The high-performance design of pickleball paddles relies heavily on selecting the right materials and manufacturing processes. In short, understanding and comparing options like carbon fiber1, fiberglass2 and various composite materials3—as well as production methods such as hot pressing4, cold pressing, and thermoforming—is essential for procurement managers to make informed, cost-effective decisions.

Pickleball paddle quality is built on two key factors: the material composition and the production process. Differences in paddle material—ranging from carbon fiber variants (3K, 12K, T300) to fiberglass and composite constructions—directly influence durability, impact resistance, and control on the court. Meanwhile, production techniques such as hot pressing, cold pressing, and thermoforming further impact the paddle’s performance characteristics. For procurement managers, understanding these factors is fundamental when evaluating products for retail or custom orders.

Procurement specialists often face several challenges:

• Balancing cost with performance.

• Ensuring consistency in production quality.

• Making decisions based on detailed technical data.

• Staying updated with manufacturing innovations.

These challenges necessitate a detailed technical overview and a quantitative comparison table to transparently present the merits and shortcomings of different material and production choices.

Different materials offer distinct advantages:

3K Carbon Fiber is known for its flexibility and good rebound force. It allows for excellent durability while reducing vibrations, which is ideal for players who demand responsiveness.

12K Carbon Fiber has a higher thread density. It delivers a smoother surface finish and exceptional hardness. This makes the paddle more robust against impacts in competitive play.

T300 Carbon Fiber combines outstanding tensile strength with a balanced weight. It is particularly favored for paddles that require both strength and agility.

Fiberglass paddles, especially those using E-Glass Fiberglass, offer an inherent balance between power and control. Their elasticity provides a wider sweet spot resulting in better ball control, making them suitable for both recreational and competitive players.

Composite options include blends such as:

• Carbon Fiber and Fiberglass Composite: Merges the strength and lightweight benefits of both materials.

• Bamboo Core Composite: Known for its impact resistance and lightweight quality. Provides a clear, consistent feel during prolonged play.

• Honeycomb Core5 (Nomex, Aluminum, Polymer): These offer various profiles:

- Nomex Honeycomb Core delivers excellent shock absorption and stability.

- Aluminum Honeycomb Core provides balanced weight distribution, resulting in both power and control.

- Polymer Honeycomb Core is specially designed to reduce vibration, ideal for players needing extra comfort.

These material options allow for industry innovation by tailoring the performance characteristics to meet specific competitive or recreational needs.

| Material | Durability | Impact Resistance | Flexibility | Weight Control | Ideal For |

|---|---|---|---|---|---|

| 3K Carbon Fiber | High | Moderate | High | Moderate | Recreational to intermediate |

| 12K Carbon Fiber | Very High | High | Moderate | Light | High-level competitive play |

| T300 Carbon Fiber | High | High | Balanced | Very Light | Performance and agility |

| E-Glass Fiberglass | Moderate | Moderate | High | Moderate | Enhanced ball control |

| Bamboo Core Composite | Moderate to High | High | Moderate | Very Light | Long-duration performance |

| Nomex / Aluminum/ Polymer Honeycomb | High | Very High | Moderate | Well Balanced | High precision and comfort |

This table helps highlight why selecting the right material matters. The trade-offs between durability, weight, and softness significantly affect paddle performance on the court.

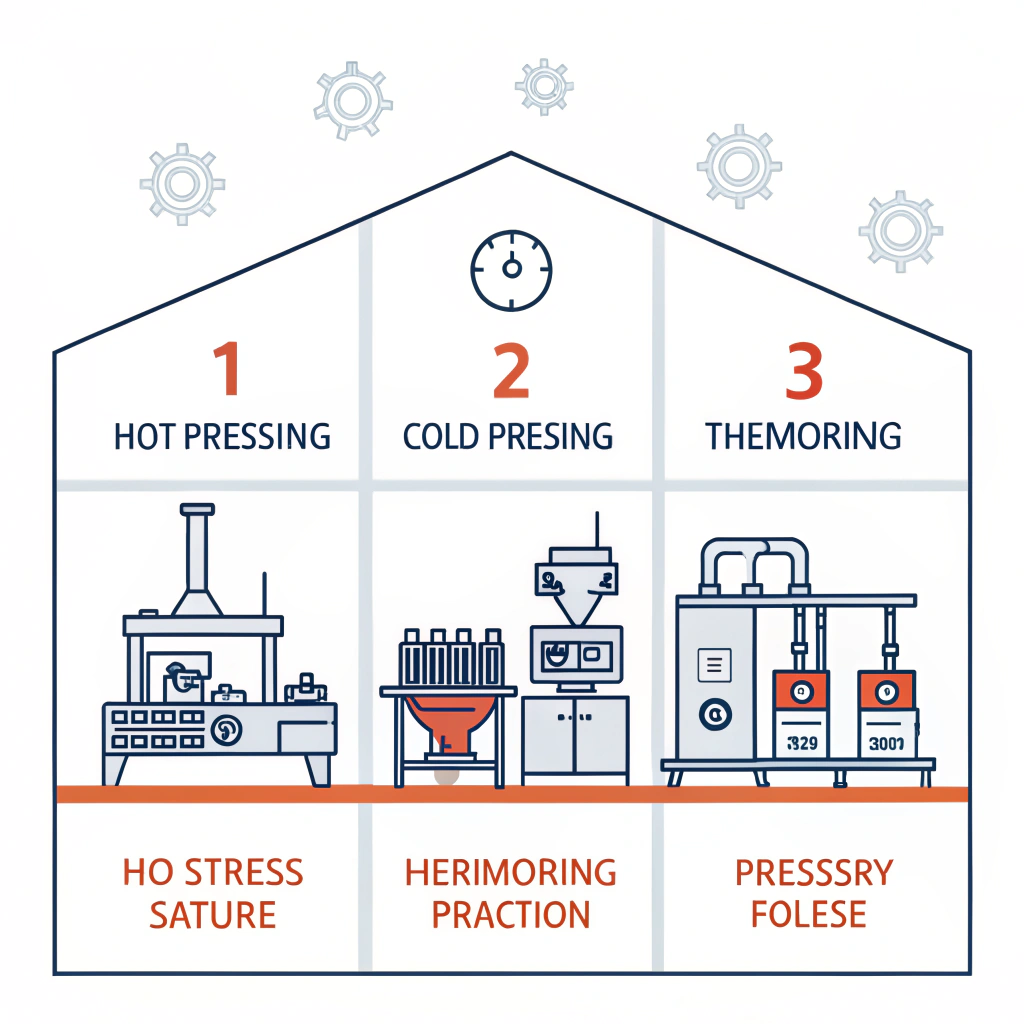

The production process is as critical as the materials used. Each method brings unique advantages and limitations that ultimately affect performance, cost, and production speed.

Hot Pressing4 involves heating the material and applying pressure to form a secure, integrated structure.

- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Results in extremely robust paddles with excellent shock absorption.

- Ensures structural integrity even under high-intensity play.

- Disadvantages:

- High initial equipment investments.

- May alter inherent material properties, potentially affecting the paddle’s nuanced feel.

Cold pressing utilizes ambient temperatures combined with mechanical pressure to shape the paddle.

- Advantages:

- Greater precision in controlling thickness and material distribution.

- Preserves essential material properties, enhancing paddle control and responsiveness.

- Ideal for designs where a refined tactile response is needed.

- Disadvantages:

- Production cycles are longer compared to hot pressing.

- Requires sophisticated pressure control systems to avoid material inconsistencies.

Thermoforming uses heat to soften the material, which is then molded into shape through custom molds.

- Advantages:

- Allows for the creation of complex, intricate paddle designs.

- Maintains excellent stability and balance by ensuring even material distribution.

- Best suited for premium products or custom designs.

- Disadvantages:

- Increased production time and higher associated costs.

- Demands high technical expertise to ensure quality consistency.

| Production Process | Efficiency | Precision Control | Investment Cost | Ideal Application |

|---|---|---|---|---|

| Hot Pressing | Very High | Moderate | High | Mass-produced, high-impact paddles |

| Cold Pressing | Moderate | High | Moderate | Custom designs requiring enhanced tactile feel |

| Thermoforming | Moderate to Low | Very High | High | Premium, intricate designs with custom specifications |

Understanding these processes helps clarify why a high-performance paddle might justify a longer production cycle or higher cost—if it means a significantly better playing experience.

At NEX Pickleball, we combine advanced manufacturing techniques with premium materials to deliver products that consistently meet rigorous quality control standards. Each paddle undergoes extensive testing to ensure it adheres to performance specifications.

- Performance Testing: Rigorous impact tests have shown that paddles manufactured with 12K Carbon Fiber and hot pressing can withstand repeated high-speed impacts while maintaining structural integrity.

- Customer Feedback: Competitive players frequently note the difference in rebound force and vibration dampening when using paddles that incorporate honeycomb cores.

- Quality Consistency: Utilizing strict quality control across our three main production processes ensures that every paddle performs reliably, a critical factor for bulk purchasers and distribution alike.

These real-world insights underscore the importance of technical precision and consistent production practices in delivering a product that not only meets but exceeds performance expectations.

- Equipment Investment: Ensure that production facilities are equipped with the latest technology for pressure control and temperature regulation.

- Material Handling: Pay attention to the properties of each material during the assembly process—small changes can lead to significant differences in playability.

- Customization Options: Leverage custom paddle options for targeted markets. Select materials and production methods that align with the needs of specific player segments (e.g., competitive vs. recreational).

In addition, our commitment to ongoing research and collaboration with global partners like Joola and Selkirk positions us to continuously innovate. This proactive approach helps maintain NEX Pickleball's reputation as a reliable manufacturer of high-performance pickleball paddles.

To sum up, when selecting a pickleball paddle, procurement managers should consider both the material composition and the production process. The material properties—from carbon fiber varieties to fiberglass and composite constructions—directly impact the paddle’s agility, control, and durability. On the other hand, the chosen manufacturing process (hot pressing, cold pressing, thermoforming) influences production efficiency and fine-tuning of the paddle’s performance characteristics.

- Analyze End-User Requirements: Determine if your target market prioritizes speed, durability, or control.

- Balance Performance with Cost: Use our comparison tables to match the right material and production method to your quality and budget constraints.

- Leverage Custom Options: Consider custom paddle solutions that allow you to tailor products for specific demographics or performance needs.

- Partner with Experienced Manufacturers: Choose suppliers like NEX Pickleball that adhere to rigorous quality controls and leverage advanced production techniques to ensure consistency.

Ultimately, detailed technical analysis combined with real-world performance data leads to smarter purchasing decisions. By keeping these considerations in mind, procurement managers can confidently select paddles that enhance performance, maintain competitive pricing, and provide a superior playing experience.

• What are the key differences between carbon fiber and fiberglass in paddle manufacturing?

Carbon fiber variants, such as 3K, 12K, and T300, offer higher strength, smoother surfaces, and better rebound characteristics compared to fiberglass. Fiberglass, notably E-Glass, typically provides a wider sweet spot and enhanced flexibility, offering greater ball control for recreational play.

• How do hot pressing, cold pressing, and thermoforming processes impact paddle performance?

Hot pressing results in high production efficiency and excellent impact resistance but may alter material feel; cold pressing allows for precise control over thickness and maintains material properties, though it requires longer cycles; thermoforming delivers intricate designs and enhanced stability, best suited for premium custom paddles despite its higher cost and longer production time.

• What factors should be considered when selecting core materials for pickleball paddles?

Key factors include durability, shock absorption, weight distribution, and the playing experience desired. For instance, Nomex honeycomb cores offer superior stability and impact resistance, while polymer cores reduce vibration for added comfort.

-

carbon fiber: Read the article to understand the properties, performance benefits, and manufacturing considerations of carbon fiber in high-performance sports equipment. ↩ ↩

-

fiberglass: Read the article to learn how fiberglass is used in paddle construction to balance durability with flexibility and ball control. ↩ ↩

-

composite materials: Read the article to explore how combining different materials creates composites that optimize strength, weight, and vibration absorption. ↩ ↩

-

hot pressing: Read the article to understand the hot pressing process, including its advantages, limitations, and role in large-scale manufacturing. ↩ ↩ ↩2

-

Honeycomb Core: Read the article to discover how honeycomb core structures (Nomex, Aluminum, Polymer) enhance shock absorption, weight distribution, and overall paddle performance. ↩ ↩