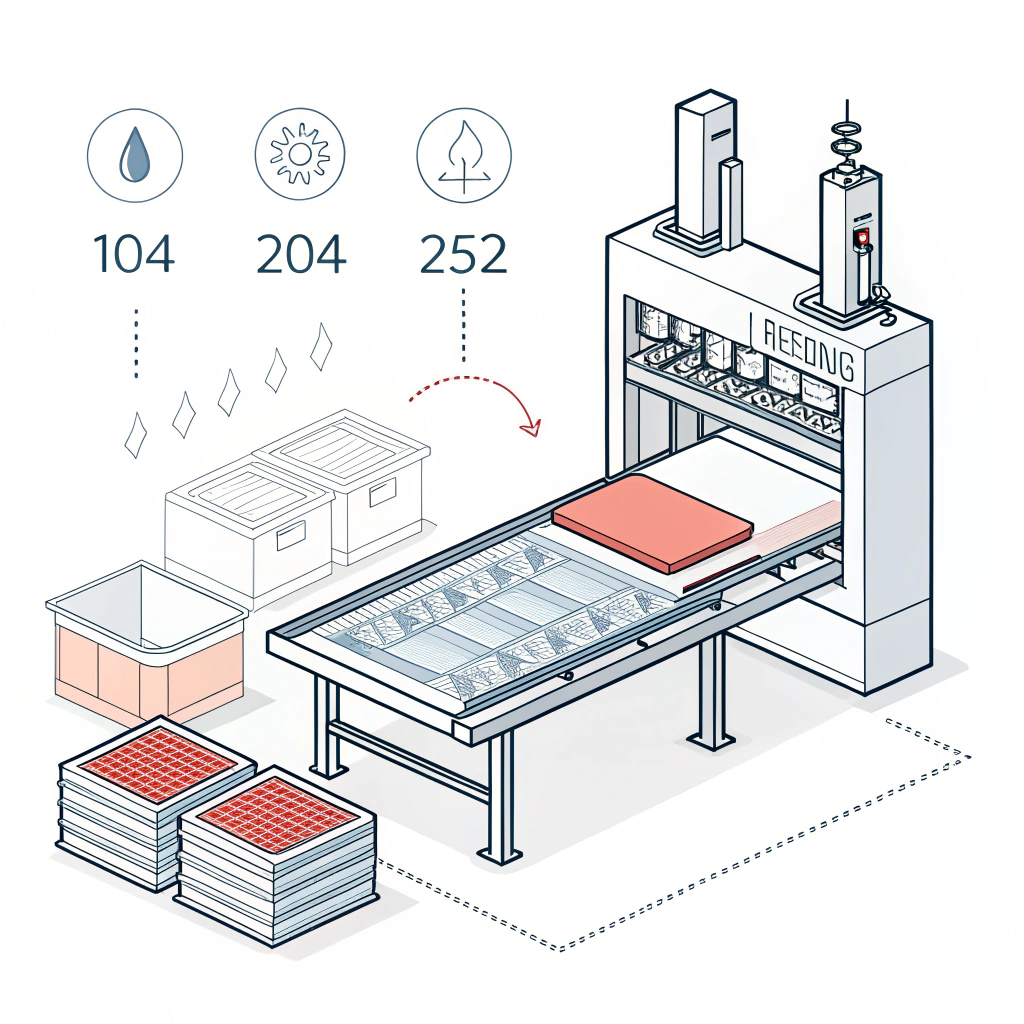

To better understand thermoforming, it’s useful to compare it with other prevalent production techniques: hot pressing and cold pressing. The following table outlines their core differences:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Strong, durable parts - Excellent impact resistance |

- Can alter material properties - High equipment investment |

| Cold Pressing | - Precise control over thickness - Preserves material properties - Superior ball feel and responsiveness |

- Longer production cycles - Requires high-quality pressure control equipment |

| Thermoforming | - Low tooling costs - Material-efficient - Ideal for complex shapes and custom designs |

- Higher equipment cost for premium molds - Requires longer production cycles for intricate designs |

As shown in the table, each process brings its own set of advantages and challenges. Thermoforming distinguishes itself by offering a balance between production efficiency, design flexibility, and cost management—attributes that are particularly valued in high-performance product manufacturing.

Drawing on industry practices and our own experience in manufacturing advanced pickleball paddles, the key benefits of thermoforming can be summarized as follows:

-

Cost-Effective Tooling:

The low initial investment in molds and equipment makes thermoforming accessible to businesses with varying scales of operation. For organizations that prioritize cost management, especially startups or niche manufacturers, thermoforming is a highly attractive option. -

Material Efficiency and Sustainability:

Thermoforming minimizes waste by using optimized sheet sizes and precision trimming techniques. This not only contributes to cost savings but also supports corporate sustainability efforts—an increasingly important factor for partners and customers globally. -

Design Flexibility and Precision:

The process allows for intricate design details to be incorporated into products. For high-performance sports equipment like pickleball paddles, ensuring precise weight distribution, surface texture, and ergonomic grip is crucial. Thermoforming provides the necessary control to achieve these design specifications while maintaining the strength and durability of the product. -

Enhanced Customization Options:

Custom fabrication is a significant advantage of thermoforming. Companies can produce limited runs of custom-designed components, ideal for sports equipment that may require tailored features for teams, branding, or performance optimization. -

Scalability:

While the method is particularly effective for producing complex and custom parts on a smaller scale, thermoforming is also scalable for larger production runs. This versatility allows manufacturers to rapidly adjust to market demands without incurring excessive costs.

While thermoforming brings many benefits, it is important to consider certain limitations and operational nuances:

• Equipment Costs:

Although the tooling costs are typically lower than those for processes such as injection molding4, thermoforming does require specialized equipment. Initial capital investments for high-quality molds and production lines can be significant. Careful cost-benefit analysis is essential before transitioning to or expanding thermoforming capabilities.

• Production Cycle Time:

The complexity of the design can affect production time. For highly detailed products, the forming and cooling stages may require longer cycles compared to simpler manufacturing methods. This may impact overall production efficiency, especially in high-volume manufacturing contexts.

• Material Limitations:

Not all materials are ideal for thermoforming, and the choice of thermoplastic must be compatible with the desired product characteristics. Manufacturers need to work closely with material scientists to ensure that the selected materials meet performance and durability standards. For example, when designing high-performance pickleball paddles, the chosen materials must offer a balance of impact resistance, lightness, and precise ball control.

• Quality Control:

Maintaining consistency across production runs requires rigorous quality control protocols. Variations in temperature, pressure, or cooling rates can lead to inconsistencies in the final product. Advanced monitoring systems and standardized processes are necessary to mitigate these issues.

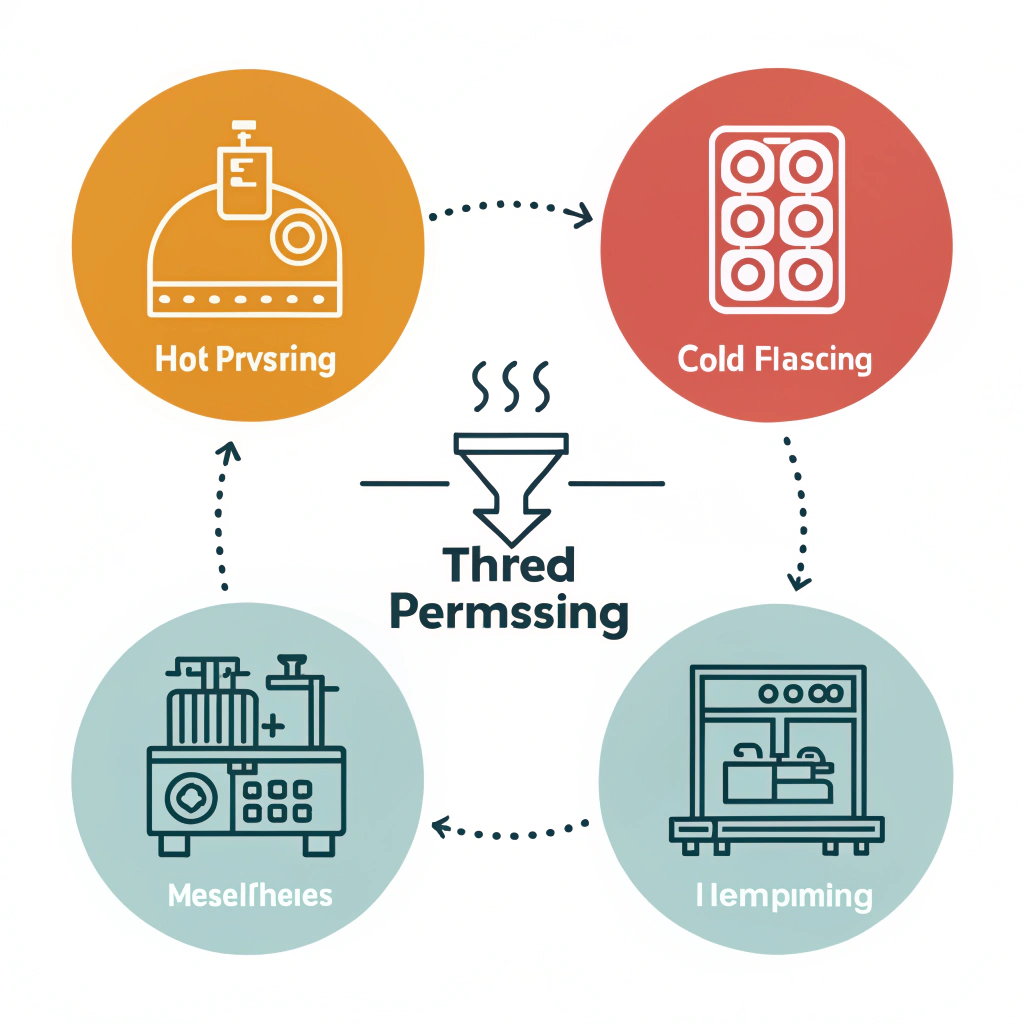

At NEX Pickleball, we leverage advanced thermoforming techniques to produce paddles that meet and exceed industry demands. By integrating thermoforming with other production processes such as hot and cold pressing, we achieve an optimal balance between performance, weight distribution, and durability. Here’s how thermoforming plays a pivotal role in our manufacturing process:

-

Optimized Material Use:

We use premium materials like T300 Carbon Fiber5 and specialized fiberglass composites. Thermoforming allows us to create paddles that are not only lightweight but also exceptionally strong and durable, ensuring a high rebound and comfortable ball control during competitive play. -

Custom Fabrication:

Our custom paddle options are highly valued by clients who require specific design features. Thermoforming enables us to tailor the paddle’s structure to meet individual performance criteria, including grip size, surface texture, and overall paddle balance. -

Enhanced Production Quality:

Through careful monitoring of the temperature and forming conditions, our quality control team ensures that every paddle meets strict performance standards. This consistent quality is pivotal in maintaining our reputation as a leading manufacturer in the competitive sports equipment industry.

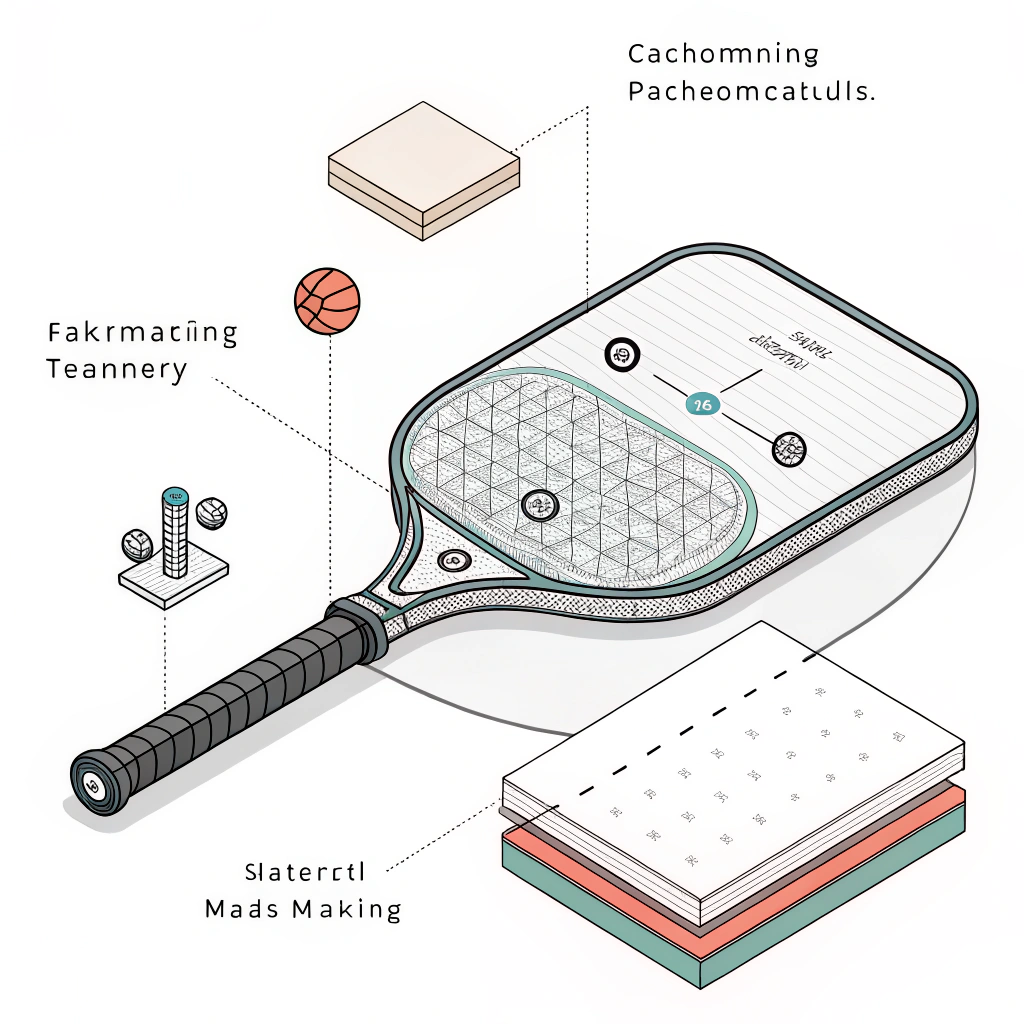

The following table details the specific advantages that thermoforming brings to our paddle manufacturing process:

| Feature | Benefit | Impact on Product Quality |

|---|---|---|

| Material Distribution | Precise manipulation of materials across the paddle surface | Improved impact resistance and control |

| Customization | Ability to produce custom shapes tailored to ergonomic needs | Enhanced player comfort and performance |

| Cost-Effectiveness | Low initial tooling investment | Lower production costs and competitive pricing |

| Durability | Incorporation of advanced composites | Extended product lifespan and reduced vibrations |

For businesses considering thermoforming as a production technique, here are some best practices and actionable steps:

-

Conduct a Feasibility Study:

Evaluate your product specifications, production volume, and budget to determine if thermoforming is the right fit. Engage with technical experts to analyze compatibility with desired materials and product complexity. -

Invest in Quality Equipment:

While the initial investment may be higher, modern thermoforming equipment provides more consistent results and reduces long-term operational costs. Look for machinery that offers precise control over heating, forming, and cooling conditions. -

Develop Rigorous Quality Control Protocols:

Implement advanced monitoring systems to track process parameters such as temperature and pressure. This helps minimize variations and ensures that every product meets strict quality standards. -

Explore Custom Fabrication Opportunities:

Utilize thermoforming’s flexibility to offer custom solutions tailored to specific market needs or brand requirements. This can be a significant competitive advantage in industries where product personalization is highly valued. -

Leverage Data and Case Studies:

Draw on industry data and success stories—such as our own experiences at NEX Pickleball—to build a compelling business case. Quantitative benefits like reduced waste, improved performance metrics, and customer satisfaction can help drive decision-making.

Thermoforming represents a critical advancement in modern manufacturing, particularly for industries that demand precision, efficiency, and customization. Its ability to produce complex, high-performance products with relatively low tooling costs positions it as a key process for companies in the sports equipment and industrial markets. By understanding the process, benefits, and limitations of thermoforming, technical decision-makers can make informed choices to enhance product offerings and drive competitive innovation.

For B2B manufacturers looking to optimize production while maintaining exceptional quality, thermoforming offers a balanced solution that addresses common challenges found in traditional manufacturing processes. Embracing this advanced technique not only improves production efficiency but also opens new avenues for design innovation and market differentiation.

We encourage you to evaluate your production needs and consider integrating thermoforming into your manufacturing strategy to achieve superior product quality and operational efficiency.

People Also Ask

Q: What are the benefits of thermoforming?

A: Thermoforming is highly cost-effective and material-efficient. It offers advantages such as lower tooling costs, reduced material waste, and significant flexibility in producing complex, high-performance parts. These benefits make it an ideal process for applications requiring detailed designs and customization.

Q: What is thermoforming explained?

A: Thermoforming is a plastic manufacturing process where a thermoplastic sheet is heated until pliable, then molded over a shaped form using vacuum, pressure, or mechanical methods. This process creates a three-dimensional part from a flat sheet by cooling it in the mold shape.

Q: What are the three types of thermoforming?

A: Thermoforming methods mainly include vacuum forming, pressure forming, and mechanical (or twin sheet) forming. These methods vary in how the forming force is applied and how the material is shaped, ultimately producing 3D parts with distinct characteristics.

-

Thermoforming: Click to learn more about the fundamental process of reshaping heated thermoplastic sheets into complex, high-performance products through various molding techniques. ↩ ↩

-

Vacuum Forming: Click to understand the vacuum forming method, where air pressure is used to shape heated plastics over molds, offering precision and cost benefits in production. ↩ ↩

-

Composite Materials: Click to explore how composite materials combine different substances to enhance performance, durability, and weight efficiency in manufacturing applications. ↩ ↩

-

Injection Molding: Click to review injection molding, a process where melted plastic is injected into molds under high pressure, often compared with thermoforming for its tooling and production attributes. ↩ ↩

-

T300 Carbon Fiber: Click to learn about T300 Carbon Fiber, a high-strength, lightweight composite material commonly used in high-performance manufacturing for enhanced durability and rigidity. ↩ ↩