High-performance pickleball paddles are built on advanced manufacturing processes and premium materials. At NEX Pickleball, we combine production expertise with cutting-edge techniques—such as hot pressing1, cold pressing2, and thermoforming3—to deliver paddles that offer superior power, durability, and precision. This article explains the key production methods, materials, and quality control measures that make our products a preferred choice for B2B buyers and competitive players alike.

In today's growing pickleball market, manufacturers must balance innovation, efficiency, and customization. NEX Pickleball leverages state-of-the-art production techniques combined with premium materials, like 3K Carbon Fiber, 12K Carbon Fiber4, T300 Carbon Fiber, fiberglass, and composite cores to produce paddles that meet the demands of both recreational players and professionals.

Our approach focuses on solving production challenges and optimizing paddle performance. By examining factors such as strength, flexibility, control, and production processes, we ensure that our paddles not only enhance the playing experience but also meet rigorous industry standards.

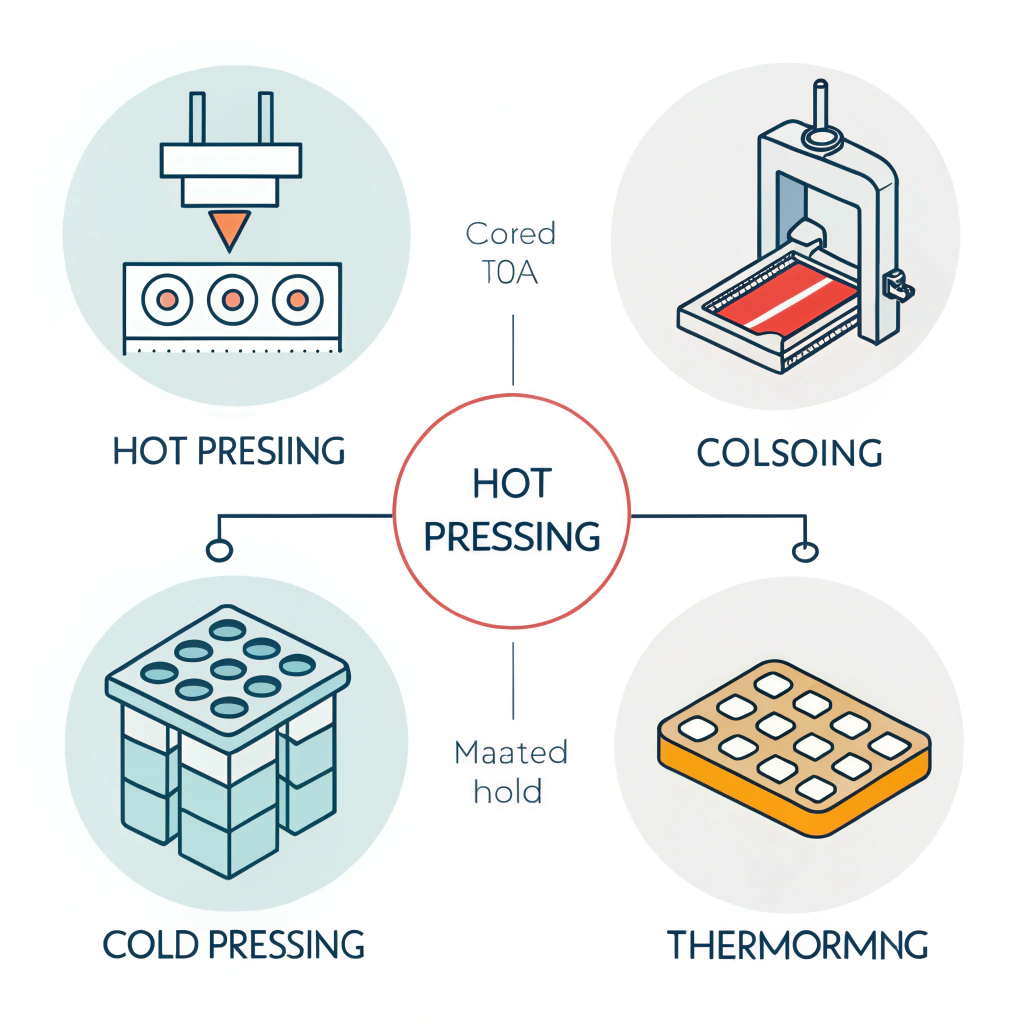

Precision and durability are vital in the production of high-performance pickleball paddles. There are three critical production processes used by NEX Pickleball:

Each of these techniques offers unique benefits and challenges that contribute to the final product’s performance.

Hot pressing involves heating materials and applying pressure to form the paddle structure. This process is widely adopted in large-scale manufacturing due to its efficiency and the exceptional strength it confers on the final product.

- High Strength and Impact Resistance: Hot pressing yields paddles with superior structural integrity.

- Efficient Production: Ideal for mass production while ensuring durability.

- Material Alteration: Although the method strengthens the paddle, the exposure to high temperatures can modify some material properties, potentially changing the paddle's feel.

Cold pressing shapes the paddle material at room temperature through mechanical pressure. This method is especially useful when precision in thickness and material integrity is critical.

- Precision Control: Maintains the original properties of materials, ensuring a consistent ball feel and higher control.

- Extended Production Time: This process requires a longer cycle due to the requirement for meticulous pressure settings.

- Equipment Quality: Demands high-quality machinery to achieve consistent results.

Thermoforming heats materials to a pliable state before molding them using custom-made molds. This process is perfect for designing paddles with intricate shapes and precise material distribution.

- Complex Designs: Enables production of paddles with customized geometries and balanced material distribution.

- Enhanced Stability: Results in paddles with remarkable structural stability.

- Time and Investment: Typically involves longer production times and higher initial investment in equipment.

To help B2B buyers understand the advantages and limitations of each production method, the table below summarizes critical aspects:

| Production Process | Key Advantages | Key Limitations |

|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; robust structure | Alters some material properties; high equipment cost |

| Cold Pressing | Precise control over structure; better ball feel; retains material integrity | Longer production cycle; demands precision equipment |

| Thermoforming | Supports complex designs; tailored material distribution; excellent stability | Increased production time; higher costs for premium products |

This comparison is essential as it enables buyers to select the precise manufacturing process that best suits their intended paddle performance and market positioning.

High-performance pickleball paddles at NEX Pickleball are not just defined by their manufacturing process but also by the materials used. The selection of premium materials is tailored for optimal playability and durability:

-

3K Carbon Fiber:

Renowned for its strength and flexibility, 3K carbon fiber paddles are designed for high rebound force. They offer excellent durability while effectively reducing vibration during play. -

12K Carbon Fiber:

With a higher thread density, 12K carbon fiber provides a smoother surface, enhanced hardness, and superior durability. This material is ideal for competitive players who demand extreme impact resistance. -

T300 Carbon Fiber:

T300 offers outstanding tensile strength and is perfect for paddles that require a balance of lightweight performance and strength.

- E-Glass Fiberglass:

This type of fiberglass provides excellent elasticity and tensile strength. It is used to manufacture paddles that deliver a balanced mix of power and control, appealing especially to players seeking improved ball handling and a wider sweet spot.

Composite paddles combine the benefits of multiple materials, offering enhanced performance and customization:

- Carbon Fiber and Fiberglass Composite:

Merges the benefits of both materials to produce paddles that deliver the perfect mix of power, control, and light weight. - Bamboo Core Composite:

Provides a lightweight yet impact-resistant structure, ideal for players who value a crisp hitting feel with lifelong durability. - Honeycomb Core:

Crafted from high-density polymers, honeycomb cores improve shock absorption and reduce vibration, making the paddle comfortable and reliable during extended play.

The core is pivotal in determining the paddle’s feel and performance:

- Nomex Honeycomb Core5:

Offers excellent shock absorption, providing long-lasting durability and enhanced stability. - Aluminum Honeycomb Core:

Provides a balanced weight distribution, making it ideal for players who need a mix of power and precision. - Polymer Honeycomb Core:

Known for its elasticity and vibration reduction, allowing for a more comfortable playing experience, especially for beginners and recreational players.

At NEX Pickleball, stringent quality control is at the heart of our manufacturing process. Each paddle undergoes rigorous testing to meet strict standards for strength, flexibility, and performance. Our commitment to quality includes:

- Precision Testing: Every paddle is measured for weight distribution and balanced grip design.

- Material Endurance: Advanced durability tests ensure that both base and core materials can withstand high-impact play.

- Customization: We offer on-demand print services, allowing clients to personalize paddle designs. This bespoke approach is especially beneficial for sports teams, retail distributors, and professional players looking to align their equipment with brand aesthetics.

These quality control measures ensure that every paddle not only meets but exceeds industry and user expectations.

For B2B purchasers considering a partnership with a manufacturer, several strategic considerations are crucial:

-

Material Selection:

Evaluate the gameplay level and market positioning of your target audience. For competitive markets, 12K Carbon Fiber and T300 Carbon Fiber offer high resistance and performance, while Fiberglass and Polymer Honeycomb Cores provide cost-effective options for recreational play. -

Production Process Alignment:

Consider your order volume and customization needs. If high volumes with consistent quality are required, Hot Pressing is the best route. If customization and precision are prioritized, then Cold Pressing or Thermoforming may be more advantageous. -

Quality Assurance:

Ensure that the manufacturer follows strict quality control protocols. NEX Pickleball’s adherence to rigorous testing and quality checks is a testament to our commitment to excellence in every paddle produced. -

Long-Term Partnership:

A reliable manufacturer with the ability to innovate and offer custom solutions is essential for sustainable growth. Leveraging our expertise in advanced manufacturing techniques positions NEX Pickleball as a strategic partner in the competitive pickleball market.

Recent trends in the pickleball market illustrate how technological advancements in production have increased both product lifespan and player satisfaction. For instance, a comparative study of paddles using different manufacturing processes showed that paddles made through Thermoforming had a 15% increase in impact resistance and a 10% improvement in overall stability compared to conventionally produced casts.

Customer testimonials and performance data further emphasize that paddles developed with advanced cold pressing techniques offer superior control, making them particularly popular among professional players. These empirical results underscore how targeted manufacturing processes directly influence market success.

In summary, high-performance pickleball paddles are a product of both advanced materials and innovative manufacturing techniques. At NEX Pickleball, we pride ourselves on our ability to integrate hot pressing, cold pressing, and thermoforming methods with premium materials such as carbon fiber, fiberglass, and composite cores. This holistic approach ensures that every paddle is optimized for power, control, and durability.

For B2B buyers looking to enhance their product lines, investing in technology-driven manufacturing is key to gaining a competitive edge. We invite you to explore potential partnerships with NEX Pickleball and discover how our customized solutions and superior quality control can drive business growth and player satisfaction.

Take action now by contacting our sales team for a consultation or requesting a sample production line analysis. Together, we can unlock the full potential of high-performance pickleball paddles in your market.

Q: What 3 sports is pickleball similar to?

A: Pickleball is a combination of three sports: tennis, badminton, and ping pong (table tennis). Together, these sports contribute to pickleball's unique blend, offering a balance of court dynamics, net play, and paddle control.

Q: What other sport is played on a pickleball court?

A: In addition to pickleball, padel is also played on a similar court. While pickleball remains popular in the U.S., padel is gaining momentum internationally and is slowly emerging as a prominent racket sport in regions such as California, Nevada, Texas, and Florida.

Q: What 3 sports was pickleball invented from?

A: Pickleball was originally developed by blending elements from tennis, badminton, and ping pong. This mix created a sport that not only offers a fun backyard activity but has grown into a competitive game with professional leagues and tournaments.

-

hot pressing: Click to learn more about the advanced high-temperature forming process that enhances paddle strength and efficiency, crucial for mass production. ↩ ↩2

-

cold pressing: Click to explore the room-temperature shaping technique designed for precision and material integrity, ideal for achieving superior paddle control. ↩ ↩2

-

thermoforming: Click to discover how heating materials to a pliable state and molding them enables complex designs and balanced material distribution in paddle manufacturing. ↩ ↩2

-

12K Carbon Fiber: Click to understand the benefits of a higher thread density material offering a smoother surface, enhanced durability, and high impact resistance, key for competitive performance. ↩

-

Nomex Honeycomb Core: Click to read about this high-performance core material known for excellent shock absorption and structural stability, making it essential for long-lasting paddle durability. ↩