USAPA-approved pickleball paddles are rigorously evaluated through a series of standardized tests focusing on dimensional accuracy, impact response, and overall performance reliability. This article explores USAPA paddle testing in depth, outlines the challenges and solutions in the testing process, and provides a clear framework for data-driven decision-making1 in paddle manufacturing and selection.

In today’s competitive pickleball market, sports equipment distributors and quality assurance specialists face significant challenges in ensuring that paddles meet USAPA standards. The primary issue lies in verifying that each paddle conforms to strict dimensional requirements and performs consistently under varied conditions. Without effective testing mechanisms, businesses risk investing in products that may fail to deliver optimal performance or comply with regulatory standards.

Key challenges include:

- Accurate measurement of paddle dimensions such as length, width, and overall size.

- Consistent performance during high-speed ball impacts.

- Maintaining material integrity through different manufacturing processes.

- Monitoring impact resistance and vibration reduction.

These challenges necessitate a comprehensive testing protocol that leverages advanced technology and precise measurement tools.

Before delving into testing protocols, it is essential to understand the USAPA standards2 for pickleball paddles. USAPA requires that:

- The paddle length does not exceed 17 inches.

- The combined length and width of the paddle does not exceed 24 inches.

- There is no stipulated requirement regarding thickness.

These dimensional tests are only one part of the equation. Performance tests simulate real-game conditions to ensure that paddles offer the necessary rebound, control, and vibration damping during play.

USAPA compliance provides assurance to end-users, sports organizations, and distribution partners that the product adheres to industry benchmarks for both safety and performance.

To ensure that each paddle meets or exceeds USAPA standards, our testing process is divided into several phases:

This phase involves precise measurements of the paddle’s length and combined length and width. Using advanced measurement tools like digital calipers3 and laser measurement systems, every paddle is verified against USAPA criteria. Any paddle that shifts outside the permissible dimensions is flagged for further inspection or rejection.

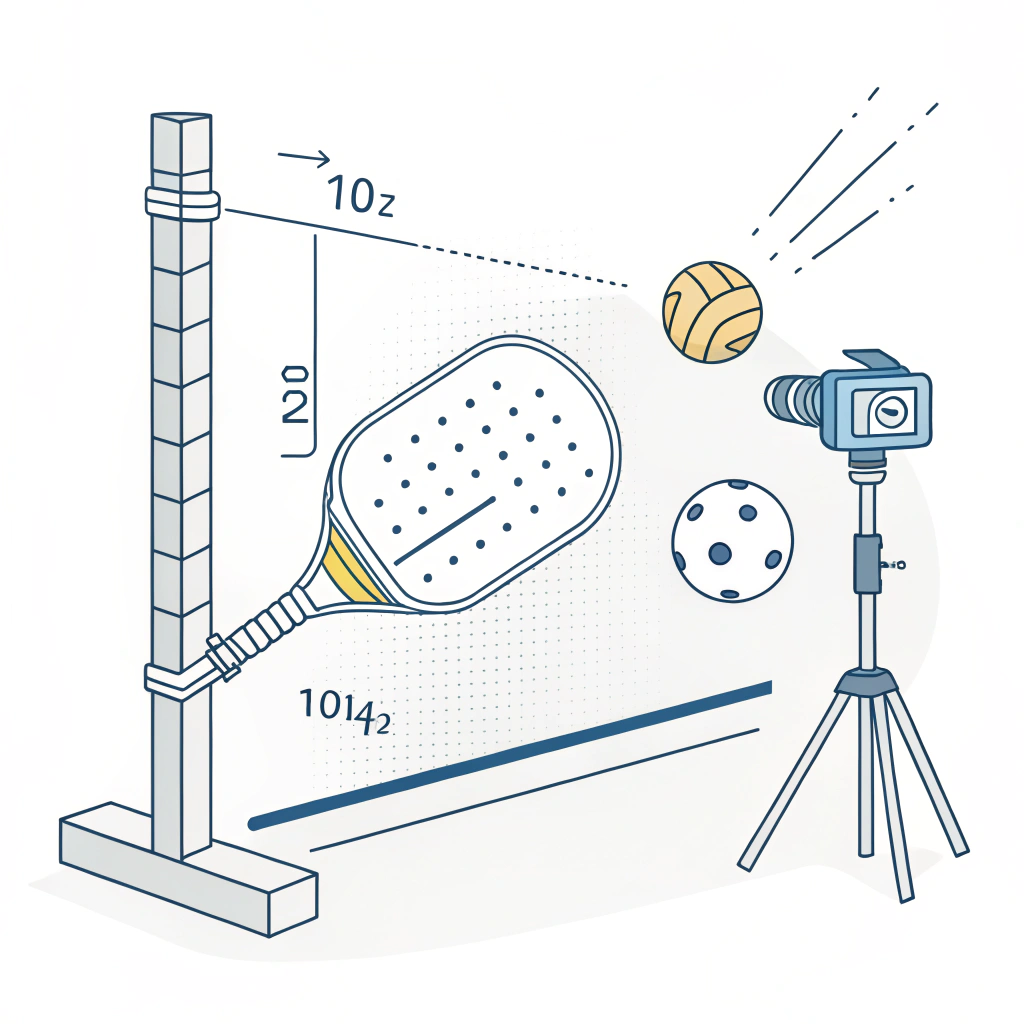

In the impact testing stage, paddles are assessed under simulated play conditions. The standard procedure includes:

- Securing the paddle in a handle clamp for stability.

- Orienting the paddle using an inclinometer4 to ensure consistency.

- Using a high-speed camera to record the ball’s impact at the center of the paddle face.

The following step-by-step procedure is observed:

- Secure the paddle in the handle clamp.

- Orient the paddle correctly, verifying angles and centering using tools such as inclinometers and lasers.

- Initiate the spin test by firing a ball at a constant ball speed using a piston mechanism.

- Record the impact using a high-speed camera to capture fine details like rebound effect, vibration, and surface reaction.

This methodology ensures that the paddle’s response to high-speed impacts is documented and analyzed to meet industry benchmarks.

The materials used in paddle construction play a crucial role in both performance and durability. Testing here involves:

- Carbon Fiber Analysis: Evaluating different types (3K, 12K, T300) to measure their strength, flexibility, and vibration absorption.

- Fiberglass Evaluation: Testing E-Glass fiberglass for elasticity and control.

- Composite Structures: Combining carbon fiber with fiberglass or bamboo to balance strength and feel.

- Core Material Assessment: Verifying the properties of Nomex, aluminum, and polymer honeycomb cores for shock absorption and structural integrity.

Each material is evaluated for its contribution to the paddle’s overall performance, ensuring that the final product not only meets USAPA dimensional criteria but also performs reliably in competitive play.

Different manufacturing processes affect the paddle’s performance. Below is a detailed comparison table showcasing the three primary production techniques used at NEX Pickleball:

| Production Process | Key Advantages | Limitations | Impact on Paddle Performance |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong, durable paddles; excellent impact resistance | May alter some material properties; requires high equipment investment | Ensures structural integrity and is ideal for high-performance play |

| Cold Pressing | Precise control over thickness and structure; maintains material properties; excellent ball feel | Longer production cycle; requires high-quality equipment for precise pressure control | Provides enhanced control and flexibility, improving player responsiveness |

| Thermoforming5 | Excellent for intricate designs; precise material distribution; maintained stability improvement | Longer production time; higher equipment costs | Balances design intricacies with performance, suited for custom-made, premium paddles |

Each process is chosen based on the desired balance between performance, cost, and production scalability. The choice of process directly influences the paddle’s behavior under pro-level testing protocols.

At the heart of our testing is a commitment to quality control and data validation. Quality assurance specialists use a mix of automated and manual inspection methods to ensure that every paddle aligns with USAPA standards and meets the rigorous demands of professional gameplay.

- Consistent Measurement: Every paddle undergoes precise dimensional checks to ensure conformity to USAPA size limits.

- Impact Analysis: High-speed cameras and calibrated sensors capture and analyze data on ball impact, rebound, and paddle vibration.

- Material Durability: Repeated stress tests and thermal cycling assess material fatigue over time.

- Operator Precision: Experts oversee testing procedures, ensuring consistent measurement and adherence to protocol.

The results from these tests are compiled into comprehensive reports that detail:

- Rebound speeds

- Vibration damping measurements

- Impact force distribution

- Dimensional tolerances

These metrics allow us to benchmark against competitors and ensure that our paddles deliver optimum performance regardless of play intensity.

To illustrate the impact of rigorous testing protocols, consider a recent case study involving a batch of paddles undergoing USAPA testing. The objective was to compare the performance of paddles produced via hot pressing versus those produced via cold pressing.

- Batch Size: 500 paddles from each production process.

- Testing Methods: Dimensional measurements, impact testing with high-speed recording, and material fatigue tests.

- Key Findings:

- Hot Pressed Paddles: Exhibited superior impact resistance and structural integrity. However, slight alterations in material properties were observed, which may affect the paddle’s feel.

- Cold Pressed Paddles: Provided enhanced ball control and improved surface feel, though the production cycle was longer and more sensitive to precision deviations.

- Result Analysis: The data strongly indicated that while both processes meet the required standards, the choice between them should be driven by the target market's emphasis on durability versus control and feel.

This case study underscores the importance of data-driven testing in identifying key performance indicators that matter in real-world gameplay and compliance scenarios.

Despite robust testing protocols, there are considerations to keep in mind:

- Environmental Variability: Testing conditions need to be standardized to ensure the repeatability of results. Temperature, humidity, and even operator handling can impact outcomes.

- Process Sensitivity: Each manufacturing process requires distinct calibrations. Minor deviations can have a significant impact on performance outcomes.

- Cost vs. Precision: High-end testing equipment and procedures enhance precision but also increase production costs. Balancing cost and quality is crucial, especially for large-scale manufacturing.

- Technological Upgradation: As advances in production and testing technology emerge, ongoing upgrades to testing protocols may be needed. Maintaining alignment with industry trends ensures continued compliance and competitive advantage.

In summary, USAPA Pickleball Paddle Testing is a multi-faceted process that integrates dimensional accuracy checks, advanced performance and material testing, and detailed data analysis. By adhering to standardized testing protocols, manufacturers can ensure their paddles comply with regulatory standards while delivering the performance required by high-level players.

Action recommendations for quality assurance professionals and product managers:

- Invest in precision measurement tools: Ensure all paddles meet USAPA dimensional criteria using state-of-the-art equipment.

- Monitor production processes: Balance the pros and cons of hot pressing, cold pressing, and thermoforming based on your market needs.

- Utilize data analytics: Leverage high-speed imaging and sensor data to refine quality control protocols and enhance product performance.

- Review and adapt standards: Stay updated with evolving USAPA guidelines and adjust your testing procedures accordingly.

By following these steps, businesses will be better positioned to make informed, data-driven purchasing decisions, thereby enhancing overall customer satisfaction and improving product reliability in the market.

-

How to know if pickleball paddle is USAPA approved?

To determine if a pickleball paddle is USAPA approved, check the approved paddle list available on the USAPA website at https://equipment.usapa.org. This ensures the paddle meets all specified size and performance standards. -

What are the standards for USAP paddles?

USAP standards require that pickleball paddles have a maximum length of 17 inches, while the combined length and width should not exceed 24 inches. There is no specific requirement for thickness, but the paddle must perform reliably under standardized tests. -

How to test a pickleball paddle?

Testing a pickleball paddle involves securing it in a handle clamp, ensuring proper orientation with an inclinometer and laser alignment, firing a ball at a constant speed to initiate a spin test, and recording the impact via a high-speed camera for detailed analysis of rebound and vibration characteristics.

-

data-driven decision-making: Reading this article will help you explore how leveraging analytics and objective data can optimize manufacturing processes and quality assurance in paddle production. ↩ ↩

-

USAPA standards: Click to understand the regulatory benchmarks and performance requirements that ensure pickleball paddles are safe and meet competitive play criteria. ↩ ↩

-

digital calipers: Learn about precision measurement tools used for verifying dimensions, which are critical in maintaining compliance with industry standards. ↩ ↩

-

inclinometer: Discover how devices that measure angles and tilt help ensure consistent setup during testing, leading to reliable performance assessments. ↩ ↩

-

thermoforming: Explore the manufacturing process that uses heat to shape materials, balancing intricate design capabilities with performance requirements. ↩ ↩