Pickleball is affordable for players, but when analyzing the cost from a business perspective—whether considering facility development or investing in high-quality equipment—the financial picture involves multiple components. In this article, we break down the key cost drivers involved in bringing a pickleball program to life and explain how to make smart, informed decisions for sustainable, profitable operations.

The cost of playing pickleball isn’t just about the end-user equipment price. For sports facility managers, club owners, and business developers, the investment spans across multiple areas:

-

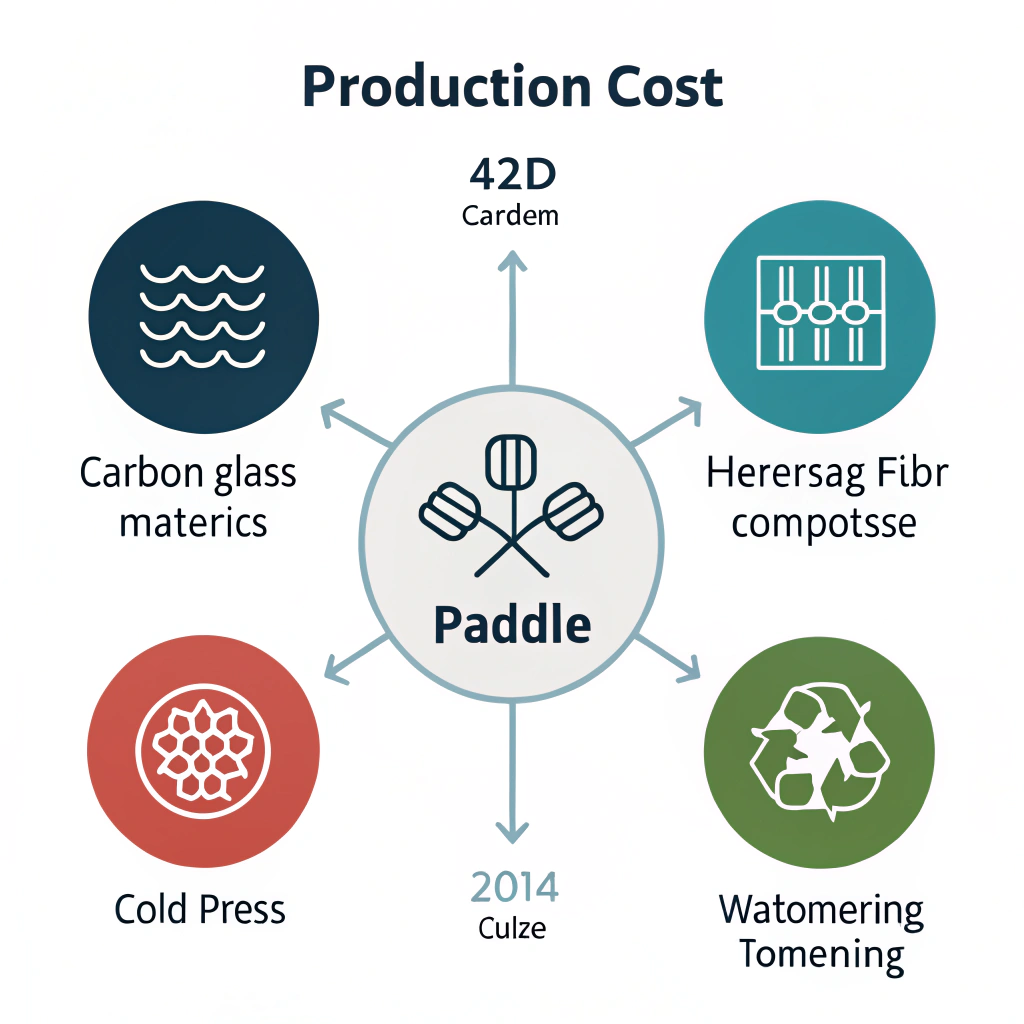

Equipment Investment: This includes the paddles, balls, nets, and specialized gear. Manufacturers like NEX Pickleball utilize high-performance materials such as carbon fiber1 (3K, 12K, T300), fiberglass, and composite materials to create paddles with superior performance. Each material type comes with a different pricing structure, reflecting its production complexity and performance capabilities.

-

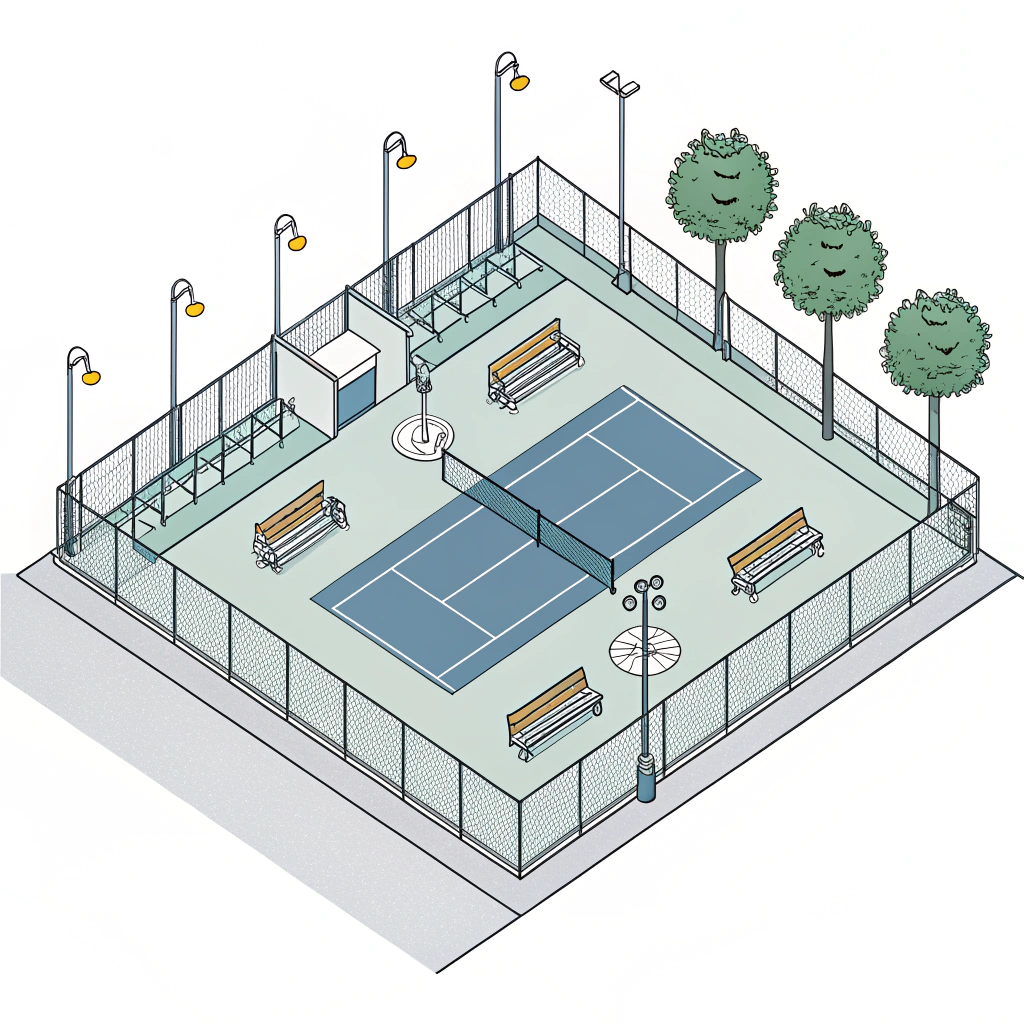

Facility Setup and Maintenance2: Building or retrofitting facility courts to meet pickleball standards involves costs for surfaces, fencing, lighting, and nets. Additionally, ongoing maintenance such as surface repairs, cleaning, and periodic equipment updates plays a significant role in the overall expense.

-

Operational and Ancillary Costs3: Staffing, marketing, and customer service expenses are important for maintaining a successful pickleball center. This also covers community engagement, training programs, and on-demand services like custom printing on paddles.

High-end pickleball paddles are at the forefront of cost considerations. Thanks to our advanced production techniques like hot pressing, cold pressing, and thermoforming, we ensure each paddle offers precision, durability, and optimum performance. Below are key factors that influence paddle pricing:

-

Raw Material Selection:

- Carbon Fiber Options:

• 3K Carbon Fiber: Offers high rebound force and durability at a cost-effective price point.

• 12K Carbon Fiber: Provides a smoother surface and enhanced impact resistance, suitable for premium paddles.

• T300 Carbon Fiber: Balances strength and lightweight properties for competitive play.

- Carbon Fiber Options:

-

Production Process4:

Each process has its advantages and trade-offs. For example, hot pressing produces durable paddles efficiently, while cold pressing offers enhanced material control but needs precise pressure adjustments. -

Customization:

Custom paddles that allow for personalized designs, grip sizes, and balance adjustments can add to the cost depending on the level of customization requested.

| Component | Description | Impact on Cost |

|---|---|---|

| Material Quality | Carbon Fiber, Fiberglass, Composite Materials | Higher quality increases price |

| Production Process | Hot Pressing, Cold Pressing, Thermoforming | Process complexity affects cost |

| Customization Level | Custom design, weight, and grip options | More customization demands higher cost |

| Scale of Production | Batch size and production efficiency | Economies of scale can reduce unit cost |

When evaluating a potential investment in a pickleball facility, consider both the initial capital expenditure and the recurring operational costs.

-

Court Installation:

Creating multiple pickleball courts involves significant investment in upgrading or constructing surfaces that are durable and safe. This includes costs for resurfacing, installing proper net systems, and applying safety measures. -

Facility Infrastructure:

Decisions about location, building amenities, lighting, and seating or viewing areas add to the overall capital expense. Proper design ensures a great player experience and helps in customer retention.

-

Surface Repairs and Cleaning:

Regular maintenance is key for safe play. Facility managers need to budget for periodic cleaning, resurfacing projects, and equipment repairs to ensure the courts remain in optimal condition. -

Equipment Updates:

Technological advances and wear and tear may necessitate upgrades in paddle technology or replacement of nets and other accessories. Investing in durable, high-quality materials can reduce these recurring costs.

Apart from tangible physical investments, the operational side of a pickleball business plays a crucial role in determining overall expenditure.

- Hiring trained staff—coaches, customer service representatives, and facility maintenance personnel—is necessary for smooth operations.

- Ongoing staff development and training programs can further enhance service quality but add to costs.

- Effective marketing campaigns, community events, and social media outreach are essential for boosting facility visits and customer satisfaction.

- Promotional events and partnerships with local organizations might also require additional budgets.

- Implementation of management systems for reservations, membership, and maintenance scheduling can streamline operations but require an initial IT investment and ongoing support.

To ensure profitability and ROI, consider taking the following steps:

-

Budgeting with Detailed Analysis:

Develop a comprehensive budget that takes into account all cost components—from equipment to operational expenses. Utilize a breakdown similar to the table provided above to estimate initial and recurring costs accurately. -

Leverage Economies of Scale5:

For equipment investments, consider bulk orders or long-term contracts with manufacturers. Companies like NEX Pickleball offer on-demand custom printing and various production options tailored to different volume requirements, which can lead to cost reductions. -

Invest in High-Quality Materials and Processes:

While premium materials like 12K or T300 carbon fiber can raise initial costs, they often result in lower long-term maintenance expenditures due to enhanced durability and performance. This quality translates to customer satisfaction and competitive differentiation. -

Optimize Facility Utilization:

Maximize usage of your courts through scheduled tournaments, leagues, and community engagement programs. Increased usage can justify the initial setup cost by generating higher revenue over time. -

Regular Financial Review and Adjustments:

Implement a system for continuous financial review to identify cost-saving opportunities and adjust budgets based on real-time data. This includes routine assessments of energy consumption, staffing efficiency, and promotional ROI. -

Consider Alternative Financing Models:

Explore leasing options for equipment or consider partnerships with established pickleball manufacturers. Innovative financing methods may ease up-front capital pressures.

A sports club in a mid-sized city recently decided to incorporate pickleball into its offerings. They invested in upgrading an existing basketball court to meet pickleball standards. Here’s how they managed the financial aspects:

-

Initial Investment:

The facility upgrade, including resurfacing and court layout modifications, accounted for 40% of the investment. Equipment purchases (paddles and nets) contributed another 30%. -

Operational Strategy:

By scheduling daily sessions and weekly tournaments, the club increased court utilization by 50% within six months. This additional revenue helped cover recurring maintenance fees and staff salaries. -

ROI Outcome:

Within the first year, the club reported an overall increase in membership and facility usage which boosted profitability. The initial inflated capital costs were quickly offset by enhanced engagement and community expansion.

In summary, the total cost of entering the pickleball market—whether from the perspective of a player or a business owner—involves multiple layers. For sports facility managers and club owners, understanding the detailed cost components helps in making informed decisions. Key takeaways include:

- A well-rounded cost analysis that includes equipment, facility setup, and operational expenses is essential.

- Investing in high-quality materials may have a higher upfront cost but results in considerable savings over time due to lower maintenance and higher durability.

- Strategic marketing and optimal facility utilization ensure that revenue growth justifies the initial investments.

- Regular financial reviews and leveraging economies of scale are critical in sustaining operations and maximizing ROI.

For businesses considering entry into the pickleball market, it is crucial to balance quality, cost efficiency, and customer satisfaction—ultimately driving long-term success.

• Is it expensive to play pickleball?

No, pickleball remains one of the most affordable sports, especially when compared with high-cost sports like golf. The overall costs for recreational play are low, making it accessible while providing excellent health and recreation benefits.

• How many times a week should you play pickleball?

For optimal health benefits, playing pickleball three days a week is generally recommended. This schedule allows sufficient active play along with adequate rest and recovery, although some advanced players might choose to play more frequently.

• What is the best age to start pickleball?

Pickleball is suitable for a wide range of ages. Children as young as 5 or 6 can start learning the game, though the ideal starting age may vary based on coordination and balance. It’s a sport that can be enjoyed across generations, promoting both physical activity and social engagement.

-

carbon fiber: Click to learn about the properties, different grades (3K, 12K, T300), and production techniques that make carbon fiber a sought-after material in high-performance sports equipment. ^↩ ↩

-

Facility Setup and Maintenance: Click to explore the key components, planning strategies, and ongoing maintenance requirements necessary to build and sustain a sports facility that meets industry standards. ^↩ ↩

-

Operational and Ancillary Costs: Click to understand the variety of indirect expenses such as staffing, marketing, and support services that affect the overall profitability of a sports business. ^↩ ↩

-

Production Process: Click to discover the various manufacturing techniques — including hot pressing, cold pressing, and thermoforming — that influence product quality and cost in paddle production. ^↩ ↩

-

Leverage Economies of Scale: Click to learn how bulk purchasing and long-term contractual agreements can reduce unit costs and improve the overall financial efficiency of your investment. ^↩ ↩