NEX Pickleball offers USAPA-approved high-performance pickleball paddles manufactured with advanced techniques that ensure exceptional quality, durability, and customization options for competitive and recreational markets.

In today’s competitive sports equipment market, procurement managers and distributors must evaluate production processes, material properties, and compliance credentials when selecting an OEM manufacturing partner1 for pickleball paddles. NEX Pickleball, based in Jiaxing, Zhejiang, China, delivers exactly that—a deep commitment to quality control and cutting-edge production methods such as hot pressing2, cold pressing3, and thermoforming4. In this article, we will explore the technical aspects of our production processes, compare the benefits and limitations of each technique, and provide insights into material selections and customization options. All of these factors play a crucial role in ensuring that the end product meets, and often exceeds, industry standards, including those mandated by USAPA.

Procurement managers face several key challenges when sourcing high-performance pickleball paddles:

• Determining production process reliability and scalability

• Verifying material quality and performance characteristics

• Ensuring compliance with USAPA standards and other regulatory requirements

• Evaluating the ability of a manufacturer to offer customizations for ergonomic designs and branding

At NEX Pickleball, we address these challenges not just with modern manufacturing technology but through a strategic approach that combines engineering excellence with practical factory insights. Our production capabilities are designed to provide full transparency, rigorous quality testing, and tailored solutions that fulfill the diverse requirements of our global customers.

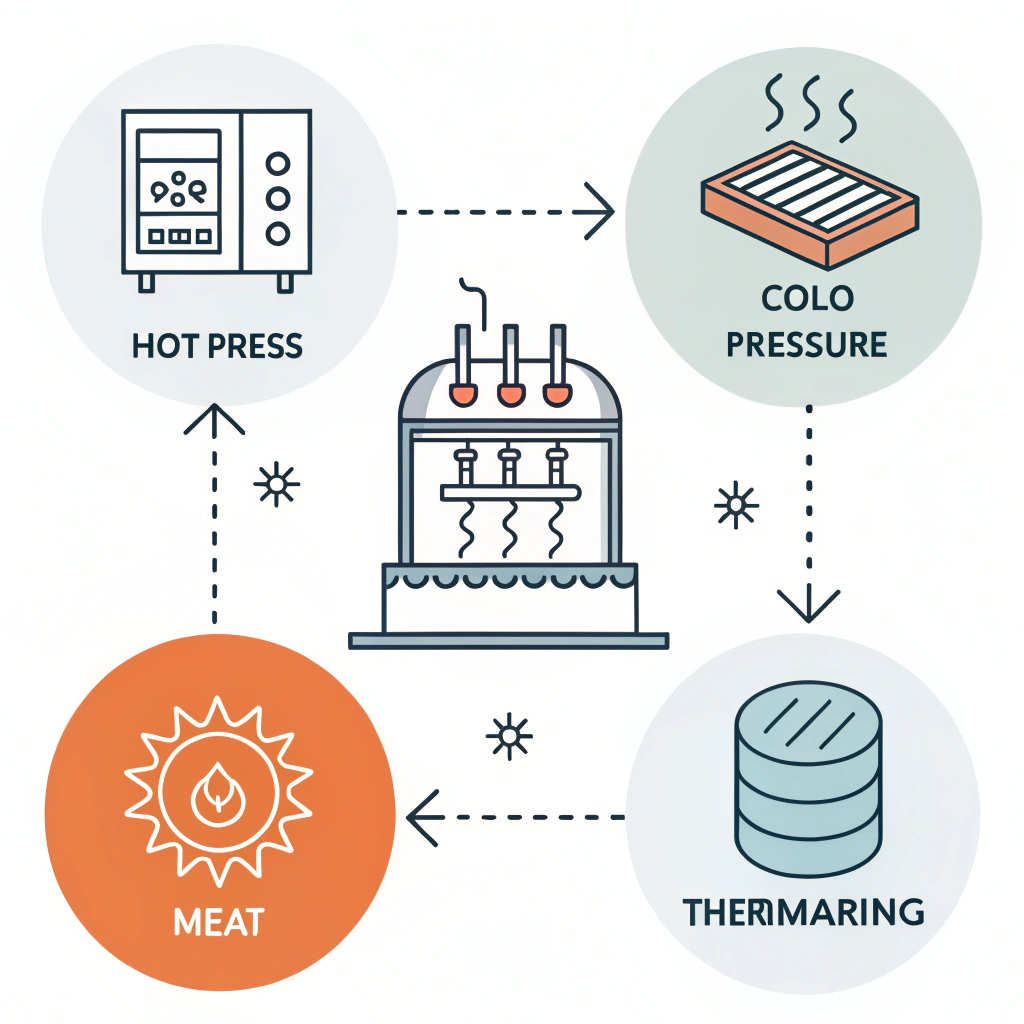

Our manufacturing process is built on three primary techniques, each with its unique strengths:

-

Hot Pressing

Hot pressing involves applying heat and pressure to shape the paddle materials into a solid, durable product. This method is widely used for producing paddles that demand high impact resistance.Advantages:

- High production efficiency, suitable for large-scale manufacturing

- Enhanced impact resistance resulting in a robust structure

- Improved structural integrity for high-performance applications

Disadvantages:

- Potential alteration of material properties that might affect paddle feel

- Significant initial investment in specialized equipment

-

Cold Pressing

Cold pressing utilizes mechanical pressure at room temperature, allowing for fine control over paddle thickness and precision design features.Advantages:

- Precise control over material dimensions and structure

- Retention of inherent material properties for a better ball feel and controlled performance

- Produces paddles that deliver exceptional responsiveness in play

Disadvantages:

- Slower production cycle compared to hot pressing

- Requires high-quality pressure control mechanisms, increasing process sensitivity

-

Thermoforming

This process involves heating the paddle material to a softening point before forming it in molds to achieve complex shapes and thickness profiles.Advantages:

- Ability to craft intricately designed paddles

- Maintains material stability and optimizes weight distribution

- Especially suitable for premium or custom-made paddles

Disadvantages:

- Longer production cycles and higher equipment costs

- Best applied for products where customization or complex geometry is a priority

The following table summarizes the pros and cons of each production method:

| Production Method | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, durable | Material property alteration, high equipment cost |

| Cold Pressing | Precise control, retains material properties, responsive | Longer production times, stringent equipment requirements |

| Thermoforming | Intricate designs, excellent weight distribution, stable | Higher costs, longer production cycles |

The quality of a pickleball paddle is highly influenced by the materials used. At NEX Pickleball, we source and combine premium materials to optimize performance parameters such as power, control, and durability.

We offer multiple grades of carbon fiber, each delivering distinct characteristics:

-

3K Carbon Fiber:

Renowned for its strength and flexibility, it provides high rebound force while reducing vibration. Ideal for competitive play where durability and performance are critical. -

12K Carbon Fiber:

With a higher thread density, this material delivers a smoother surface, enhanced hardness, and superior impact resistance. This makes it a popular choice for players seeking extreme strength. -

T300 Carbon Fiber:

Known for its excellent tensile strength and light weight, T300 is used in paddles where balanced performance is essential.

Fiberglass paddles are preferred for their balanced combination of power and control. Their wider sweet spot and enhanced durability make them ideal for players looking for comfort and flexibility, especially in recreational contexts.

- E-Glass Fiberglass:

Offers high elasticity and tensile strength, ensuring both an excellent feel and ample control.

One of the key strengths of our manufacturing is the ability to create composite paddles5 that combine the benefits of multiple materials:

-

Carbon Fiber and Fiberglass Composite:

This blend offers a mix of strength, lightness, and flexibility—ideal for players who need both power and finesse. -

Bamboo Core Composite:

Provides outstanding impact resistance and a natural hitting feel, leading to longer playability and improved durability. -

Honeycomb Core:

Constructed from high-density polymer or pulp, these cores offer superior shock absorption, reducing vibrations and enhancing durability.

The internal core significantly impacts the paddle’s overall performance:

-

Nomex Honeycomb Core:

Offers excellent shock absorption and stability, ensuring long-lasting performance and structural integrity. -

Aluminum Honeycomb Core:

Balances weight with power delivery, making it perfect for players who need precision and strength. -

Polymer Honeycomb Core:

Delivers better elasticity and reduced vibration, thereby providing a superior hitting feel suitable for beginners and recreational players.

Each material is chosen based on its specific performance attributes and compatibility with the production process, ensuring that every paddle is crafted to meet strict quality standards before it leaves our facility.

An important aspect of our offering is the ability to provide custom paddle options. We understand that different players and sports organizations have unique requirements. By using advanced manufacturing techniques, we can offer:

• Custom design specifications – clients can outline the desired weight, balance, and grip size

• Personalized branding – ideal for team or corporate branding opportunities

• Material combinations – tailored solutions based on the player's competitive level and preferences

Our custom paddle options are supported by detailed consultations and prototypes, ensuring that every adjustment meets the high-performance standards expected from USAPA-approved equipment.

Multiple layers of quality control ensure that our paddles consistently meet strict performance criteria. Every paddle undergoes comprehensive testing for factors such as:

• Strength and Durability:

Constant checks during and after production guarantee that each paddle can withstand the rigors of competitive play.

• Vibration Reduction:

Advanced damping technologies and material optimization reduce vibrations, enhancing player comfort and control.

• Ergonomic Design:

Ergonomic handles and balanced weight distribution are tested rigorously to maximize comfort and performance.

To address compliance, especially regarding USAPA standards, all paddles are continually evaluated against the approved equipment list, ensuring they meet the necessary certification requirements before being released to the market. This rigorous approach reassures procurement managers that the final product not only performs at a high level but also aligns with industry regulatory standards.

Our experience in OEM manufacturing for high-performance pickleball paddles offers unique insights into factory operations and production scalability. Here are some factors that set us apart:

-

Advanced Production Equipment

Investment in state-of-the-art machinery ensures that every production process, whether hot pressing, cold pressing, or thermoforming, is executed with high precision and reliability. This minimizes variability and guarantees consistency in paddle performance. -

Skilled Workforce and Process Oversight

Our floor is manned by professionals with extensive technical know-how. Their expertise ensures that every stage—from material handling to final quality checks—is managed focusing on efficiency and attention to detail. -

Continuous Process Improvement

Regular feedback loops and performance metrics allow us to refine production processes. This proactive approach helps in reducing waste, improving production speed, and ultimately delivering better products to our clients. -

Flexible Production for Custom Orders

We understand that in the fast-paced world of sports equipment, the ability to quickly adapt and customize orders is a competitive advantage. Our flexible manufacturing solutions enable rapid turnaround times, even when dealing with custom designs or small batch orders.

Ensuring that each pickleball paddle meets the rigorous demands of competitive play requires a thorough understanding of materials, production techniques, and quality control standards. At NEX Pickleball, our manufacturing processes are optimized for both large-scale production and specialized custom orders. By leveraging advanced methods such as hot pressing, cold pressing, and thermoforming, and by selecting premium materials including diverse grades of carbon fiber, fiberglass, and innovative composites, we provide a product that stands up to the demands of both recreational and competitive play.

For procurement managers and B2B sports equipment distributors, partnering with a supplier that offers such comprehensive insight into the production process is invaluable. It means you are not only getting a product that adheres to strict quality and compliance measures but also one that can be tailored to the specific needs of your market.

Before making your final sourcing decision, consider these actionable steps:

- Evaluate the production process details and understand how each method fits your market needs.

- Request data on quality control procedures and field test results.

- Explore custom design options and assess if the manufacturer has the flexibility to adapt to your branding requirements.

- Verify compliance with USAPA standards by cross-referencing with the official equipment list.

By following these steps, you ensure that your investment leads to the best possible outcomes—both in terms of performance on the court and reliability in competitive environments.

People Also Ask

• How to know if pickleball paddle is USAPA approved?

To verify if a pickleball paddle is USAPA approved, check the official USAPA approved equipment list by visiting the USAPA website. Manufacturers typically subject their products to rigorous testing and certification to ensure they meet the required standards, and players or distributors can refer to the list to confirm this compliance.

-

OEM manufacturing partner: Reading the linked article will help you understand what qualifies a manufacturer as an Original Equipment Manufacturing partner, including the benefits of production scalability and quality assurance. ↩ ↩

-

hot pressing: Reading the linked article will explain the hot pressing technique, detailing how heat and pressure are applied in manufacturing to enhance product durability. ↩ ↩

-

cold pressing: Reading the linked article will clarify the cold pressing process, highlighting its benefits for precision control and material integrity. ↩ ↩

-

thermoforming: Reading the linked article will provide insights into the thermoforming process, showing how heat is used to mold materials into complex, customized shapes. ↩ ↩

-

composite paddles: Reading the linked article will discuss the advantages of composite paddles, illustrating how combining different materials can optimize performance and durability. ↩ ↩