In today’s competitive sports equipment market, understanding advanced manufacturing processes is crucial for developing high-performance pickleball paddles. Thermoforming1, among other methods, emerges as a leading candidate for producing paddles with intricate designs and consistent quality. This article provides an in-depth technical overview, compares different production processes, and explains why thermoforming may be the best solution to meet modern performance and customization requirements.

Thermoforming enhances design flexibility, material distribution, and overall product quality for pickleball paddles by allowing intricate shapes and consistent performance, making it an attractive option compared to traditional methods like hot pressing2 and cold pressing3.

Procurement managers in sports equipment distribution are continually seeking reliable manufacturing techniques. The shift towards high-performance paddles requires employing advanced production methods that not only optimize durability and performance but also enhance customization. Thermoforming is recognized for its ability to create complex shapes, optimize material distribution, and maintain the structural integrity of high-end materials used in pickleball paddles.

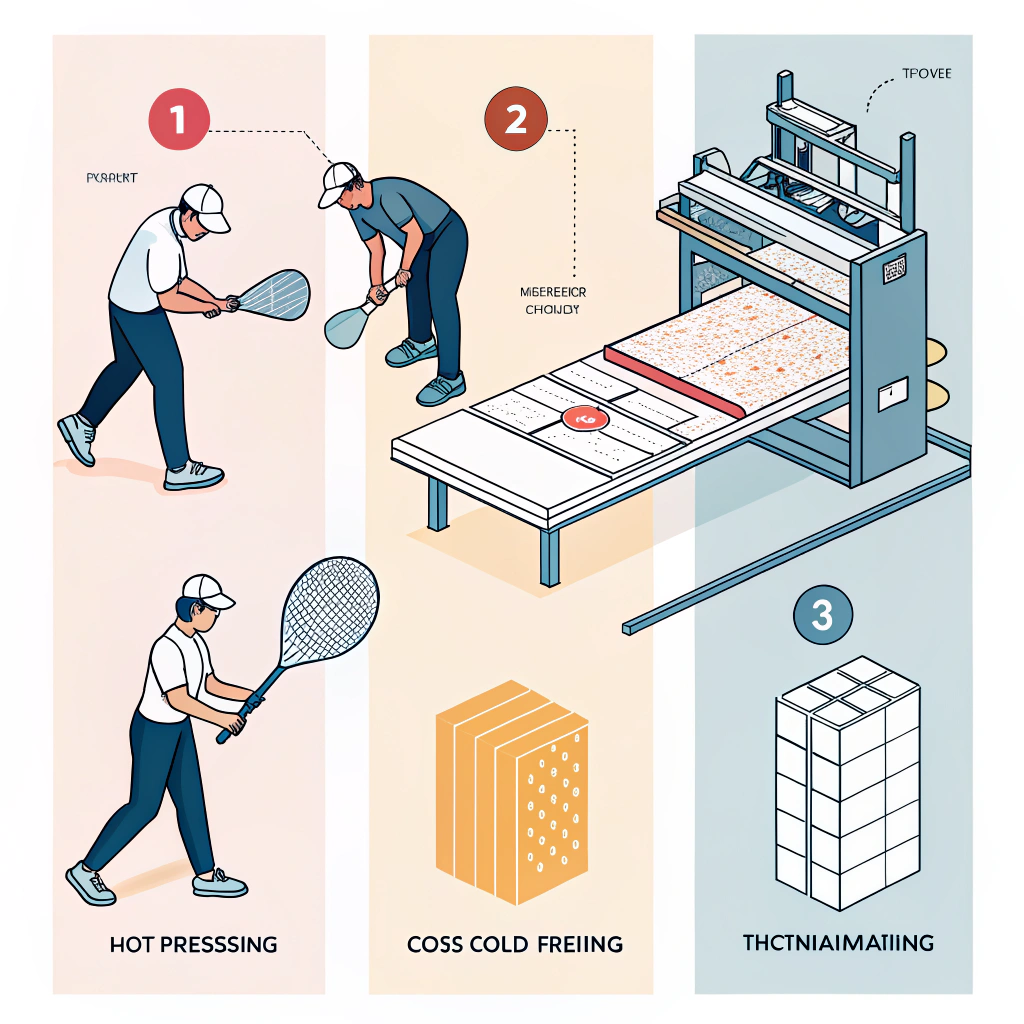

At NEX Pickleball, our manufacturing processes incorporate innovative methods such as hot pressing, cold pressing, and thermoforming. Each technique has unique advantages and limitations. However, thermoforming distinctly stands out for its ability to create paddles that fit both competitive and casual play with high precision.

Hot pressing involves heating paddle materials and then applying pressure to achieve the desired shape and compactness. This method is widely adopted in large-scale manufacturing due to its efficiency and strength in producing high-impact products.

Advantages:

- High Production Efficiency: Ideal for mass production.

- Structural Integrity: Produces paddles with excellent impact resistance.

- Strong Performance: Well-suited for high-performance play.

Disadvantages:

- Material Alteration: Elevated temperatures may impact the feel and performance of certain materials.

- Equipment Costs: Requires significant investment in specialized machinery.

Cold pressing uses mechanical pressure at room temperature to shape the paddle material. This approach allows for more precise control over the paddle’s dimensions and material properties.

Advantages:

- Precision: Better control over paddle thickness and structural details.

- Preservation of Material Properties: Maintains the intrinsic qualities of the material, offering improved ball feel.

- Better Control: Enhances flexibility and responsiveness of the paddle.

Disadvantages:

- Longer Production Cycle: More time-consuming compared to hot pressing.

- Equipment Sensitivity: Demands high-quality, precise machinery to achieve the desired result.

Thermoforming entails heating the paddle material until it softens, then molding it using custom-designed molds. This process is particularly effective for creating paddles with complex shapes and ensuring even material distribution.

Advantages:

- Design Flexibility: Accommodates intricate paddle designs and varied thicknesses.

- Enhanced Material Distribution: Ensures that critical areas of the paddle receive optimal material density.

- Stability and Durability: Maintains the paddle's overall structural integrity while reducing vibration and ensuring superior impact absorption.

Disadvantages:

- Longer Production Time: Requires a prolonged production cycle which might affect output rates.

- Higher Equipment Costs: Investments in specialized molds and machinery are necessary, particularly for custom designs.

The following table provides a concise comparison of the three primary production methods used for pickleball paddles:

| Production Method | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structure, excellent impact resistance | Potential alteration of material properties, high equipment costs | Large-scale production requiring robustness |

| Cold Pressing | Precision control, preservation of material properties, enhanced responsiveness | Longer cycle time, sensitive to pressure variations | Products prioritizing precise feel and control |

| Thermoforming | Highly adaptable design, even material distribution, excellent stability | Longer production time, higher upfront investment in equipment | Custom, high-performance paddles with intricate designs |

This table illustrates that while each method has its inherent benefits, thermoforming uniquely satisfies the advanced requirements of modern paddle design—especially in terms of design flexibility and material distribution.

In the manufacturing world, thermoforming is acknowledged for its ability to produce superior pickleball paddles. Here’s why this process is often preferred by leading manufacturers:

-

Complex Shape Design:

Traditional processes like hot pressing and cold pressing can be limiting when it comes to shaping paddles with complex geometries. Thermoforming allows manufacturers to explore innovative designs, achieving smoother curves and more ergonomic profiles. This means that the paddle can be designed to optimize weight distribution and maximize performance based on the sophisticated contours of the mold. -

Optimized Material Distribution:

The success of a pickleball paddle depends significantly on how materials such as carbon fiber4 and fiberglass5 are utilized. During thermoforming, the material is evenly distributed, ensuring consistent density throughout the paddle. This process enhances both impact resistance and flexibility, leading to superior ball control and less vibration upon impact. -

Customization and Performance Tuning:

For procurement managers aiming to differentiate their product lines, customization is key. Thermoforming supports the creation of special edition paddles or tailored designs for professional teams. With the ability to modify molds, precise control over parameters like hole placement, thickness, and surface texture can be achieved, making each paddle unique in performance attributes. For instance, players requiring a specific balance for power versus control can now receive paddles engineered with those precise needs in mind. -

Enhanced Durability and Vibration Dampening:

High-performance paddles must withstand repeated impacts without compromising structural integrity. By ensuring that the material is uniformly set during thermoforming, the paddle gains better shock absorption properties. This not only reduces the risk of delamination or material fatigue but also improves the player's experience by decreasing unwanted vibrations.

Consider a scenario where a sports equipment distributor aims to supply paddles that meet both recreational and competitive standards. Traditional hot pressing might yield robust paddles, but if a player’s comfort and performance depend on nuanced control during quick transitions, cold pressing might offer the requisite sensitivity. However, thermoforming provides a middle ground where both durability and nuanced performance can coexist.

For example, a recent collaboration with a professional team involved developing a paddle that required:

- Fine-tuned weight distribution for rapid response.

- A surface design that enhanced grip on the ball.

- Consistency in paddle performance despite complex geometric design elements.

By leveraging thermoforming, it was possible to create paddles that delivered on all these fronts. The process ensured that players experienced less fatigue from vibration and maintained comfort even during extended play sessions. This case underscores how thermoforming can meet the diverse needs of high-stakes sporting environments.

For decision-makers considering manufacturing enhancements or introducing new product lines, the following steps can be taken:

-

Evaluate Current Production Capabilities:

Assess your current manufacturing methods and compare them with the demands of today's market. Consider if your present techniques can achieve the desired balance of performance, customization, and production efficiency. -

Analyze Material Benefits:

Review the materials used—such as different types of carbon fiber (3K, 12K, T300) and composites. Compare how these materials behave under different production methods. Thermoforming often brings out the best in high-tech materials by ensuring optimal distribution and structural integrity. -

Consult with Manufacturers:

Engage with partners who offer advanced production methods. Ask detailed technical questions about how they handle complex designs and what quality control measures are implemented to guarantee consistent performance. -

Start Small with Pilot Projects:

Run test projects with thermoforming to validate the process on a smaller scale. Use detailed KPIs (Key Performance Indicators) such as ball control, durability, and weight distribution to measure success. -

Review Customer Feedback and Market Trends:

Collect insights from professional players as well as recreational users about paddle performance. This data can be invaluable when deciding whether to continue with or scale up the thermoforming approach.

By following these steps, procurement managers can make well-informed decisions that balance innovation, quality, and efficiency, helping to elevate their product offerings in the competitive sports equipment market.

Advanced manufacturing techniques, especially thermoforming, represent a significant leap forward for pickleball paddle production. With its superior ability to mold intricate designs, ensure uniform material distribution, and enhance overall product performance, thermoforming proves to be an excellent choice for manufacturers aiming for innovation. In comparison to traditional methods like hot pressing and cold pressing, thermoforming offers a higher degree of customization, making it particularly beneficial for competitive and professional sports equipment.

As the pickleball industry continues to evolve with performance-driven demands, companies looking to secure a competitive edge must evaluate their manufacturing processes carefully. The adoption of thermoforming can drive product innovation, improve player performance, and ultimately lead to superior market differentiation.

Taking action now by exploring thermoforming as your manufacturing strategy could set you apart as a forward-thinking leader in sports equipment procurement and distribution.

Q: What's the best material for pickleball paddles?

A: Experts note that carbon fiber is often the top choice due to its exceptional strength, flexibility, and lightweight properties which enhance durability and performance during play.

Q: What paddle do most pickleball pros use?

A: Many professionals favor paddles that balance control with power; models featuring advanced materials like carbon fiber and specialized cores are popular choices among leading brands.

Q: Do more expensive pickleball paddles make a difference?

A: Yes, higher-end paddles usually incorporate advanced materials like carbon fiber, raw carbon, and fiberglass, which provide improved control, power, and spin, enhancing overall playing performance.

-

Thermoforming: Click to learn about the process of heating and molding materials into complex shapes, enabling customization and improved material distribution in manufacturing. ↩

-

hot pressing: Click to understand how applying heat and pressure can rapidly form products while ensuring structural strength in high-volume production. ↩

-

cold pressing: Click to explore the technique of using mechanical pressure without heat, which preserves material properties for precision applications. ↩

-

carbon fiber: Click to delve into the properties of carbon fiber, a high-strength, lightweight material commonly used in advanced manufacturing for performance enhancement. ↩

-

fiberglass: Click to examine fiberglass as a composite material, valued for its durability, lightweight nature, and versatility in various high-performance applications. ↩